A movable position platform for large wind power castings

A large-scale casting, movable technology, applied in the direction of molding table, molding machine, casting and molding equipment, etc., can solve the problem of difficult positioning of large-scale casting molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

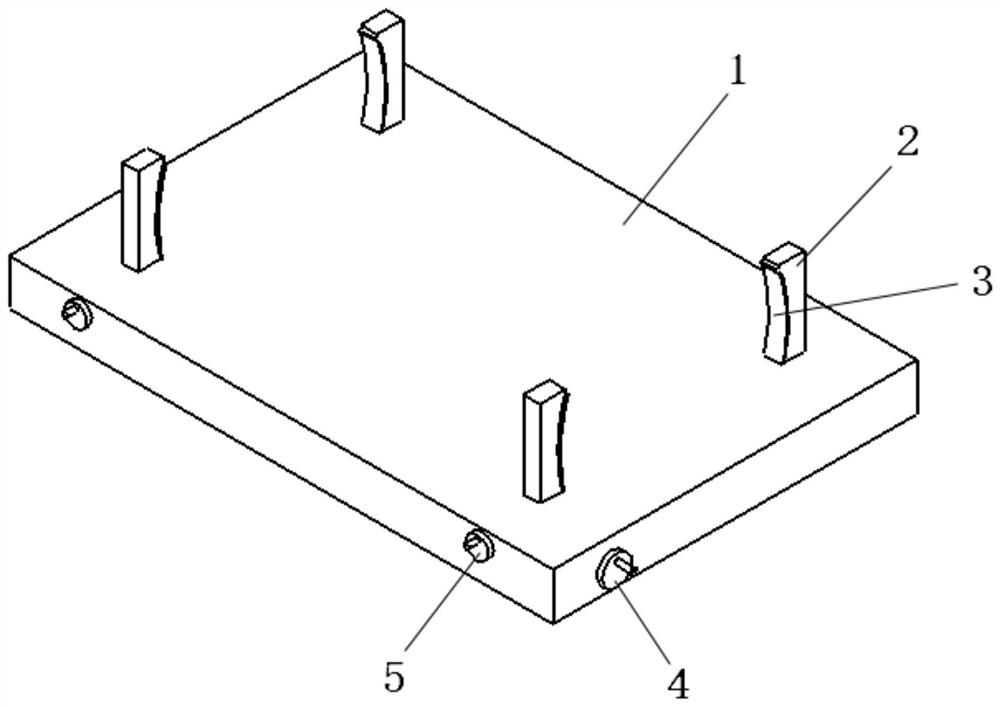

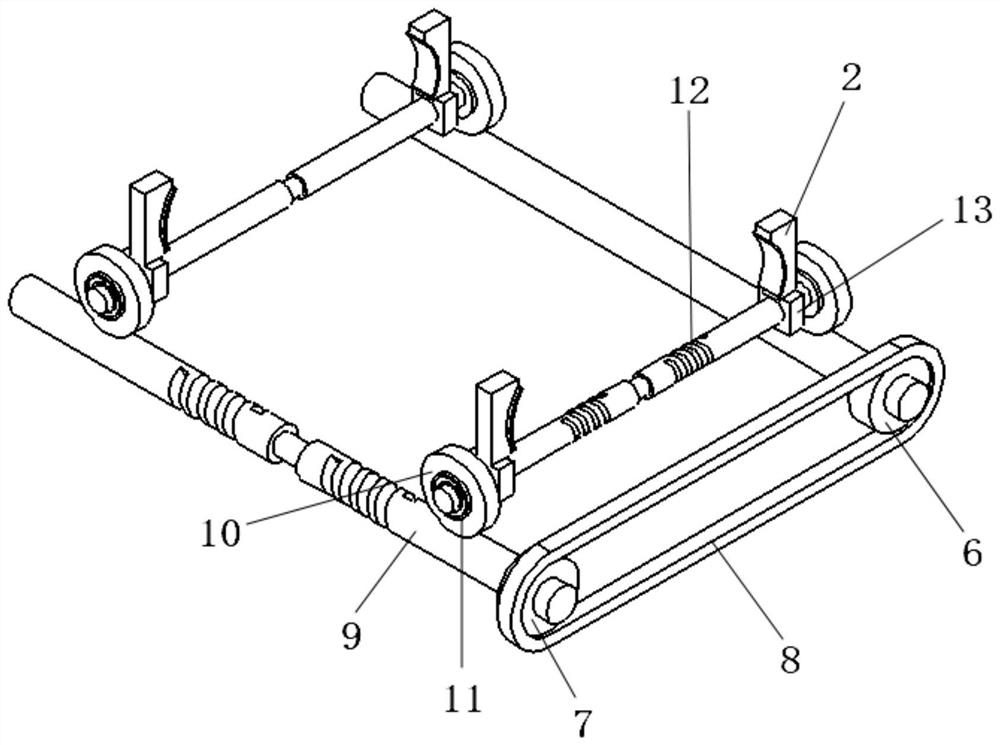

[0024] Such as Figure 1 to 3 As shown, the present invention provides a moving position platform of a wind power large-scale casting, including a microseisman bracket 1, and a moving jaw 2, and the moving jaw 2 is located at the upper portion of the microseisman bracket 1 and can be moved before the micro-shock bracket 1. A large casting clamping; two-way worm 9 is mounted on the microseisman bracket 1, the bidirectional worm 9 has a positive rotation segment and a reverse rotation direction, and there is a connection on the routing segment and the reflection section. The adapted worm wheel 10 is mounted on the worm wheel 10, and the two worm gear 10 on the positive rotation section and the reflection section can be driven by the rotating worm 9 to drive two pairs mounted on the worm wheel 10. The clamping mechanism is inverted; the pairing clamping mechanism includes a bidirectional screw 12, a nut block, and a connecting member 11, the connecting member 11 being a bearing, and t...

specific Embodiment approach 2

[0028] This specific embodiment is different from the specific embodiment 1: The bidirectional worm 9 is provided with a bidirectional worm 9 located in the intermediate position of the bidirectional screw 12, the worm wheel 10 mounted in the middle of the bidirectional screw 12, the chormhing and the front and rear The worm wheel 10 on the root bidirectional screw 12 is driven, and a first hand wheel 4 is connected to the worm, the first hand wheel 4 located outside the microseisman bracket 1.

specific Embodiment approach 3

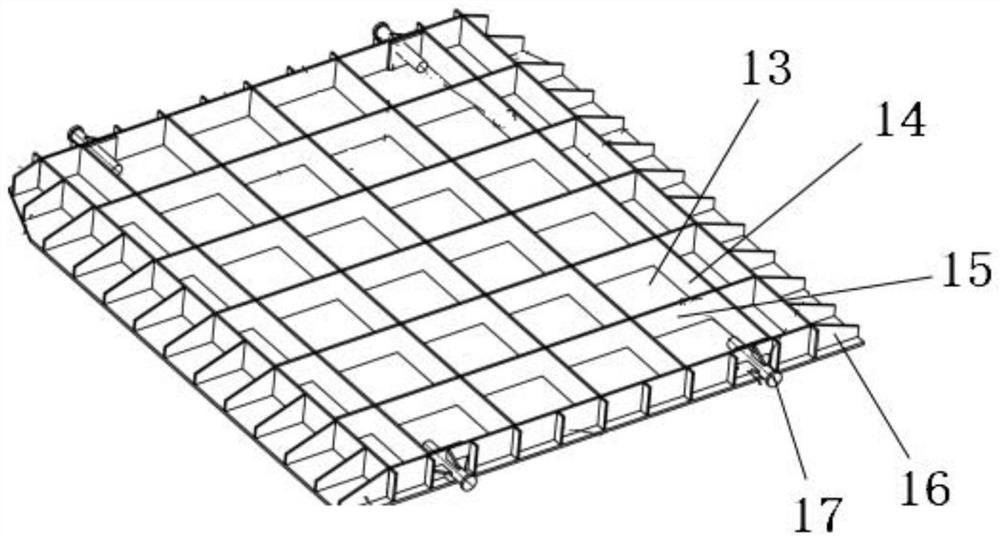

[0029] Such as image 3 As shown, the specific embodiment is improved on the basis of the specific embodiment 1 or 2, the improvement point is that the microseisman bracket 1 includes a soldering fixed on a piece of bottom plate 13, a lateral steel plate 15, and a longitudinal steel plate 14, which is said. A checker is formed between the lateral steel plate 15 and the longitudinal steel plate 14, the lateral steel plate 15 and the tip end of the longitudinal steel sheet 14, and supports a reinforcing rib 16 on the outer longitudinal steel plate 14, and the upper portion of the rib 16 is supported. In order to incline the downward, the slope is lower than the placement surface. The microseisman bracket 1 is welded in transverse, longitudinally thick high-strength steel sheet to ensure the strength of the microseisman bracket 1, the bottom is consistent with the micro-resistance space, the upper portion is consistent with the mold size, ensuring the load-bearing effect, and there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com