Clamp for machining hydraulic valve block datum plane

A technology of hydraulic valves and reference surfaces, which is applied in the field of hydraulic parts processing, and can solve the problem that fixtures cannot be reused

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

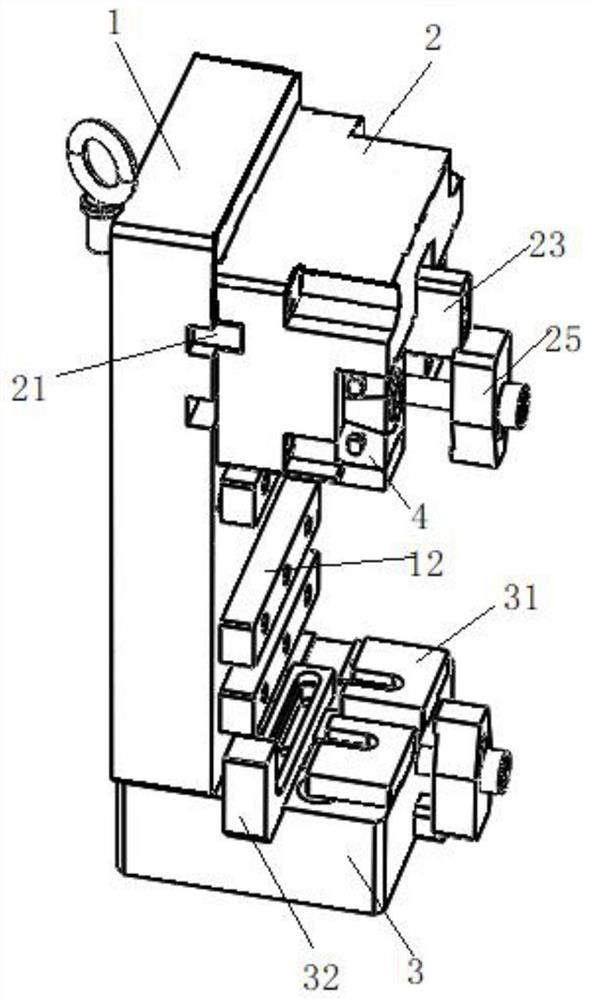

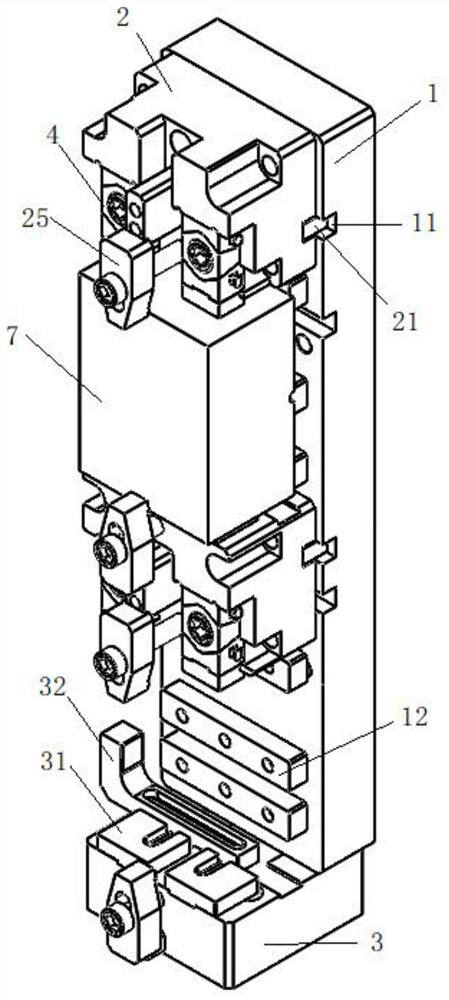

[0035] Embodiment 1: as figure 1 as well as Figure 4-8 As shown, including the vertical plate 1, the upper and lower ends of the vertical plate 1 are respectively fixed with a compression seat 2 and a positioning seat 3, and two adjustment grooves 11 are formed on one side of the vertical plate 1, and the vertical plate 1 is connected with the pressure by the adjustment groove 11. The tight seat 2 is clamped, and the surroundings are tightened by screws.

[0036] like figure 1 , Upper positioning: The side of the pressing seat 2 close to the vertical plate 1 is provided with a block 21 that matches the adjustment groove 11 .

[0037] In the process of processing, the faces of some hydraulic valve blocks 7 are non-parallel faces, and the existing clamps cannot clamp the non-parallel faces. Therefore, the present invention forms slide grooves at the two ends on the other side of the pressing seat 2. 22. A micro-adjustment mechanism 4 is slidably connected in the chute 22, an...

Embodiment 2

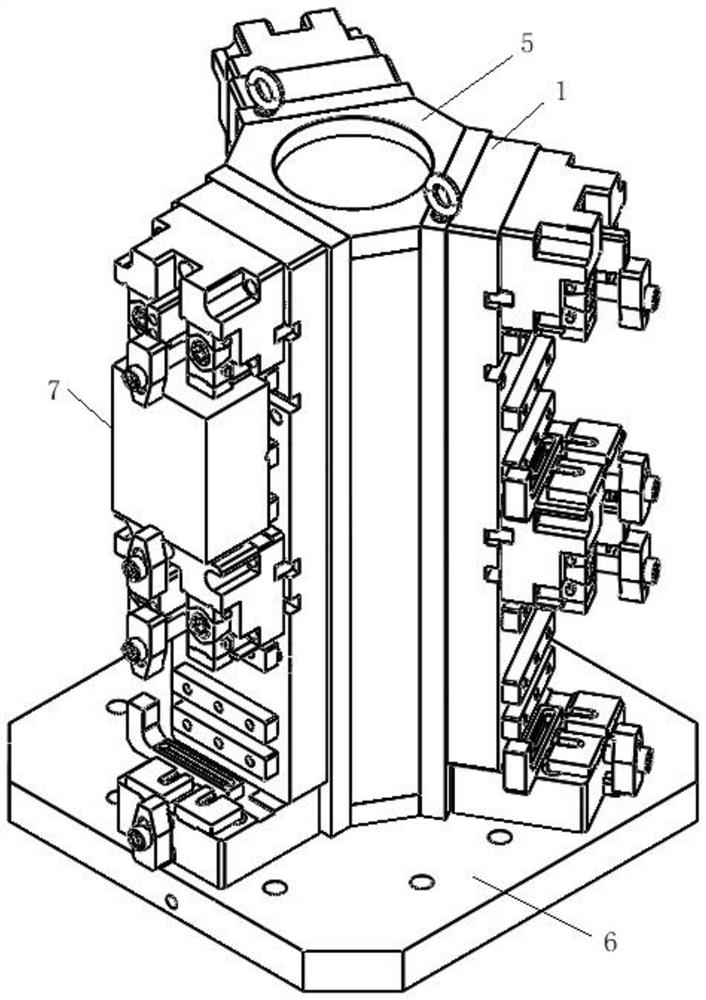

[0044] Embodiment 2: as figure 2 , 3 As shown, a fixture for processing the reference plane of the hydraulic valve block can clamp six hydraulic valve blocks 7 at one time, including the support column 5 and the bottom plate 6 arranged perpendicular to each other. The support column 5 is a regular hexagonal prism to avoid Interference, three vertical plates 1 are distributed on the side of the regular hexagonal prism at intervals, and one side of the vertical plate 1 is fixed on the support column 5. On the basis of embodiment 1, this embodiment is based on the compression seat 2 and the positioning seat 3. A pressing seat 2 is added in the middle, and an adjustment groove 11 and a second positioning block 12 are correspondingly added to the vertical plate 1. The above structure can process the upper and lower hydraulic valve blocks 7 at the same time, saving the time required for processing and reducing the cost. A first positioning block 31 is respectively fixed on both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com