Automatic alignment and detection system based on diesel engine cylinder cover machining machine tool

A technology for processing machine tools and diesel engines, which is applied to metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of lava, diesel engine mechanical efficiency decline, unfavorable numerical control automation, real-time monitoring and management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

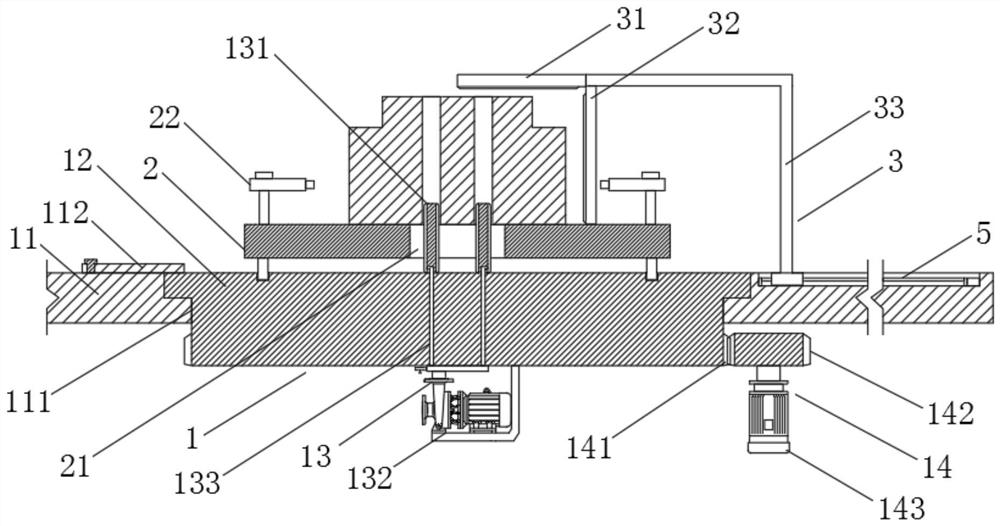

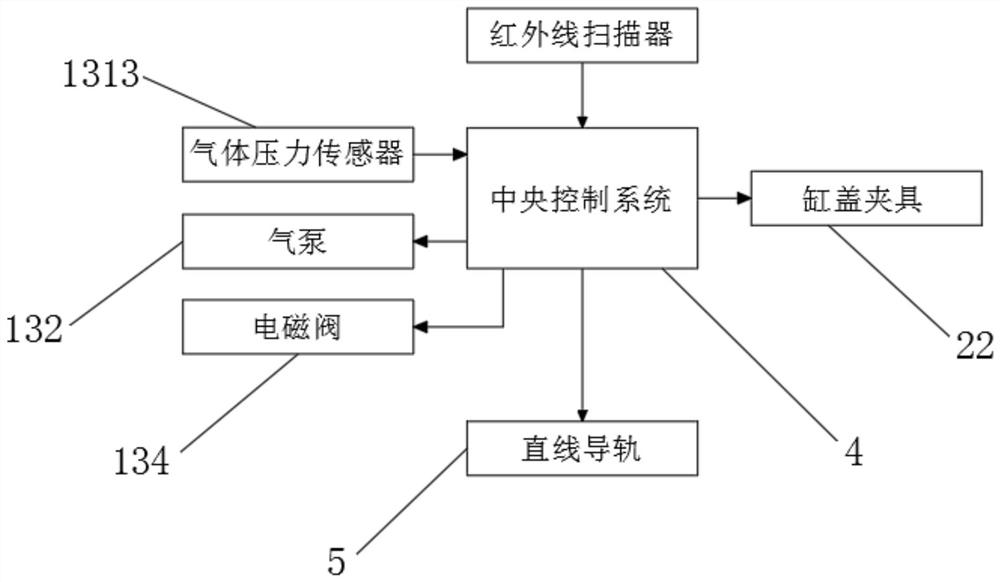

[0028] Such as Figure 1-3 As shown, an automatic alignment and inspection system based on a diesel engine cylinder head processing machine tool includes a machine tool workbench 1 , fixture 2 , cylinder head surface scanning device 3 , and a central control system 4 .

[0029] The machine tool table 1 includes a fixed table 11, a rotary table 12 clamped in the middle of the fixed table 11, a cylinder head limit assembly 13 fixed on the rotary table 12, and a driving device 14 that drives the rotary table 12 to rotate;

[0030] A perforation 111 is opened through the fixed table 11, and the section of the perforation 111 is set to be T-shaped. The lower surface of one end of the limit rod 112 is attached to the upper surface of the rotary table 12, and the other end is arranged on the fixed table 11 through the rotation of the rotating shaft;

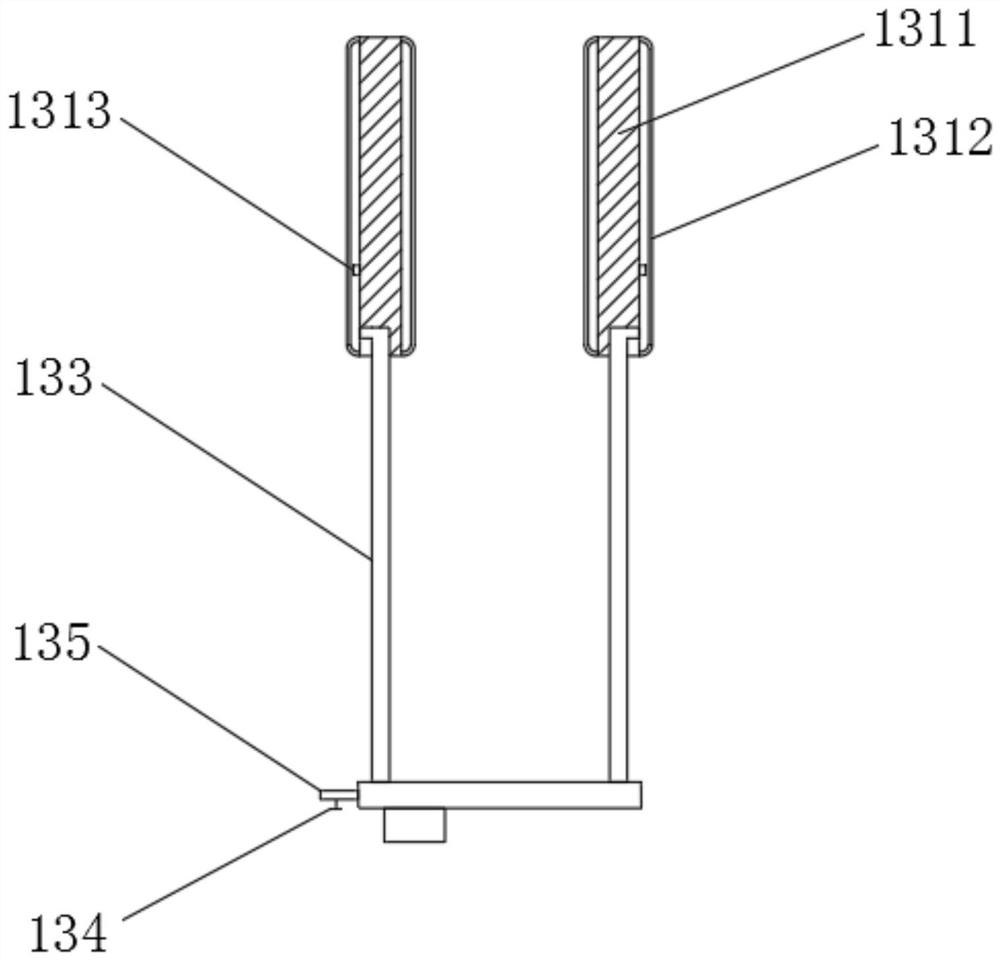

[0031] The cylinder head limiting assembly 13 includes at least one expansion head 131 arranged in the through hole 21 and extending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com