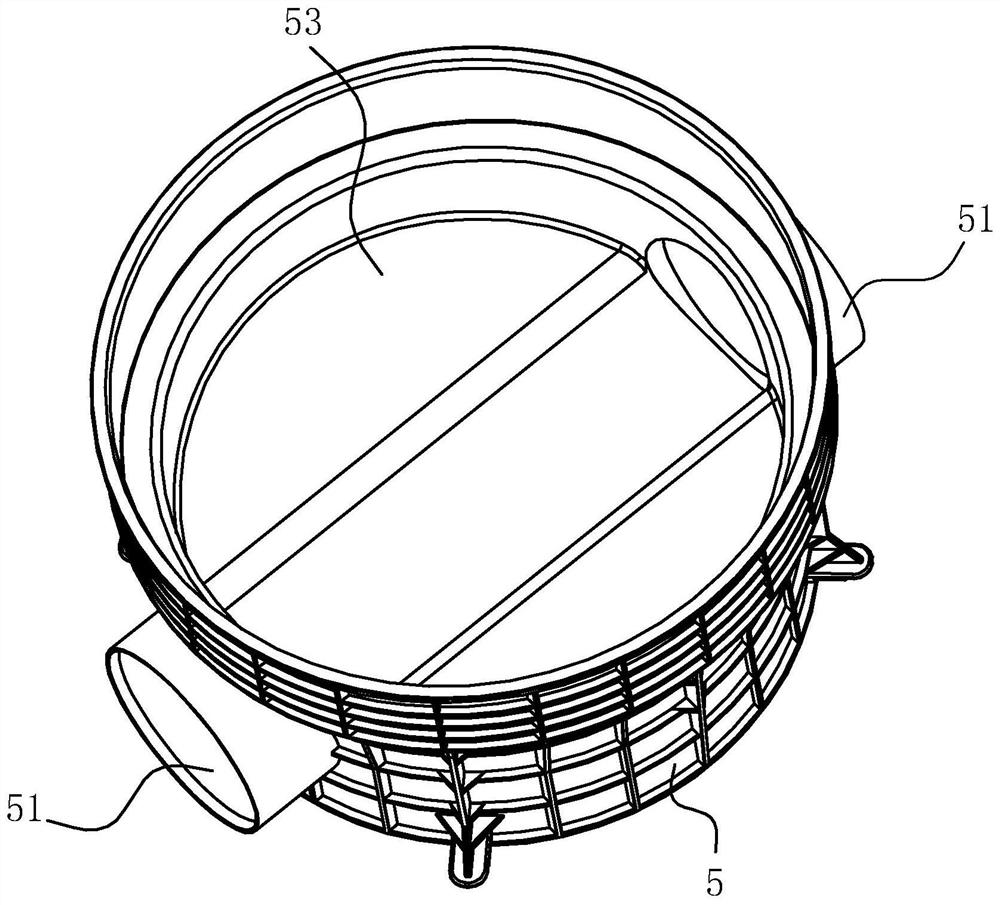

Inspection well mold

A technology for inspecting wells and molds, which is applied to household appliances, other household appliances, and household components. It can solve problems such as difficult to design mold structures for stable injection molding and easy demoulding, achieving high injection molding pressure, stable overall structure, and improved The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

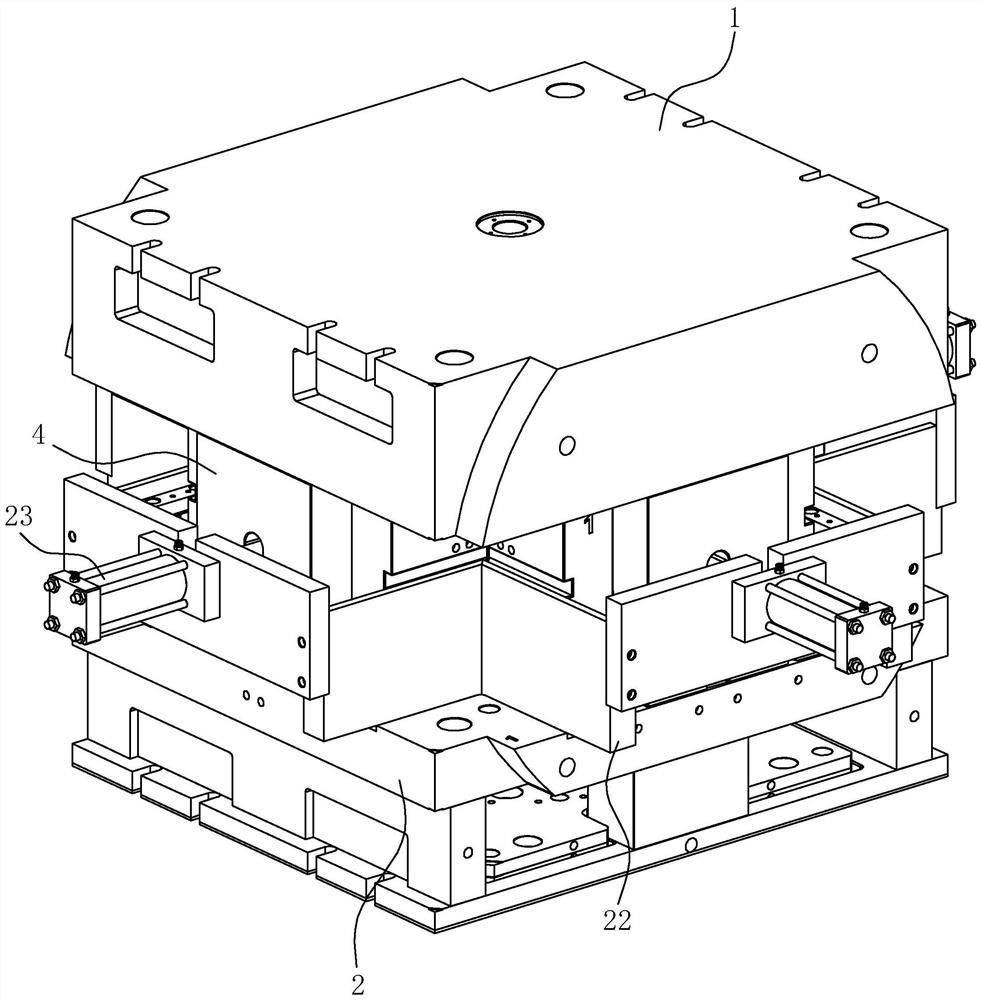

[0038] Such as figure 2 As shown, an inspection well mold includes an upper module 1 and a lower module 2 that can be relatively closed or separated, and the upper module 1 can move away or approach relative to the lower module 2 . The lower module 2 is provided with four side drawer blocks 3 that respectively move forward, backward, left, and right. When the side drawer blocks 3 are closed, the upper module 1 can be closed to the top of the side drawer block 3 recently.

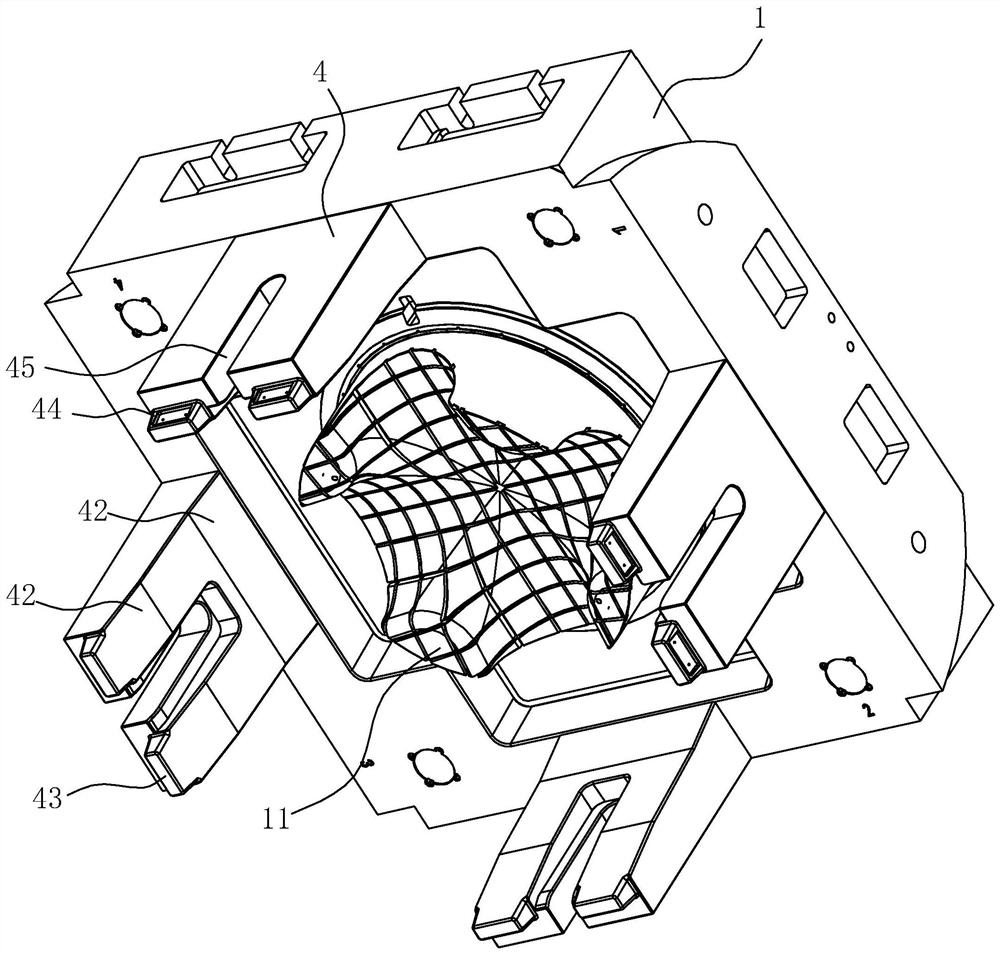

[0039] Such as image 3 and Figure 5 As shown, the upper module 1 is provided with an upper core 11, and the lower module 2 is provided with a lower core 21 opposite to the upper core 11. When closing the mold, when the side drawing block 3 is closed to the innermost, It wraps the lower core 21, and at the same time, the upper core 11 can also be inserted into the inside of the side dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com