A warehouse lifting system

A lifting system and storage technology, applied in elevators, electric components, electromechanical devices, etc., can solve problems such as insufficient flexibility, hidden dangers, time-consuming and labor-intensive, etc., to improve operation safety, ensure structural strength, and reduce assembly difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

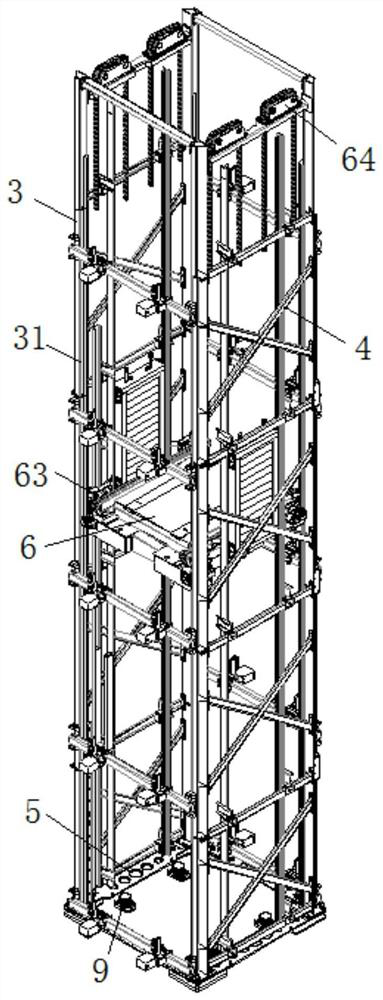

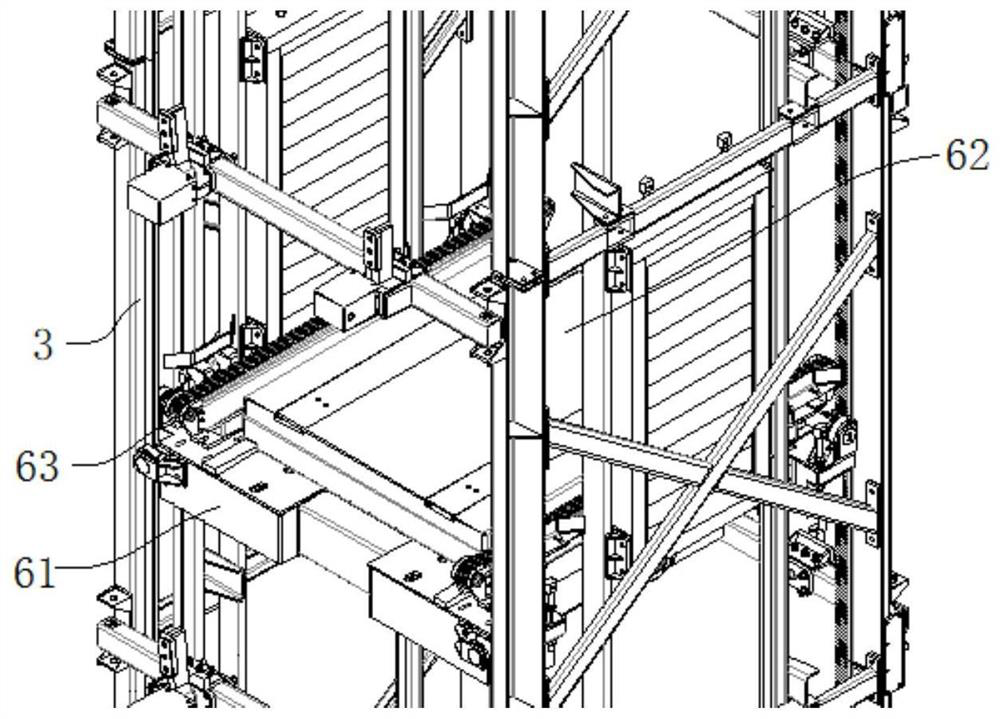

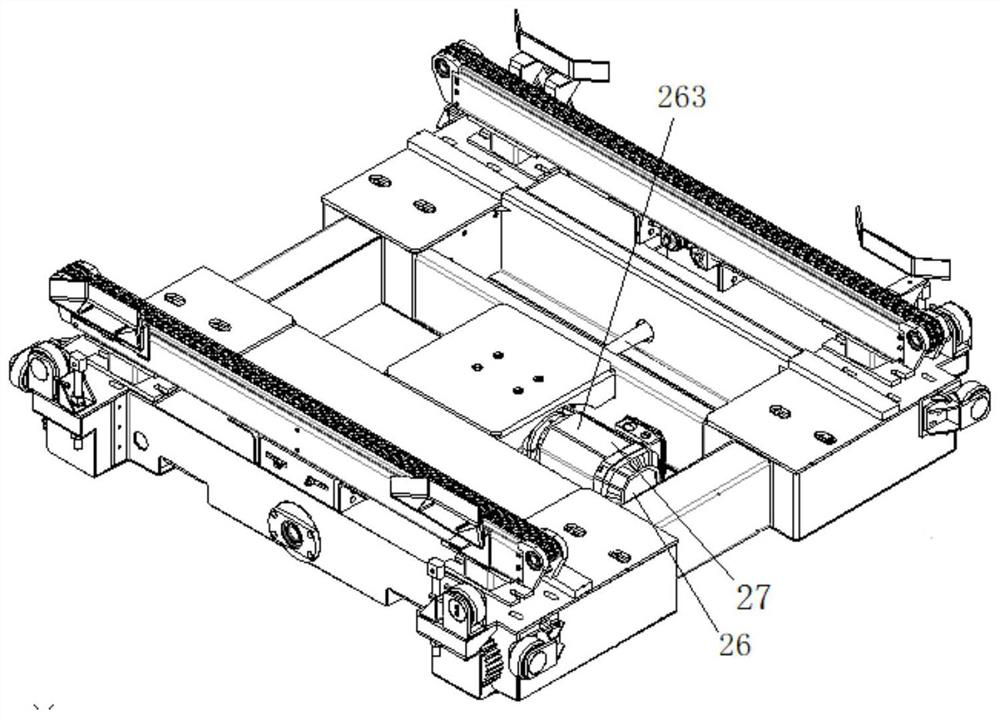

[0029] A warehouse lifting system, such as figure 1 As shown, it includes a lifting frame 3, a reinforcing frame 4 and a base 5; the lifting frame 3 includes vertical rods 31 distributed in an array; the reinforcing frame 4 is connected and arranged between adjacent vertical rods 31 The base 5 is connected to the bottom of the lifting frame 3; the lifting frame 3 is slidingly provided with a loading platform 6; the loading platform 6 is free to move in the vertical direction; the loading platform 6 includes First platform 61 and second platform 62; Described first platform 61 top edge places are symmetrically provided with several first chain machines 63; Described elevating frame 3 tops are provided with several second chain machines 64; Said first The chain machine 63 and the second chain machine 64 are matched one by one, and the chain 7 is wound around each other....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com