Soft foundation reinforcing equipment for highway engineering construction

A soft foundation and engineering technology, applied in roads, roads, buildings, etc., can solve problems such as affecting physical health, dust inhalation into the lungs, breathing difficulties, etc., to ensure the service life, reduce equipment investment, and clean and beautiful surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

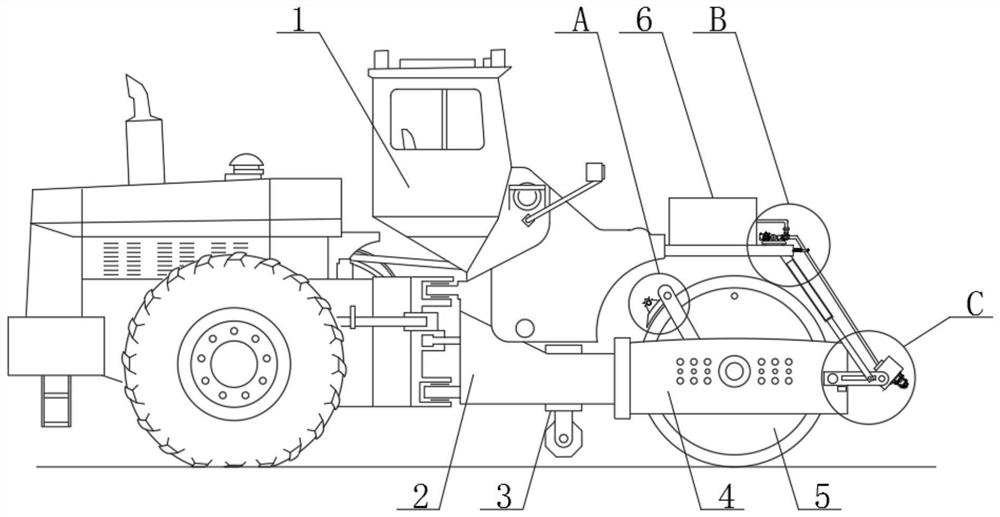

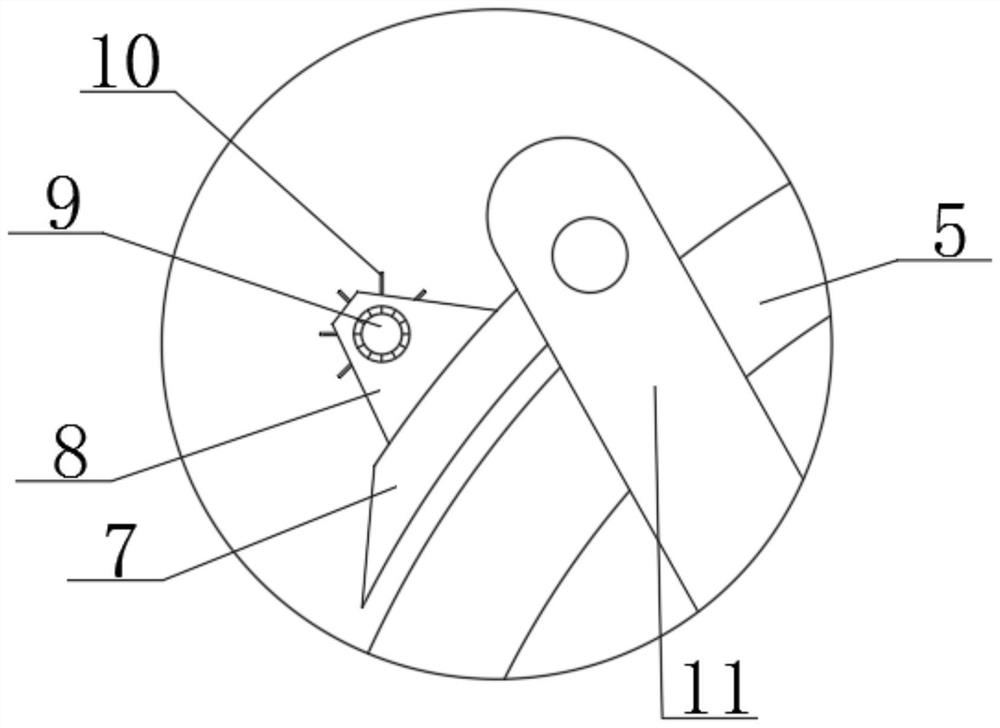

[0025] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the present invention provides a technical solution:

[0026]A soft ground reinforcement equipment for highway engineering construction, comprising a road roller 1 and a connecting body 2, the connecting body 2 is fixedly connected under the road roller 1, and a rapping mechanism 3 is fixedly connected inside the connecting body 2, and the rapping mechanism 3 includes a fixed frame 301 and The sliding plate 302, the outside of the fixed frame 301 is fixedly connected with the connecting body 2, the inside of the fixed frame 301 is slidably connected with the sliding plate 302, the upper end surface of the sliding plate 302 is fixedly connected with the sliding rod 303, and the lower end surface of the sliding plate 302 is fixedly connected with the front and back distribution. The fixed plate 309 and the rapping roller 310 are arranged under the sliding plate 302. The front and rear end sur...

Embodiment 2

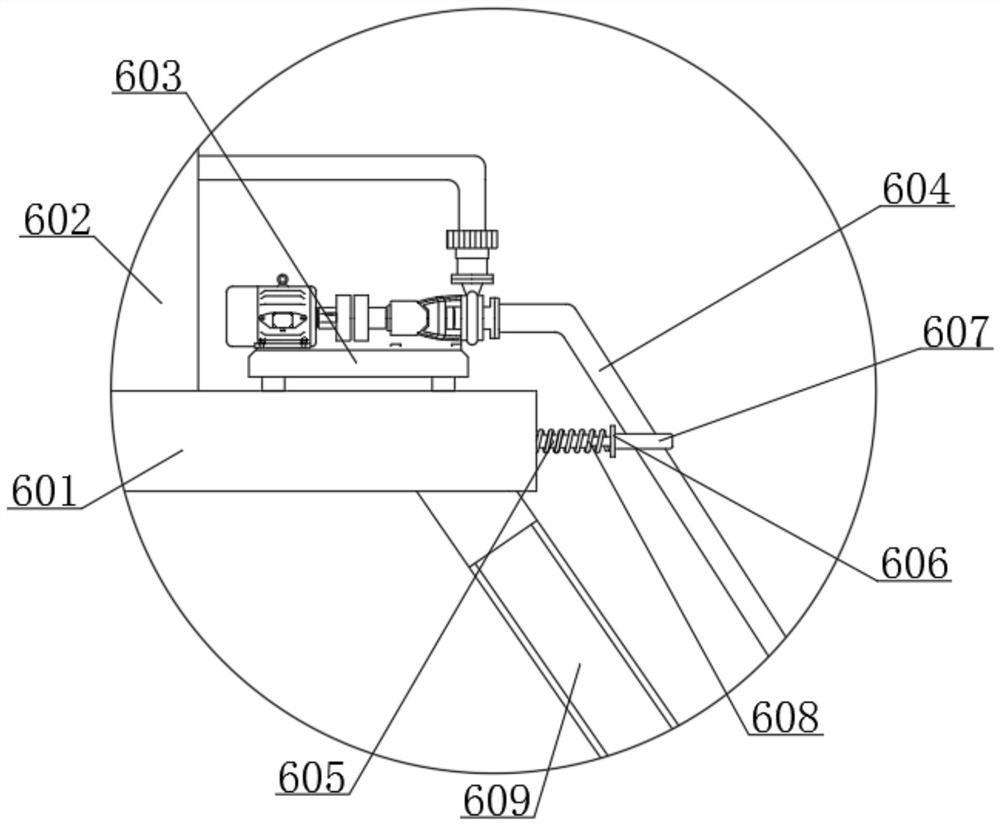

[0029] In Embodiment 2, the same parts as in Embodiment 1 will not be repeated. The difference is that when the device is not in use, the sliding block 610 can be driven to slide on the outside of the rotating plate 611 by starting the electric telescopic rod 609 at this time, thereby turning the rotating plate 611 drives the upward rotation, and then drives the hollow tube 614 upward rotation to make it vertically placed, saving space. At this time, under the action of the telescopic spring 608, it pushes the fixed block 606 to move to the right, and the telescopic rod 605 is in a stretched state, ensuring The water pipe 604 moves to the right to make it stretched, avoiding its entanglement, avoiding its contact with the roller 5, and ensuring the normal use of the water pipe 604, and the set stopper 613 can play the purpose of supporting the rotating plate 611.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com