A method for excavating a vertical cavern with a large diameter

A cavern and large hole technology, applied in the field of large-diameter vertical cavern excavation, can solve the problems of high risk factor and high cost, and achieve the goal of improving the level of mechanization, saving construction period and economic cost, and improving construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the specific embodiments, which further illustrate the principles of the present invention and do not limit the present invention in any way, and the same or similar technologies as the present invention do not exceed the protection scope of the present invention.

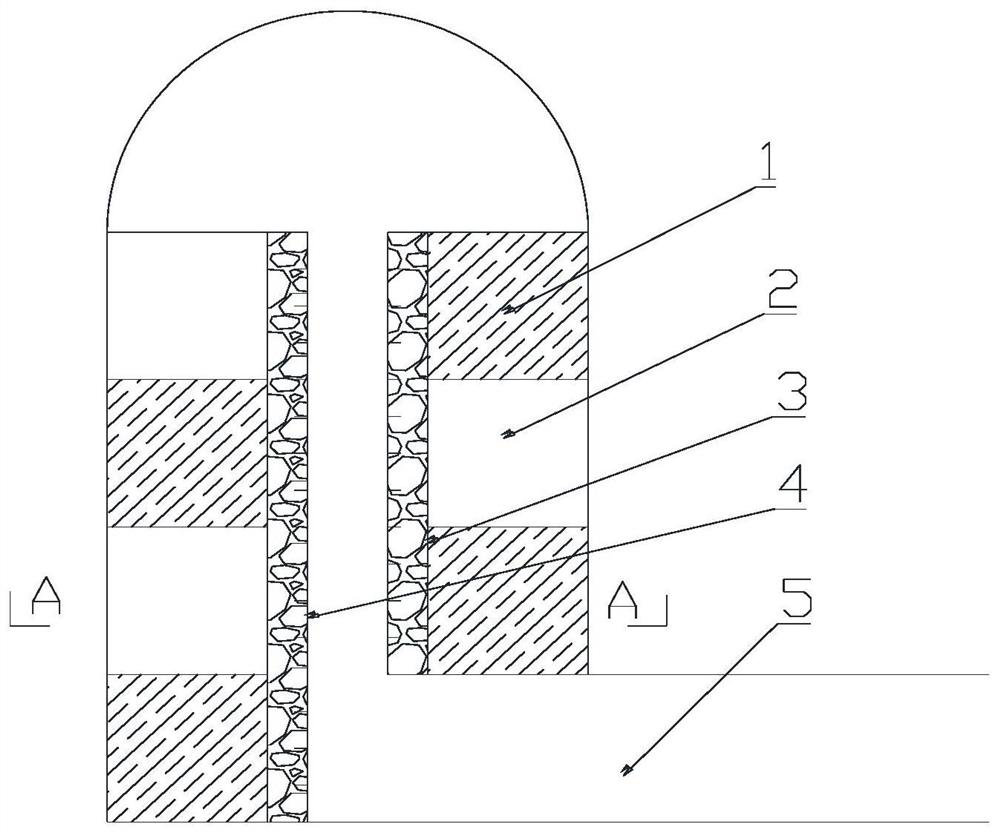

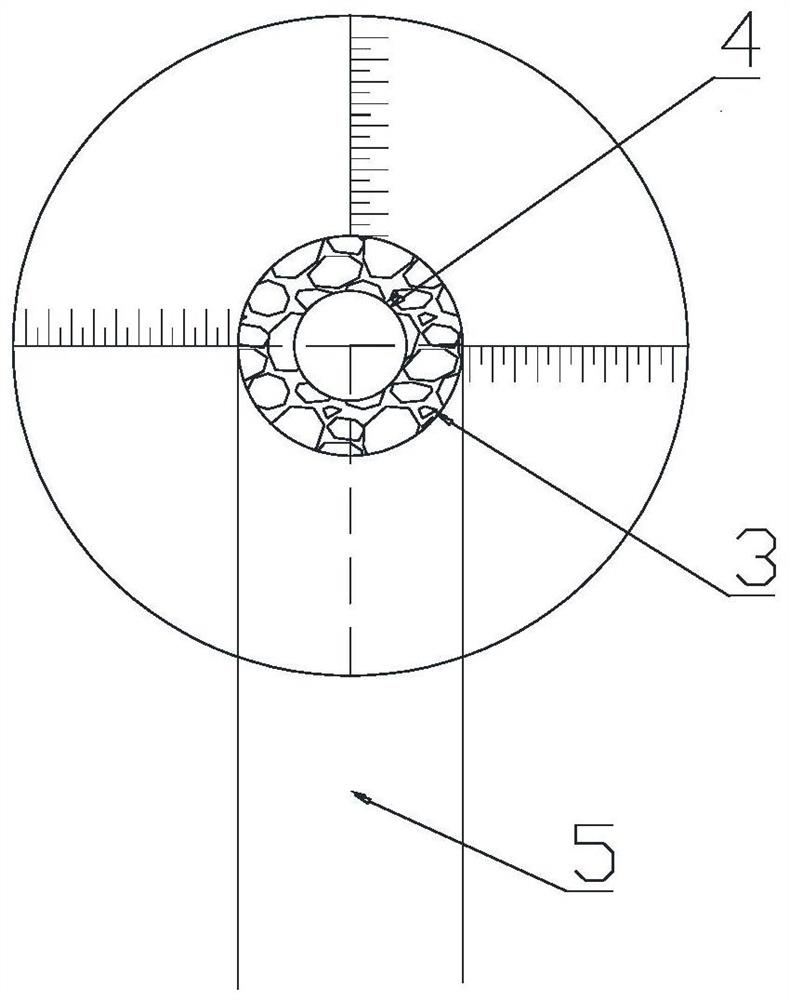

[0016] In conjunction with the attached drawings.

[0017] The method of the invention adopts the technical method of excavation from bottom to top, and sets a central steel box culvert as a slag slag channel. excavation.

[0018] First, excavate the large cavern of the shaft, starting from the bottom up, starting from the right or left side, taking the center of the cavern as the center of the circle, and spirally rising. The slope and height are determined according to the climbing and traffic capacity of the site equipment. It becomes a slope to excavate upward, which reduces the safety risk and improves the excavation efficiency. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com