A convergent-divergent nozzle with shock wave bypass structure

A shock wave and nozzle technology, which is applied in the field of aero-engine structure design, can solve problems such as affecting the outflow of cold air, air film coverage, and reducing cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

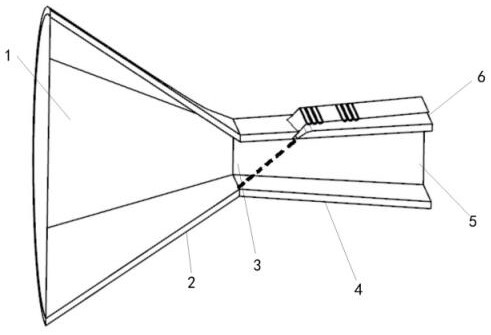

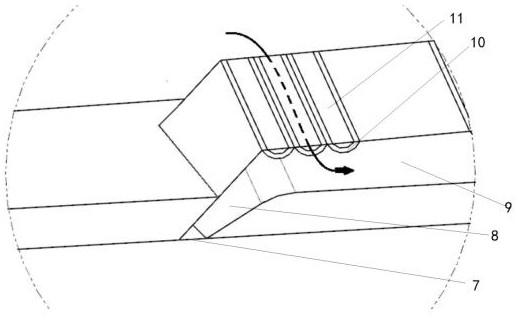

[0019] A retractable nozzle adopting a shock wave bypass structure in this embodiment, the main structure includes the main part of the nozzle, the channel 8 and the bypass channel 9 opened at the expansion section 4, and the main part of the nozzle includes the inlet of the nozzle 1. Constriction section 2, throat 3, expansion section 4, nozzle outlet 5, slot 8 is set near the first shock wave incident position in the nozzle expansion section, the slot width is 10mm, and the slot length is continuous along the circumferential direction. An elastic baffle 7 is arranged at the opening of the channel 8, and the elastic baffle 7 is arranged at the entrance of the channel to sense the pressure change, close when there is no shock wave, and open when there is a shock wave. The elasticity of the elastic baffle 7 is set according to the specific engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com