A flow control valve with flow stop function

A flow-stopping and functional technology, which is applied in the field of flow control valves, can solve the problems that valves cannot stop flow, do not have corrosion resistance, waste water resources, etc., achieve good thermal insulation characteristics, safe and convenient use, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

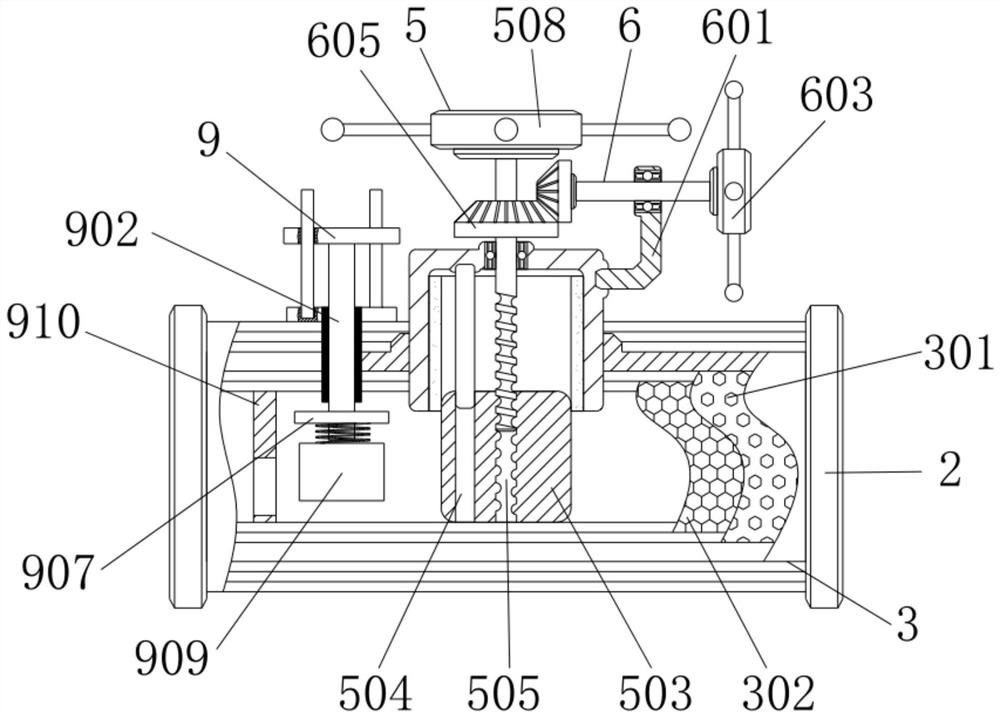

[0040]A flow regulating valve with a flow stop function, comprising a pipeline 1, flanges 2 are provided on the left and right sides of the outer wall of the pipeline 1, and the right side of the left flange 2 is fixedly connected to the left side of the pipeline 1, The flange 2 is used to connect the left and right ends of the pipeline 1 with the external delivery pipe, the left side of the right flange 2 is fixedly connected with the right side of the pipeline 1, and the left side of the pipeline 1 is provided with a flow stop mechanism 9 The flow stop mechanism 9 includes a sealing sleeve 901, a telescopic rod 902, a rotating handle 903, a fixed plate 904, a slot 905, a limit post 906, a horizontal plate 907, a torsion spring 908, a block 909 and a through-hole plate 910; The shaft sleeve 901 is connected to the top left side of the pipe 1. The top of the sealing shaft sleeve 901 is provided with a fixed plate 904. Rod 902 is rotatably connected to pipe 1 through seal bushi...

Embodiment 2

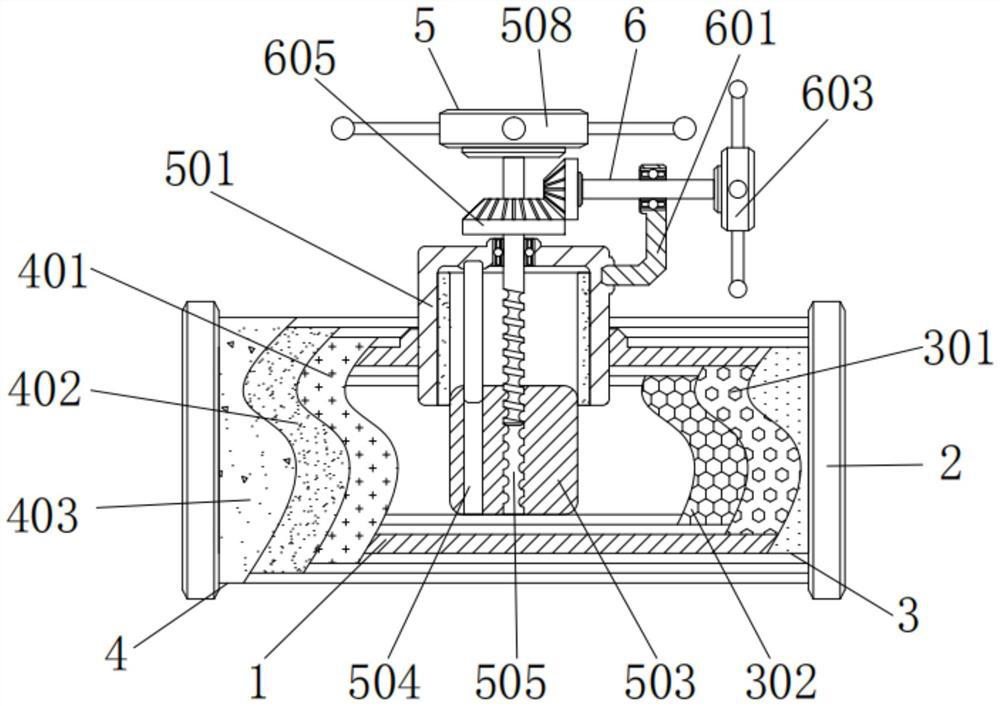

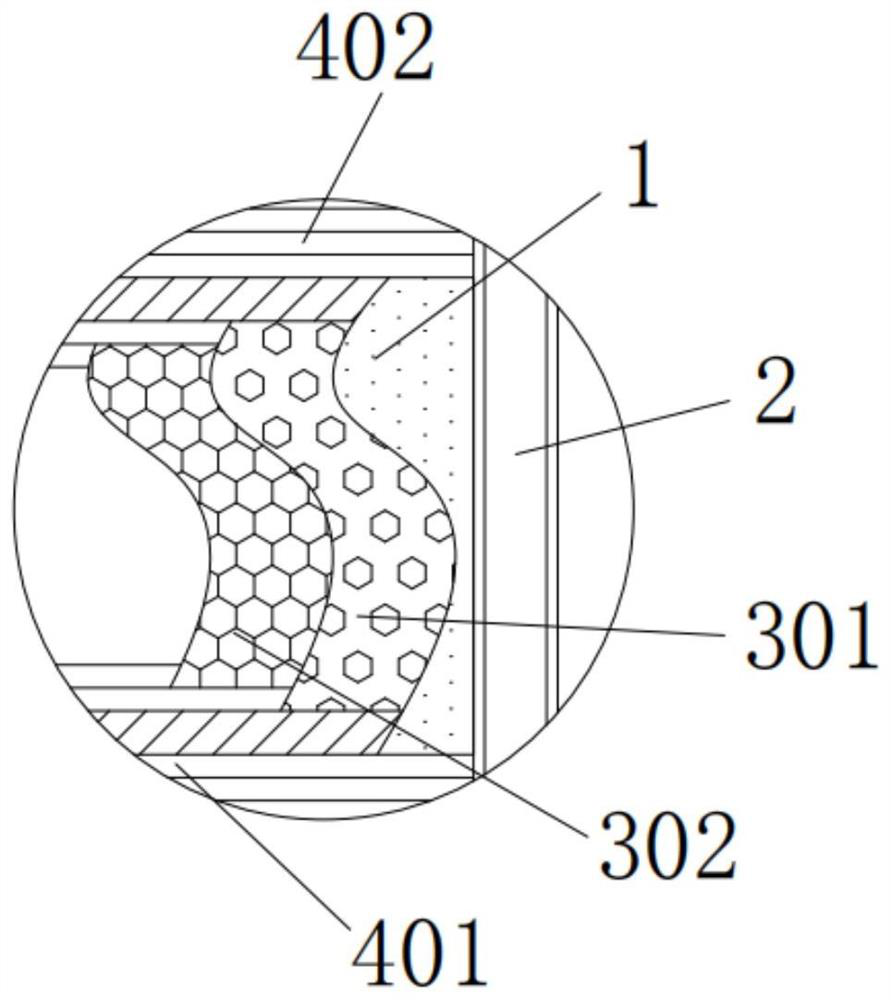

[0042] As an option, see Figure 1-2 , the inner wall of the pipeline 1 is provided with an anti-corrosion layer 3, the anti-corrosion layer 3 includes a polytetrafluoroethylene layer 301 and a copper oxide layer 302, the polytetrafluoroethylene layer 301 is located on the inner wall of the pipeline 1, and the polytetrafluoroethylene layer 301 is named "Teflon", abbreviated as PTE or F4, commonly known as the king of plastics, is one of the most corrosion-resistant materials in the world today. The PTFE layer 301 is sprayed together with the inner wall of the pipe 1. Copper oxide layer 302 is plated on the inner wall, and the copper oxide layer 302 has a chemical formula of CuO, which is a black oxide of copper and has good corrosion resistance.

[0043] The solution in this embodiment can be selectively used in combination with the solutions in other embodiments.

Embodiment 3

[0045] As an option, see Figure 1-4 , a flow control valve with a stop-flow function, the outer wall of the pipeline 1 is provided with an insulation layer 4, the insulation layer 4 includes a molded polystyrene foam layer 401, a polyurethane rigid foam layer 402 and an acrylic waterproof coating 403, molded The polystyrene foam layer 401 is sleeved on the outer wall of the pipe 1. The molded polystyrene foam layer 401 has excellent and durable thermal insulation, unique cushioning, shock resistance, aging resistance and waterproof performance. The outer wall of the ethylene foam layer 401 is provided with a polyurethane rigid foam layer 402, which has good thermal insulation effect, light weight, high specific strength, convenient construction, etc., and also has sound insulation and shock resistance. Electrical insulation, heat resistance, cold resistance, solvent resistance, etc., the inner wall of the polyurethane rigid foam layer 402 is bonded with the molded polystyrene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com