Movable installation device and installation method of microseismic sensor

A microseismic sensor and installation device technology, which is applied in the direction of measuring devices, seismic signal receivers, instruments, etc., can solve the problems of discounted signal reception performance of sensors, poor coupling quality between rock mass and probe, and influence on grouting effect, etc., to achieve Avoid poor grouting quality, good sealing effect, and prevent the effect of spraying grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following is a detailed description of the embodiments of the present invention. This embodiment is carried out based on the technical solution of the present invention, and provides detailed implementation methods and specific operation processes to further explain the technical solution of the present invention.

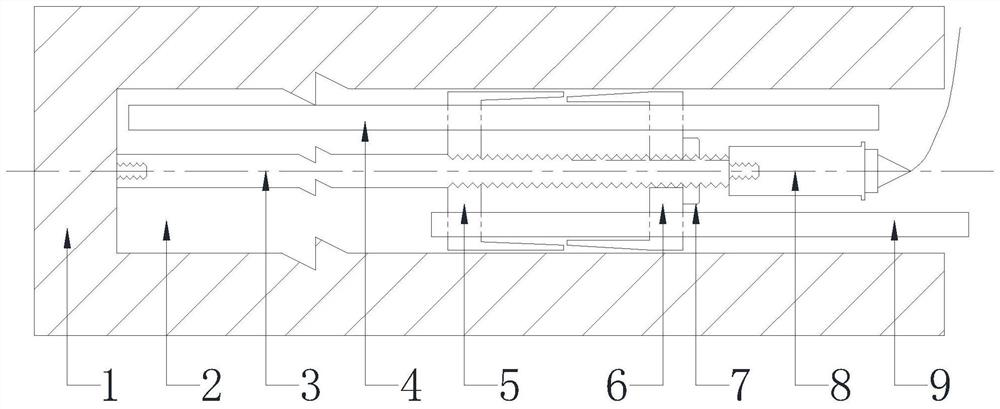

[0049] The movable mounting device of the microseismic sensor 8 provided in this embodiment, such as figure 1 As shown, it includes a grouting installation assembly and a grouting assembly, the grouting installation assembly includes an exhaust pipe 4, a grouting pipe 9 and several probes 3, and the grouting assembly includes a grouting plug near the bottom of the hole 5 , The part 6 near the orifice of the slurry plug and the compression nut 7.

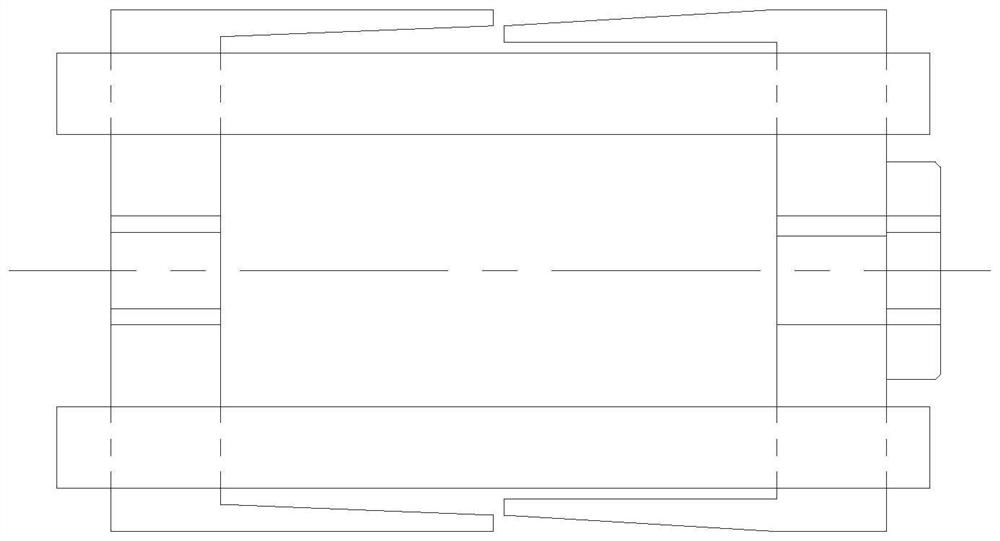

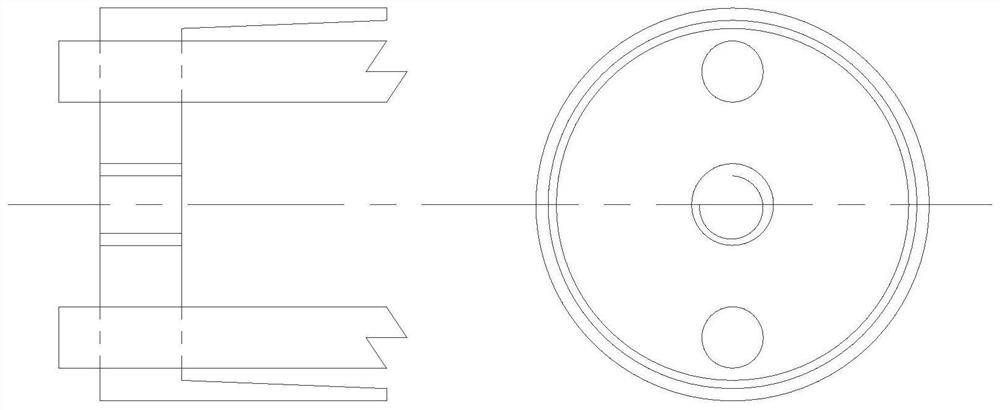

[0050] Described plugging plug near hole bottom part 5 and plugging plug near orifice part 6, such as figure 1 , 2 As shown, they are all cylindrical structures with one end open to match the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com