Onion slitting device

A technology for cutting strips and onions, applied in metal processing and other directions, can solve the problems of too small equipment, inconvenient collection, and hidden safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

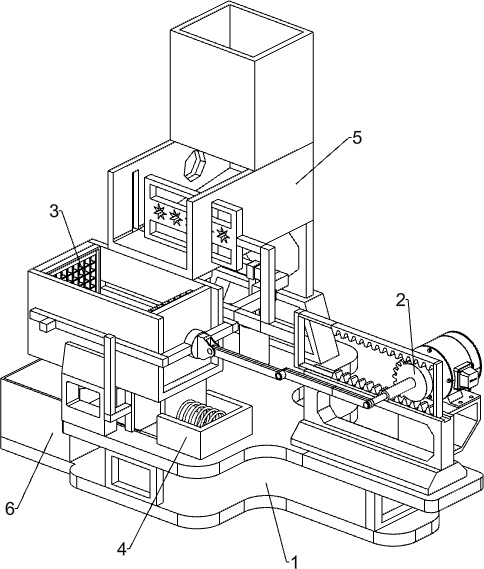

[0040] A device for cutting onion strips, such as figure 1 As shown, it includes a mounting frame 1, an output mechanism 2, a strip cutting mechanism 3 and a blanking mechanism 4. The output mechanism 2 is arranged on the right side of the top of the mounting frame 1, and a cutting mechanism is connected between the left side of the output mechanism 2 and the top of the mounting frame 1. The strip mechanism 3 is connected with a blanking mechanism 4 on the front side of the top of the mounting frame 1, and the blanking mechanism 4 is in contact with the strip cutting mechanism 3.

[0041] When the staff needs to cut the onion into strips, they can first put the onions into the strip-cutting mechanism 3 in turn, start the output mechanism 2 to drive the strip-cutting mechanism 3 to slice the onion, and after the strip-cutting is completed, pass through the strip-cutting mechanism 3 Drive the blanking mechanism 4 to drop the onions that have been cut into strips, and the staff c...

Embodiment 2

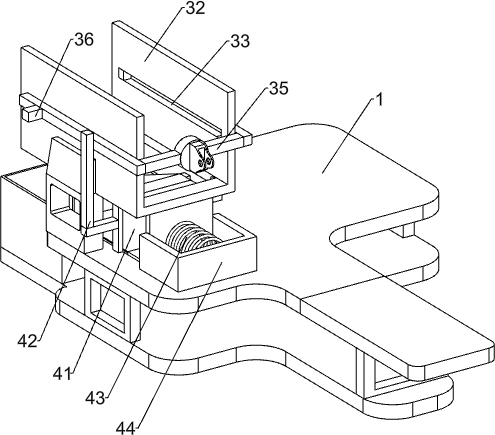

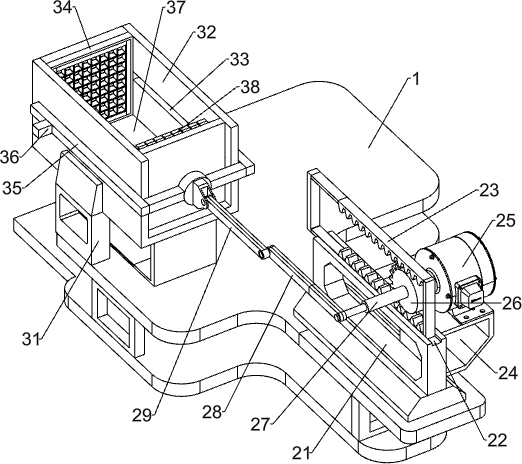

[0043] On the basis of Example 1, such as figure 2 As shown, the output mechanism 2 includes a first mounting plate 21, a guide rail 22, a rack frame 23, a second mounting plate 24, a motor 25, a missing gear 26, a rotating shaft 27, a first transmission rod 28 and a second transmission rod 29, The right side of the top of the mounting frame 1 is provided with a first mounting plate 21, the top of the first mounting plate 21 is provided with a guide rail 22, a rack frame 23 is slidably provided on the guide rail 22, and a second mounting plate is provided on the rear side of the first mounting plate 21 24, the top of the second mounting plate 24 is provided with a motor 25, the output shaft of the motor 25 is provided with a rotating shaft 27, the rotating shaft 27 is provided with a missing gear 26, the missing gear 26 is meshed with the rack frame 23, and the rotating shaft 27 front end is provided with a first A transmission rod 28, the left side of the front end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com