Patents

Literature

30results about How to "Easy automatic transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

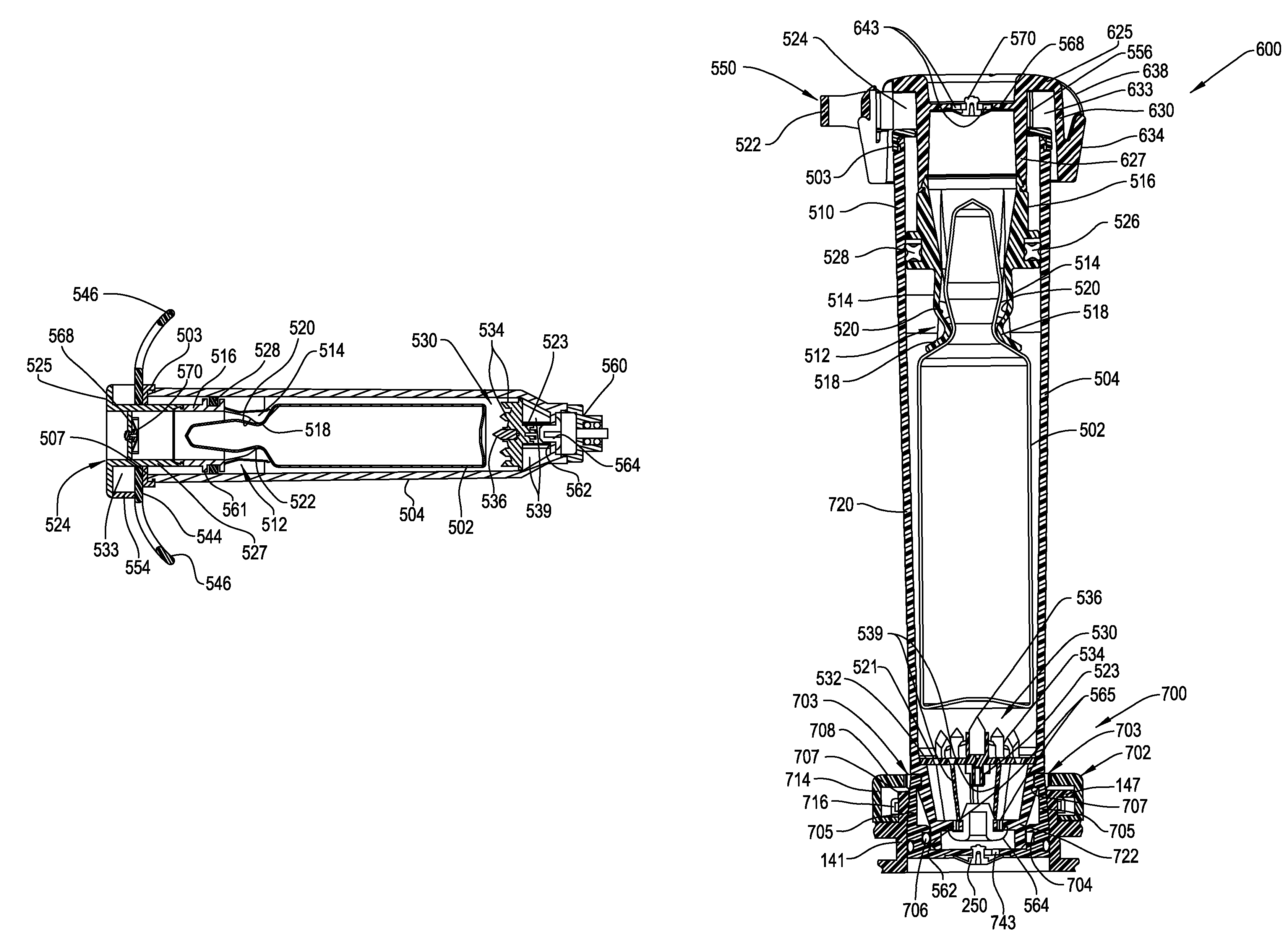

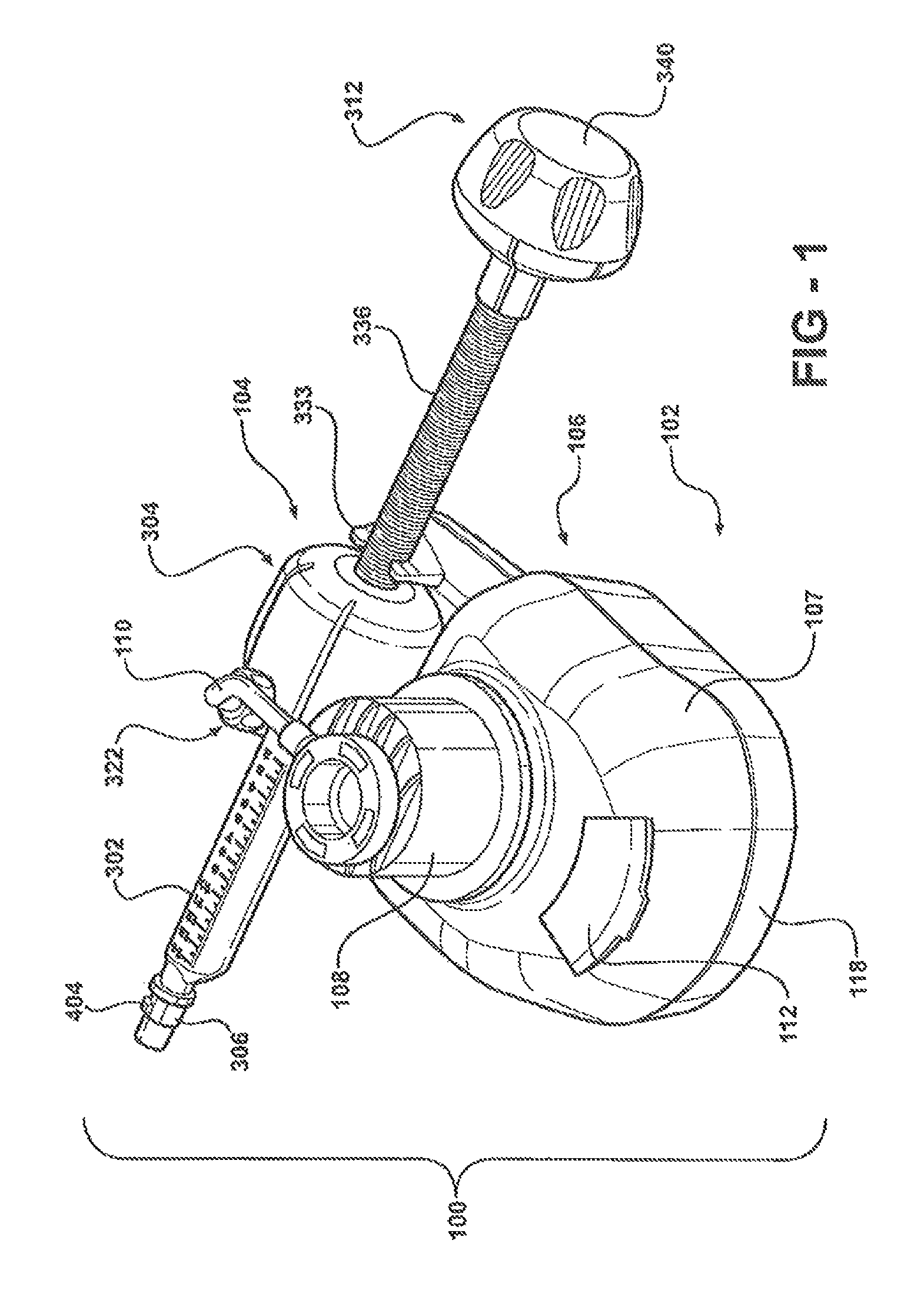

Medical cement monomer ampoule cartridge for storing the ampoule, opening the ampoule and selectively discharging the monomer from the ampoule into a mixer

ActiveUS8132959B2Easy automatic transferMinimize exposureRotary stirring mixersMixer accessoriesEngineeringBone cement

A monomer handling unit for storing a ampoule of monomer and releasing the monomer from the ampoule when desired is provided. The monomer handling unit can be used to attach to an enclosed mixer and release a monomer component of the bone cement into the mixer to be mixed with a powder component of the bone cement. The monomer handling unit can also be used to release the liquid monomer into another mixer, such as one that is not enclosed.

Owner:STRYKER CORP

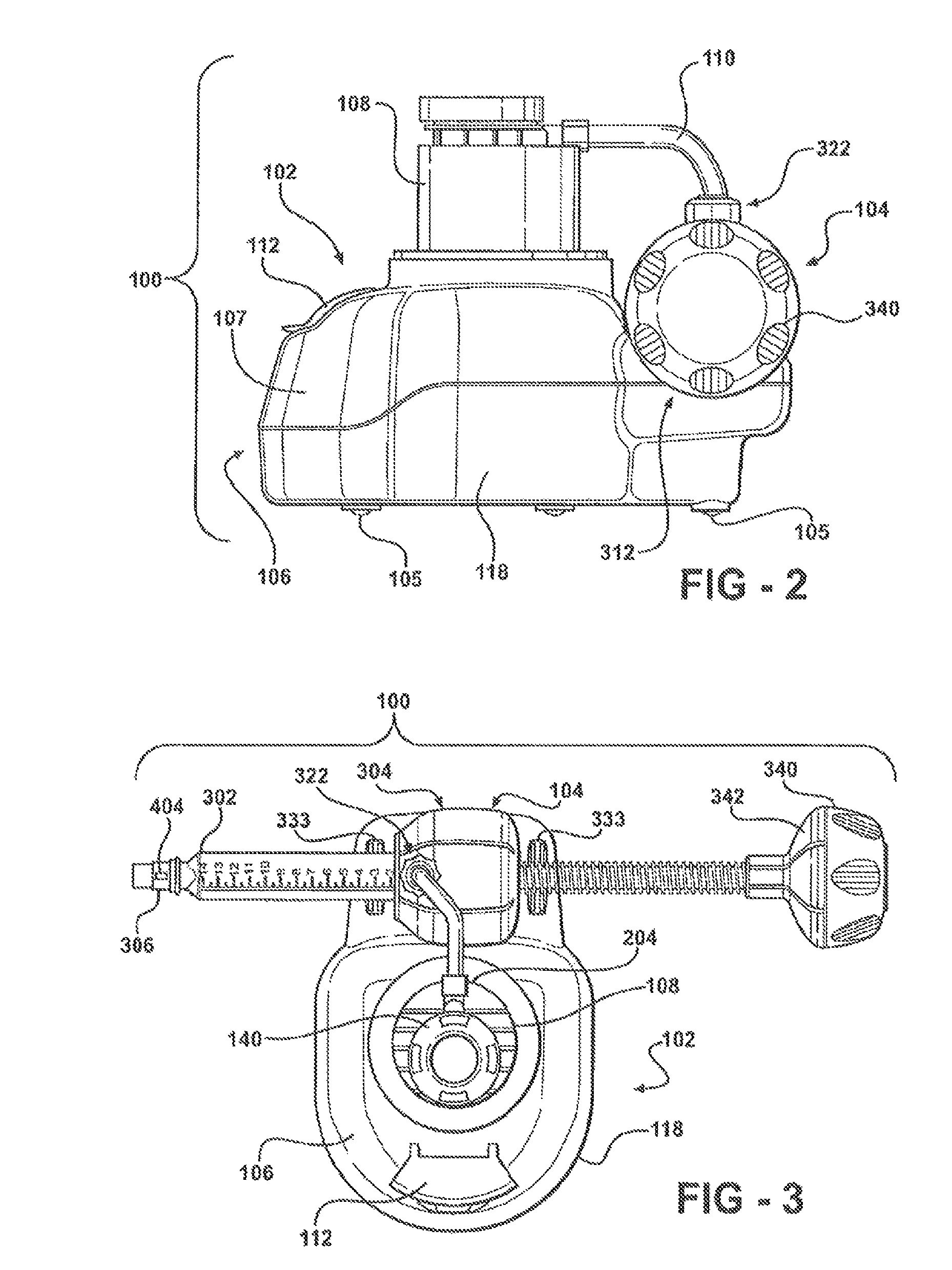

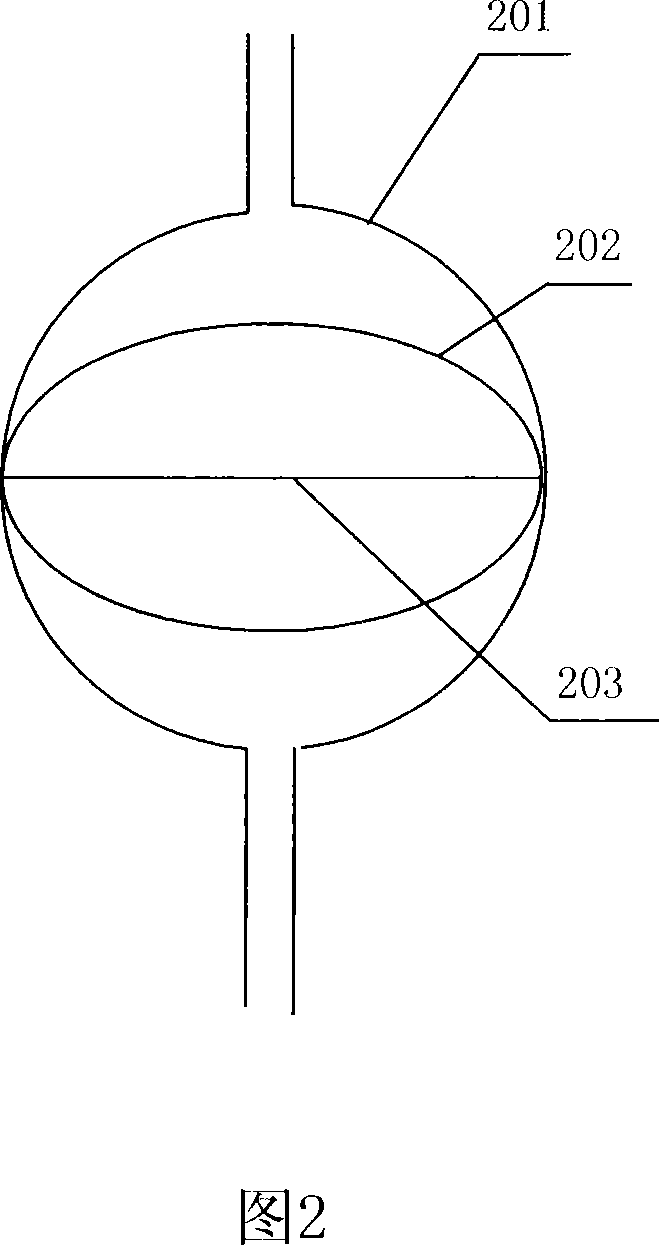

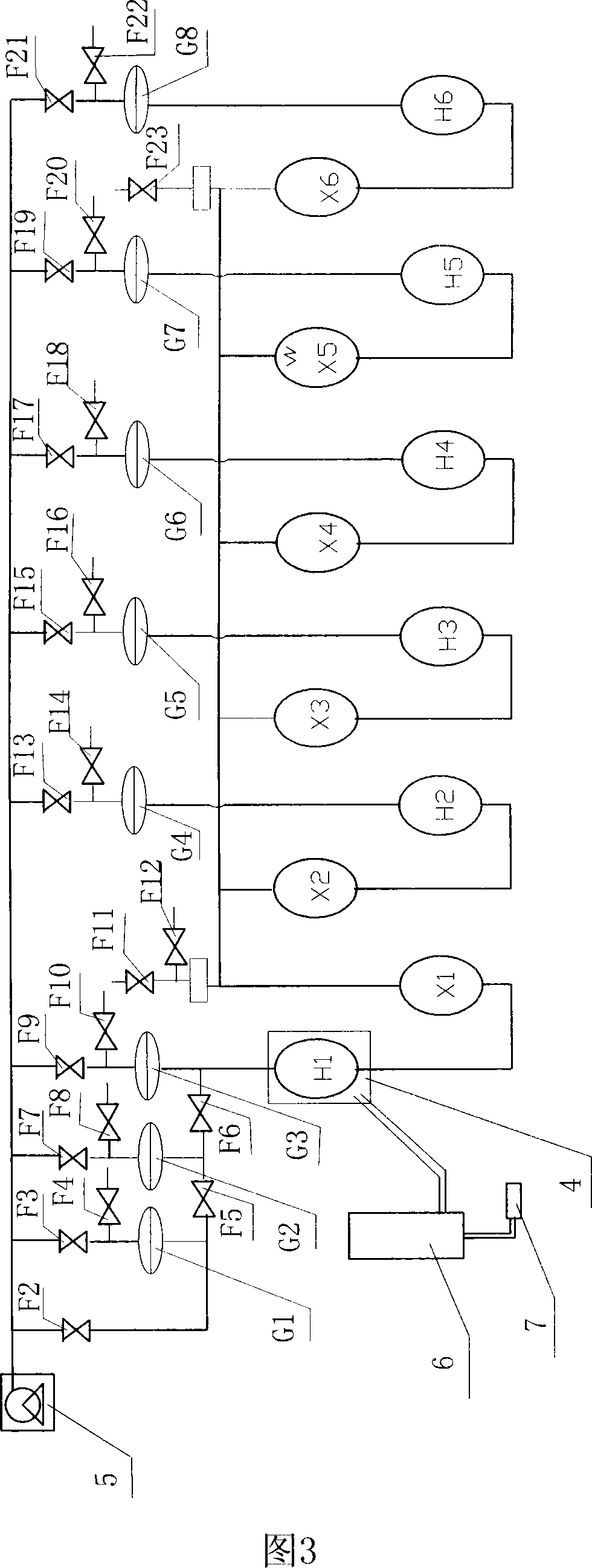

Gas analyzer

InactiveCN101196457AEasy automatic transferAccurate analysisChemical methods analysisGas compositionCombustible gas

The invention relates to the analytical instrument filed in chemistry, which provides an air analyzer and comprises an air pressure transferring pump, an air pressure transferring tube, an automatic controller, a sample introduction measuring device and an air element adsorbing device. The air element adsorbing device comprises a plurality of air element adsorbing units with same structure, and the air element adsorbing units are connected with the sample introduction measuring device, the air pressure transferring tube and an automatic controller. The adsorbing bottles of each air element adsorbing bottle is loaded with adsorbing liquid for adsorbing different air or flammable air burning wire, which can be used in the air element analyzing of complicate component, the analyzing progress is controlled by automatic controlling procedure, the manufacture cost is low, the operation progress is simple and the analyzing result is accurate and reliable.

Owner:武钢集团有限公司

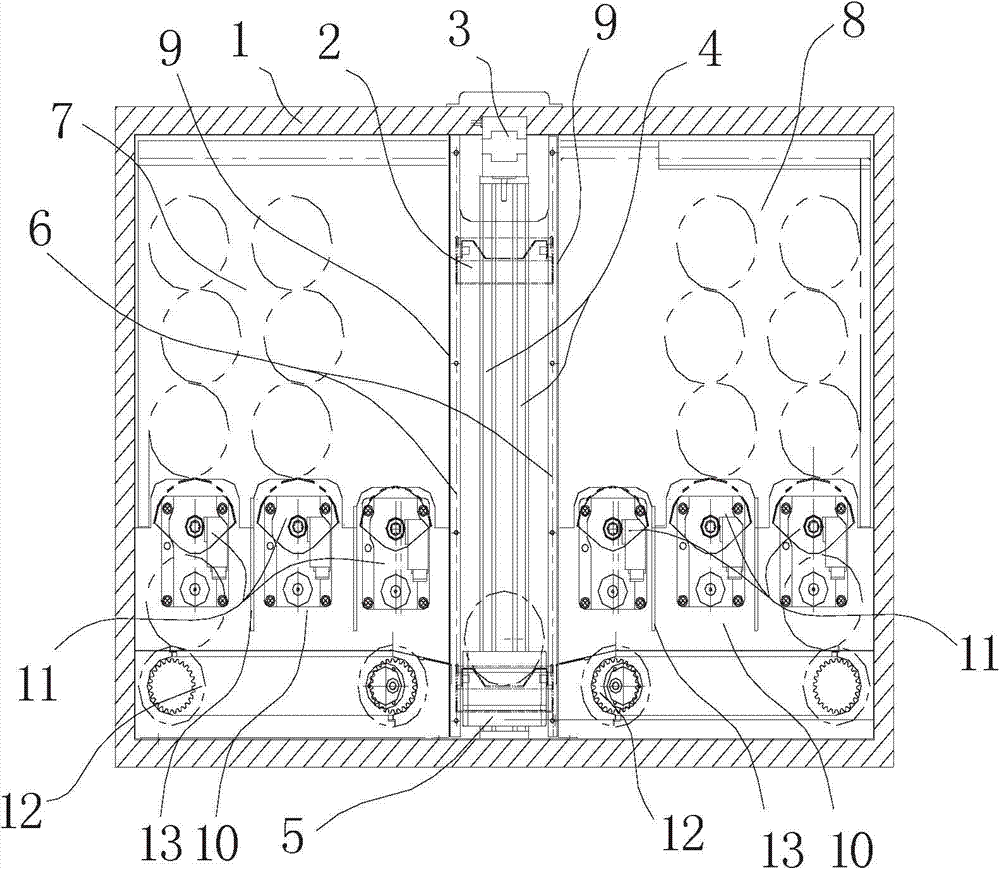

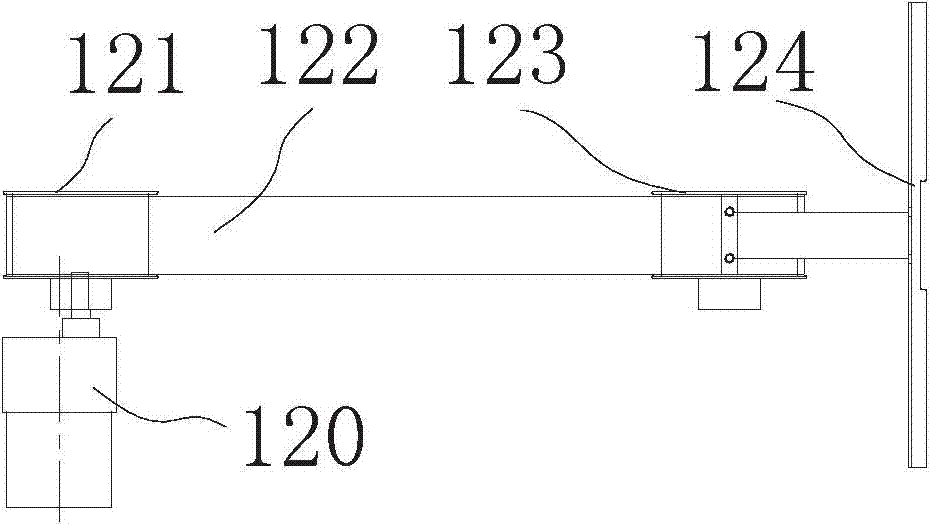

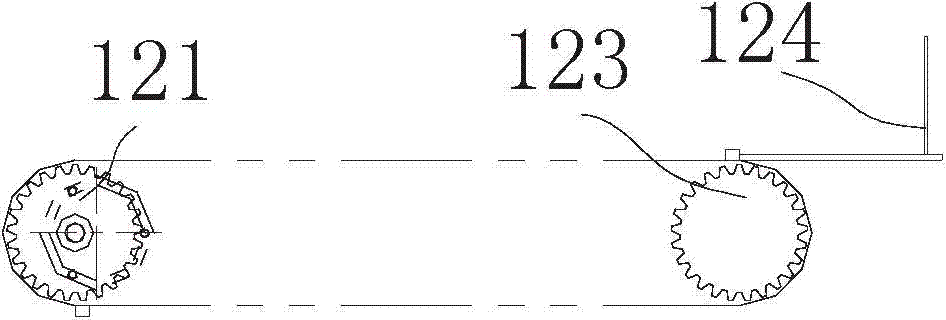

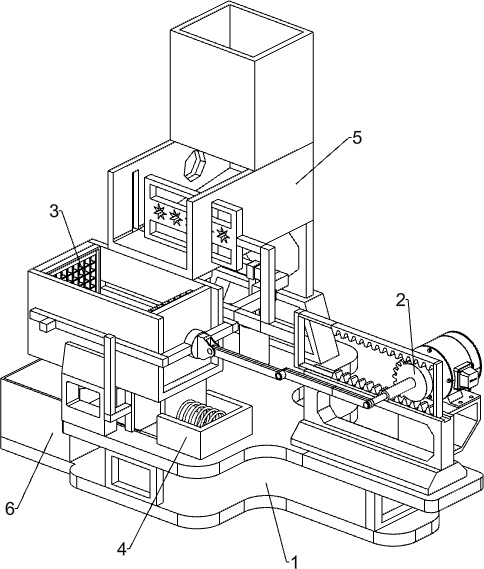

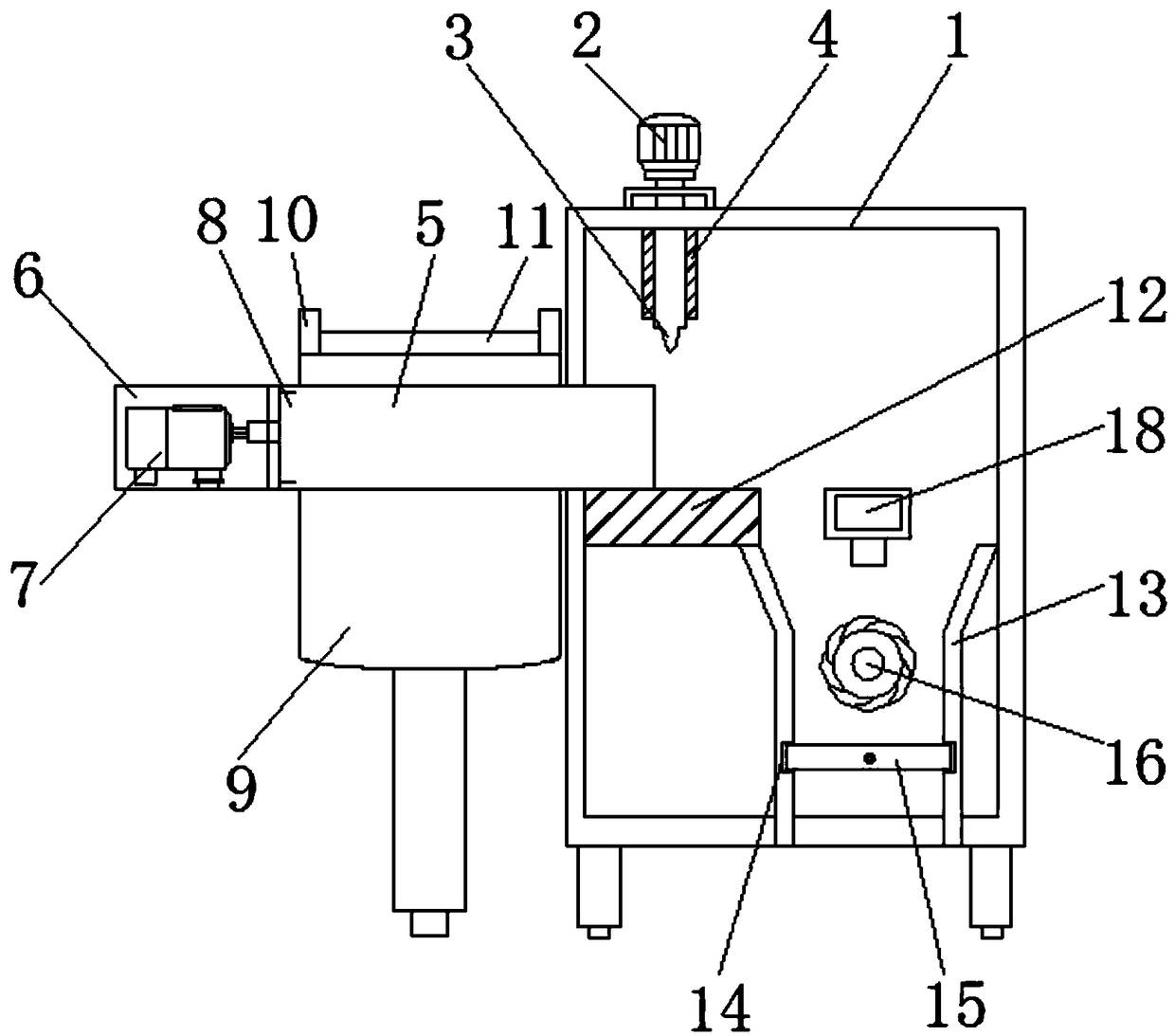

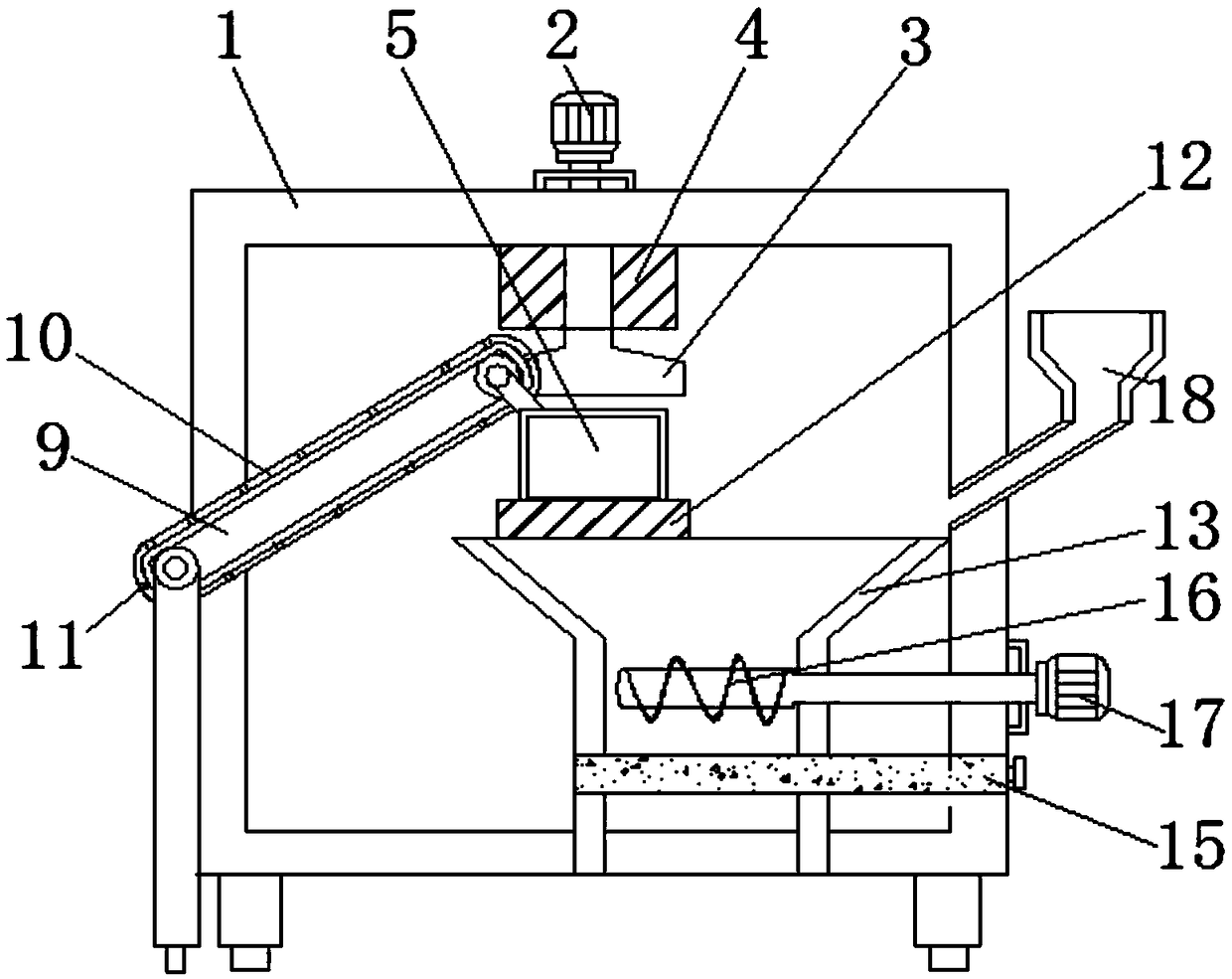

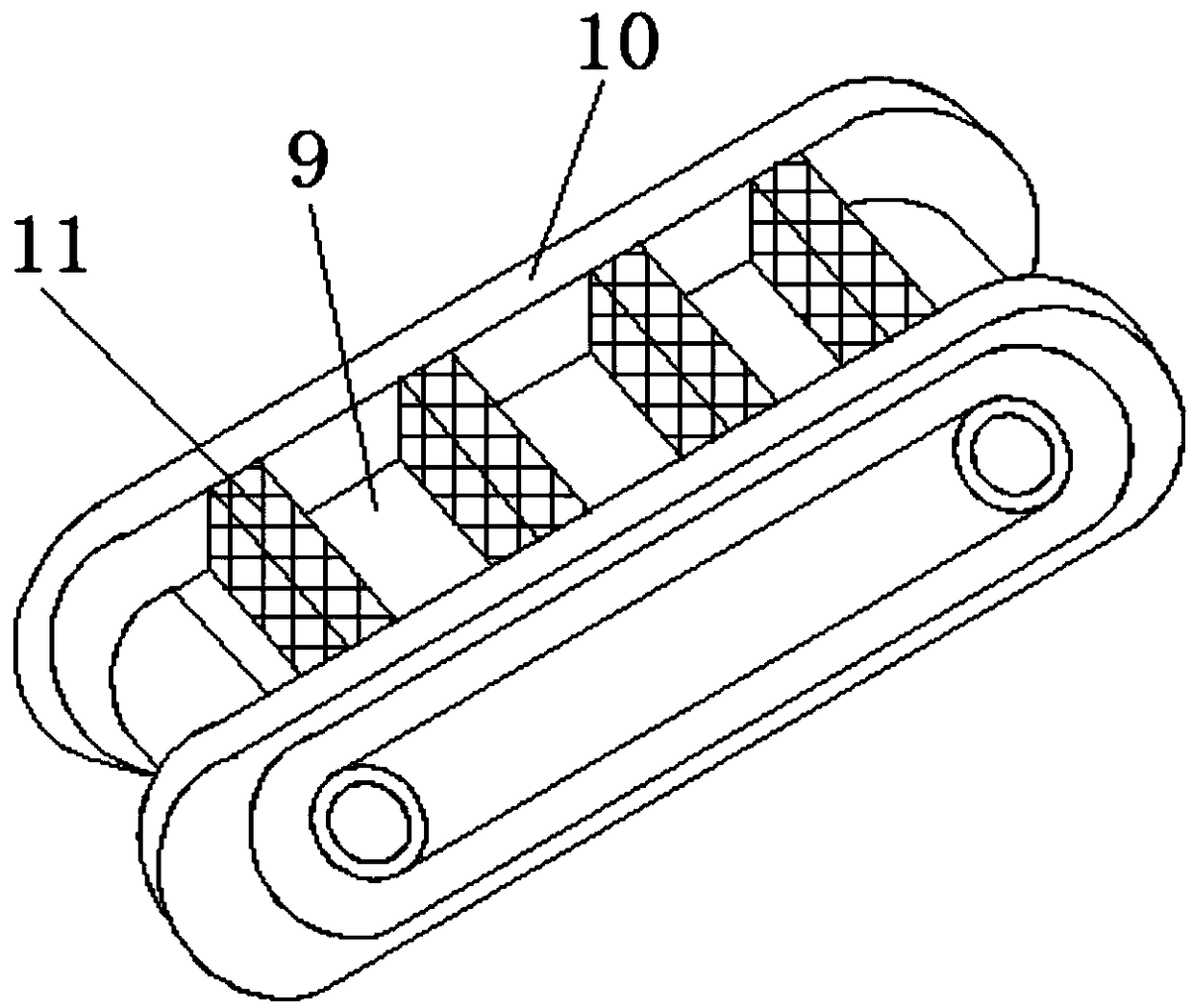

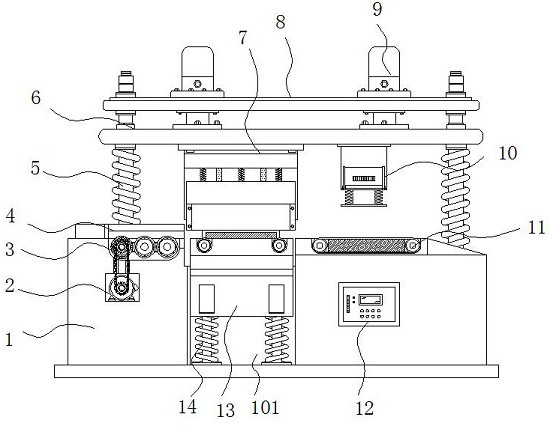

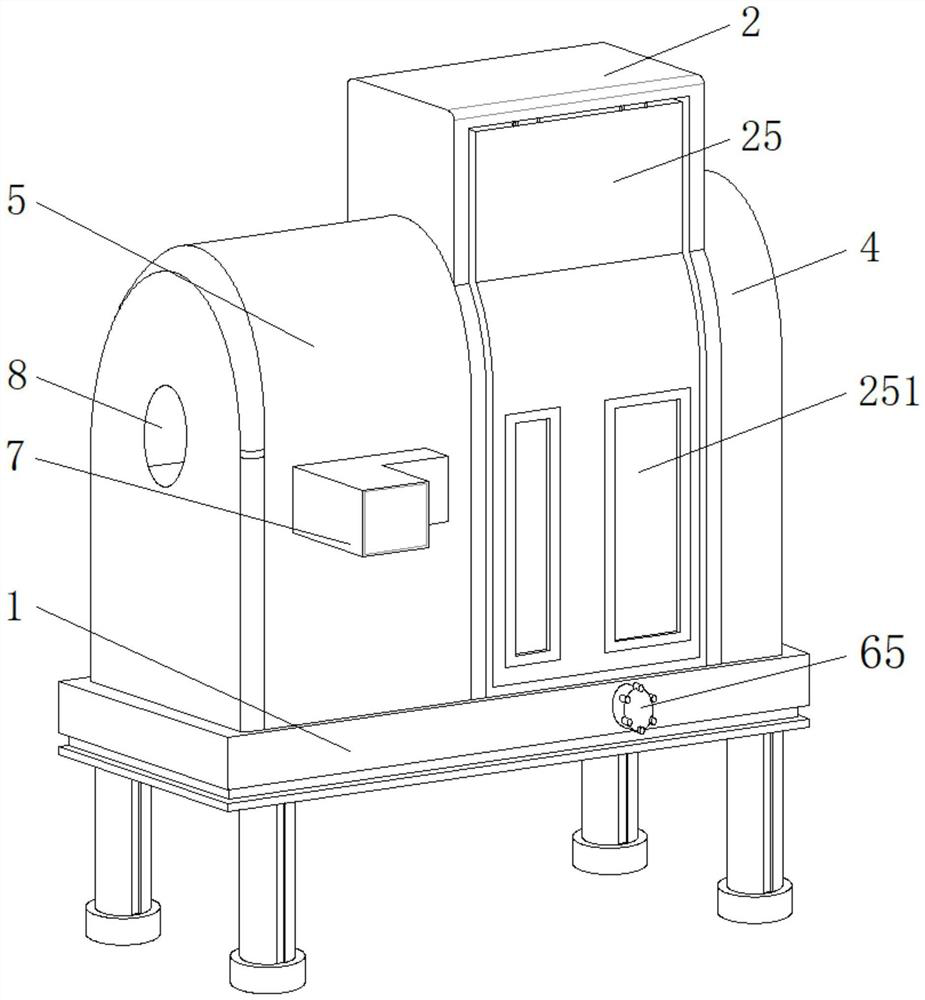

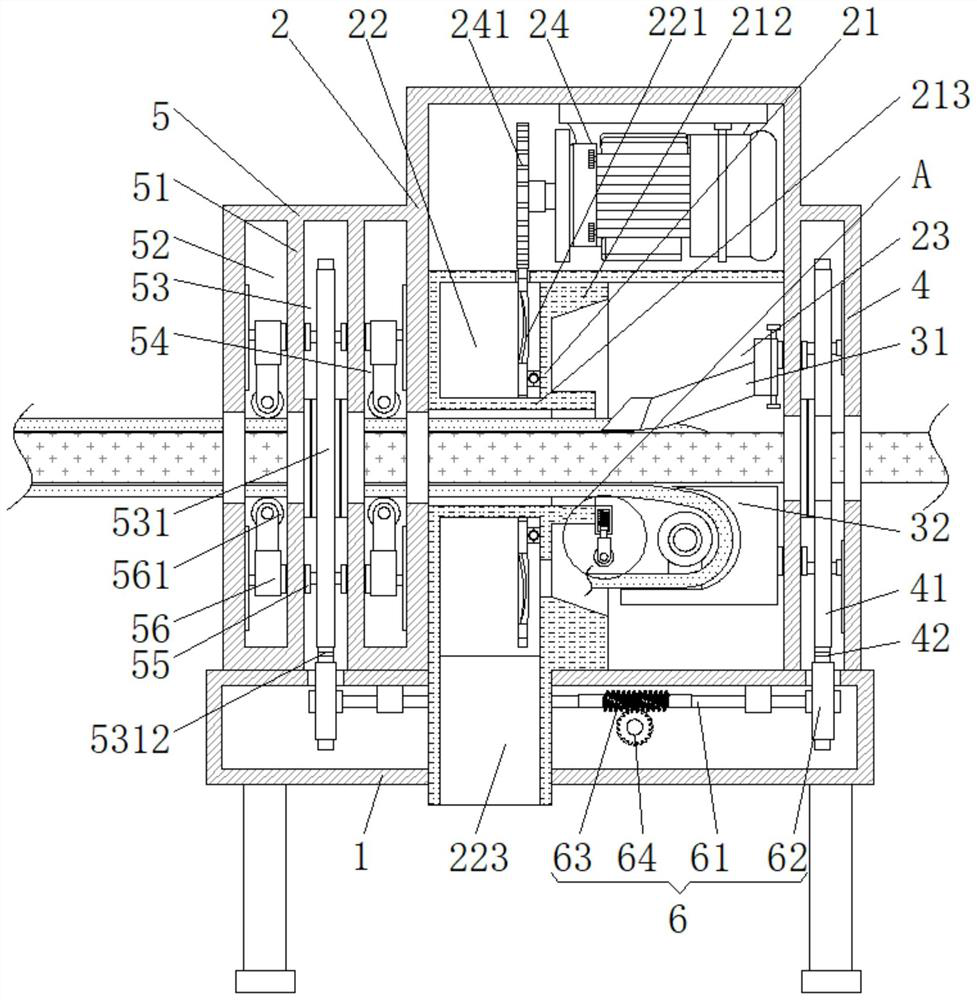

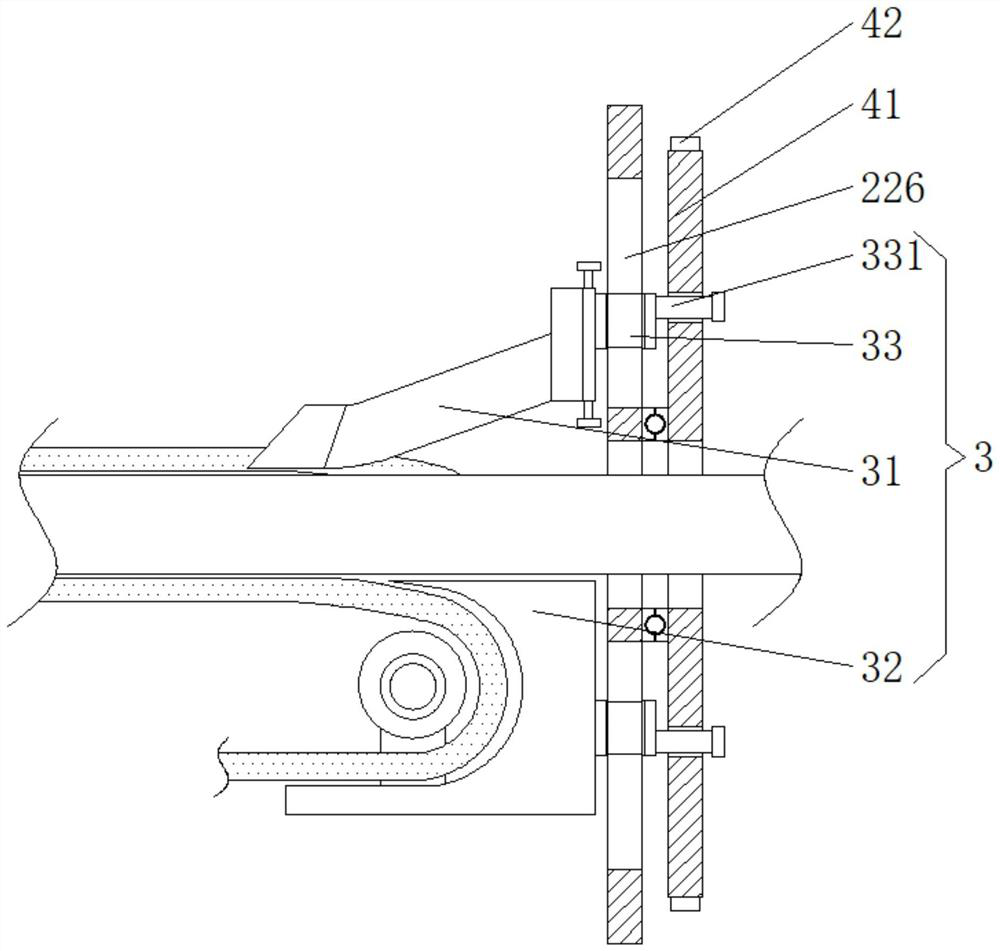

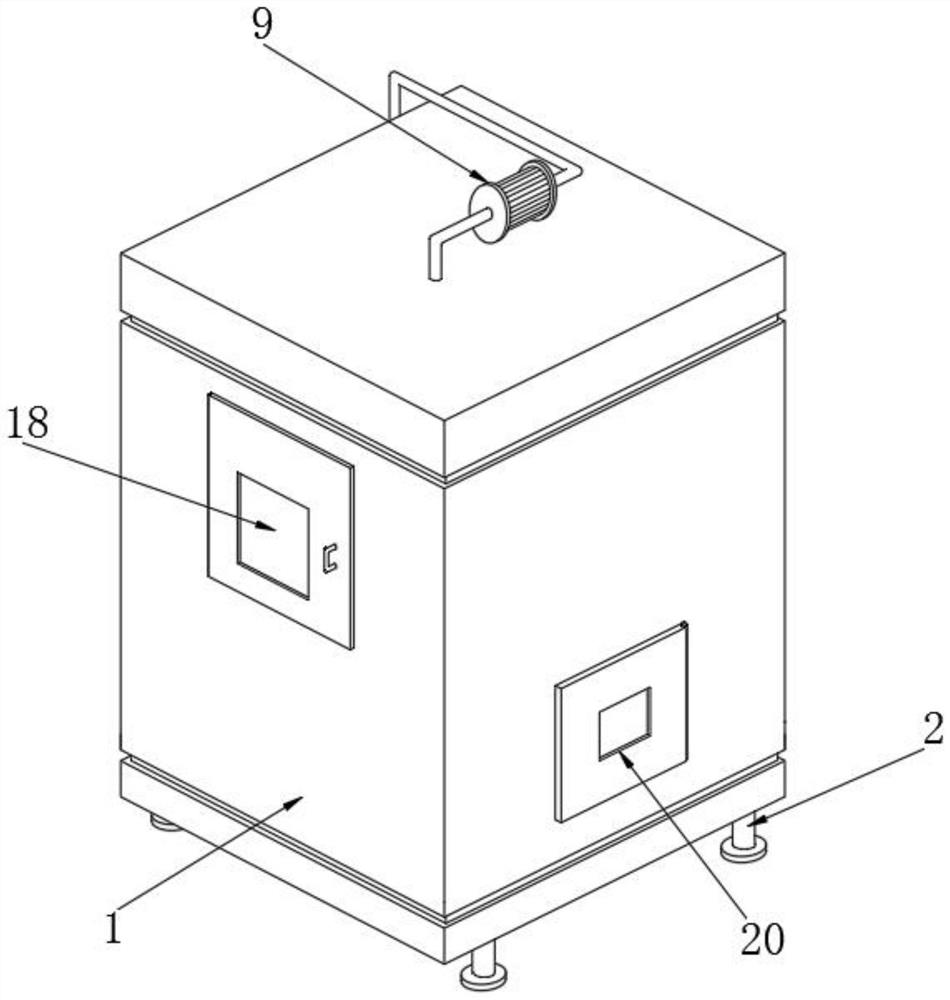

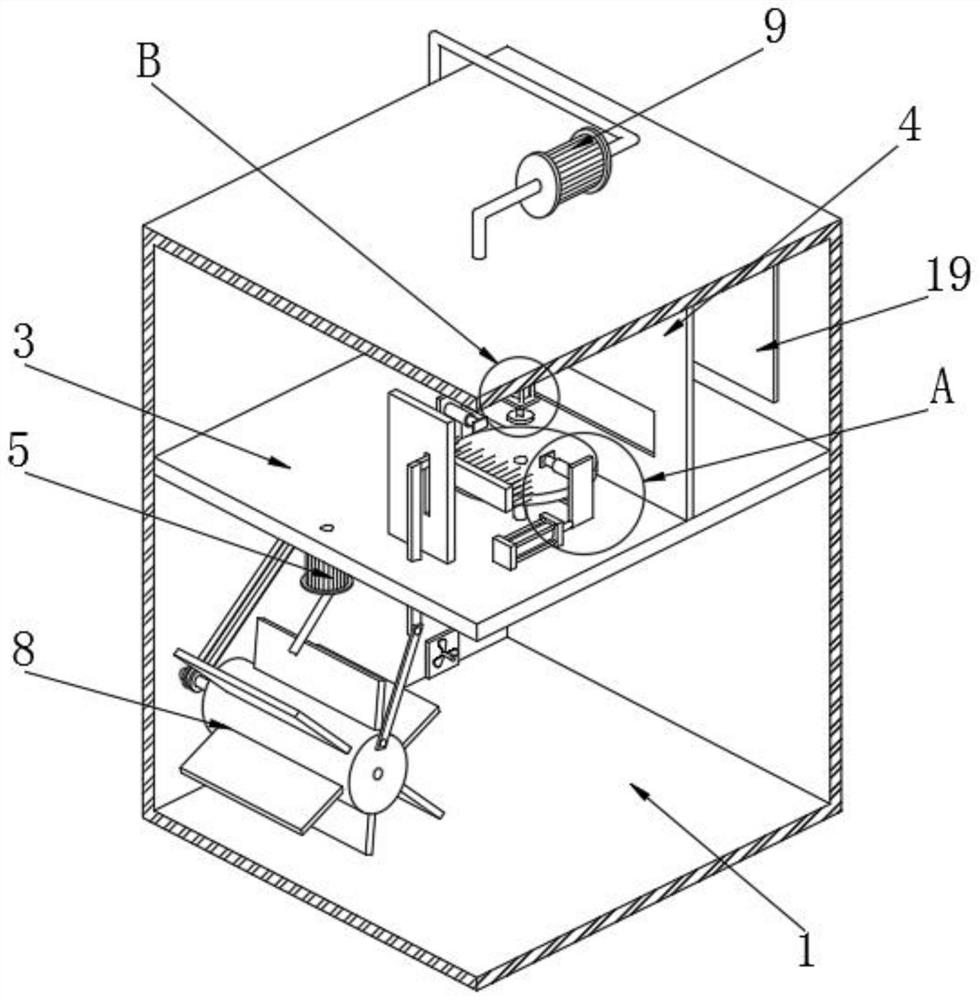

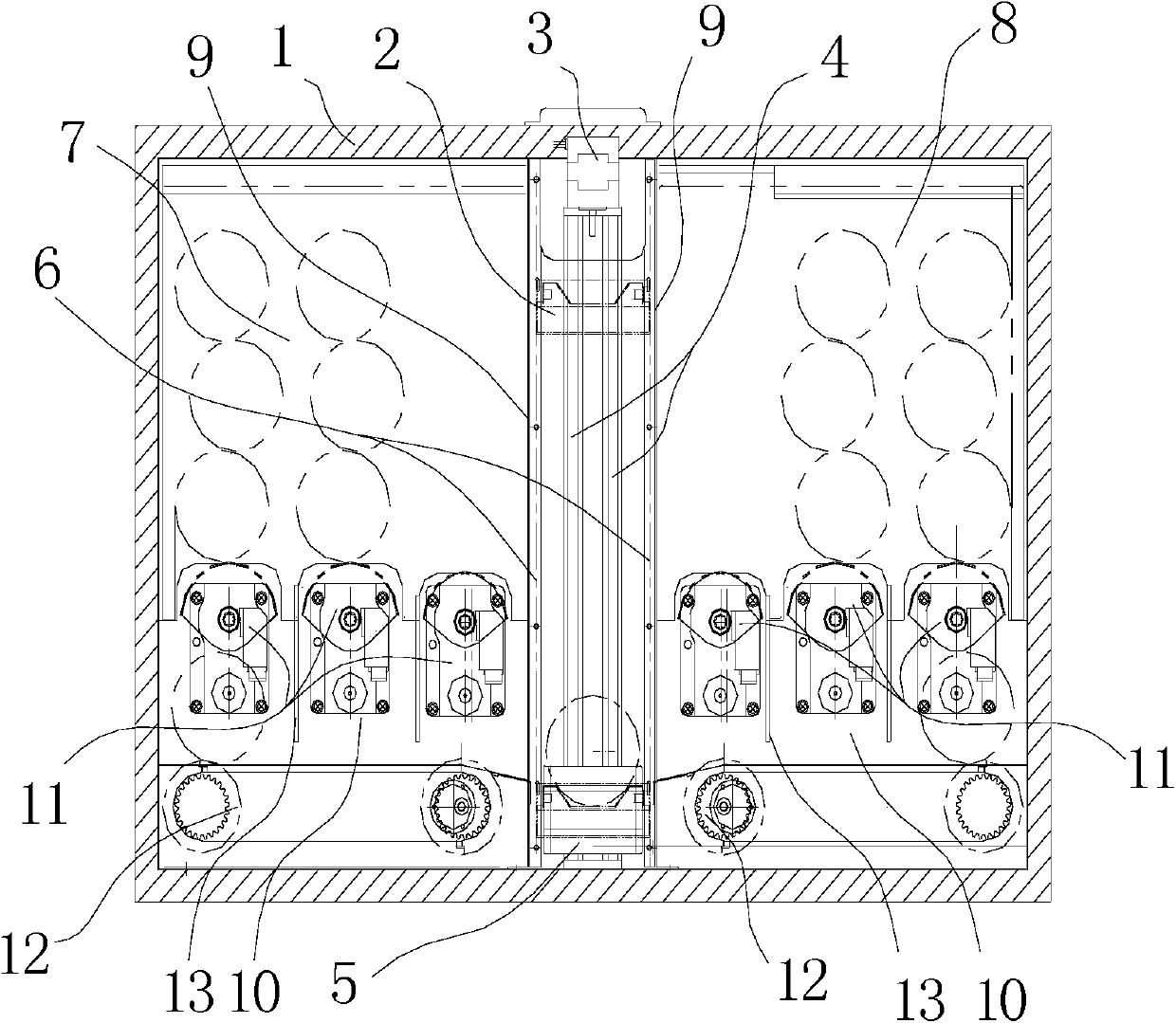

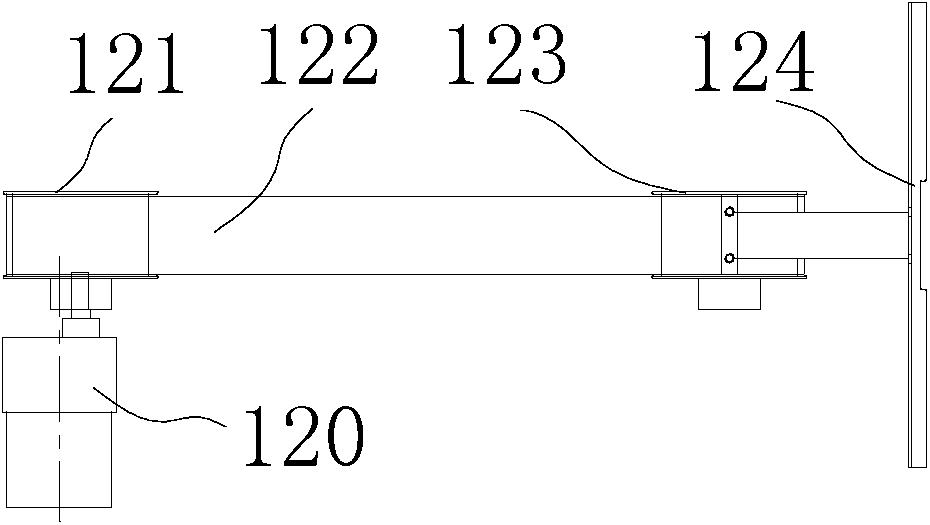

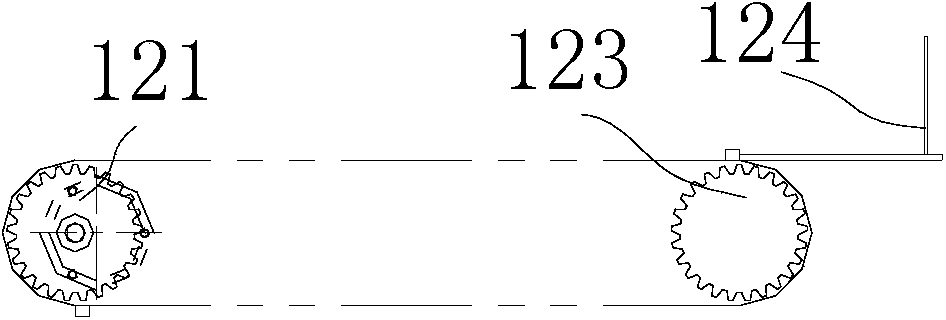

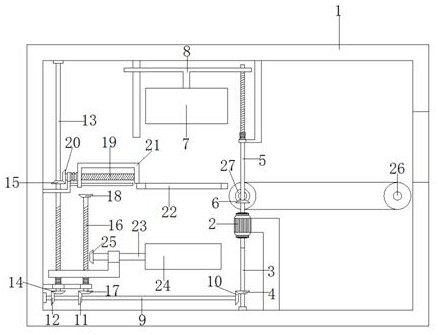

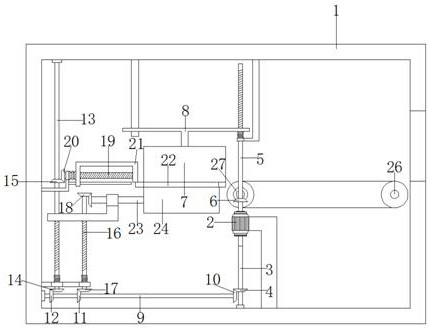

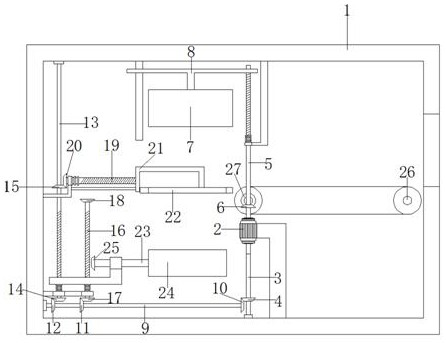

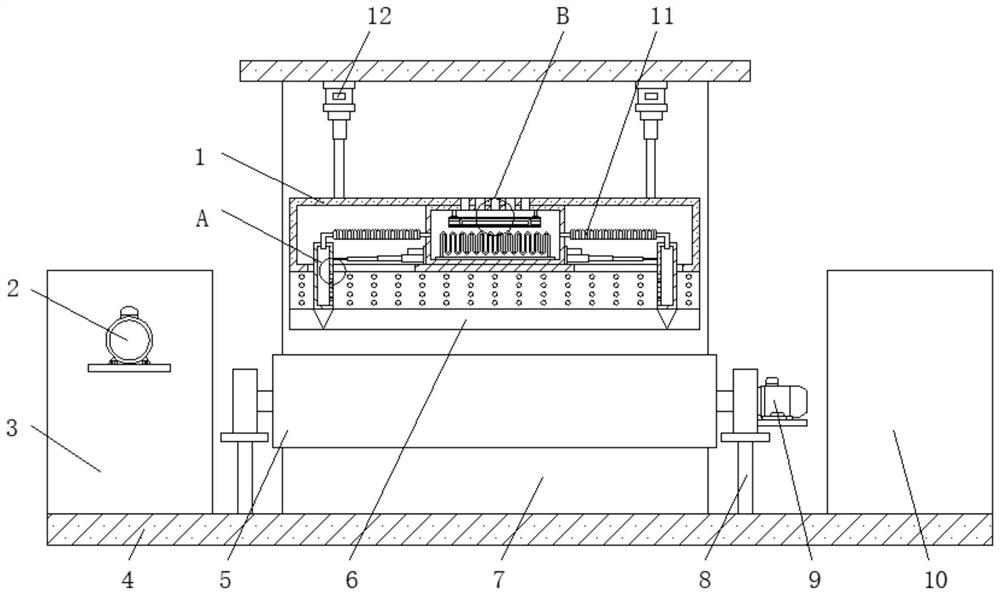

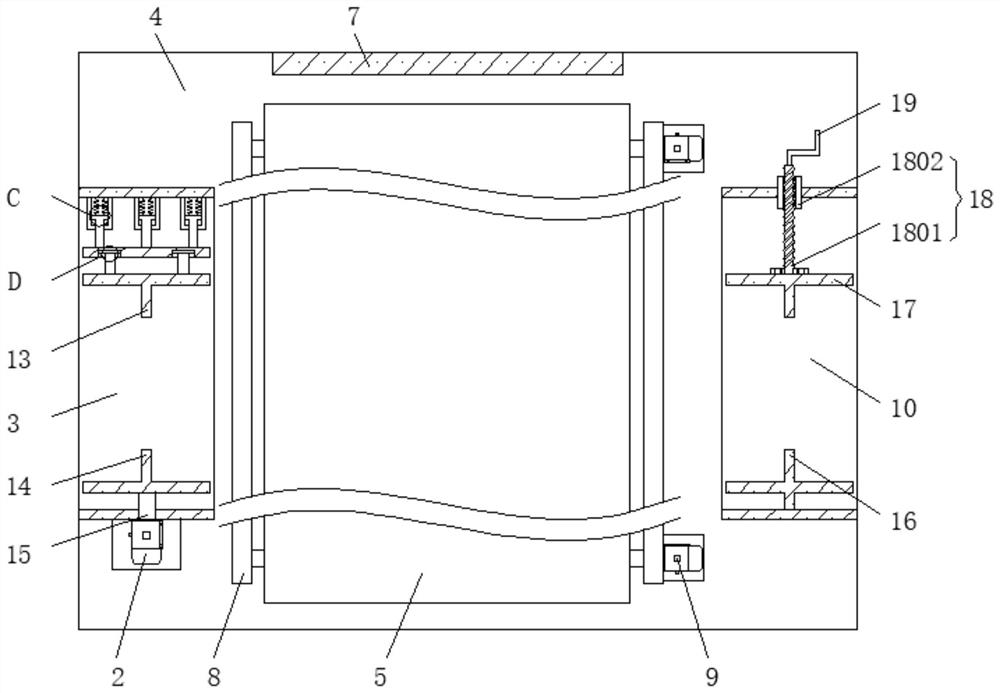

Vehicle-mounted vending machine

ActiveCN103942883ASimple structureEasy to controlCoin-freed apparatus detailsApparatus for dispensing discrete articlesDrive wheelMotor drive

The invention provides a vehicle-mounted vending machine which comprises a cabinet body, a lifting platform and a pickup opening. Guide rails facilitating the vertical motion of the lifting platform are arranged in the middle of the cabinet body, the pickup opening is formed in the upper side of the position, at the upper ends of the guide rails, of the cabinet body, a lifting motor driving the lifting platform to vertically move is arranged at the bottom or the top of the position, at the lower ends of the guider rails, of the cabinet body, and a lifting transmission mechanism driving the lifting platform to do synchronous movement is connected between the lifting motor and the lifting platform. Separation plates which divide an inner cavity of the cabinet body into a left warehouse and a right warehouse are arranged at the positions, on two sides of the guide rails, inside the cabinet body, goods channels are arranged at the bottoms of the warehouses respectively, a plurality of driving wheels feeding goods in the warehouses into the goods channels are arranged on the upper sides of the goods channels, track pushing devices for conveying the goods to the lifting platform are arranged in the goods channels, and correction mechanisms preventing articles from being transverse in the goods channel conveying process are arranged in the positions, above the track pushing devices, of the goods channels. The correction mechanisms effectively prevent a vehicle-mounted movable platform from influencing article conveying in the moving process, and the reliability of outputting the goods is improved.

Owner:FOSHAN BLUEWAY ELECTRIC APPLIANCES

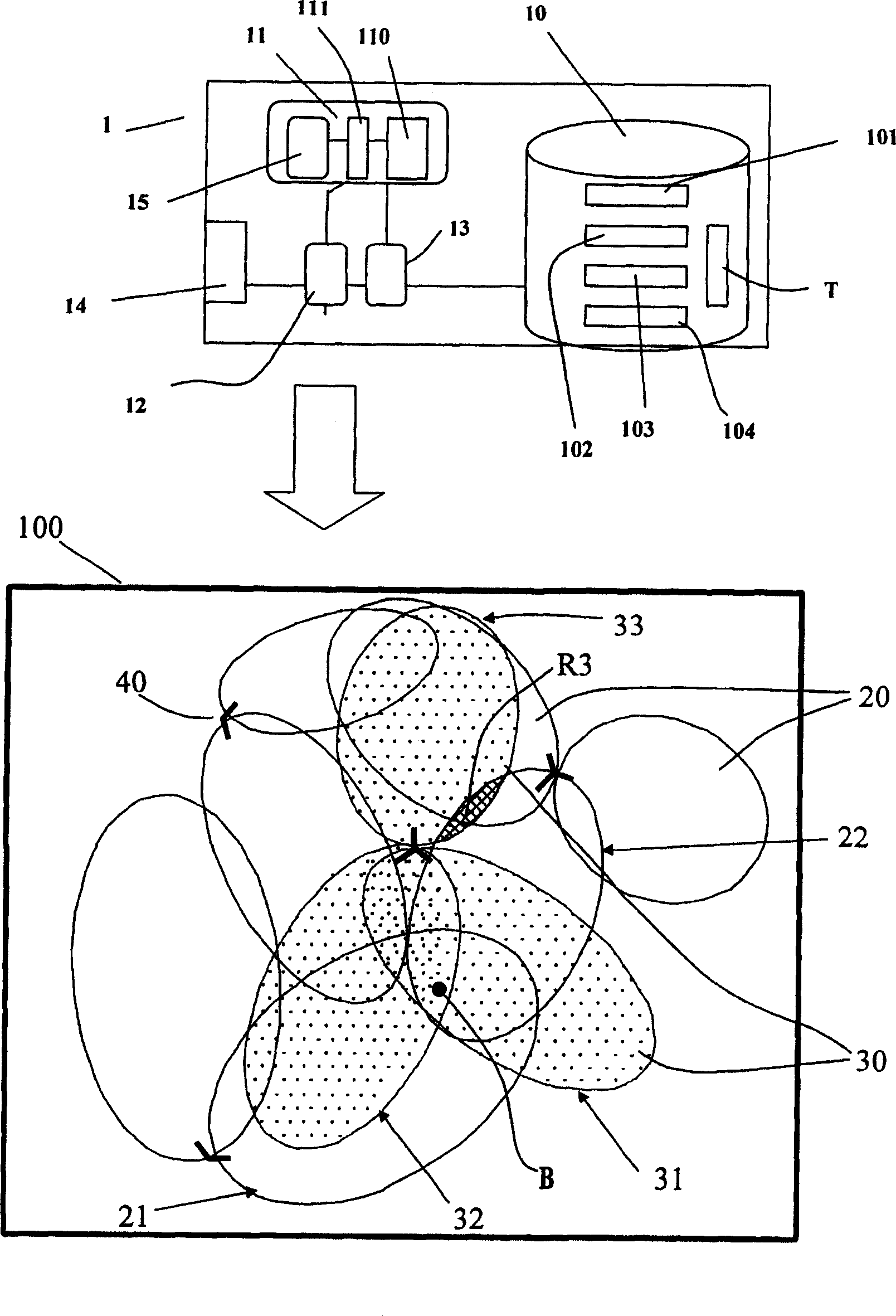

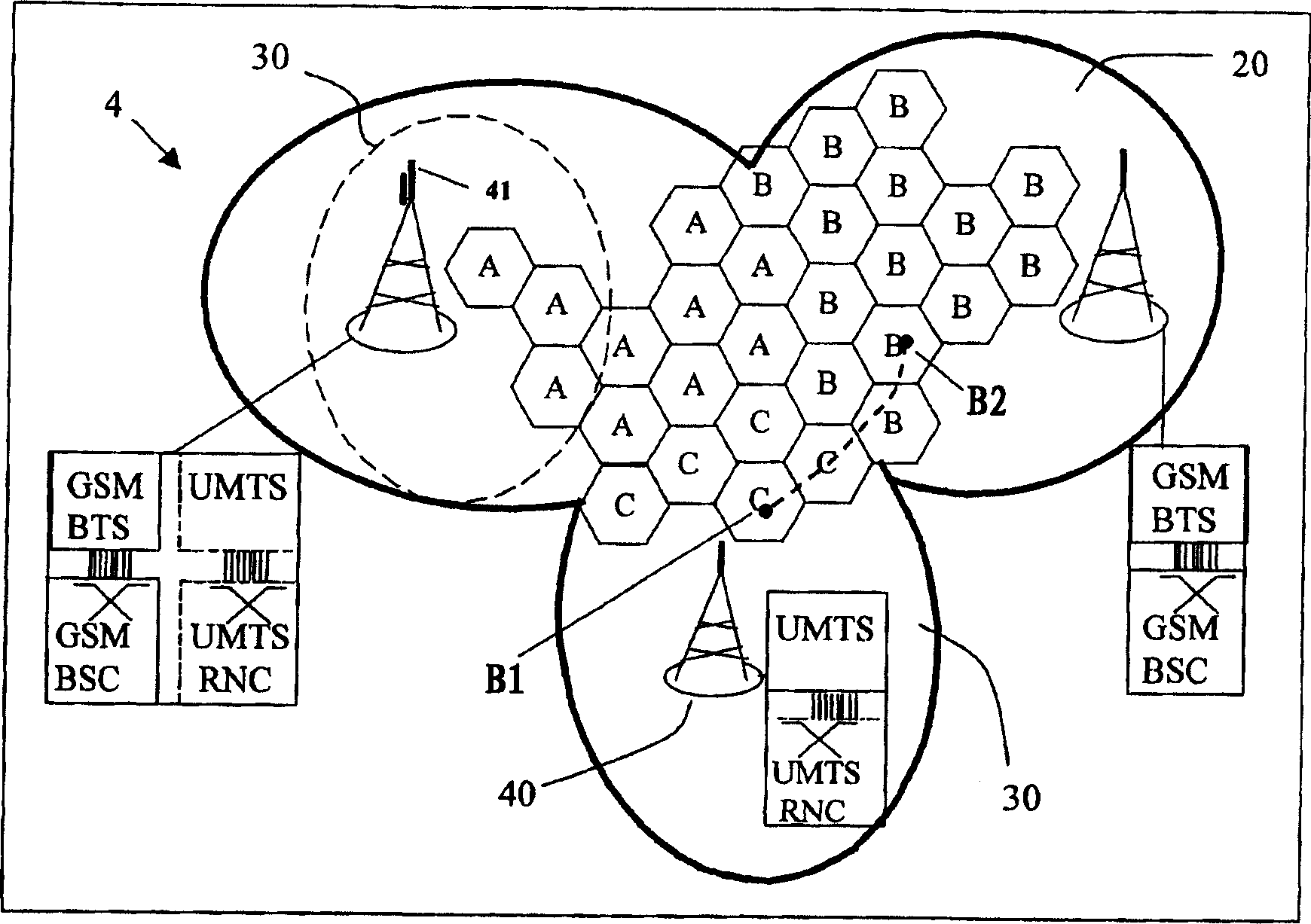

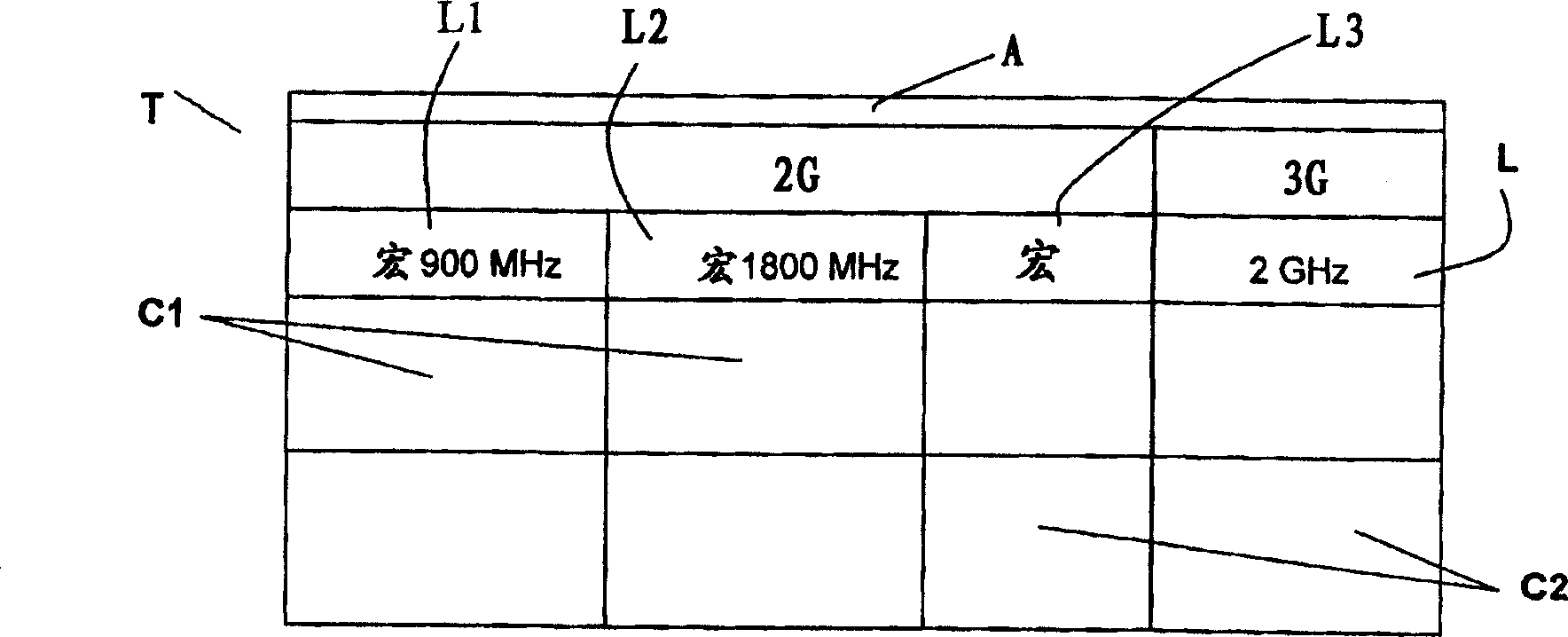

Method and system for calculating the 2G-3G neighborhood

InactiveCN1713774AEasy automatic transferRadio/inductive link selection arrangementsNetwork planningSelection criterionCell based

The method involves determining a wireless cell zone (A) and a source frequency band utilized in one system. An output cell corresponding to the zone (A) and the determined band is selected in a hierarchy table (T). A list of cells belonging to another system and neighborhood of the output cells is generated from the table. An input cell is selected in the list of cells based on a selection criterion. An independent claim is also included for computing equipment implementing a method of calculating second and third generation systems` neighborhood.

Owner:SOC FR DU RADIOTELEPHONE SFR

Onion slitting device

The invention relates to a slitting device, in particular to an onion slitting device. The utility model mainly provides an onion slitting device. The onion slitting device is continuously operated bya machine, does not need hands to contact onions, guarantees safety and attractiveness and can collect slit onions at a time. The onion slitting device comprises an output mechanism and a slitting mechanism, wherein the output mechanism is arranged at the top of a mounting frame; and the slitting mechanism is connected between one side of the output mechanism and the top of the mounting frame, and a discharging mechanism is arranged at the top of the mounting frame. By means of a net-shaped cutting plate and an ejection plate matched with the cutting plate, onions can be completely slitted ata time; and a bottom plate rotating with the right side as the fulcrum is arranged at the bottom of a cutting box, when a wedge-shaped block is away from the bottom plate, the bottom plate can slightly rotate to be inclined, slit onions fall to the left side of the cutting box, meanwhile, a collecting frame is placed on the lower left portion of the cutting box, and workers can collect the onionsin a unified mode.

Owner:李美霞

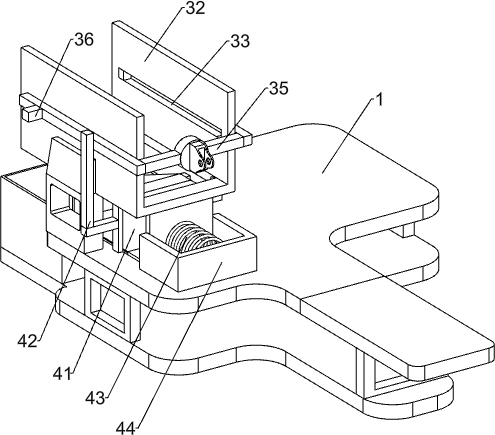

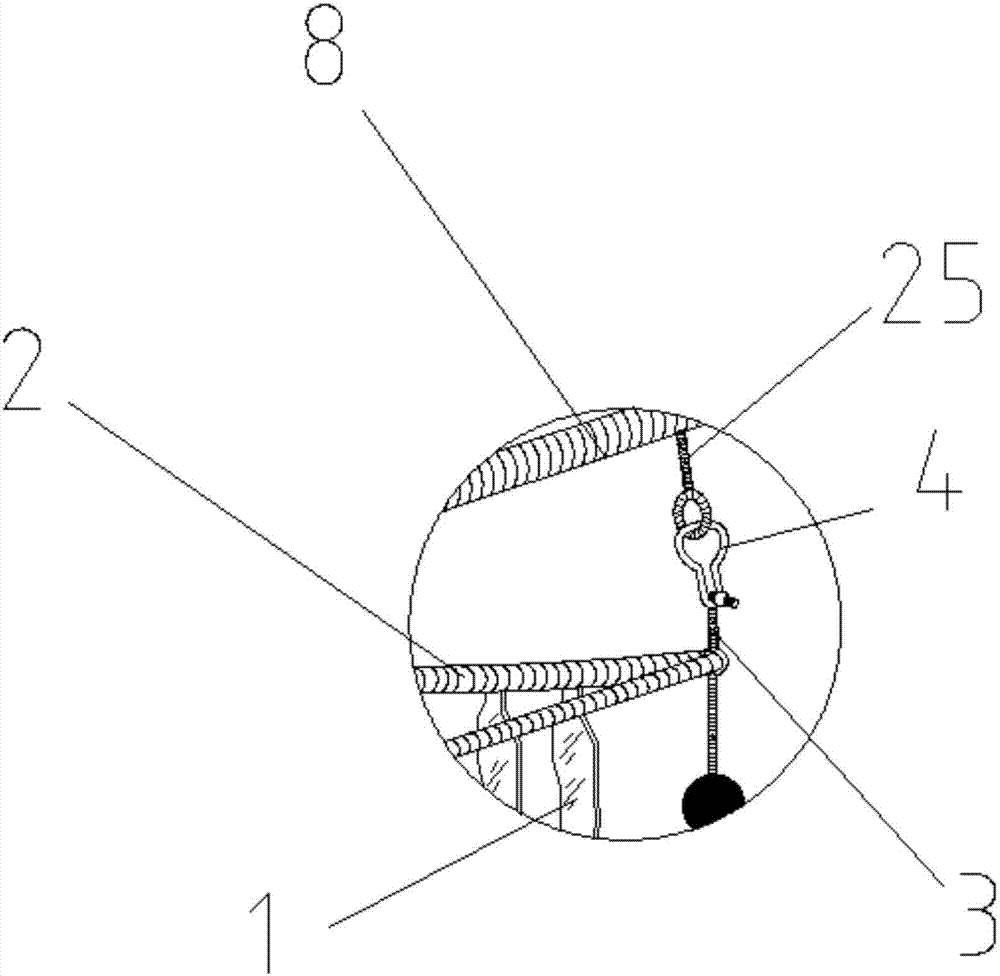

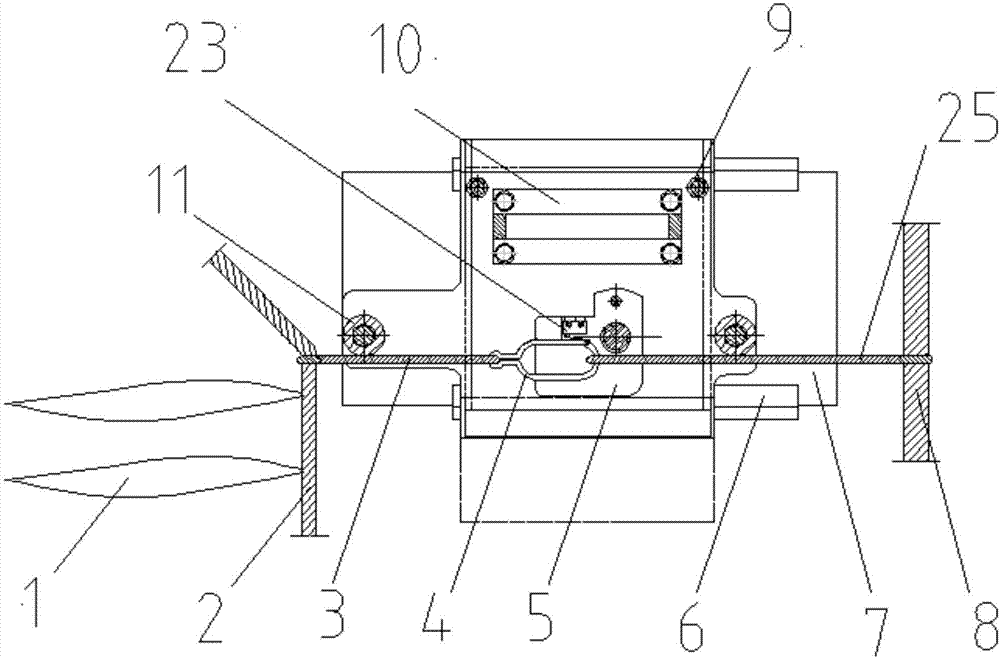

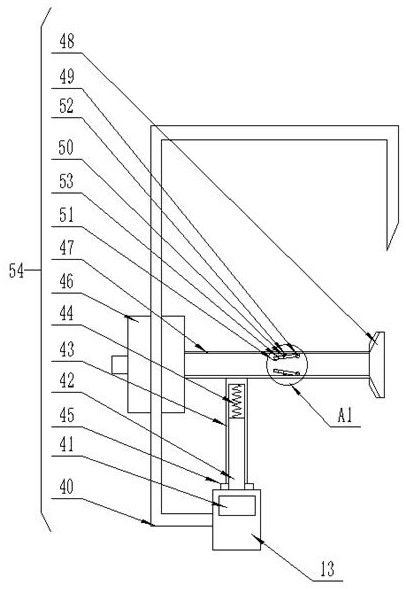

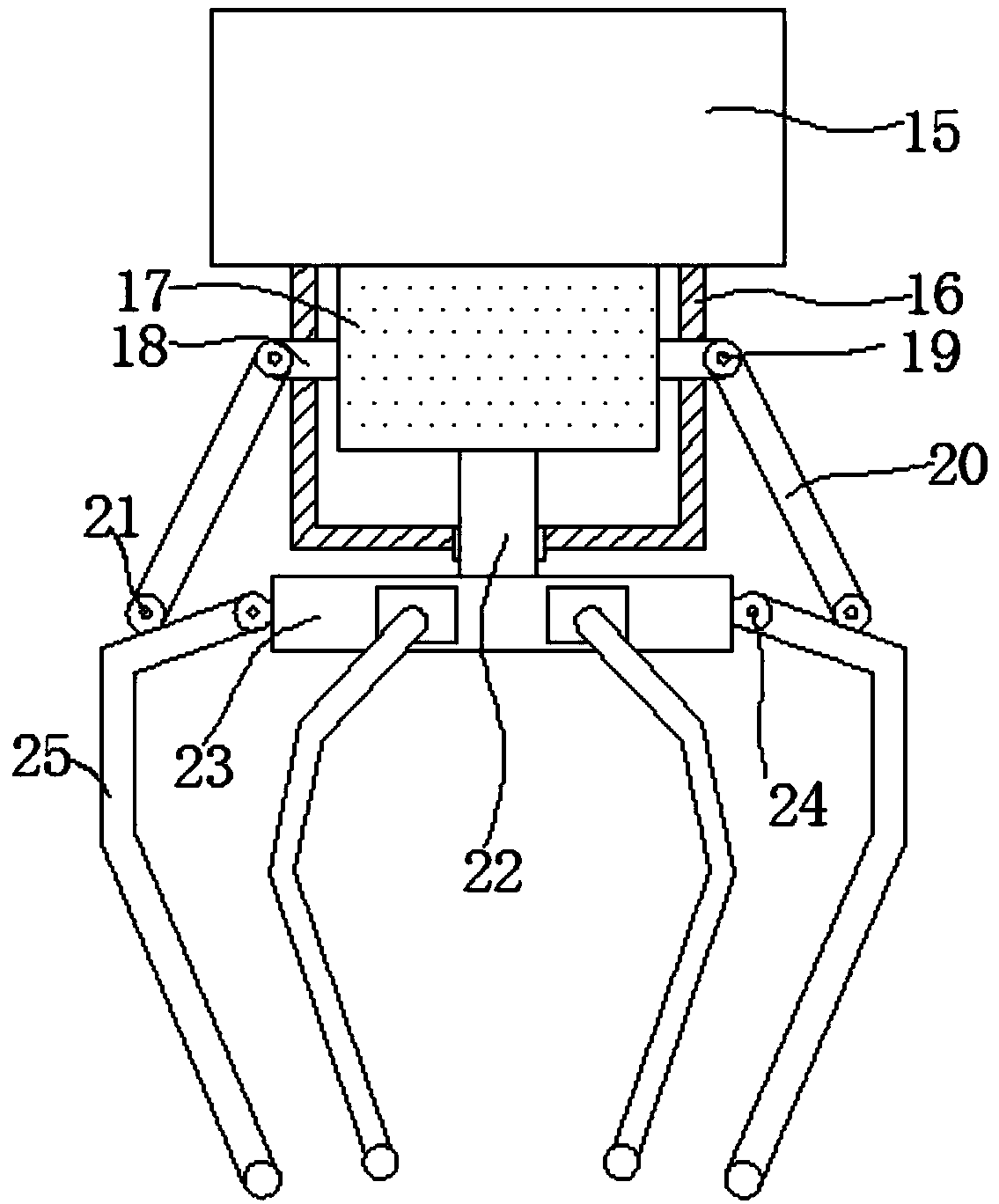

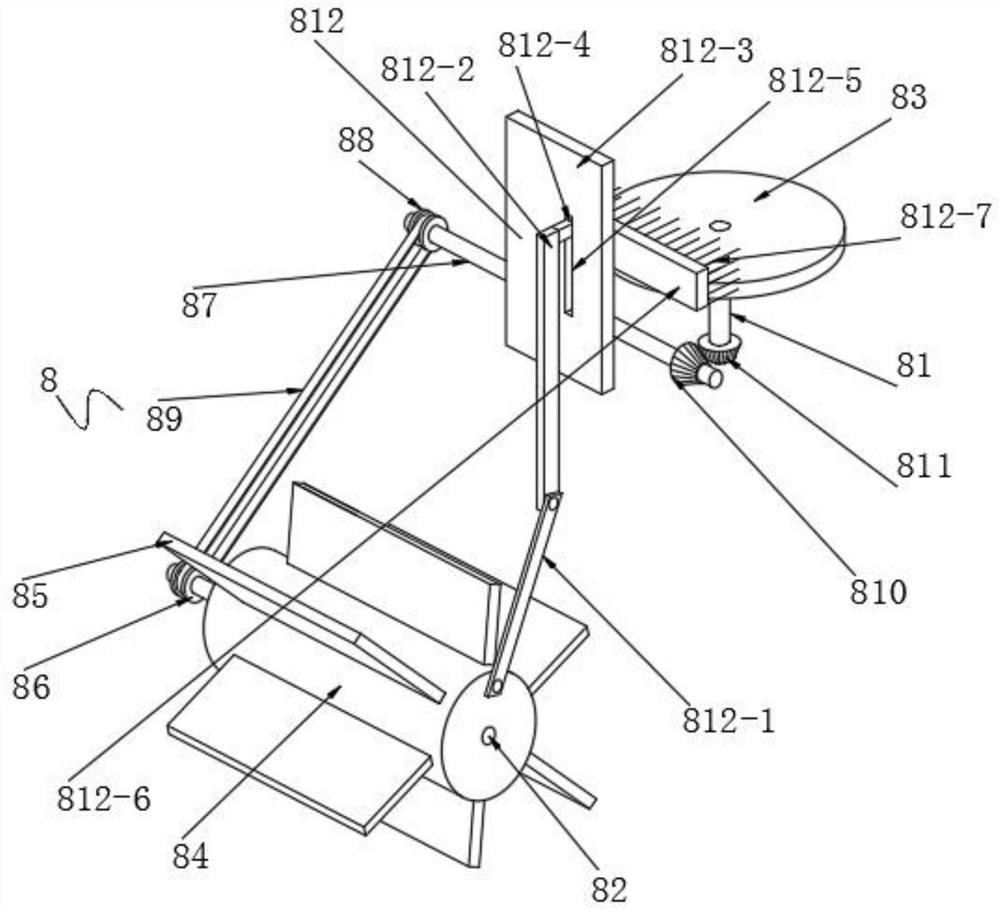

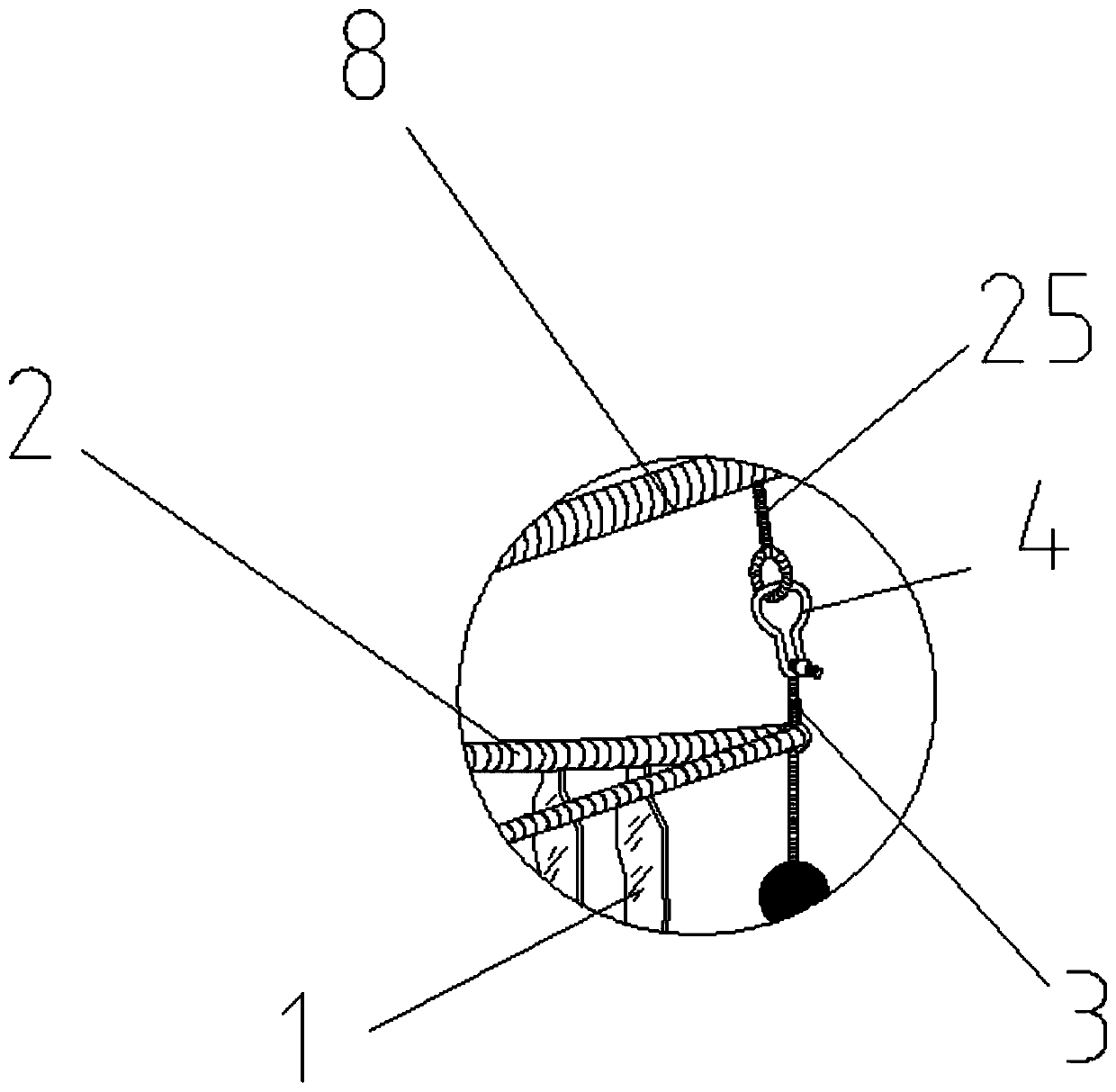

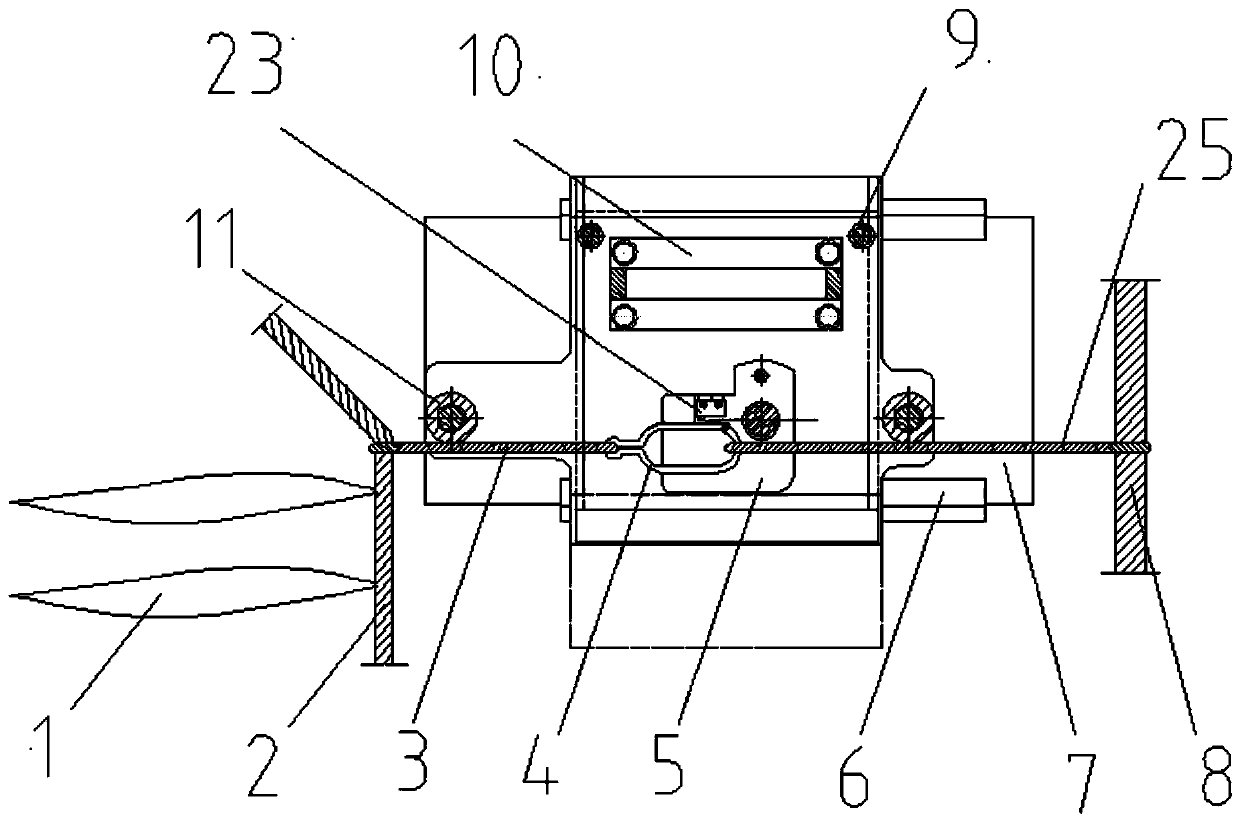

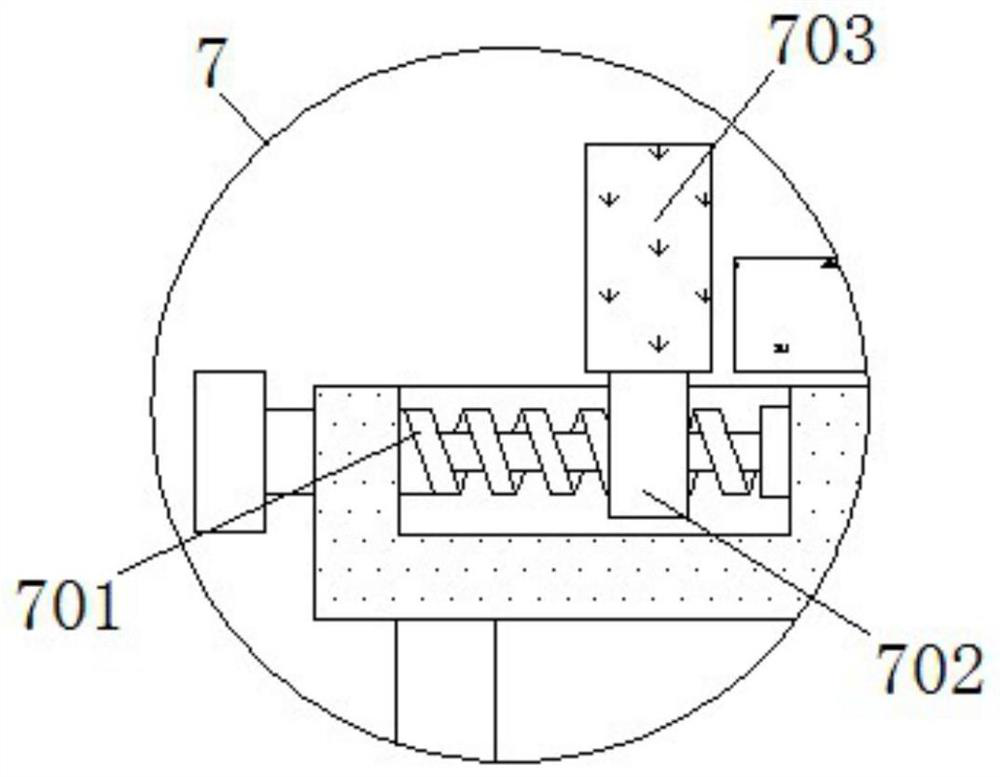

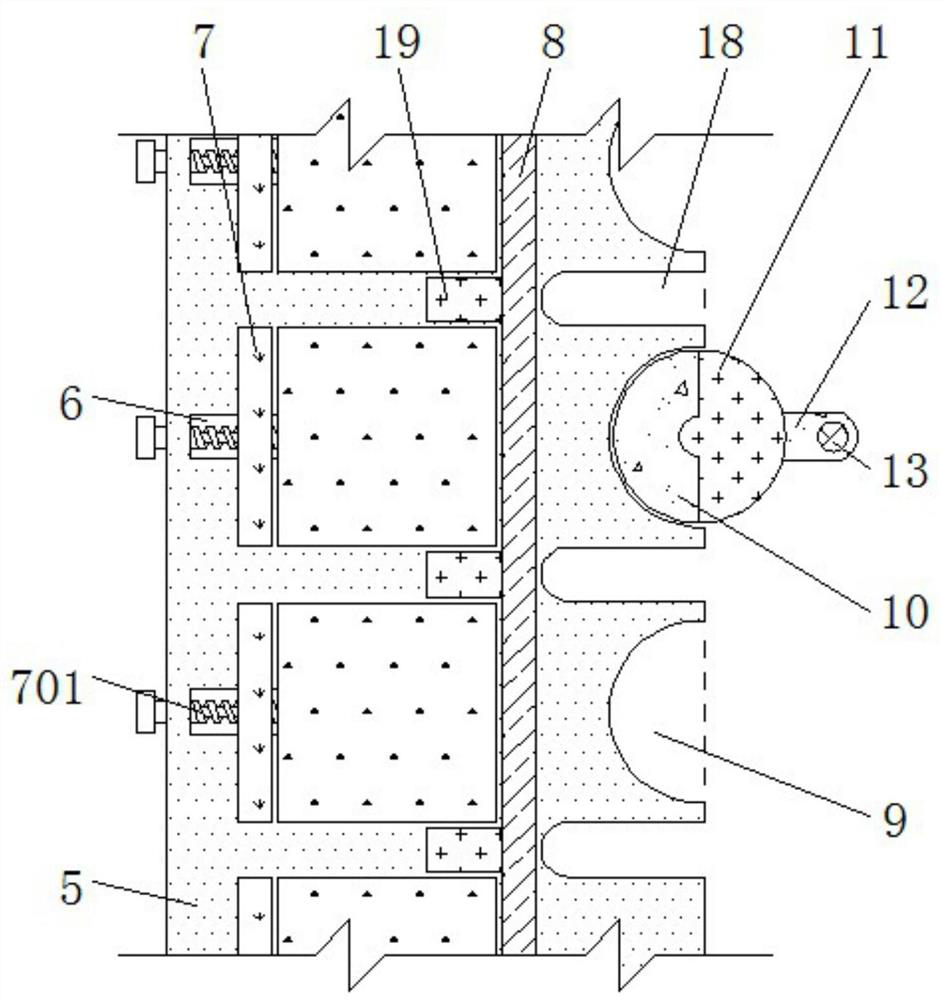

Automatic unfastening device for kelp harvesting

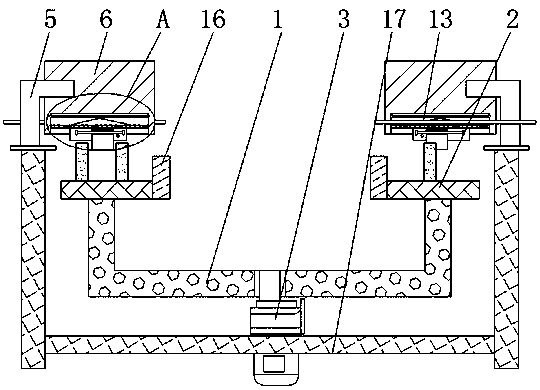

The invention relates to an automatic unfastening device for kelp harvesting. The device comprises an upper lifting rope, a lower lifting rope and a rope fastener, wherein the width of a narrow groove in the lower part of the rope fastener is smaller than the external diameter of a knot at the head of the lower lifting rope. The device further comprises a pressure block, a driver and a screw rod, wherein the driver is connected with the screw rod, and the pressure block is driven by the screw rod to transversely move; the knot is attached to a platform, a micro switch is arranged on the platform, and is used for feeding back an electric signal to a control unit to trigger the driver to work after receiving a touch signal of the knot, and the screw rod is driven by the driver to transversely move until the knot is tightly pressed by the pressure block; a torsional spring is arranged on the platform, the resistance of the torsional spring is overcome by the rotating force of the screw rod, the pressure block and the platform are driven by a guide pin shaft to rotate to one side of a rope groove, the knot enters the rope groove, and when the pressure block rotates approximately to 90 degrees, the knot is transversely moved and separated from the narrow groove in the lower part of the rope fastener by the lower lifting rope under the action of tensioning force, and the lower lifting rope is separated from the rope fastener.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

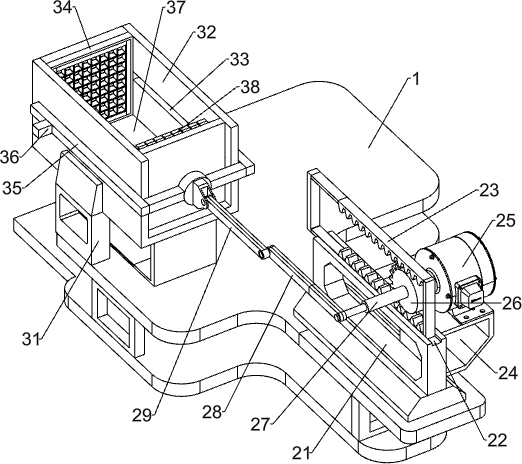

Forage cutting device for feeding

InactiveCN109005959AEasy automatic transferEasy to placeFeeding-stuffCuttersEngineeringConveyor belt

The invention discloses a forage cutting device for feeding. The forage cutting device comprises a shell, a conveying channel and a grass cutting plate, wherein the top of the shell is fixedly provided with a first motor, and one end of the first motor is connected with a knife switch. A fixing plate is arranged on the inner side of the shell, the conveying channel is fixed on the side of the shell, and one end of the conveying channel is connected with a containing box. One end of a telescopic air cylinder is provided with a push plate, the pushing plate is located in the conveying channel, and a conveying belt is fixed on one side of the conveying channel. The grass cutting plate is fixed on the inner side of the shell, and a discharging pipe is arranged at the bottom of the inner side of the shell. A stirring roller is arranged in the discharging pipe, and a feeding hole is reserved in the side of the shell. The forage cutting device for feeding is provided with a conveyor belt anda telescopic air cylinder, the forage to be cut is transmitted to the knife switch, and the knife switch is driven by the first motor to cut forage. A stirring roller and a baffle are arranged, so that the cut forage and other feed can be conveniently stirred.

Owner:湖州德飞机械科技有限公司

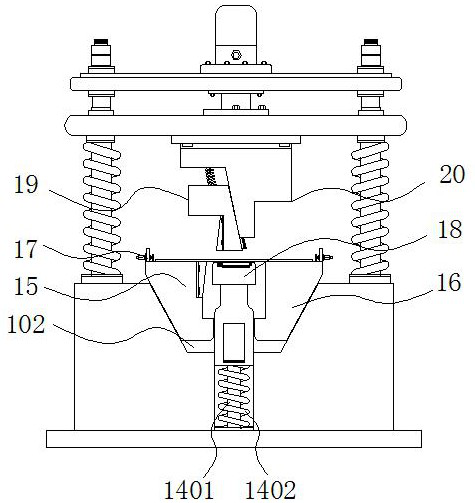

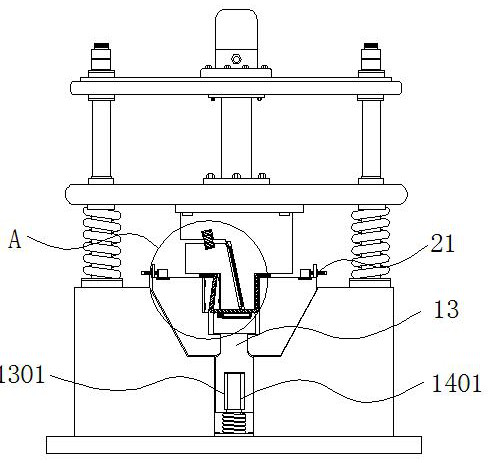

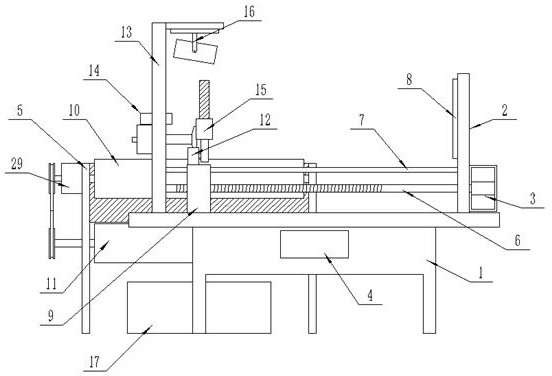

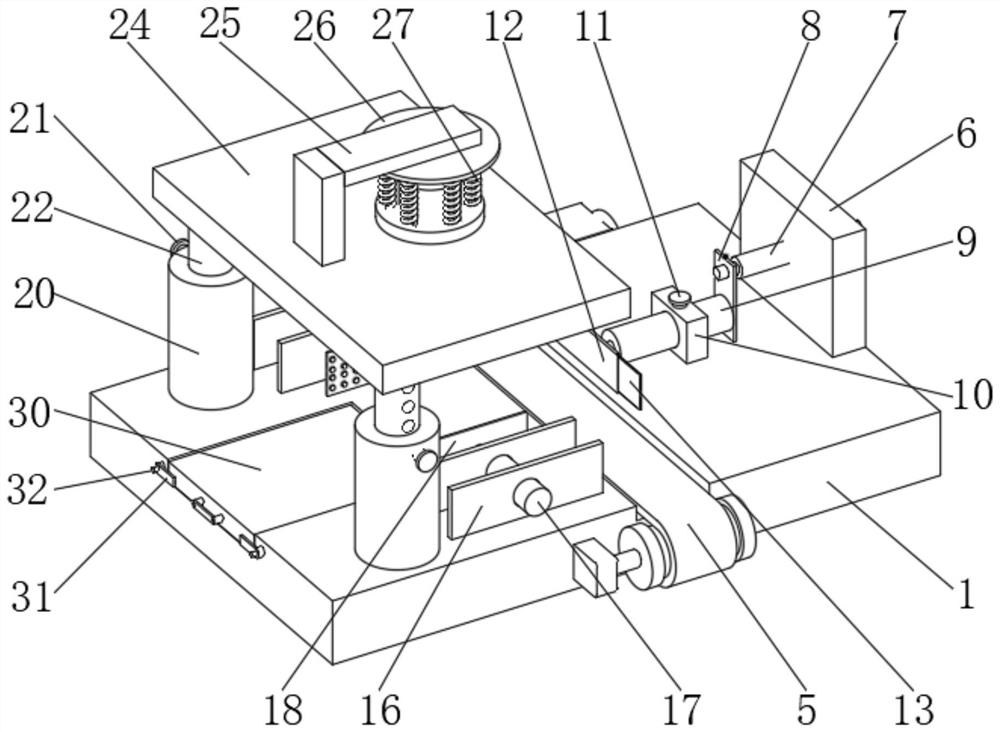

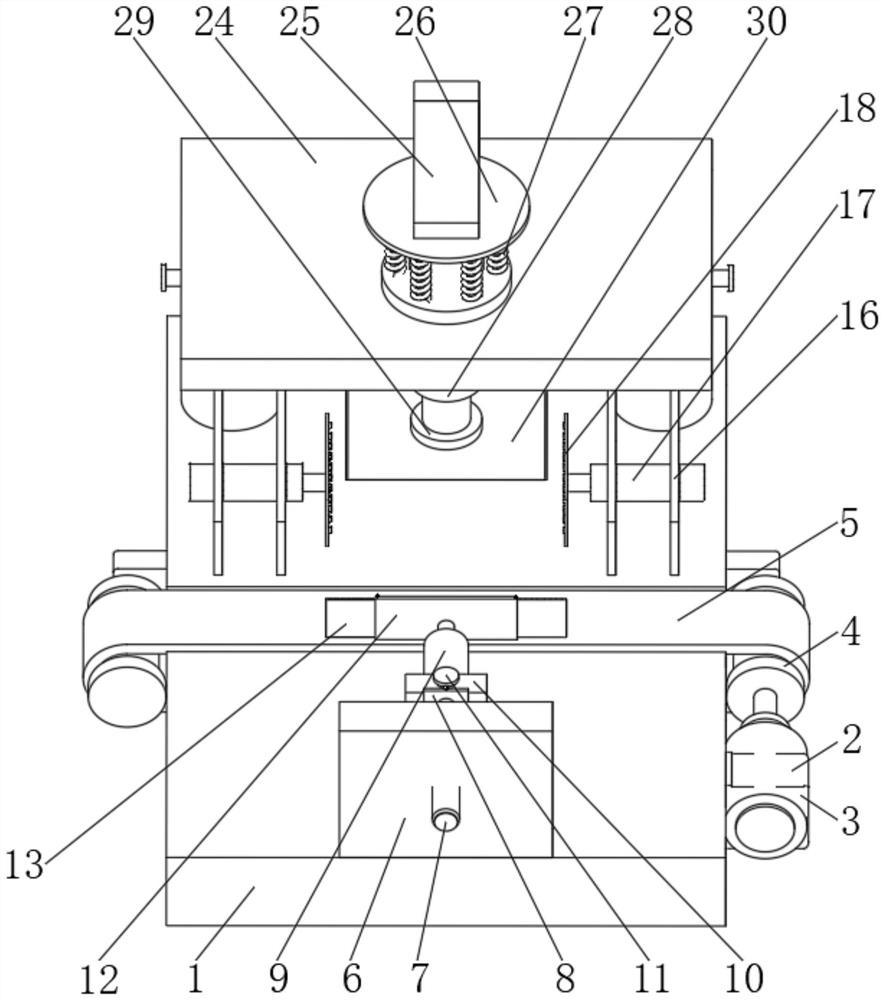

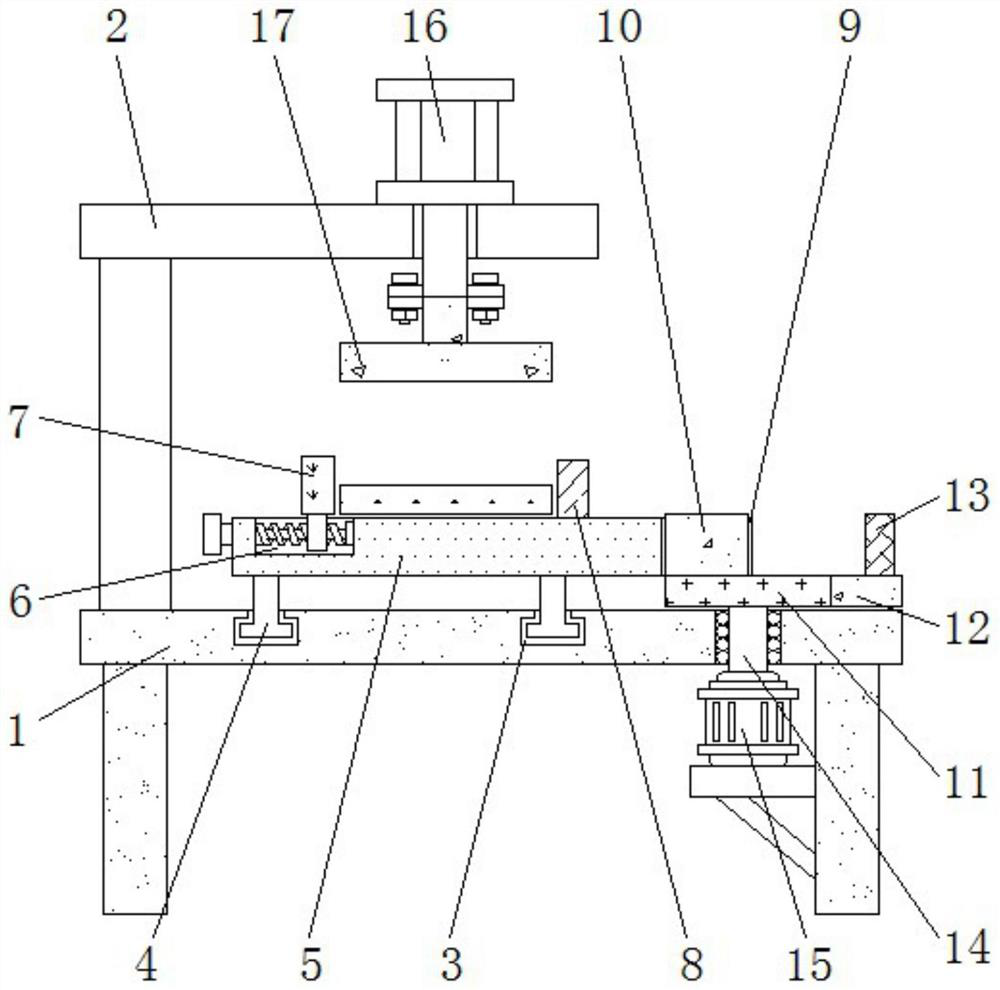

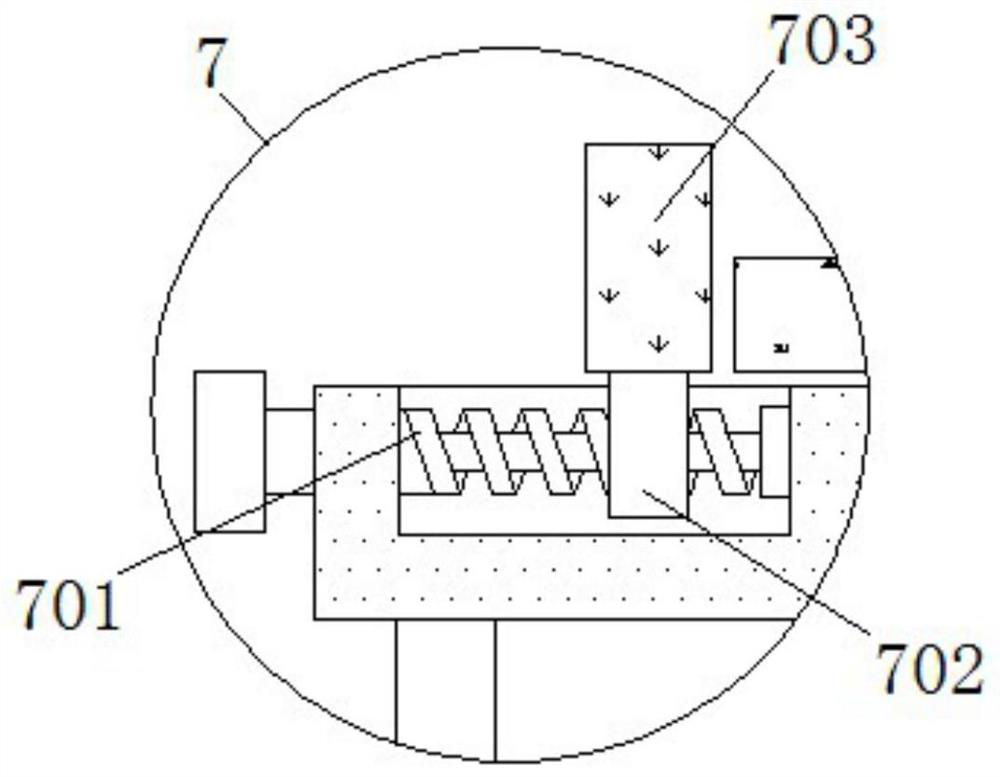

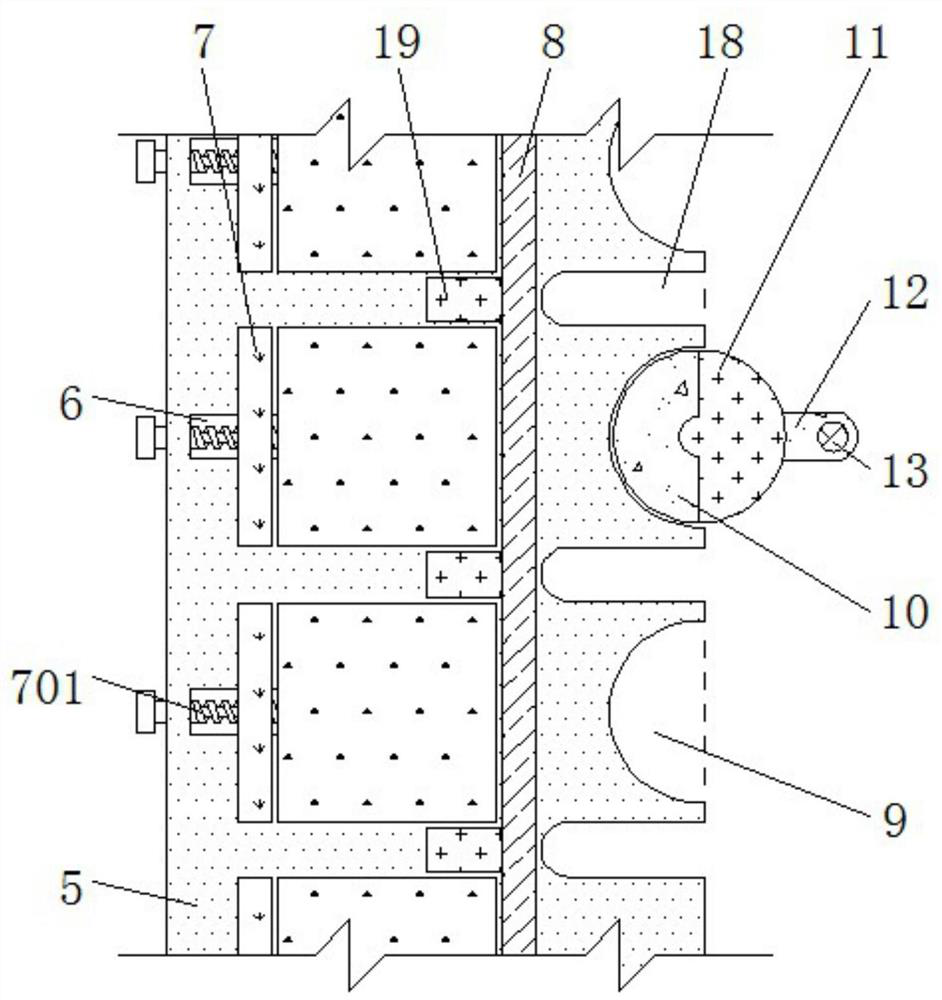

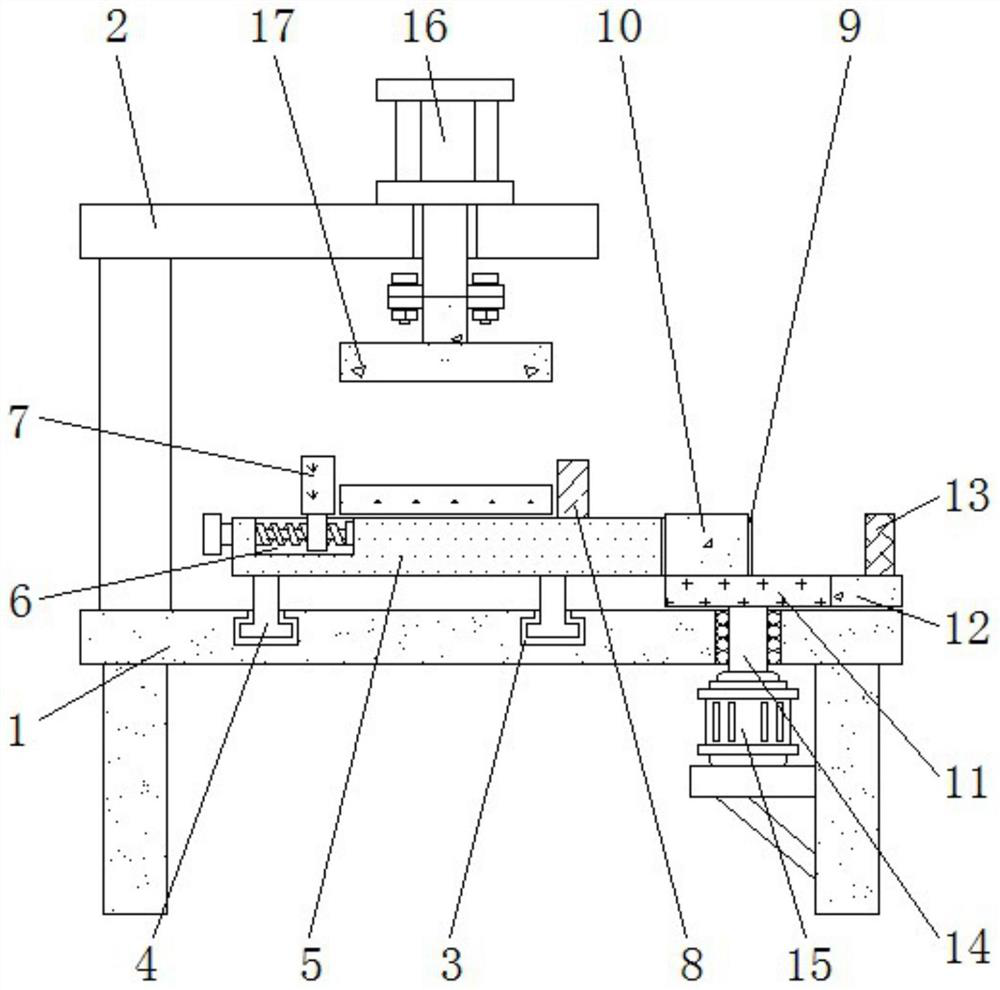

Sheet metal multi-bending machining device capable of detecting bending angle

InactiveCN113290135AQuality improvementImprove processing efficiencyMetal-working feeding devicesMetal working apparatusHydraulic cylinderStructural engineering

The invention discloses a sheet metal multi-bending machining device capable of detecting a bending angle. The device particularly comprises a workbench, a bending mechanism, a detection mechanism and a pressure bearing table, wherein supporting columns are installed at the four corners of the top of the workbench, a top plate is fixed to the top ends of the supporting columns, a lifting plate is installed on the portions, below the top plate, of the supporting columns, the bending mechanism is installed on one side of the bottom of the lifting plate, hydraulic cylinders are installed on the two sides of the top of the top plate, and the output ends of the hydraulic cylinders penetrate through the top plate to be connected with the lifting plate. According to the sheet metal multi-bending machining device capable of detecting the bending angle, the bending mechanism, a first edge pressing seat and a second edge pressing seat are installed, all bending operation can be achieved through one-time downward pressing of the bending mechanism, the whole process is completed in one step, multi-step bending operation is completed in one step, the machining efficiency is higher, it can be guaranteed that the bending positions on the two sides are symmetrical, and the quality of finished products is higher.

Owner:长沙市雄武自动化设备有限公司

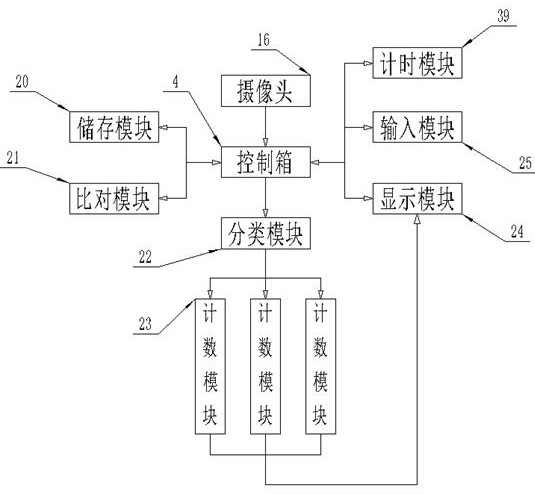

Optical glass lens testing system and testing method thereof

InactiveCN113042400ATimely processing of workEasy automatic transferSortingComputer hardwareData display

The invention discloses an optical glass lens testing system and a testing method thereof. The system comprises a first supporting frame, a second supporting frame and a first vertical plate, the right side of the upper end of the first supporting frame is vertically and fixedly provided with a second vertical plate, and the left side end of the second vertical plate is fixedly provided with a projection plate. An image result generated by movement of a lens is shot by a camera and then transmitted into a control box, after the image is transmitted into the control box, the control box compares the image with various image results stored in a storage module through a comparison module, after comparison, the results are classified through a classification module, each category corresponds to different defect results and qualified results, after classification is completed, each result is counted by different counting modules, the total number is recorded, then data is displayed on a display module, if one defect result suddenly rises, equipment corresponding to the step goes wrong during production, and timely processing work is facilitated.

Owner:裴方虚

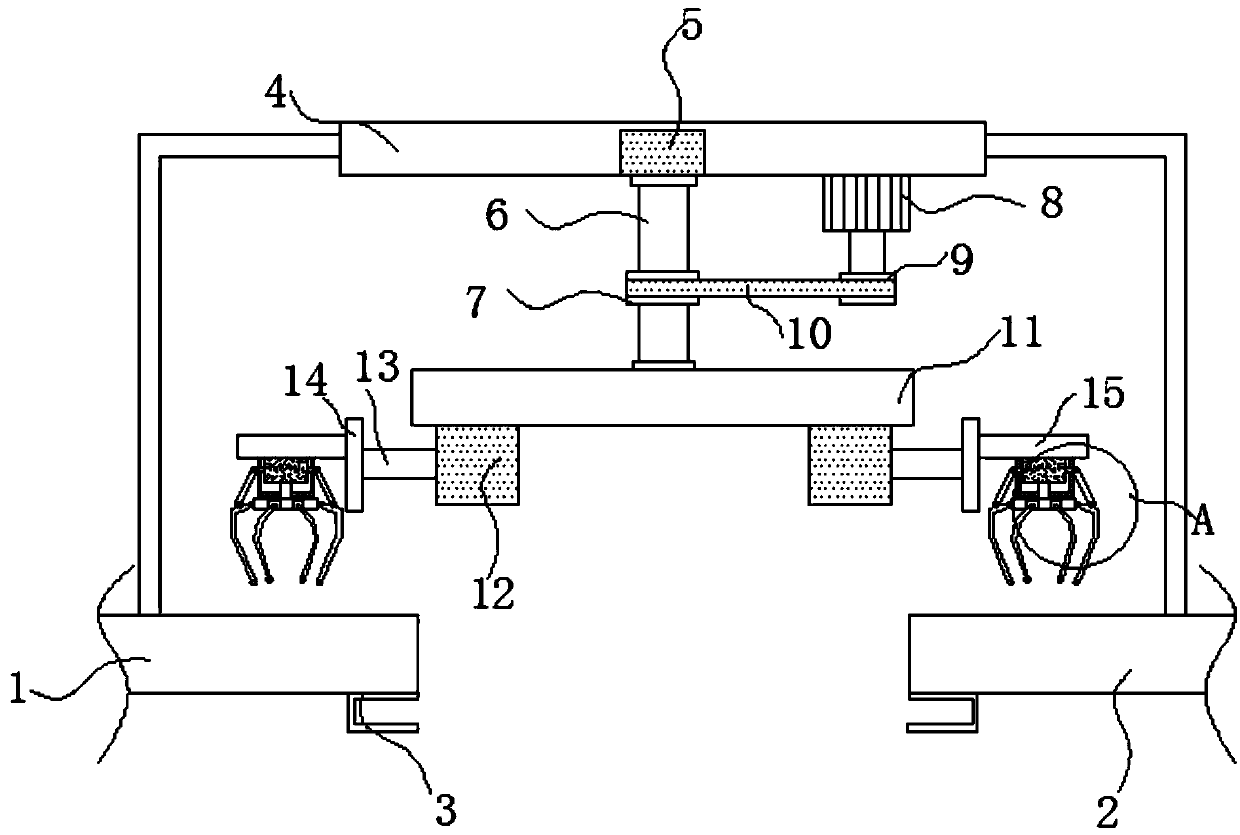

Clamping transfer device used for numerical control machine tool machining

The invention discloses a clamping transfer device used for numerical control machine tool machining. The clamping transfer device comprises a first platform and a second platform; the first platformand the second platform are parallel; by installing first hydraulic cylinders at the two sides of the bottom part of a rotating plate, a positioning plate and a fixed plate can be convenient to shifthorizontally; by installing a mounting frame, a very good supporting effect can be exerted on each of first supporting rods conveniently; by starting each of second hydraulic cylinders, a corresponding second piston rod is driven to go up and down; the bottom part of each second hydraulic cylinder is provided with a supporting plate, and each supporting plate is circular and is provided with arc-shaped clamping heads in an annular matrix, and thus, workpieces which need to be machined can be convenient to clamp rapidly and stably; by a design that the first platform and the second platform represent two different production lines, workpieces on the first platform can be conveniently transferred to the second platform, and therefore, transfer of the workpieces is realized; the use functionality of the clamping transfer device used for numerical control machine tool machining is greatly promoted; the use effect and the use efficiency of the clamping transfer device are guaranteed; and the clamping transfer device is suitable for being popularized widely.

Owner:吴豪

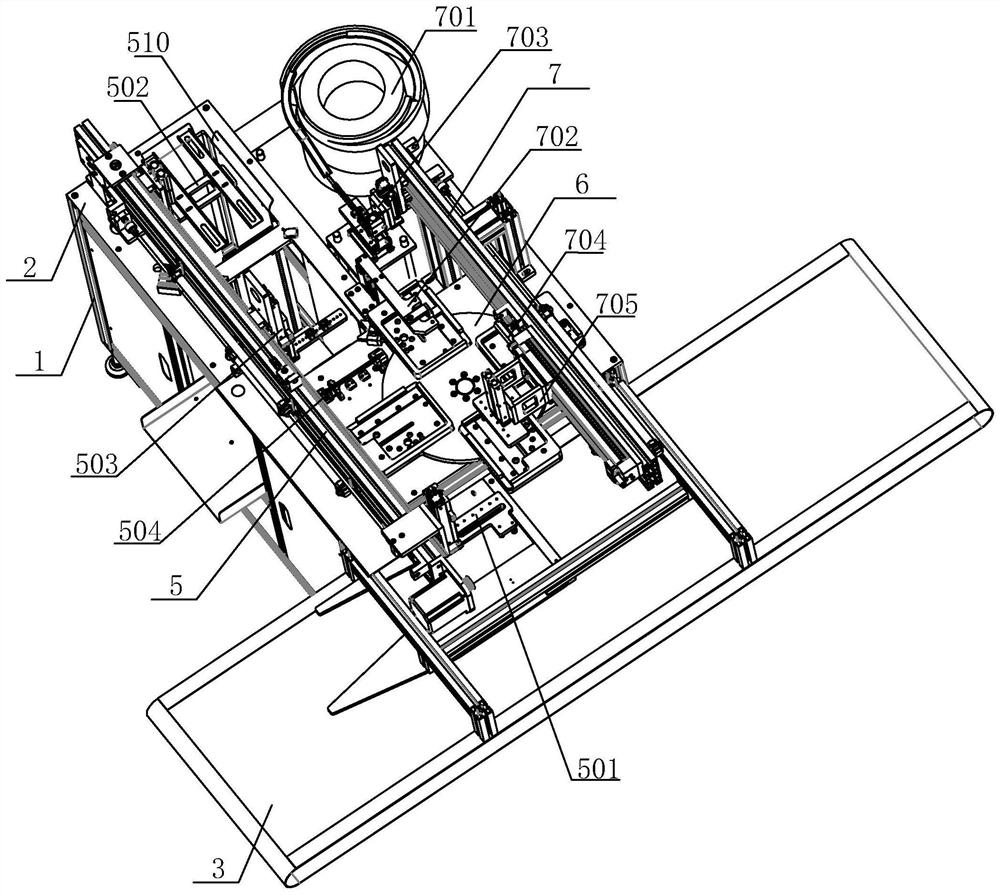

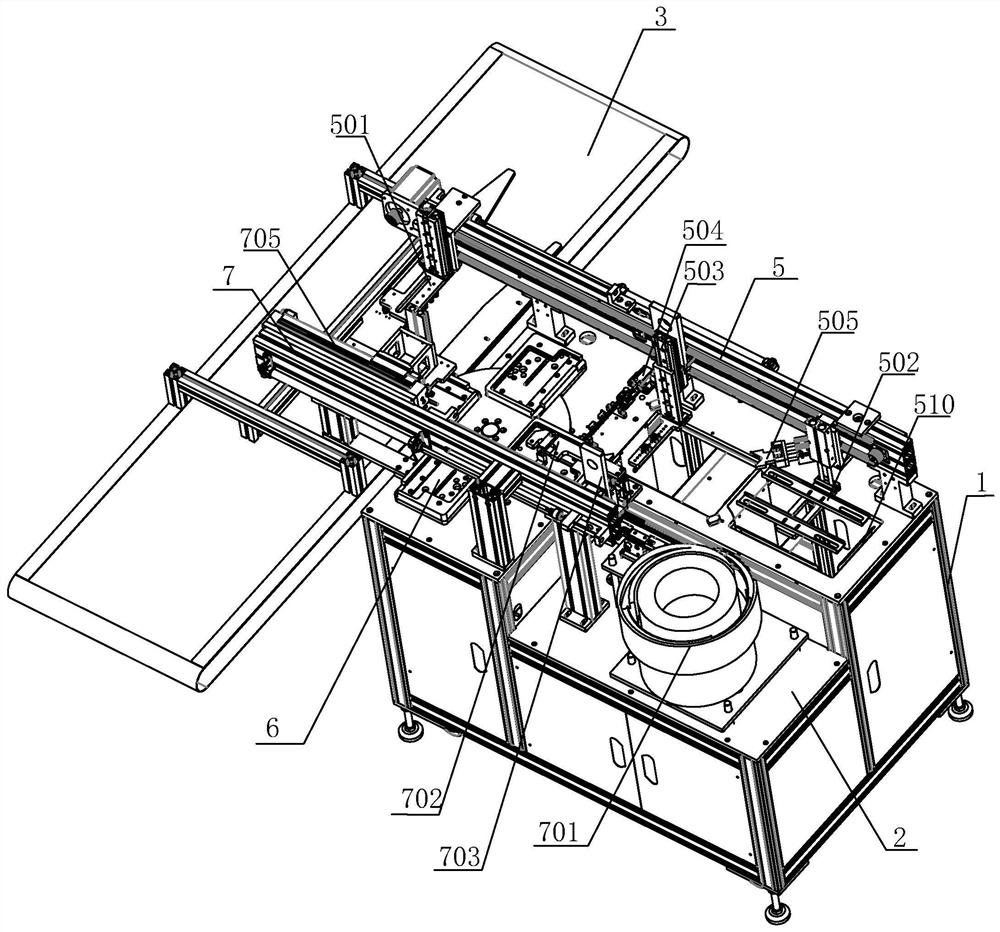

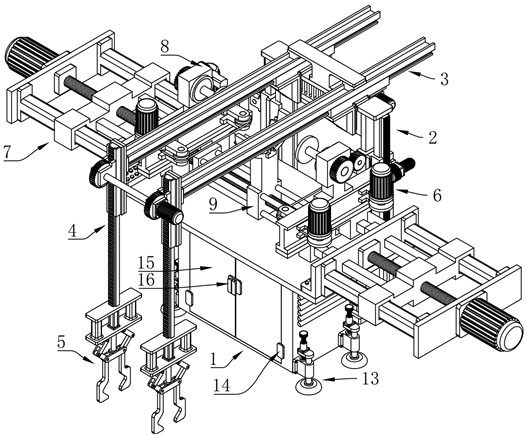

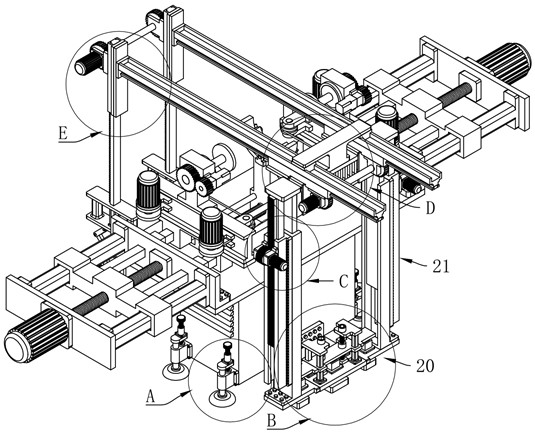

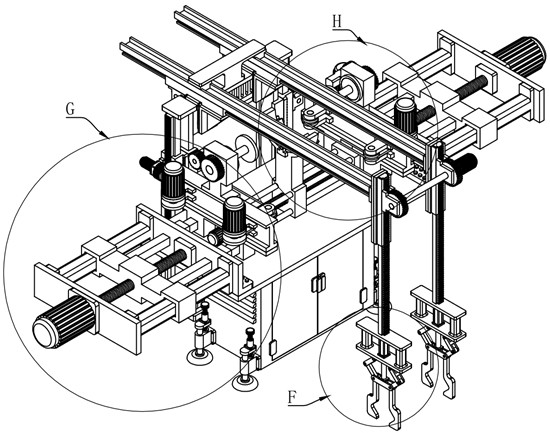

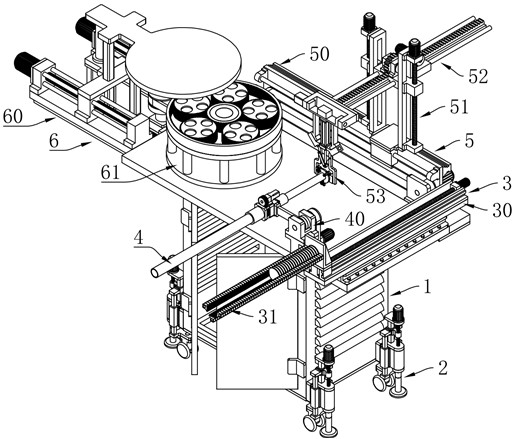

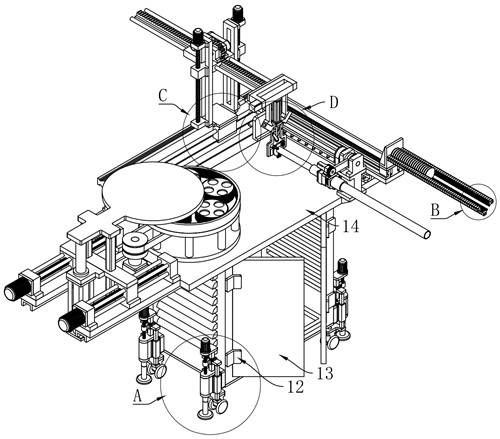

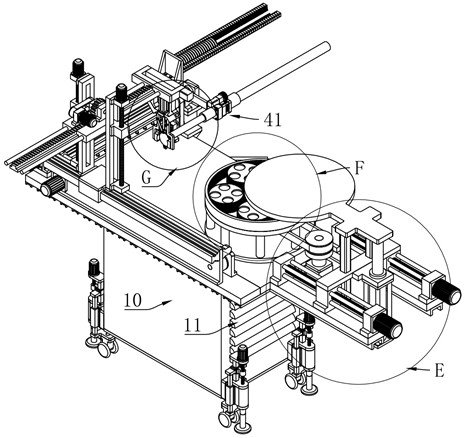

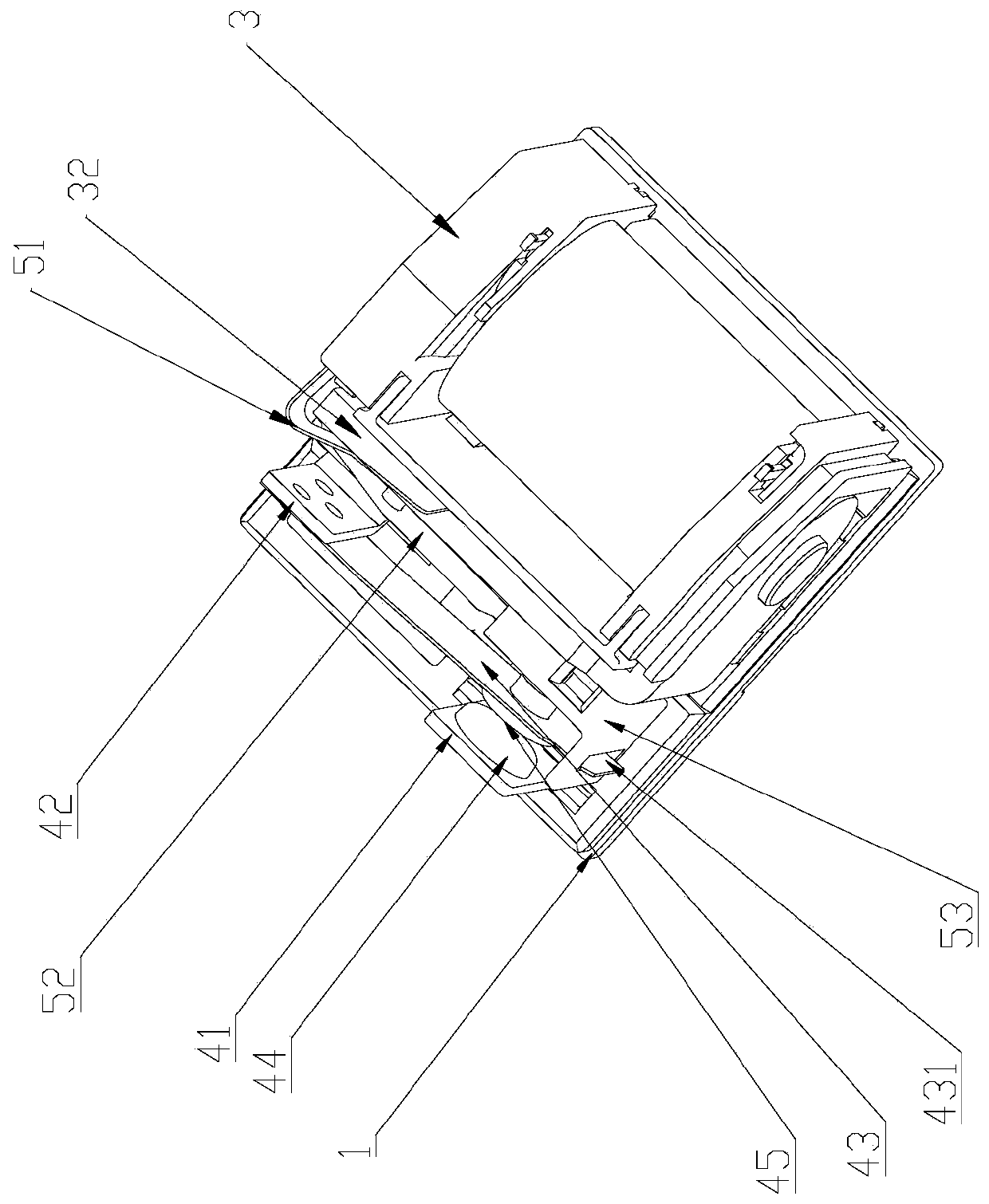

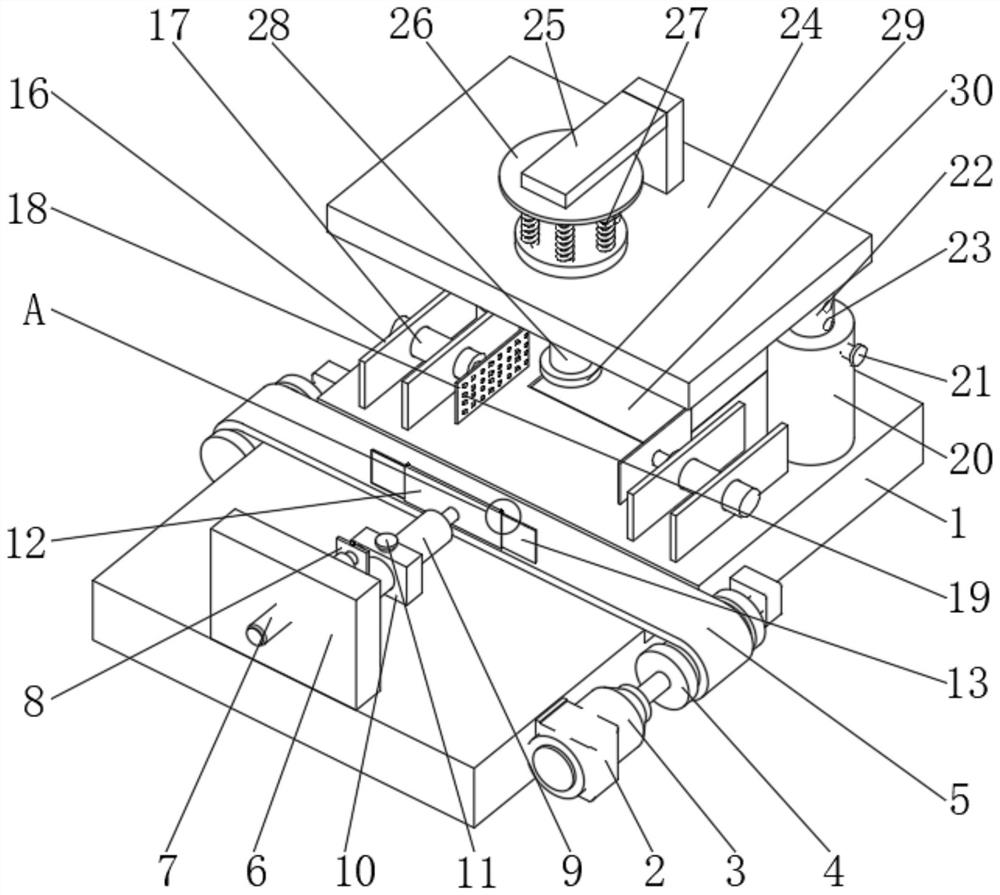

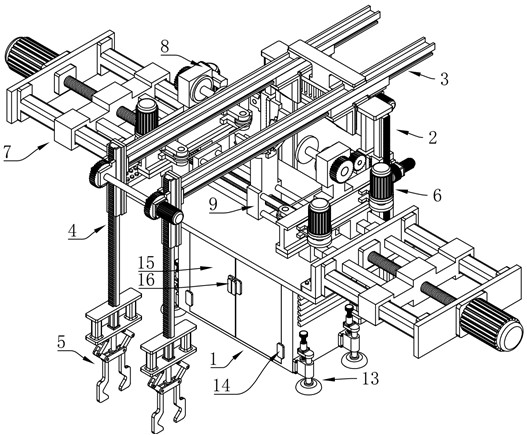

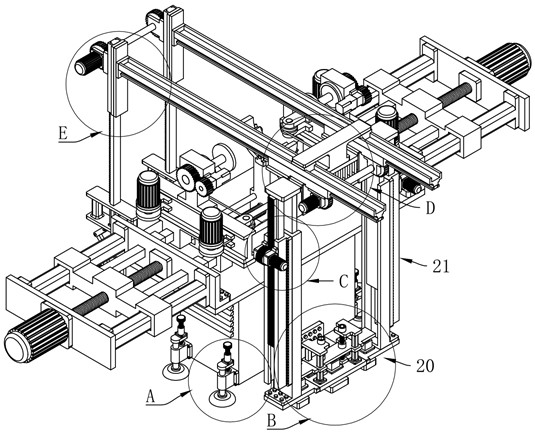

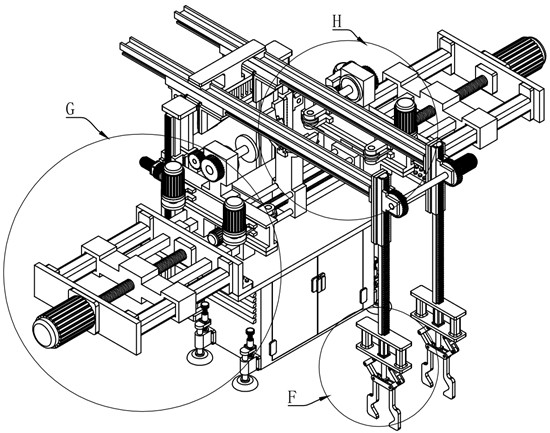

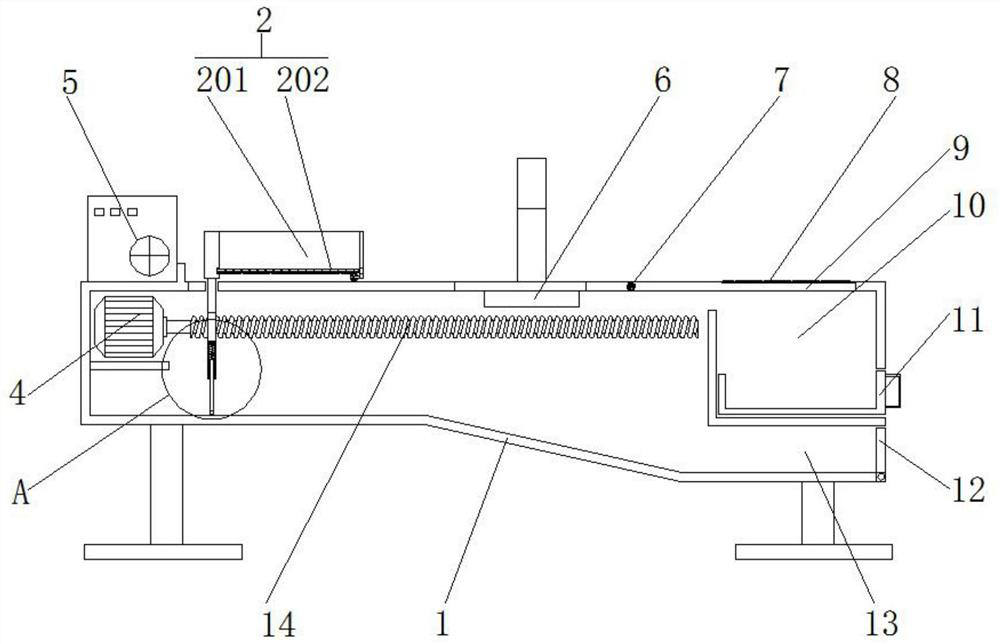

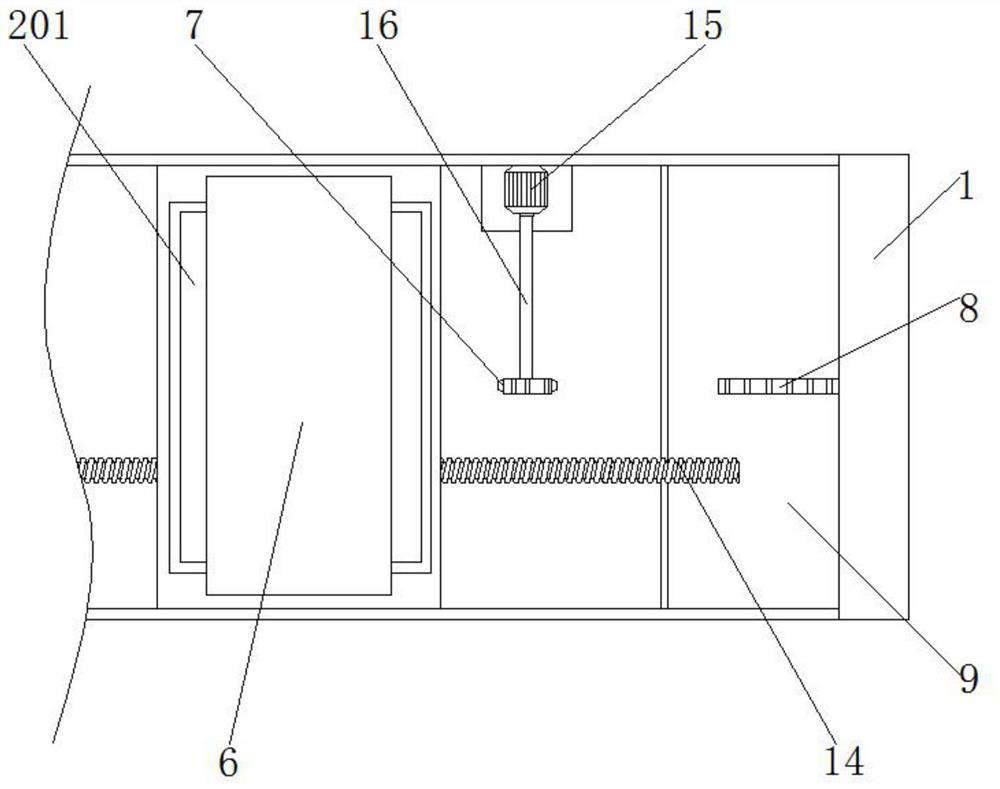

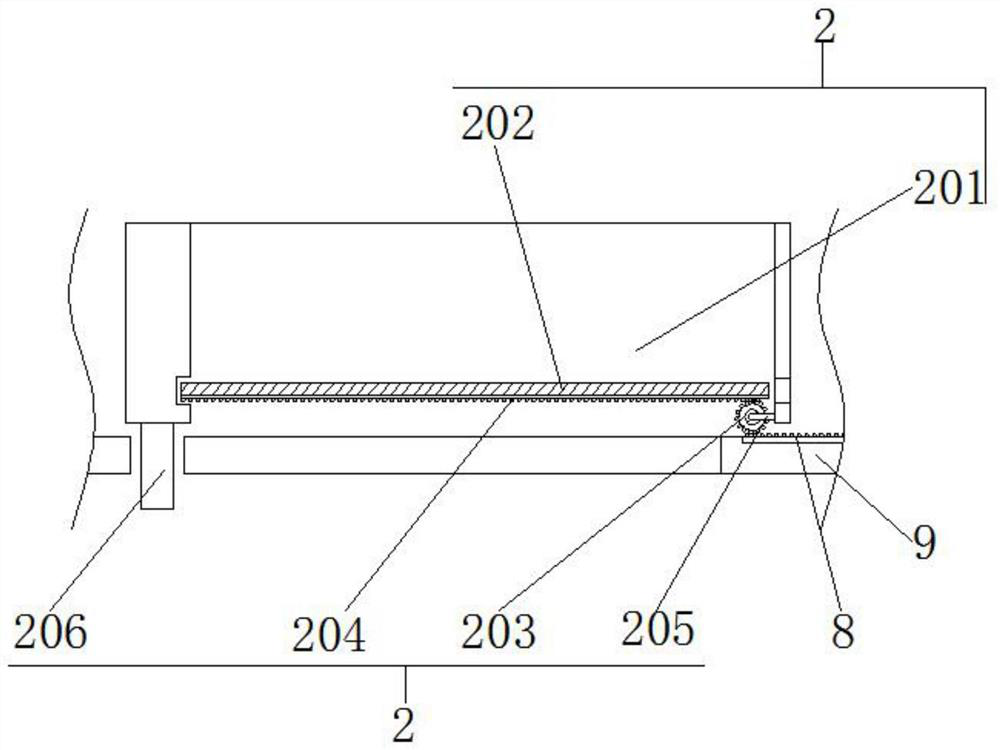

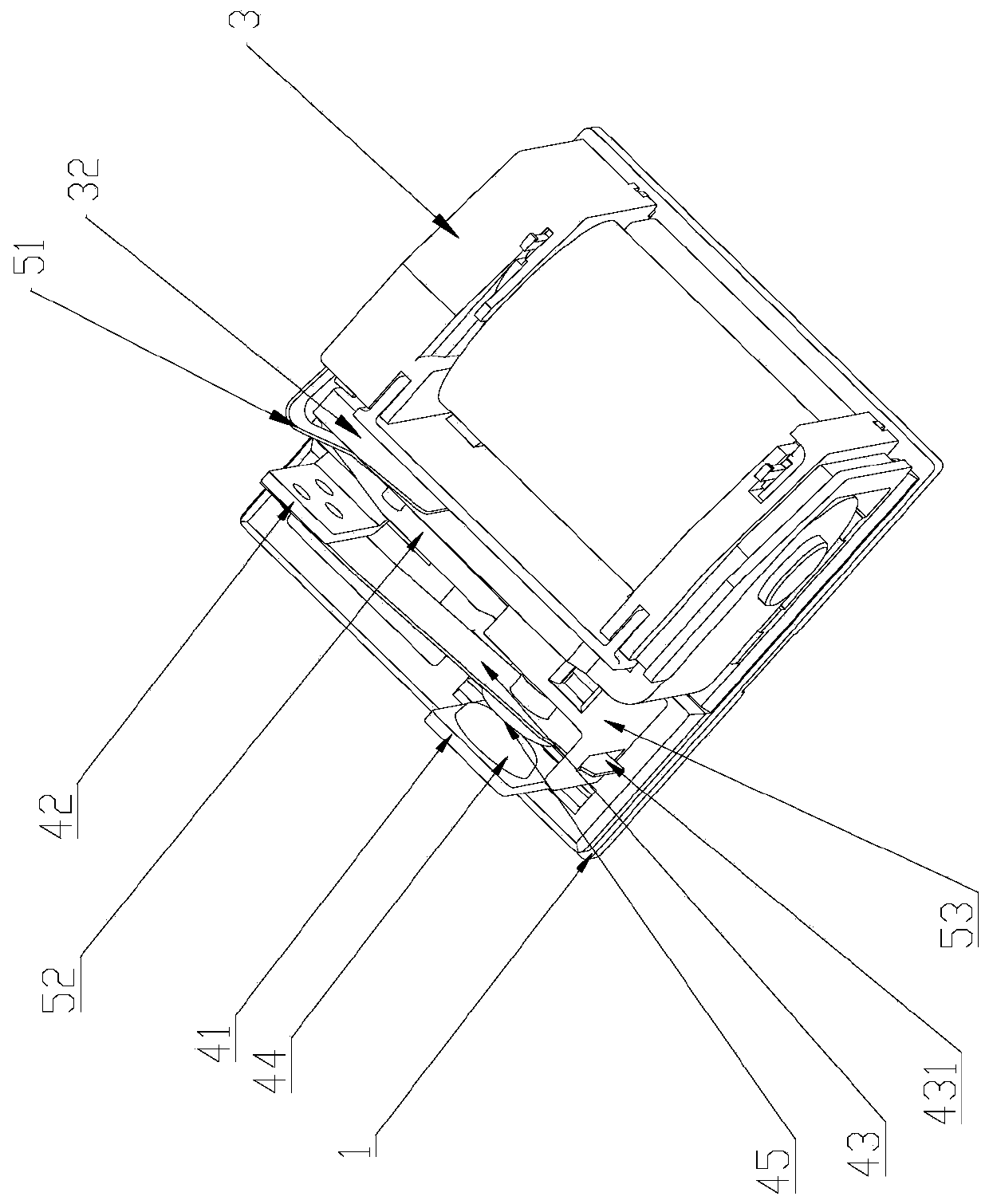

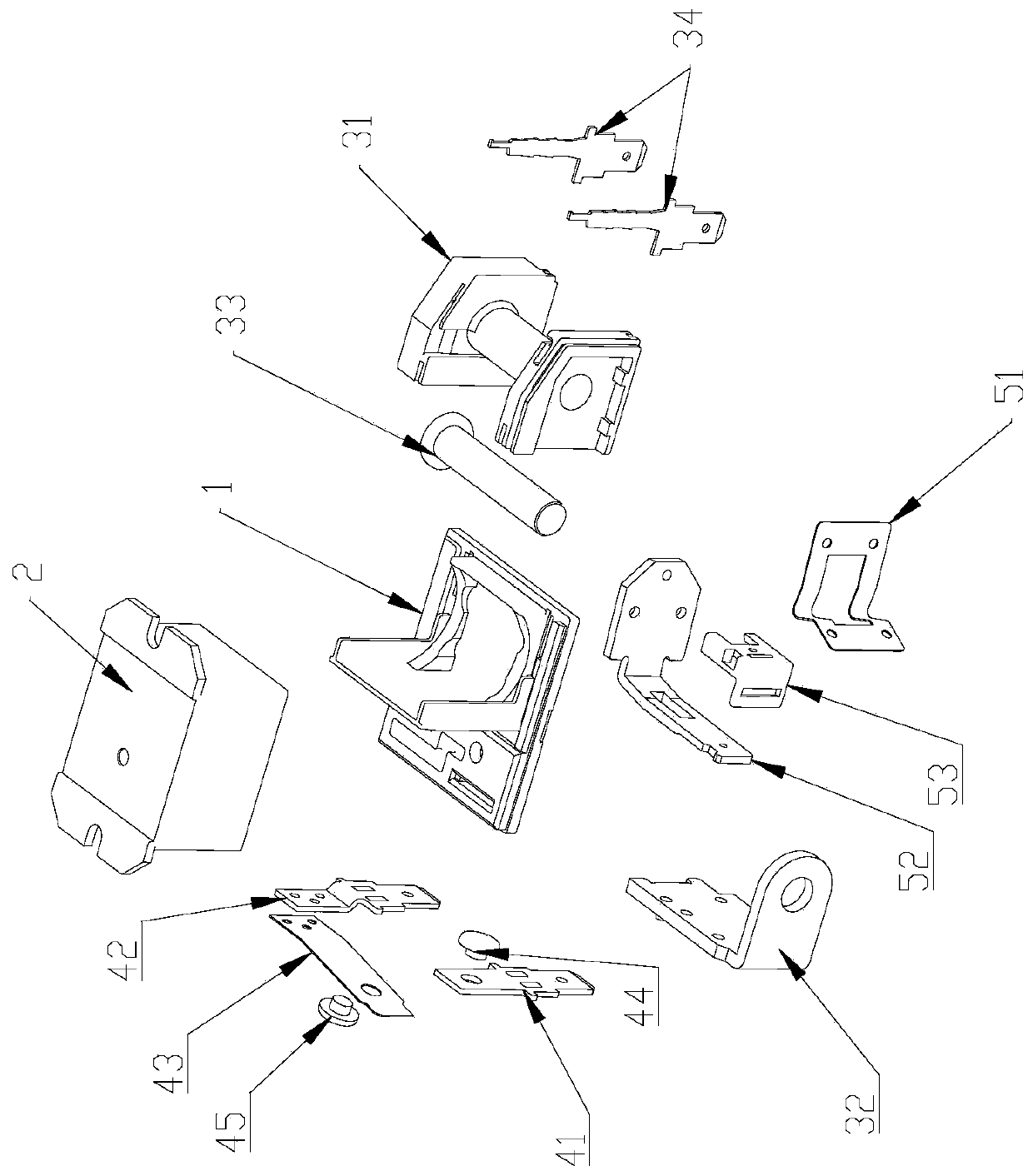

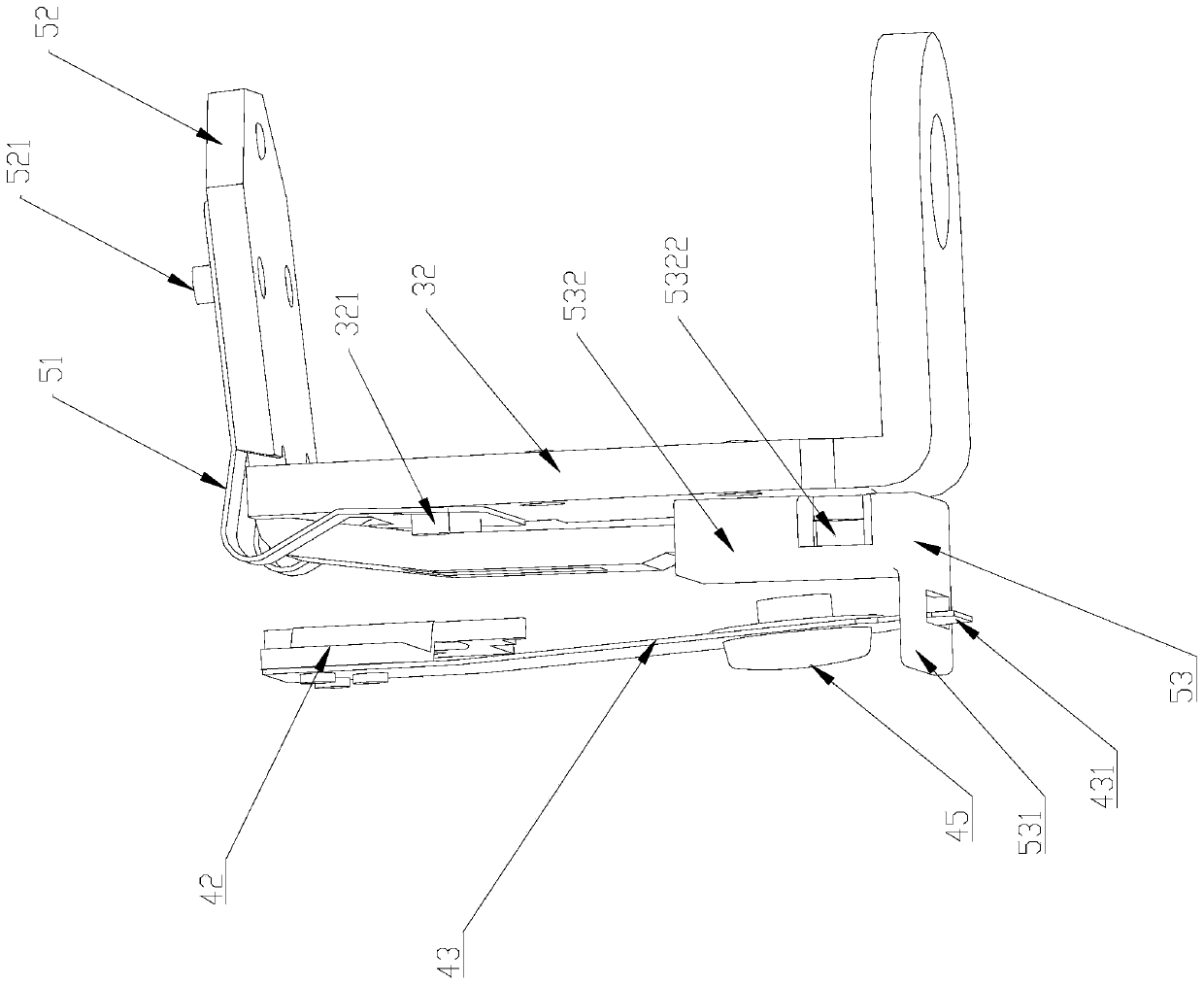

Automatic feeding and assembling device for printer components

ActiveCN113579726ARealize automatic transmissionFacilitate automatic transferAssembly machinesComputer printingEngineering

The invention discloses an automatic feeding and assembling device for printer components. The automatic feeding and assembling device comprises a supporting frame, a deck plate, a workpiece transferring and assembling device, a rotary disc feeding device, a clip feeding and assembling device and a controller, the deck plate is fixed to the supporting frame, the rotary disc feeding device is arranged on the deck plate, the workpiece transferring and assembling device is arranged on the front side of the rotary disc feeding device, and the clip feeding and assembling device is arranged on the rear side of the rotary disc feeding device. The workpiece transferring and assembling device, the rotary disc feeding device and the clip feeding and assembling device are connected with the controller, and the workpiece transferring and assembling device comprises a supporting stand column A, a horizontal sliding rail supporting plate A, a workpiece taking and transferring device and a glass taking and transferring and assembling device; and the clip feeding and assembling device comprises a supporting stand column B, a horizontal sliding rail supporting plate B, a clip feeding device, a clip taking, transferring and assembling device and a finished product taking and transferring device. The automatic feeding and assembling device for the printer components has the advantages that the structure is compact, the automation degree is high, the labor intensity of workers is relieved, the production efficiency is high, and the yield is high.

Owner:王泓霖

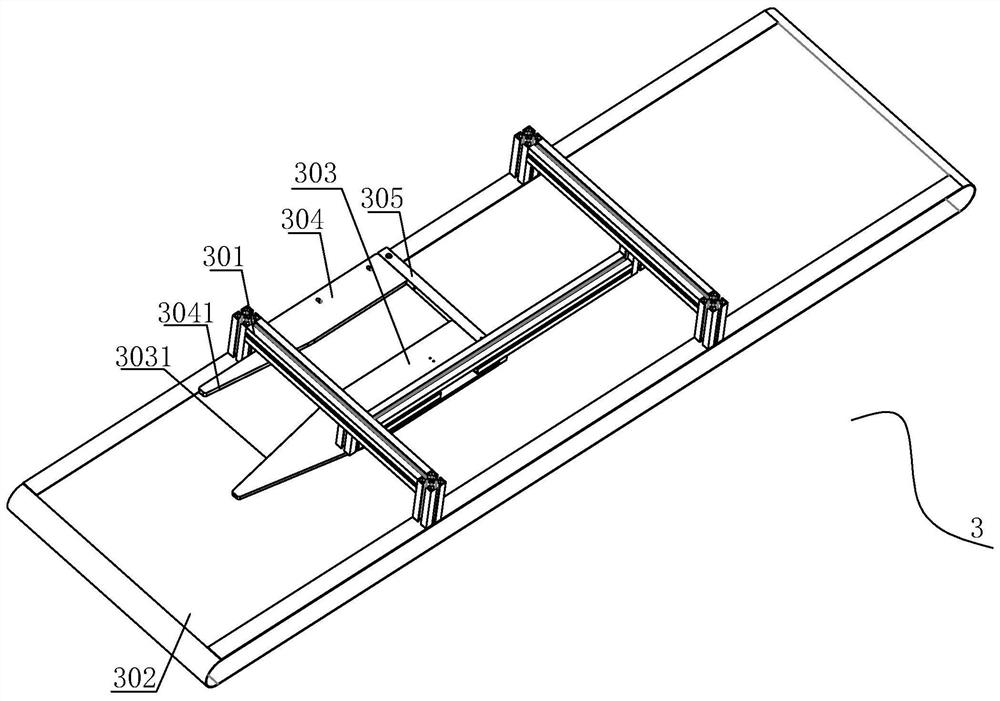

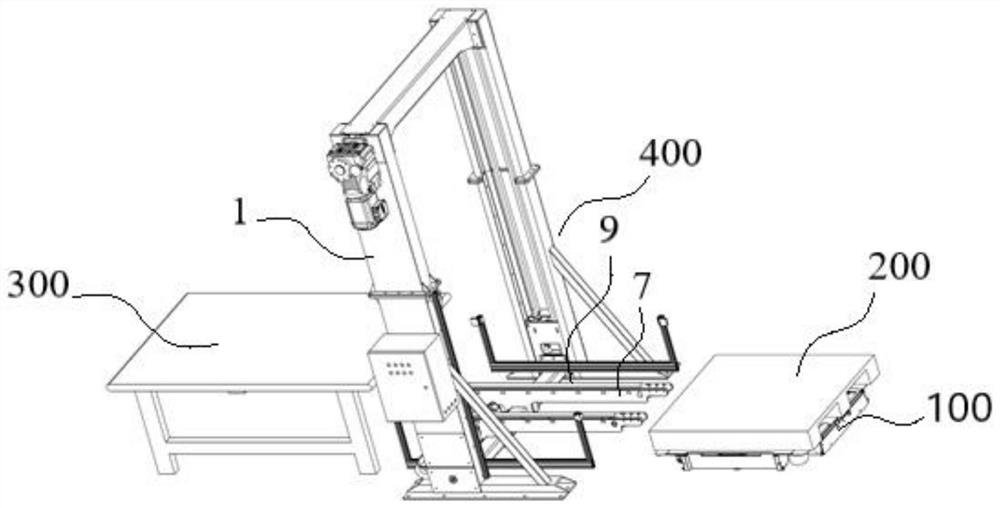

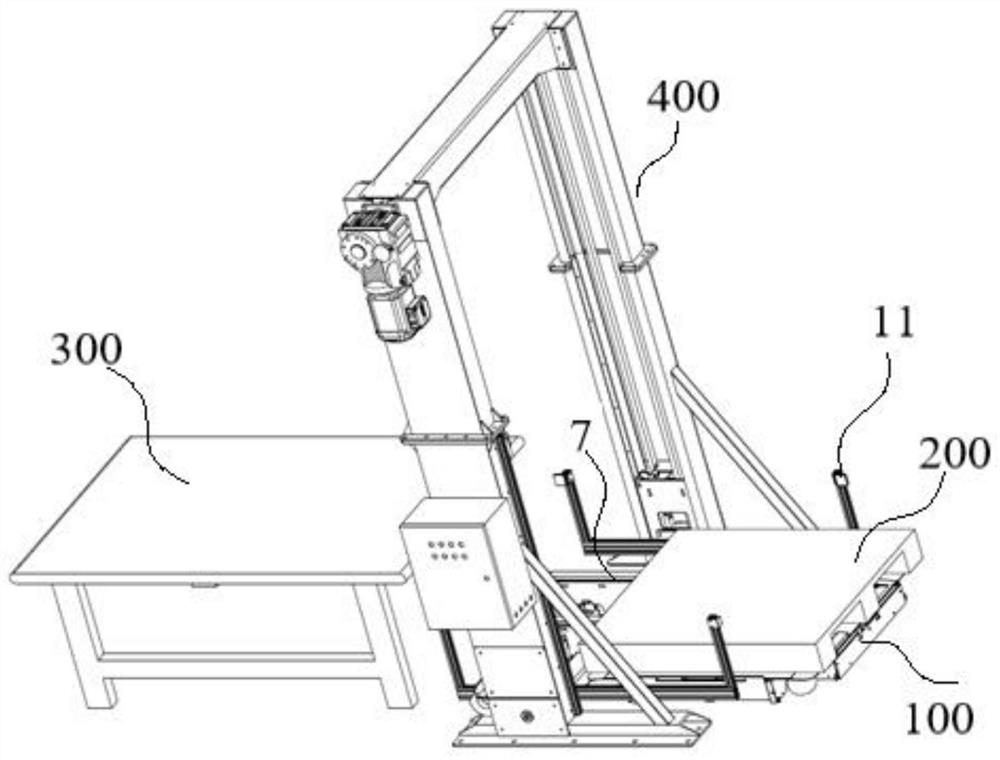

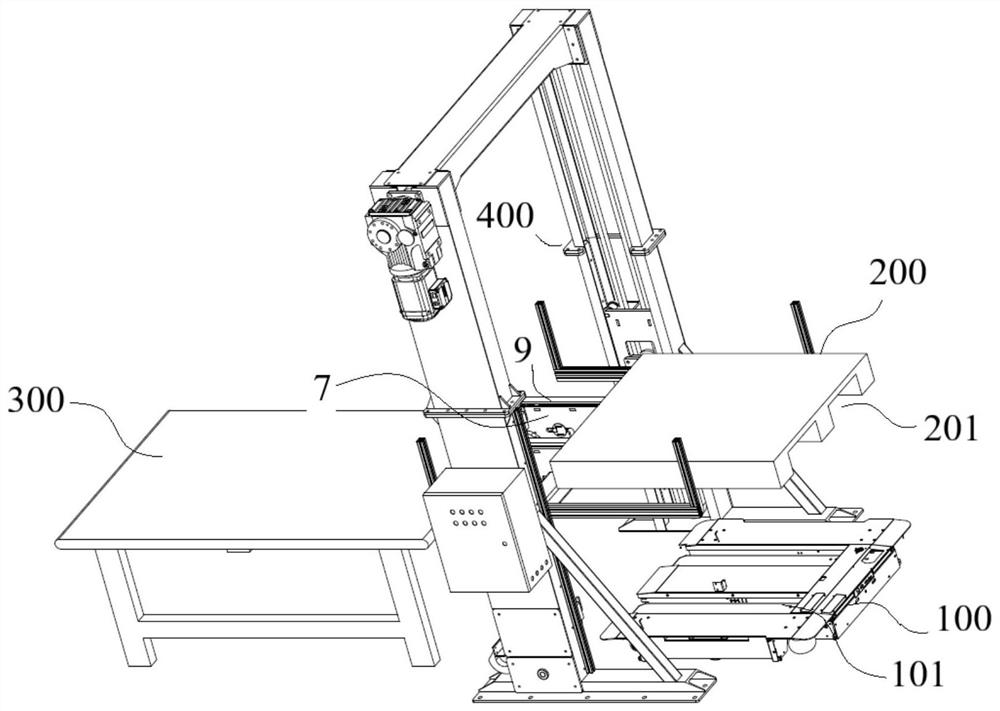

Tray butt joint conveying system based on AGV and assembly line of different heights

PendingCN113636299AConvenient automatic transferRealize automatic transferControl devices for conveyorsVehiclesEngineeringStructural engineering

The invention discloses a tray butt joint conveying system based on based on an AGV and an assembly line of different heights. The tray butt joint conveying system comprises an elevator arranged at the front end of the assembly line, the elevator comprises a door frame, a lifting arm and a conveying belt, the lifting arm is installed on the door frame for lifting, the conveying belt is installed on the lifting arm for bearing and conveying trays, and when the AGV runs to a transfer station, the trays are transferred from the AGV to the assembly line or from the assembly line to the AGV by driving the lifting arm and the conveying belt. According to the tray butt joint conveying system based on based on the AGV and the assembly line of different heights, automatic transfer of trays and objects between the AGV and the assembly line can be realized.

Owner:广东塔斯克机器人有限公司

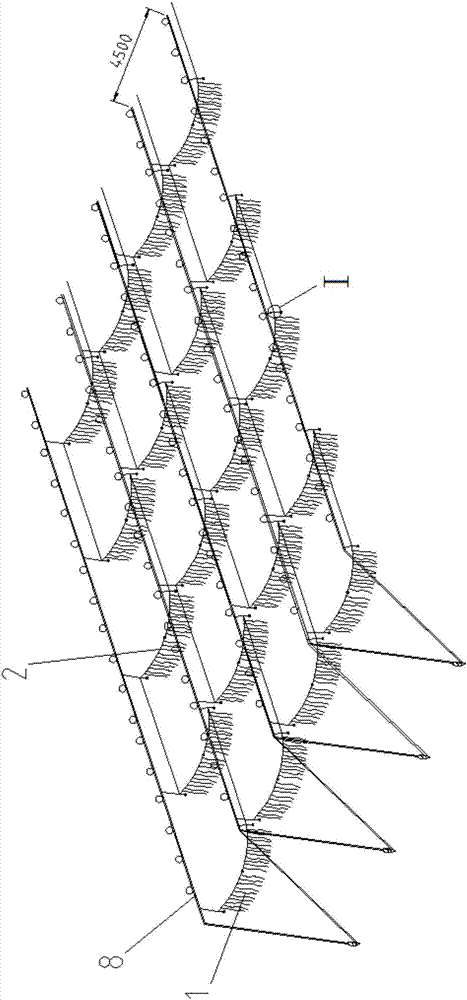

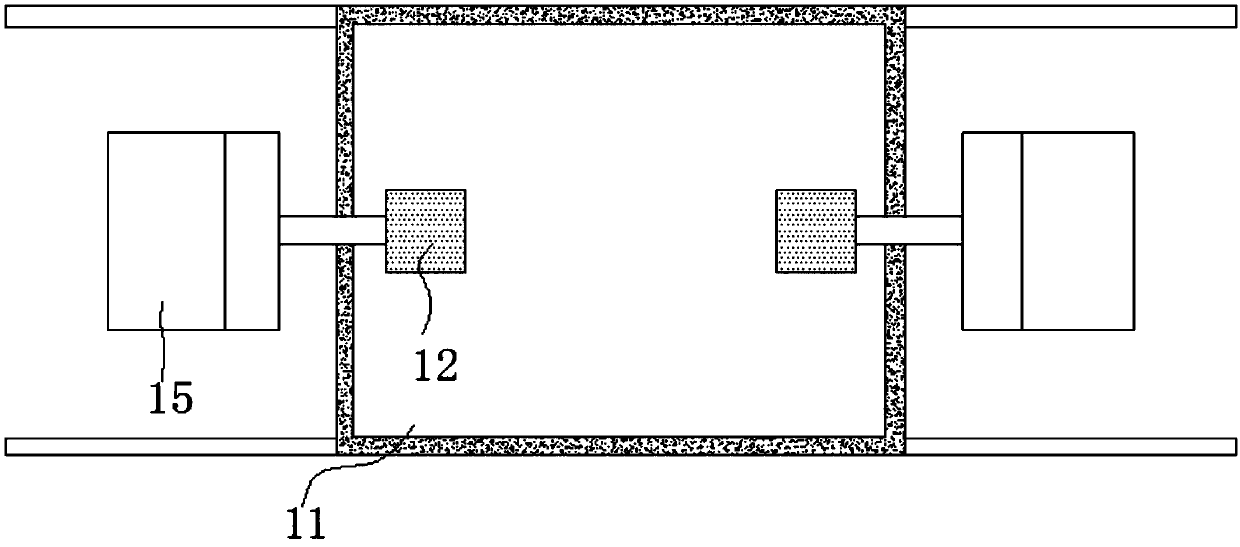

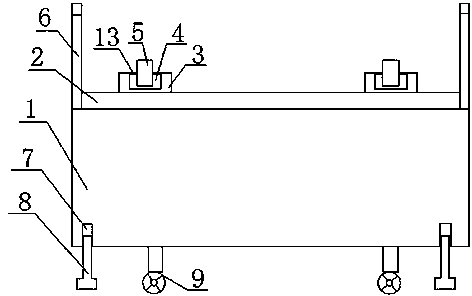

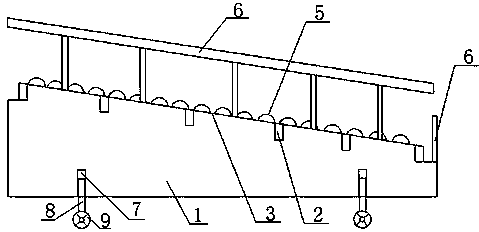

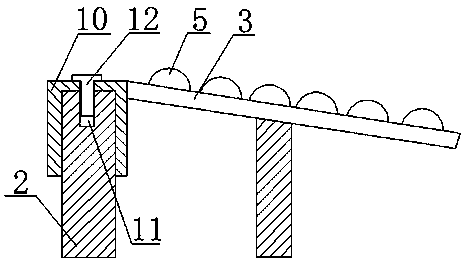

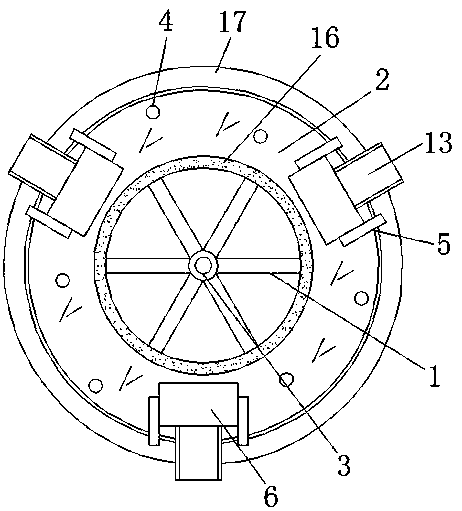

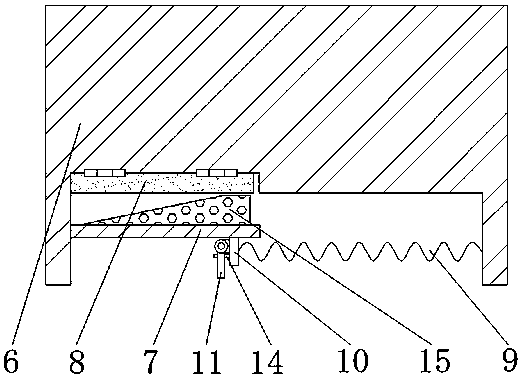

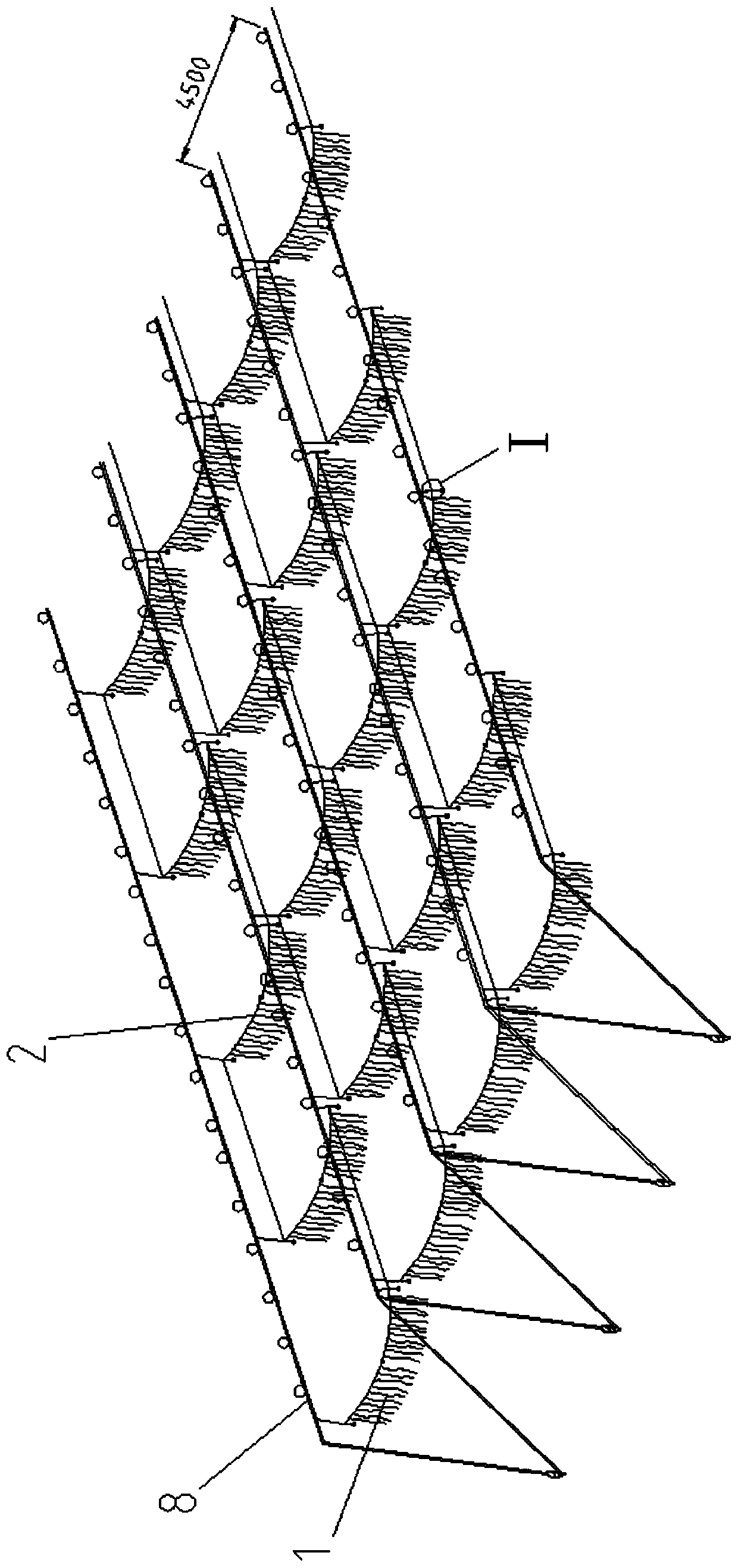

Material conveying mechanism for skylight production line

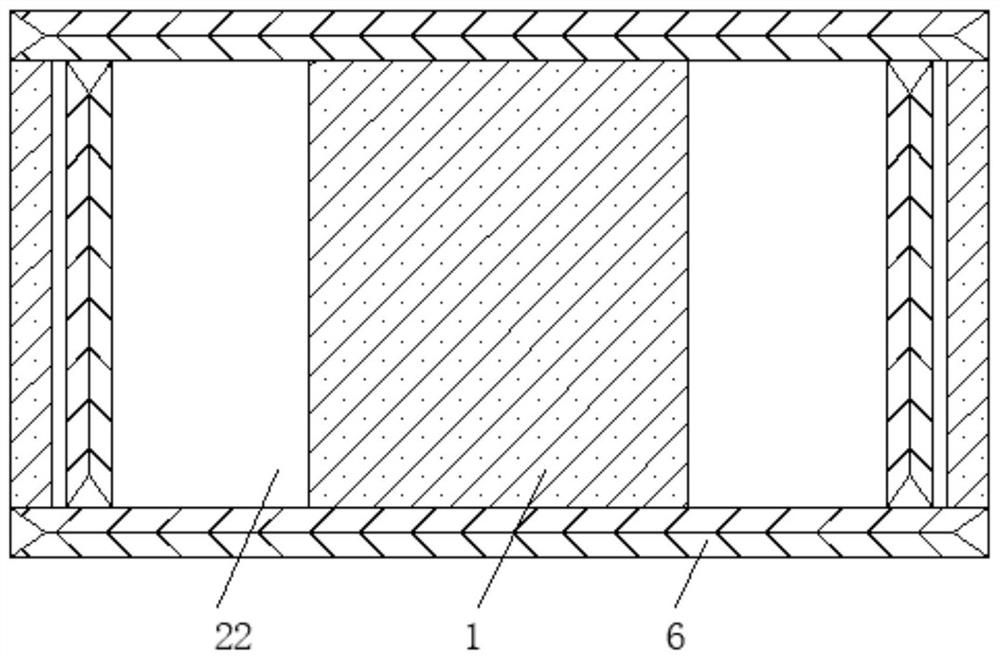

InactiveCN104071517AImprove transfer efficiencyAvoid frequent feedingChutesProduction lineEngineering

The invention aims to provide a material conveying mechanism for a skylight production line. The material conveying mechanism comprises a base, a plurality of beams are arranged on the upper end face of the base and provided with two tracks, the tracks are provided with grooves, rolling wheels are evenly arranged in the grooves, the beams are slantly arranged, each track and the plane form an included angle of 5-30 degrees, and baffles are arranged on the left sides and the right sides and at the front ends of the beams and positioned on the base. A feeding mechanism is arranged beside the skylight production line and is perpendicular to the running direction of the skylight production line, and a plurality of boxes for bearing materials are placed on the inclined tracks in one time. After the materials in the front boxes are used up and the empty boxes are taken down, the rear boxes can automatically slide down on the tracks, the goal of automatic feeding is achieved, frequent feeding by material workers can be effectively avoided, material conveying efficiency is improved, and accordingly assembly efficiency is improved.

Owner:WUHU MOTIONTEC AUTOMOTIVE

Wafer bar end cutting device

ActiveCN113085041AEasy automatic transferStable clampingRevolution surface grinding machinesWorking accessoriesWaferRound bar

A wafer bar end cutting device comprises a supporting assembly, a first lifting assembly, backward pulling mechanisms, second lifting mechanisms, clamping mechanisms, adjusting mechanisms, end cutting mechanisms, rotating mechanisms and rounding mechanisms. When a wafer bar is machined by the wafer bar end cutting device, automatic transfer of the wafer bar is convenient, when the wafer bar is transferred, the wafer bar can be stably clamped, the transfer safety of the wafer bar is improved, end cutting operation of the wafer bar is facilitated, and meanwhile, the outer wall of the wafer bar can be coarsely ground; and by means of the wafer bar end cutting device, the machining efficiency of the wafer bar can be remarkably improved, the working intensity of operators is lowered, and the device has high practicability.

Owner:四川上特科技有限公司

Mobile phone processing part transfer mechanism and method

PendingCN110239901AEasy for automatic loadingIncrease productivityConveyor partsRotary conveyorsLow speedEngineering

The invention discloses a mobile phone processing part transfer mechanism and method. The transfer mechanism comprises a bracket, a low speed motor and an outer frame; a rotating disk is arranged above the bracket, and the low speed motor is arranged below the bracket; the outer frame is arranged on the outer side of the rotating disk, and the top end of the outer frame is connected with a support frame of which the top end is provided with a material box; the top end of a switch plate is provided with a material control block, and a discharging plate is installed above the switch plate; a fixing plate is installed below the switch plate, and the fixing plate is connected with a movable plate through a connecting shaft; the middle part of the front side of the fixing plate is provided with a clamping block, and the outer side of the fixing plate is provided with a spring of which the outer end is connected with the bottom end of the material box; and a material guide plate is arranged below the material box. The mobile phone processing part transfer mechanism facilitates placement and automatic feeding of a mobile phone part, and the production efficiency of mobile phones is improved, so that the benefits of an enterprise are improved.

Owner:JIANGSU SAIBO YUHUA TECH CO LTD

Environment-friendly recycling process for waste wires and cables for electric power engineering

PendingCN114334302ASimple structureEasy to adjustBasic electric elementsApparatus for removing/armouring cablesProcess engineeringCopper wire

The invention discloses an environment-friendly recycling process for waste wires and cables for electric power engineering, which comprises a base box, the middle of the upper side of the base box is fixedly connected with a separation recycling box, the left side and the right side of the inner cavity of the separation recycling box are separately provided with a crushing cavity and a stripping cavity through a first partition plate, and the inner side of the crushing cavity is provided with a stripping mechanism; and the stripping mechanism comprises a plurality of groups of skin cutting components and stripping components, and the skin cutting components and the stripping components are fixedly connected with first limiting sliding blocks. According to the environment-friendly recycling process for the waste wires and cables for the electric power engineering, a first limiting sliding block slides in a first linear limiting sliding groove, so that a skin cutting component and a peeling component move, the caliber between multiple sets of peeling teeth and multiple sets of skin cutting knives is consistent with the diameter of a copper wire in a to-be-processed cable, the structure is simple, adjustment is convenient, and the recycling efficiency is high. And the equipment can be used for stripping processing of various different cables, and the use efficiency of the equipment is improved.

Owner:林祖德

Wafer end surface fine grinding device

ActiveCN113246004BConvenient automatic feedingEasy automatic transferGrinding carriagesPolishing machinesWaferEngineering

A wafer end surface fine grinding device, comprising: a support body, a support component, a feeding component, a transfer component, a transfer component and a fine grinding component. The feeding component is used to place multiple wafers and drive multiple wafers to move inward. The transfer component is used to clamp a single wafer located in the feeding component and drive the single wafer to move towards the transfer component. , the transfer assembly is used to hold the single wafer held by the transfer assembly, and drive the single wafer to the fine grinding assembly, and is used for turning over the single wafer, the fine grinding assembly is used for multiple wafers Round end faces fine ground. The invention facilitates the end face polishing operation of the wafer, facilitates the automatic feeding of the wafer, facilitates the automatic transfer of the wafer, facilitates the automatic flipping of the wafer, and facilitates the automatic flipping of the wafer during the end face polishing of the wafer. Automatic placement facilitates automatic wafer end face grinding and polishing operations, improves the automation of wafer end face polishing, and improves the efficiency and quality of wafer end face polishing.

Owner:四川上特科技有限公司

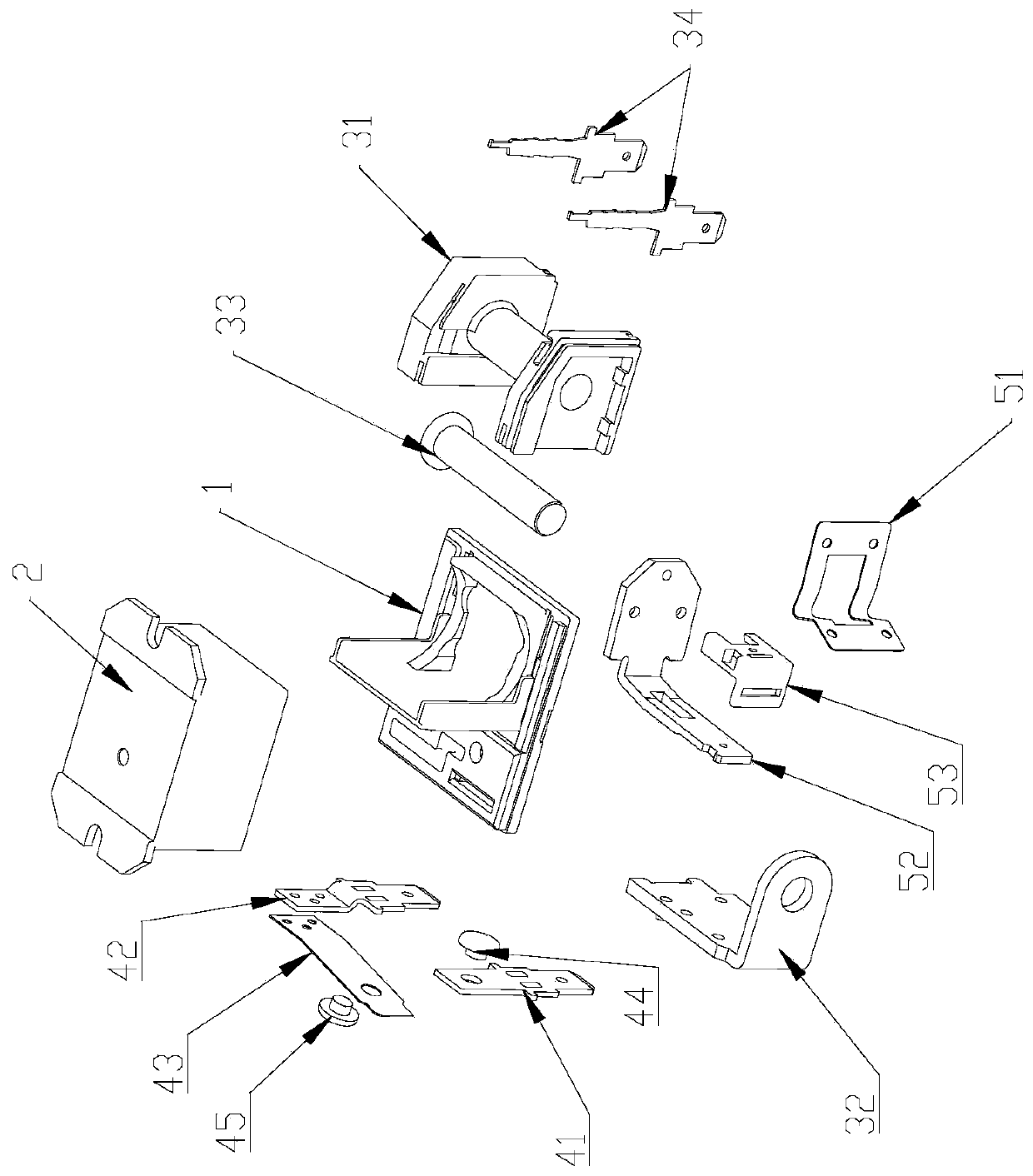

Universal relay convenient for automatic assembling

PendingCN111009447AAids in automated debuggingEasy to assembleElectromagnetic relay detailsStructural engineeringSmart manufacturing

The invention relates to an electromagnetic relay, especially relates to a universal relay convenient for automatic assembling, and belongs to the technical field of electrical equipment. The universal relay convenient for automatic assembling is composed of a base, a shell, a contact assembly, a magnetic circuit assembly and a transmission assembly, the contact assembly and the magnetic circuit assembly are inserted into the base, an elastic piece of the transmission assembly is riveted with a yoke and an armature respectively, a tail end of the armature is inserted into a mounting groove ofa push rod, the structure is simple, and automatic assembling is facilitated. A base bottom plate and the shell are buckled together. Compared with a traditional universal relay, the universal relay has simple functional component structures and simple assembling and matching of the functional components, is convenient to achieve automatic assembling, and satisfies an industrial intelligent manufacturing requirement.

Owner:YUEQING MEISHUO ELECTRIC

Storage and containing device for film magazine cleaned by film magazine cleaning machine and storage method

InactiveCN113877913AEasy to cleanAchieve reuseHollow article cleaningDrying gas arrangementsProcess engineeringMechanical engineering

The invention discloses a storage and containing device for a film magazine cleaned by a film magazine cleaning machine and a storage method. The storage and containing device comprises a cleaning and storing box and supporting legs fixed at the four corners of the bottom of the cleaning and storing box, a partition plate is fixed among the peripheries of the inner wall of the cleaning and storing box, and a sealing plate is fixed between the top of the partition plate and the inner wall of the cleaning and storing box; and a driving pump is fixed to the bottom of the partition plate. The invention relates to the technical field of film magazine storage. According to the storage and containing device for the film magazine cleaned by the film magazine cleaning machine and the storage method, through the arrangement of the driving pump, a water outlet pipe, a water inlet pipe and a driving rotary cleaning mechanism, the film magazine can be conveniently driven to rotate by 360 degrees; then a brushing cleaning mechanism is matched for brushing cleaning, so that the cleaning effect is good; through the arrangement of the sealing plate, the film magazine can be cleaned and stored in one cleaning and storing box; and water resources can be recycled through the arrangement of a circulating self-filtering and flushing mechanism, a filter screen in the circulating self-filtering and flushing mechanism can be automatically dredged, and the automation degree is high.

Owner:杭州中欣晶圆半导体股份有限公司

Full-automatic stamping production line

PendingCN113210521ASimple and efficient connection transmission modeEasy connectionMetal-working feeding devicesShaping safety devicesServoStructural engineering

The invention belongs to the technical field of stamping production lines, and particularly discloses a full-automatic stamping production line. The full-automatic stamping production line comprises a ground foot and sliding rails, wherein a fixing frame is arranged at the side of a bottom plate; a servo motor is arranged at the inner side of the fixing frame; a transmission wheel is arranged at the end of the servo motor; a transmission band is arranged at the outer side of the transmission wheel; a vertical plate is arranged at the end of the bottom plate; a first electric telescopic rod is installed at the inner side of the vertical plate; a connecting plate is installed at the end of the first electric telescopic rod; a second electric telescopic rod is installed in the connecting plate; a fixing seat is arranged at the side of the second electric telescopic rod; a fixing nail penetrates through the top of the fixing seat; and a push plate is arranged at the end of the second electric telescopic rod. According to the full-automatic stamping production line, a user can conveniently and automatically convey and shift parts of the device, conveniently clamp and fix the parts of the device, conveniently adjust and set the stamping height and conveniently conduct damping on the structure of the device.

Owner:芮玲美

Vehicle Vending Machine

ActiveCN103942883BSimple structureEasy to controlCoin-freed apparatus detailsApparatus for dispensing discrete articlesMotor driveDrive wheel

The invention provides a vehicle-mounted vending machine which comprises a cabinet body, a lifting platform and a pickup opening. Guide rails facilitating the vertical motion of the lifting platform are arranged in the middle of the cabinet body, the pickup opening is formed in the upper side of the position, at the upper ends of the guide rails, of the cabinet body, a lifting motor driving the lifting platform to vertically move is arranged at the bottom or the top of the position, at the lower ends of the guider rails, of the cabinet body, and a lifting transmission mechanism driving the lifting platform to do synchronous movement is connected between the lifting motor and the lifting platform. Separation plates which divide an inner cavity of the cabinet body into a left warehouse and a right warehouse are arranged at the positions, on two sides of the guide rails, inside the cabinet body, goods channels are arranged at the bottoms of the warehouses respectively, a plurality of driving wheels feeding goods in the warehouses into the goods channels are arranged on the upper sides of the goods channels, track pushing devices for conveying the goods to the lifting platform are arranged in the goods channels, and correction mechanisms preventing articles from being transverse in the goods channel conveying process are arranged in the positions, above the track pushing devices, of the goods channels. The correction mechanisms effectively prevent a vehicle-mounted movable platform from influencing article conveying in the moving process, and the reliability of outputting the goods is improved.

Owner:FOSHAN BLUEWAY ELECTRIC APPLIANCES

An automatic buckle-unlocking device for harvesting kelp and its working method

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Chassis cleaning device for patrol robot

The invention discloses a chassis cleaning device for a patrol robot, and relates to the technical field of cleaning devices. In order to solve the problems that a chassis of an existing patrol robotis inconvenient to clean, fixing and conveying are inconvenient, manual operation is generally adopted, and time and labor are wasted, the following scheme is provided, wherein the chassis cleaning device comprises an external support; a power mechanism is fixedly connected to the inner wall of the bottom of the external support; a fixing mechanism is arranged outside the power mechanism in a threaded sleeving mode; a conveying mechanism is fixedly connected to the back face of the external support; a transmission mechanism is fixedly connected to the inner wall of the left side of the external support; a cleaning mechanism is arranged above the transmission mechanism; a pushing mechanism is arranged above the cleaning mechanism; a feeding inlet is formed in the right side of the externalsupport; and a first fixing rod is fixedly connected to the inner wall of the bottom of the power mechanism. The chassis of the patrol robot can be cleaned conveniently, automatic fixing and conveyingare facilitated, automatic operation is achieved, and the chassis cleaning device is suitable for market use.

Owner:合肥中科创奥数字科技有限公司

Wafer bar end cutting device

ActiveCN113085041BEasy automatic transferStable clampingRevolution surface grinding machinesWorking accessoriesWaferEngineering

A wafer bar end cutting device, comprising: a support assembly, a first lifting assembly, a rear pulling mechanism, a second lifting mechanism, a clamping mechanism, an adjusting mechanism, an end cutting mechanism, a rotating mechanism and a rounding mechanism. The invention facilitates the automatic transfer of the wafer rod when processing the wafer rod, and can stably clamp the wafer rod when the wafer rod is transferred, thereby improving the safety of the wafer rod transfer , it is convenient to carry out the end cutting operation of the wafer bar, and at the same time, it can roughly grind the outer wall of the wafer plate. Through this device, the processing efficiency of the wafer bar can be significantly improved, and the working intensity of the operator can be reduced. It has a strong practicality.

Owner:四川上特科技有限公司

Stamping device for antioxidant film-coated ceiling board

ActiveCN112109478AEasy to limitEasy automatic transferEmbossing decorationsCircular discElectric machinery

The invention discloses a stamping device for an antioxidant film-coated suspended ceiling board. The stamping device comprises a workbench, a motor, a cylinder and a die, wherein a bracket is connected to the upper left end of the workbench in a welding manner; a supporting block is connected into a rail in a sliding way; a mounting groove is formed in the left end of a bearing plate; a second limiting strip is fixedly connected to the right side of a limiting mechanism; a first connecting groove is formed in the right end of the bearing plate; a first disc is arranged in the first connectinggroove; a connecting handle is connected to the right end of a second disc in a welding manner; a rotating shaft is fixedly connected to the center of the second disc; the motor is mounted at the lower end of the rotating shaft; the cylinder is mounted at the upper end of the bracket; and the lower end of the cylinder is in bolted connection with the die. According to the stamping device for theantioxidant film-coated suspended ceiling board, an integrated ceiling can be easily limited, and can be conveniently and automatically conveyed, and the stamped integrated ceiling can be convenientlyunloaded.

Owner:浙江森杰集成吊顶有限公司

Rare earth magnetic material quality detection device based on machine vision

PendingCN114509385AEasy automatic transferEasy to automateMaterial analysis by optical meansSortingMachine visionGear wheel

The invention discloses a rare earth magnetic material quality detection device based on machine vision, which comprises a device main body, a display screen is arranged above the device main body, a first motor is arranged below the display screen, one side of the first motor is connected with a driving screw rod, one side of the driving screw rod is connected with a moving block, and the moving block is connected with a motor. A conveying mechanism is arranged above the moving block, and a cleaning mechanism is arranged below the moving block. According to the rare earth magnetic material quality detection device based on machine vision, a first motor and a second motor are controlled to be switched on and off through the detection device, when a rare earth magnetic material is detected to be qualified, a first gear and a second gear block are matched with each other, and the rare earth magnetic material in a transmission box is transmitted into a first storage box; and when the rare earth magnetic material is detected to be unqualified, the second gear is matched with the first gear, and the system magnetic material is conveyed into the second storage box, so that the magnetic material is automatically conveyed, automatic operation of the device is facilitated, and the working efficiency is improved.

Owner:JIANGXI UNIV OF SCI & TECH

Orderly covering device with conveying mechanism for preservative film and use method

InactiveCN111717438AEasy automatic transferEasy to useWrapping material feeding apparatusConveyor wrappingServoPlastic wrap

The invention discloses an orderly covering device with a conveying mechanism for a preservative film. The orderly covering device comprises a covering bottom plate, a first conveying frame is fixedlymounted on the left side of the top of the covering bottom plate, and a first servo motor is fixedly mounted at the upper end of the side wall of the front face of the first conveying frame. A supporting frame is fixedly mounted in the center of the top of the covering bottom plate, the outer side of the top of the supporting frame is sleeved with a conveying belt, and second servo motors are fixedly mounted on the front side and the rear side of the side wall of the right side of the supporting frame. The output ends at the left sides of the two second servo motors are connected with the conveying belt through couplers. A second conveying frame is fixedly mounted on the right side of the top of the covering bottom plate. According to the orderly covering device with the conveying mechanism for the preservative film, after covering is completed, the first servo motor is rightly started to drive a rotary shaft to rotate, then a vacant preservative film reel is driven to rotate, meanwhile the cut preservative film is driven to be automatically wound around the vacant preservative film reel, the uncut preservative film is driven to move, and therefore the preservative film is automatically conveyed.

Owner:陈玉滢

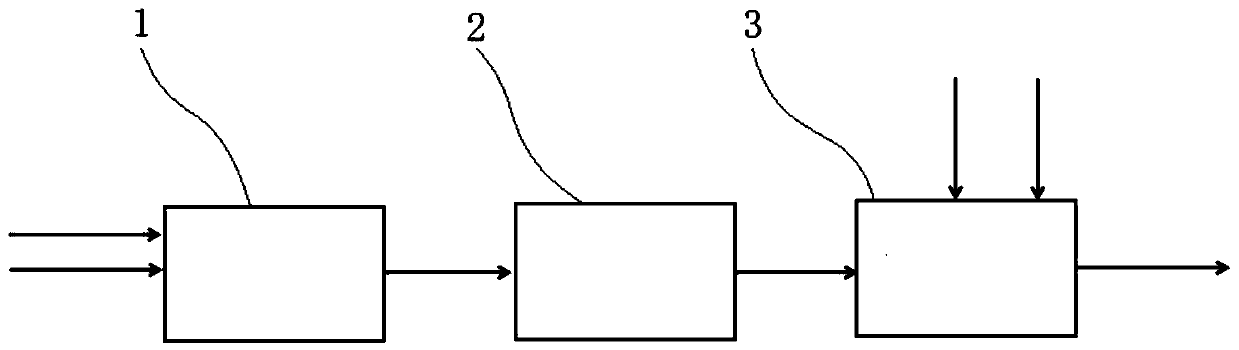

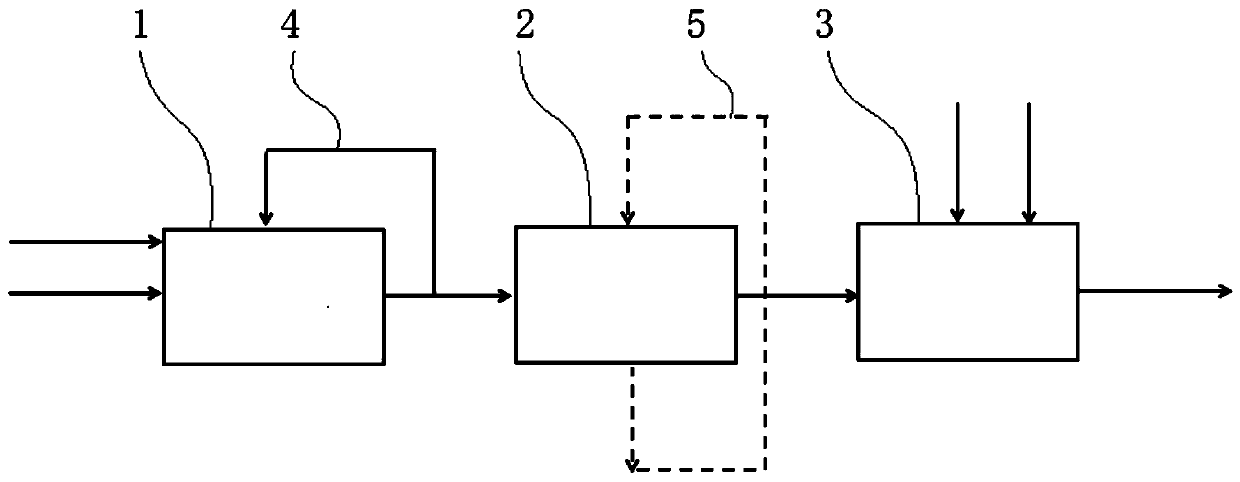

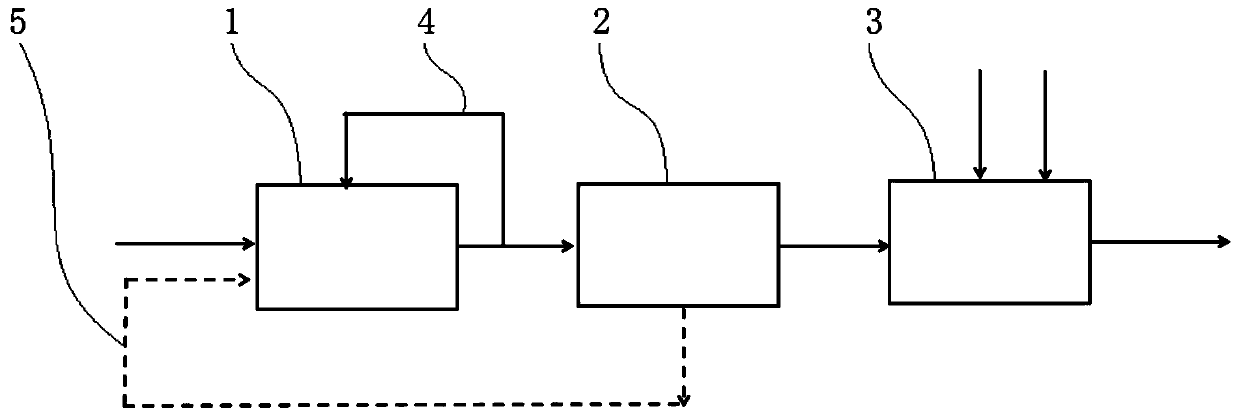

System for preparing combustible slurry from ultra-pure coal

PendingCN111266053AEasy automatic transferSolve lossTransportation and packagingMixersChemistryWet grinding

The invention discloses a system for preparing a combustible slurry by using ultra-pure coal. The system comprises a pulverization device for wet-grinding an ultra-pure coal raw material into particles of which the particle size is smaller than a preset particle size and mixing the particles with water to form ultra-pure coal suspension, an extrusion filtration device connected to the outlet of the pulverization device and used for extruding to filter the ultra-pure coal suspension, and a blending device connected to the outlet of the extrusion filtration device; and the blending device is used for mixing an ultra-pure coal filter cake obtained by extruding the ultra-pure coal suspension with an additive and water to form the combustible slurry. The pulverization device of the system for preparing the combustible slurry from the ultra-pure coal adopts a wet grinding method, so the drying process is omitted, environmental and health problems such as acid substance volatilization duringdrying and dust appearing during dry grinding are avoided, operation is simplified, the length of the technological process is shortened, continuous operation of the system is achieved, then the problem of raw material loss caused by intermittent operation is avoided, the yield is increased, and water is saved.

Owner:YANKUANG GRP CO LTD +2

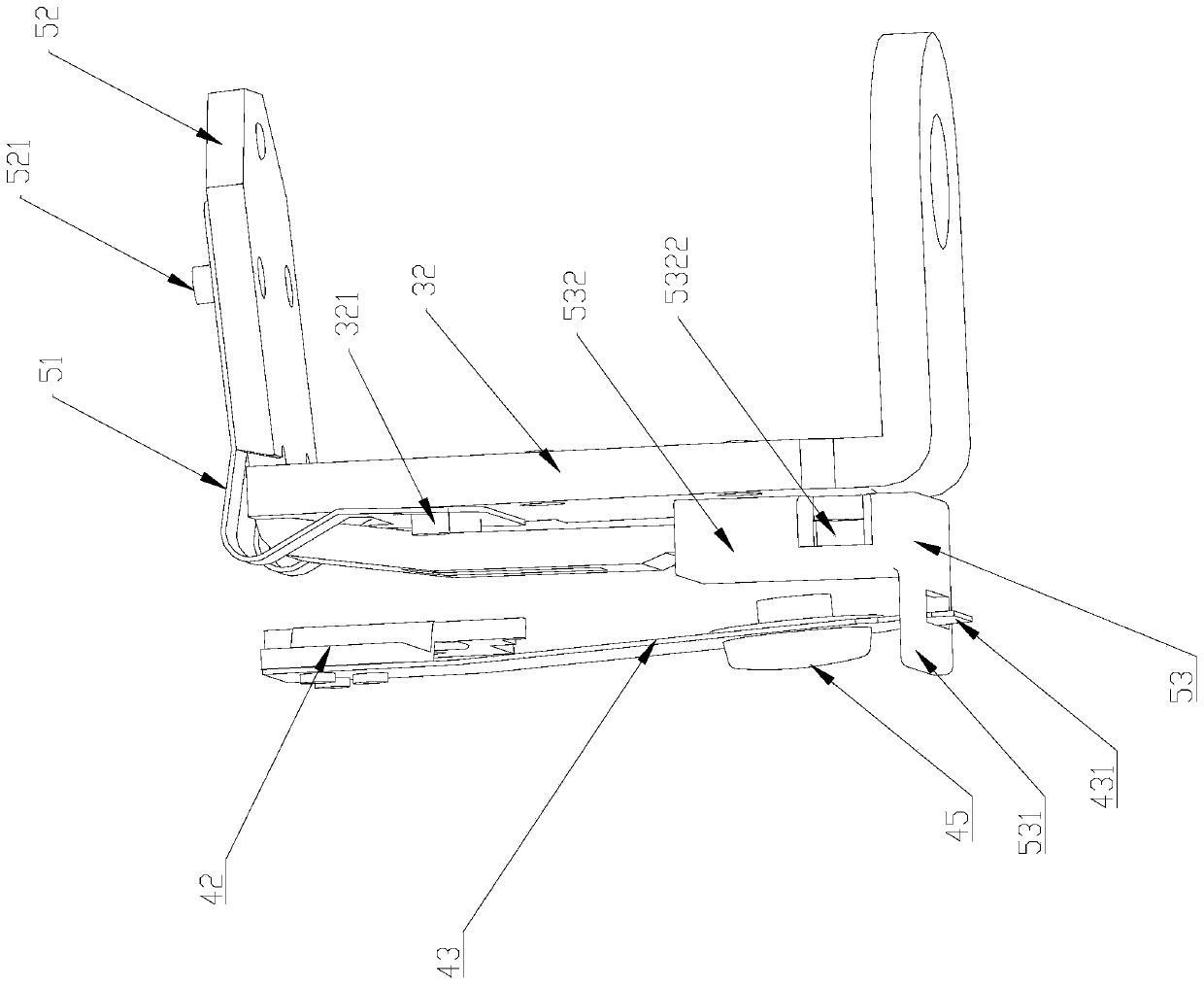

High-safety relay convenient for automatic production

PendingCN110957183AImprove securitySimple product structureElectromagnetic relay detailsStructural engineeringAutonomation

The invention relates to an electromagnetic relay, in particular to a high-safety relay convenient for automatic production, and belongs to the technical field of electrical equipment. The high-safetyrelay convenient for automatic production is composed of a base, a shell, a contact assembly, a magnetic circuit assembly and a transmission assembly, the contact assembly and the magnetic circuit assembly are inserted into the base, the elastic piece of the transmission assembly is riveted with a yoke and an armature respectively, the tail end of the armature is inserted into a mounting groove of a push rod. The structure is simple, and automatic assembly is facilitated; the shell is arranged on the base, all the functional components are sealed in the airtight sealed space formed by the shell and the base through glue sealing treatment, adverse effects of dust, harmful waste gas, flammable and combustible gas and the like on the functional components are eradicated, and safety is high.

Owner:YUEQING MEISHUO ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com