Tray butt joint conveying system based on AGV and assembly line of different heights

A conveying system and assembly line technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of high equipment cost, unmanned and automatic, etc., to improve the efficiency of handling operations and completely unmanned and the effect of automated handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

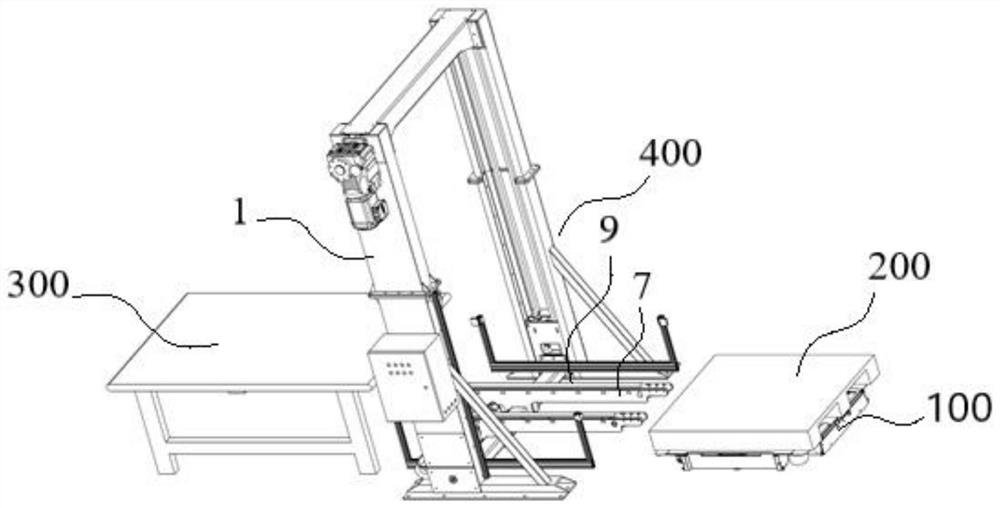

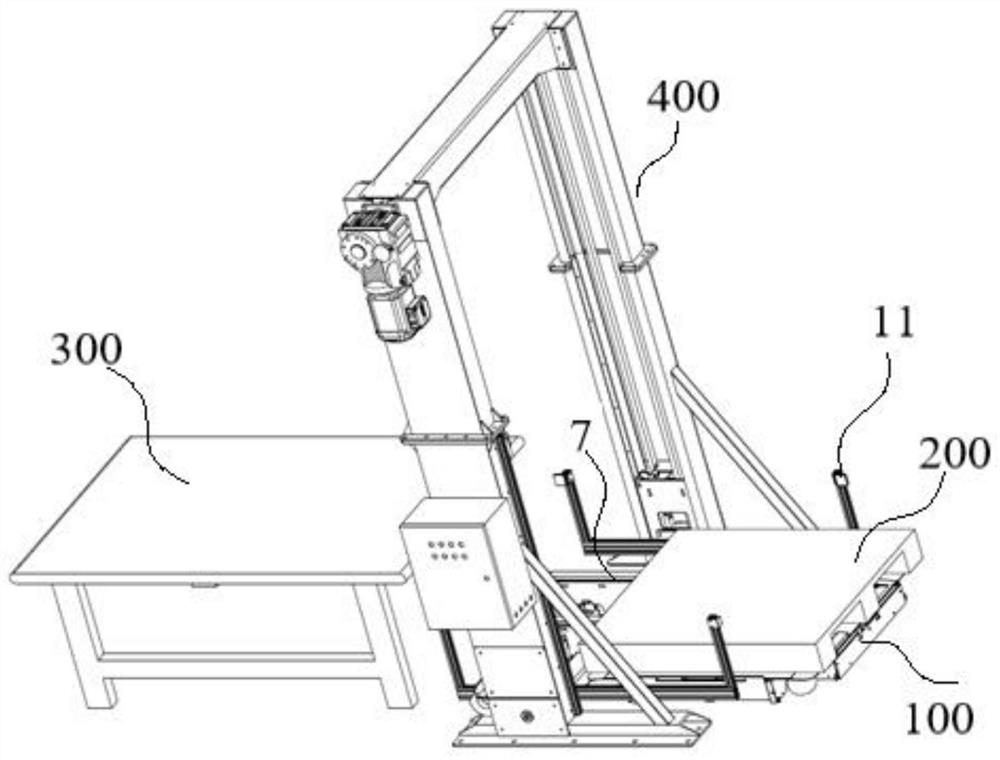

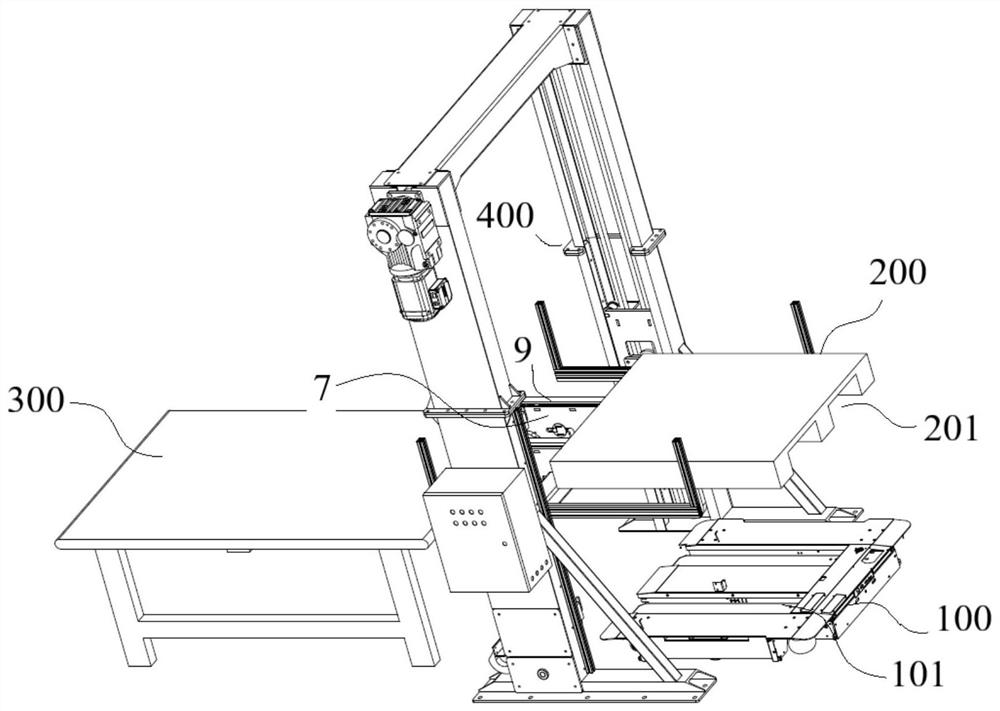

[0024] The embodiment of the present invention provides a pallet docking conveying system based on AGVs of different heights and an assembly line, which is equipped with a hoist capable of moving in two directions, which can realize lifting in the height direction and conveying in the horizontal direction, thereby conveniently transporting the pallets and The objects on it (for simplicity, the following pallets are also referred to as pallets and objects) are lifted from a lower height to a higher height, and then the pallet is moved from one end of the lifting arm to the other end to realize pallet handling on the ground The purpose of the assembly line to a certain height. Conversely, the pallet docking conveyor system based on AGVs of different heights and assembly lines can also transfer pallets from a higher assembly line to an AGV of a lower height. In this way, the present invention can better meet the requirements of automation and unmanned connection between ground ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com