Automatic unfastening device for kelp harvesting

An automatic unlocking and kelp technology, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of high labor intensity and hard work, and achieve the effect of cost saving, simple process and convenient cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

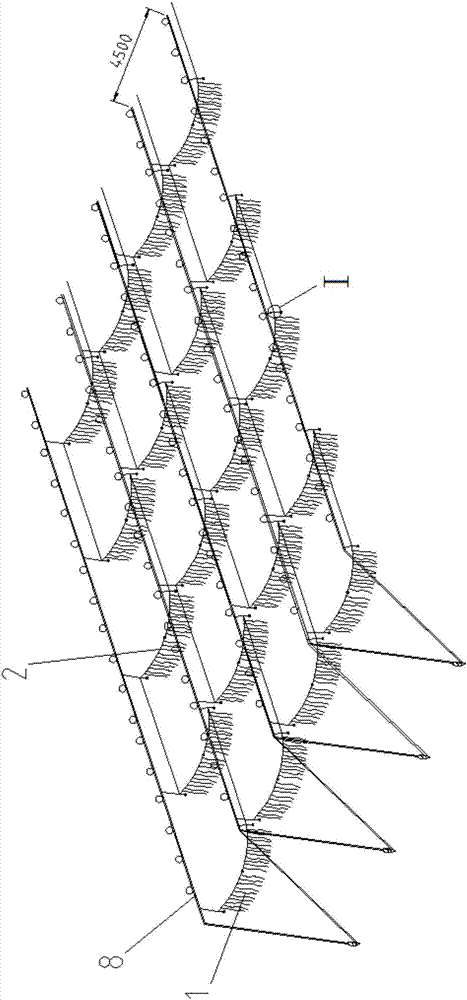

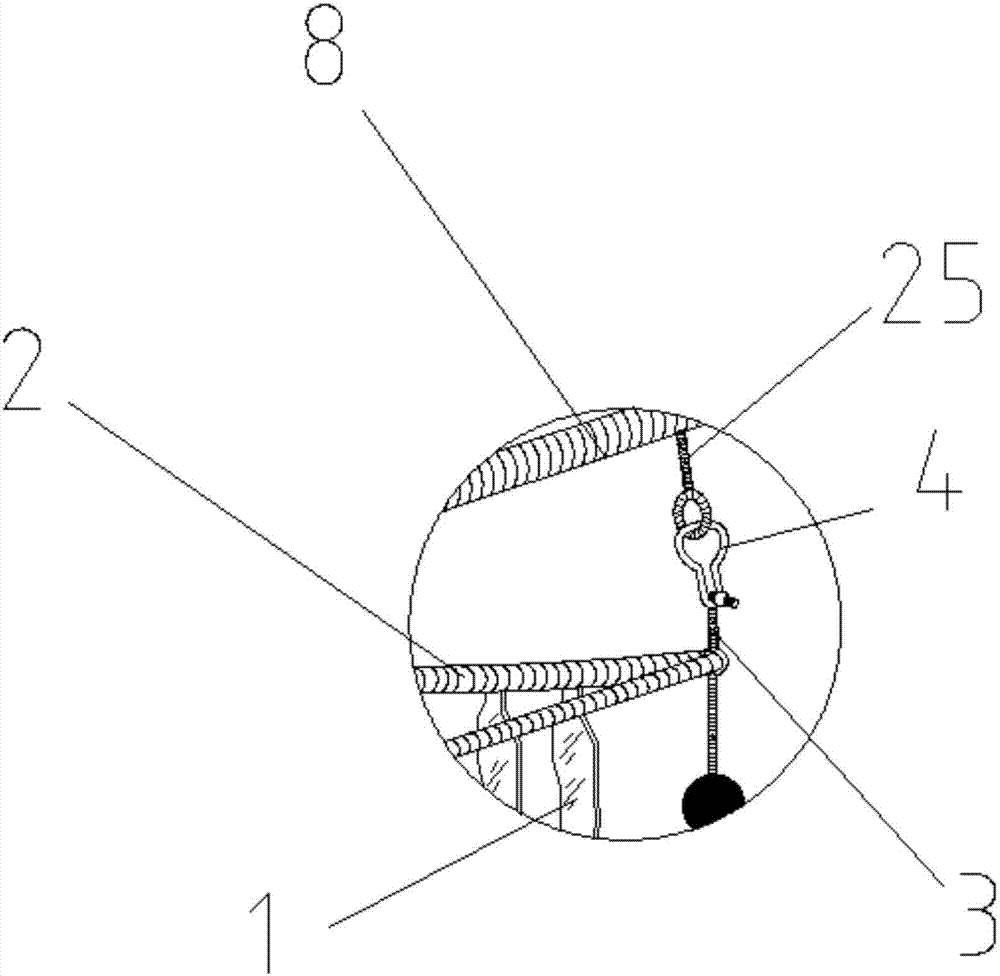

[0028] see Figure 1-3 , an automatic unlocking device for growing kelp harvesting, comprising kelp 1, kelp growing rope 2, lifting rope 3, rope buckle 4, platform 5, guide rail 6, bottom plate 7, floating rope 8, fixing bolt 9, Rope groove 10, guide roller 11, micro switch 23, lifting rope 25.

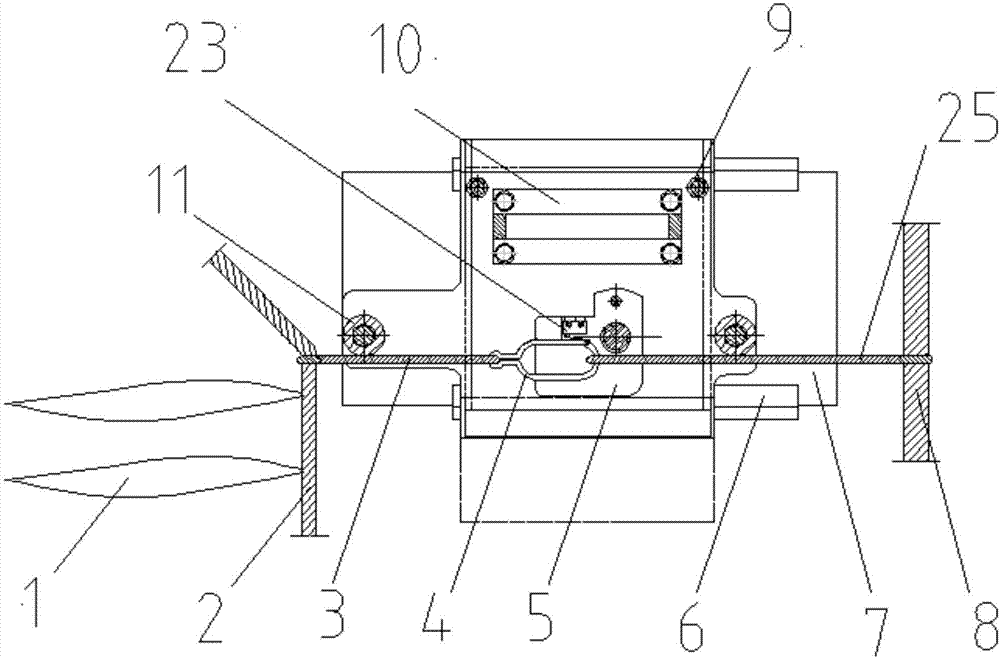

[0029] Figure 4 , Figure 5 and Figure 7 , to develop an automatic unlocking device for kelp harvesting, including a driver 12, a screw rod 13, a screw nut 14, a pressing block 15, a guide plate 16, a rotary encoder 17, a gear 18, a bracket 19, a rack 20, and a torsion spring 21 , Guide pin 22, micro switch 23, knot 24.

[0030] The automatic unlocking device for growing kelp harvesting is installed on both sides of the front of the harvesting ship such as Figure 9 Shown, when cultivating kelp and harvesting automatic unbuckle operation, be ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com