Semi-automatic slotting device for washboard

A semi-automatic, washboard technology, applied in the direction of slotting machine, mortising machine, manufacturing tools, etc., can solve the problems of easy injury and trouble, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

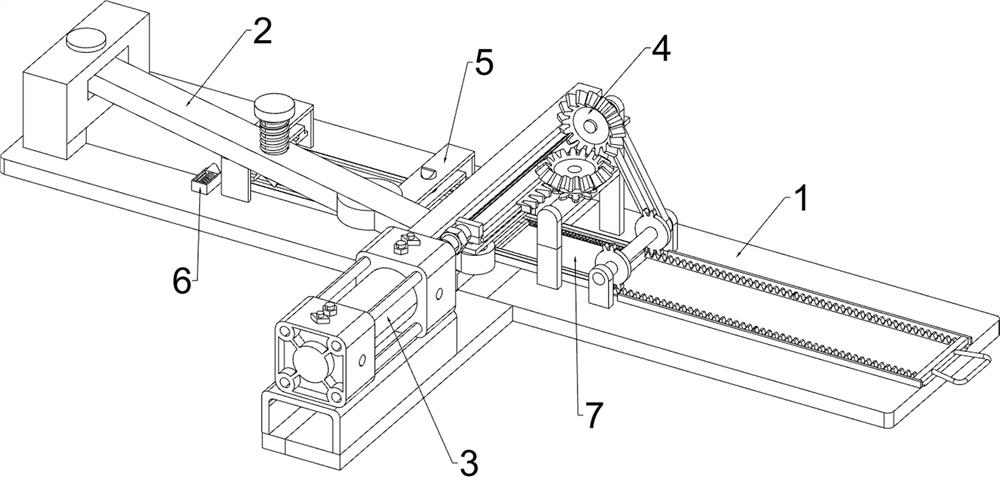

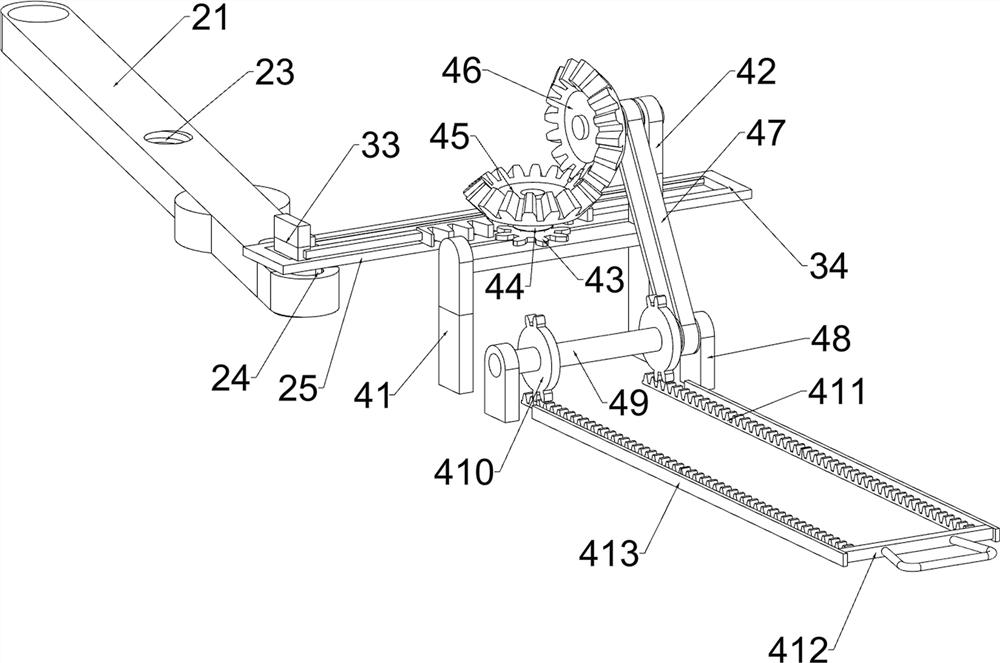

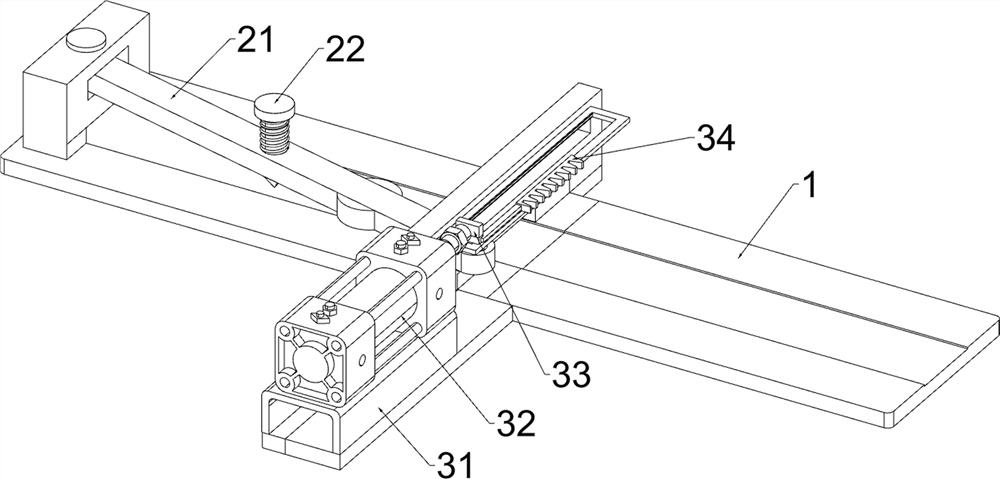

[0022] A semi-automatic slotting device for a washboard, such as Figure 1-3 As shown, it includes a base frame 1, a slotting mechanism 2, a power mechanism 3 and a moving mechanism 4. A slotting mechanism 2 for slotting by rotating is installed on the left side of the top of the base frame 1, and a A power mechanism 3 that provides power to work through a telescopic method, and a moving mechanism 4 that moves through a rotating method is installed on the right side of the top of the base frame 1 .

[0023] When the device needs to be used to make a washboard, the washboard is first placed on the top of the base frame 1, and then the power mechanism 3 is controlled to start working, and the power mechanism 3 drives the slotting mechanism 2 to perform slotting. During the process, the moving mechanism 4 drives the slotted plank to move intermittently to the left until the plank is slotted, and the power mechanism 3 is controlled to stop working.

[0024] The slotting mechanism...

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 , 4 As shown in and 5, a fixing mechanism 5 is also included, and the left side of the top of the pedestal 1 is equipped with a fixing mechanism 5 that is compressed by lifting. The fixing mechanism 5 includes a mounting plate 51, a first wedge block 52, a first spring 53 And pressing plate 54, base frame 1 top left side is fixedly connected with two mounting plates 51 by bolt, and the middle part of mounting plate 51 is provided with the first wedge-shaped block 52 slidingly, and the first wedge-shaped block 52 cooperates with slotted plate 21, the first A pressing plate 54 is welded to the bottom of the wedge block 52 , and a first spring 53 is connected between the top of the pressing plate 54 and the bottom of the mounting plate 51 .

[0032]When the grooved plate 21 rotates to contact with the first wedge-shaped block 52, it drives the first wedge-shaped block 52 to move downward, and then drives the pressing plate 54 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com