A processing method for integrally black surface of a 3D watch cover

A processing method and 3D technology, applied in the direction of printing, printing process, ink, etc. for the production of special varieties of printed matter, can solve the problems of inconsistent color difference of surface ink, ink layer processing, etc., and achieve the effect of good color consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

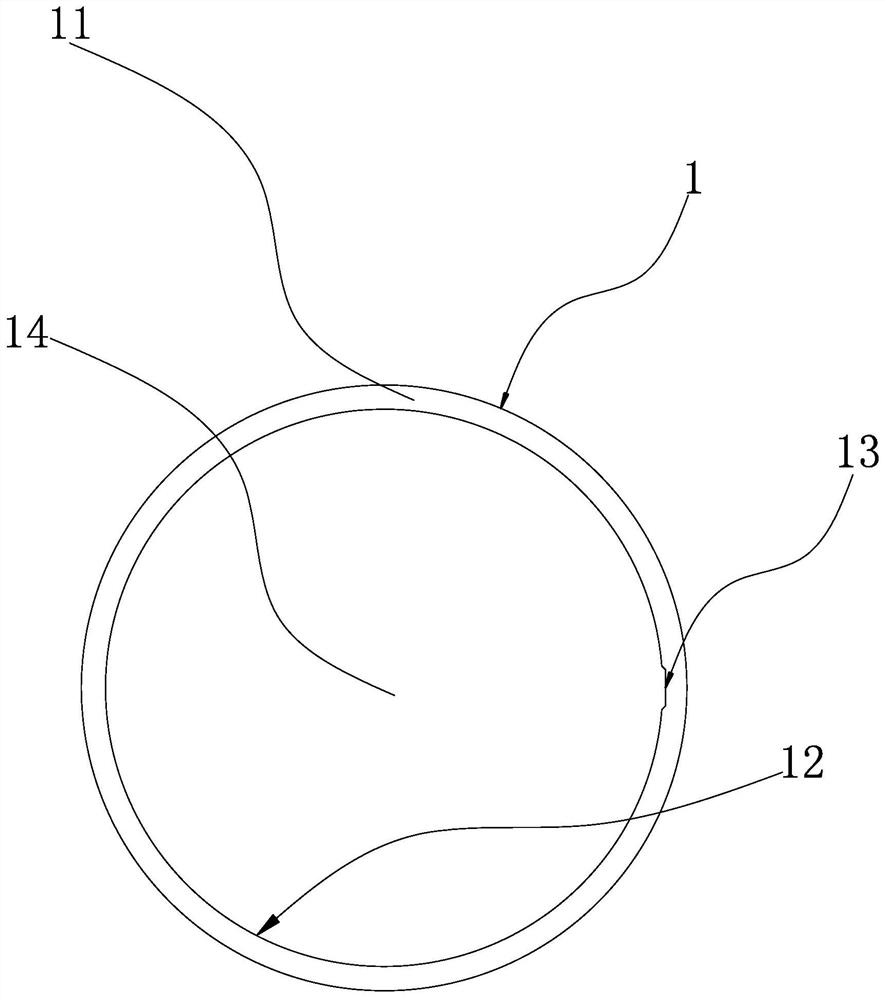

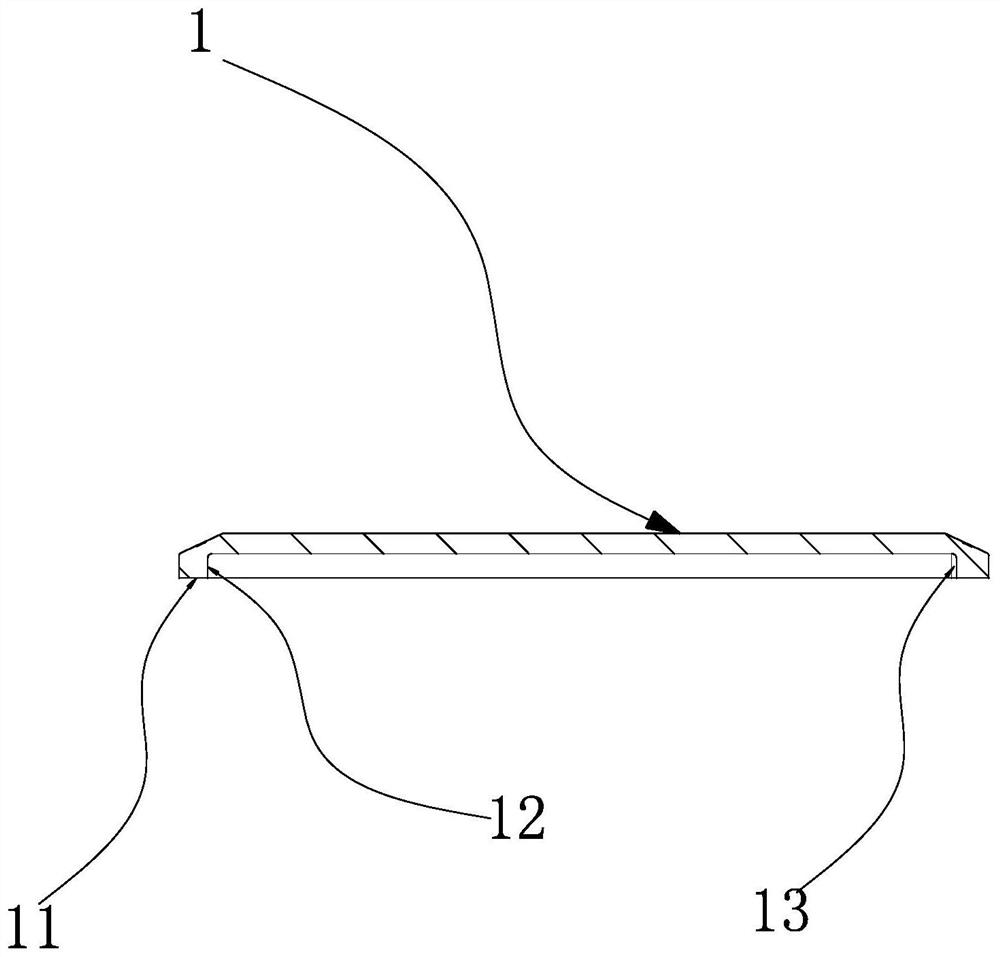

[0024] combine figure 1 and figure 2 , the back of this 3D watch cover 1 includes a flat area of the edge mounting surface 11 and an inwardly concave 3D groove, and the 3D groove includes a window area 14 located in the middle area and a 3D side wall 12 with a notch 13, figure 1 The dotted line in the middle is equivalent to the window area 14, and the area outside the dotted line to the installation surface 11 is equivalent to the 3D side wall 12, and the corresponding 3D watch cover 1 is cleaned and dried or dried naturally;

[0025] Then, the window area 14 on the back of the cleaned 3D cover 1 is covered and protected by a film, and then the screen printing process is performed first, and the plane area of the edge mounting surface 11 is screen-printed so that the ink is printed on the back of the 3D cover 1. An ink layer is formed on the surface of the plane area of the edge mounting surface 11; and then spraying is used to spray the above-mentioned ink on the 3D ...

Embodiment 2

[0030] combine figure 1 and figure 2 , the back of this 3D watch cover 1 includes a flat area of the edge mounting surface 11 and an inwardly concave 3D groove, and the 3D groove includes a window area 14 located in the middle area and a 3D side wall 12 with a notch 13, figure 1 The inside of the dotted line is equivalent to the window area 14, and the area outside the dotted line to the installation surface 11 is equivalent to the 3D side wall 12, and the corresponding 3D cover is cleaned and dried or dried naturally;

[0031] Then, the window area 14 on the back of the cleaned 3D cover 1 is covered and protected with a film. First, through screen printing, the plane area of the edge mounting surface 11 is screen printed so that the ink is printed on the edge of the back of the 3D cover. An ink layer is formed on the surface of the plane area of the mounting surface 11; and then spraying is used to spray the above-mentioned ink on the 3D sidewall 12 area on the back o...

Embodiment 3

[0036] combine figure 1 and figure 2 , the back of this 3D watch cover 1 includes a flat area of the edge mounting surface 11 and an inwardly concave 3D groove, and the 3D groove includes a window area 14 located in the middle area and a 3D side wall 12 with a notch 13, figure 1 The inside of the dotted line is equivalent to the window area 14, and the area outside the dotted line to the installation surface 11 is equivalent to the 3D side wall 12, and the corresponding 3D cover is cleaned and dried or dried naturally;

[0037] Then use a film to cover and protect the window area on the back of the 3D cover 1 after cleaning. First, through screen printing, the plane area of the edge mounting surface 11 is screen printed so that the ink is printed on the edge of the back of the 3D cover 1. An ink layer is formed on the surface of the plane area of the installation surface 11; and then spraying is used to spray the above-mentioned ink on the 3D side wall 12 on the back o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap