Automatic loading system used in shopping mall

A shopping mall, automatic technology, applied in the directions of transportation, packaging, storage devices, etc., can solve the problems of inability to realize automatic collection and management of computer information, inconvenience of sellers, and no continuous placement, so as to avoid large inventory or short-term shortages. The effect of saving the situation of goods, saving sales personnel, and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

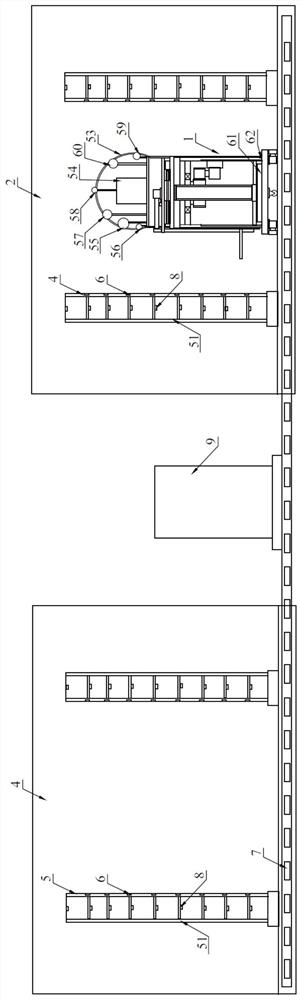

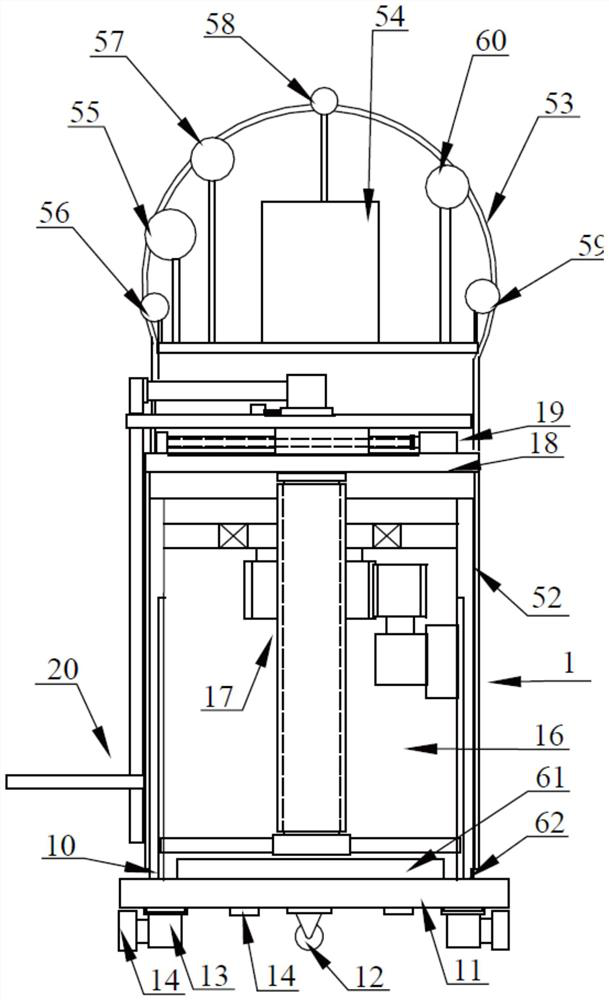

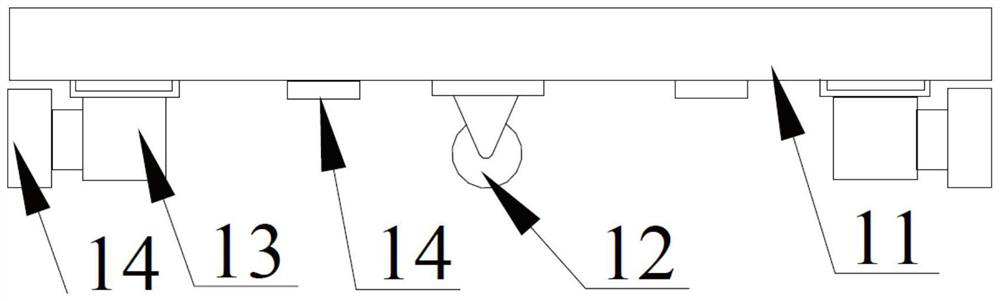

[0035] Such as figure 1 As shown, the present invention is an automatic loading system used in a shopping mall. The system includes a cargo handling robot 1. The cargo handling robot 1 takes out the goods from the storage rack 3 in the warehouse 2, and the cargo handling robot 1 takes the goods out. Delivered to the sales rack 5 of the sales place 4 in the mall; on the placement position of each kind of goods on the storage rack 3 and the sales rack 4, a corresponding code 6 (such as a two-dimensional code) is arranged, and on the storage rack 3 and the sales rack 4 The guidance sensors 7 for the running route of the cargo handling robot 1 are buried under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com