Patents

Literature

41results about How to "Avoid inventory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent fulfillment agents

ActiveUS20050256787A1Business reduced eliminatedDisadvantages and reduced eliminatedCommerceSpecial data processing applicationsInventory managementKnowledge management

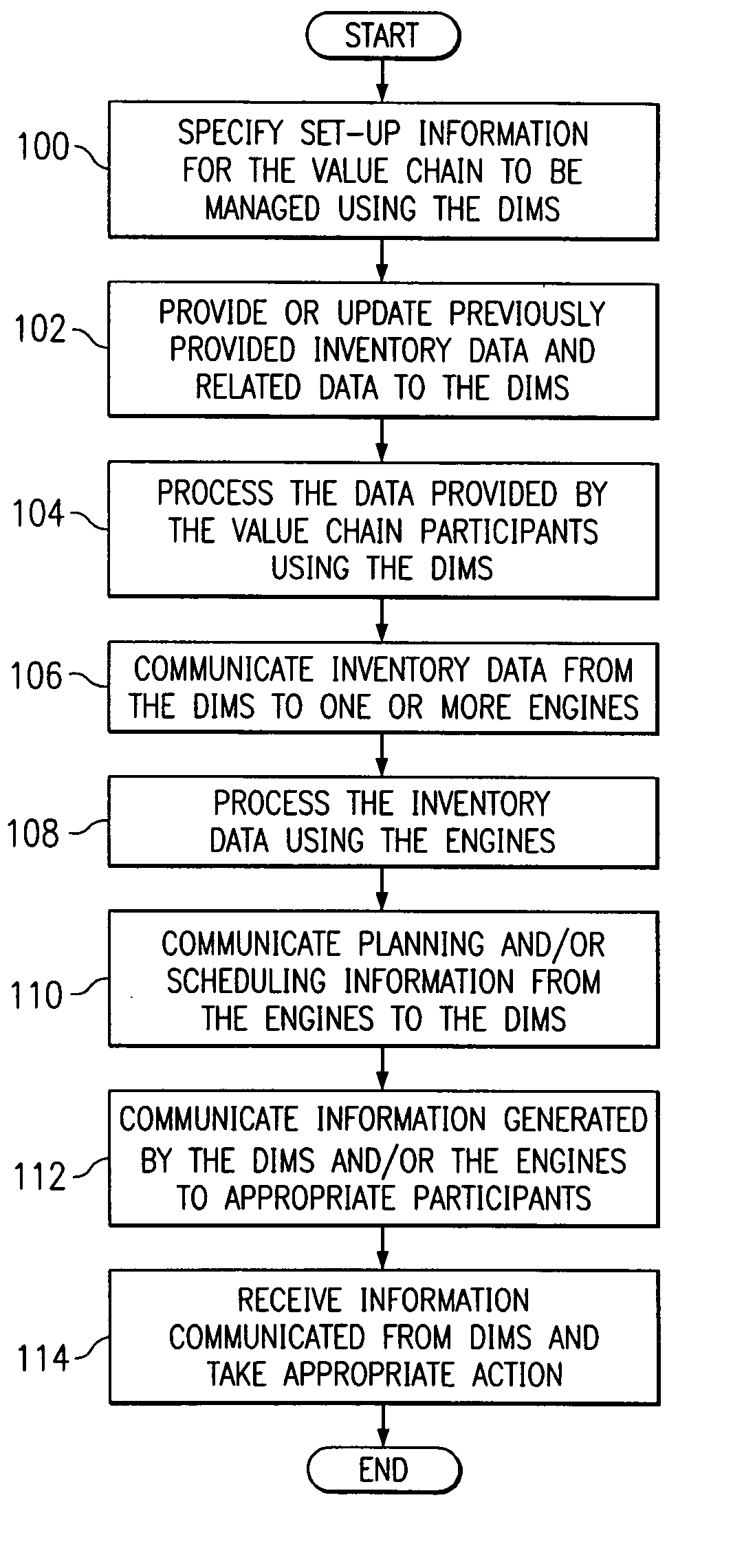

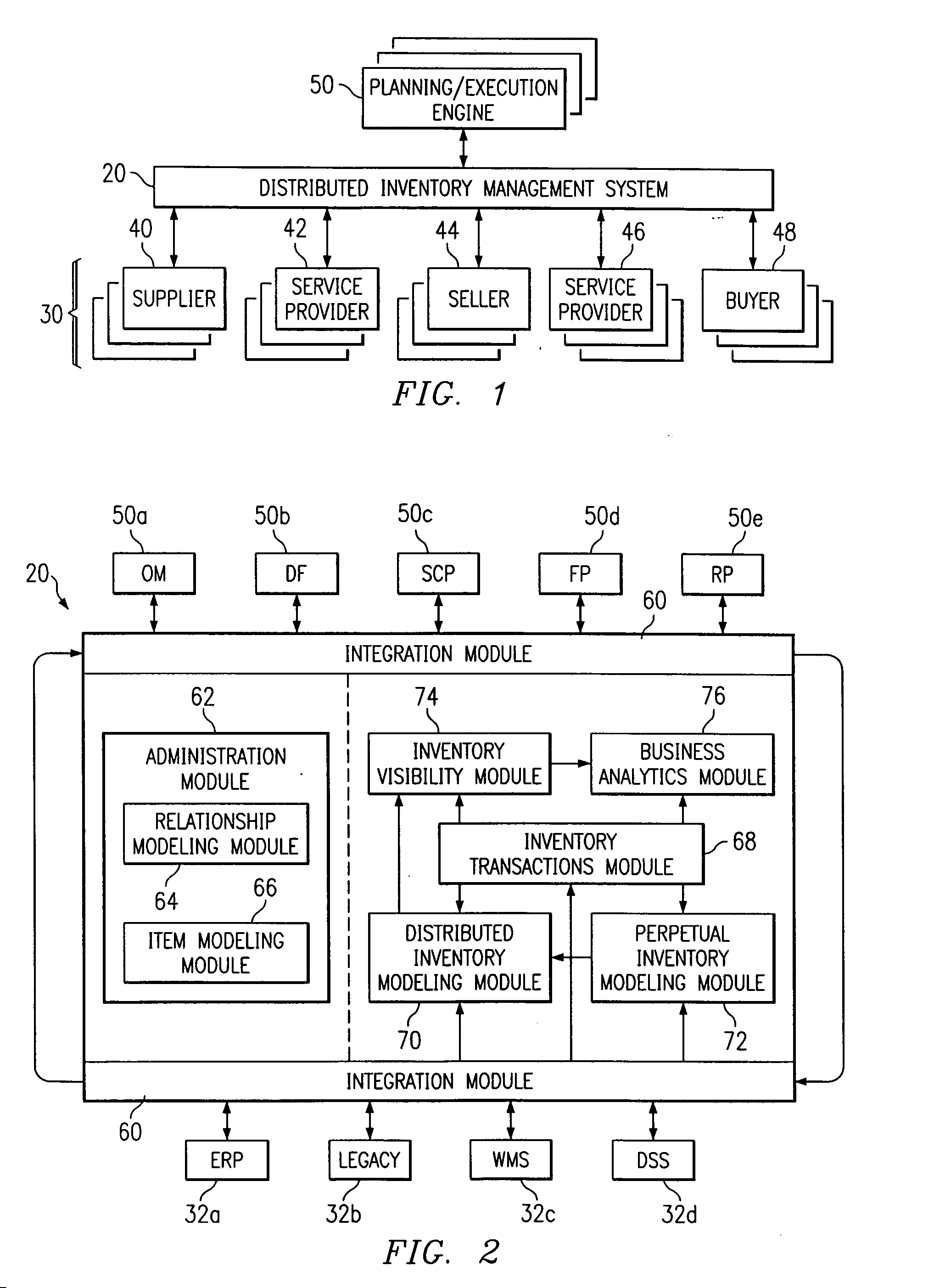

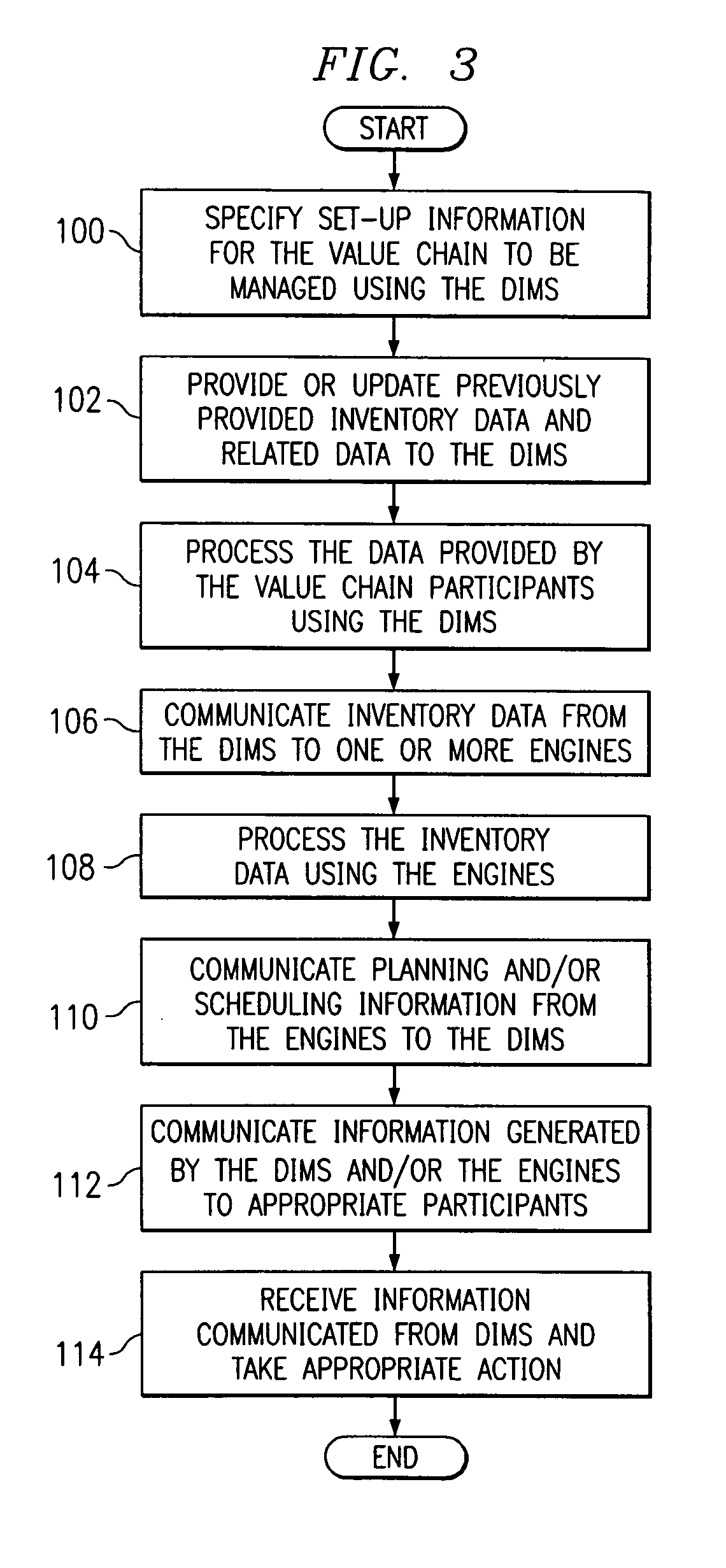

A method for distributed inventory management includes receiving information regarding a number of participants in a value chain and information regarding one or more items relevant in the value chain. The method also includes modeling relationships between two or more of the participants based on the received information and modeling the one or more items based on the received information. The method further includes receiving inventory data from the participants relating to the one or more items, evaluating the received inventory data according to one or more business rules associated with an agent, executing a business process associated with the agent based on the evaluation of the inventory data and the models of the relationships and the items, and communicating output of the business process to one or more of the participants.

Owner:BLUE YONDER GRP INC

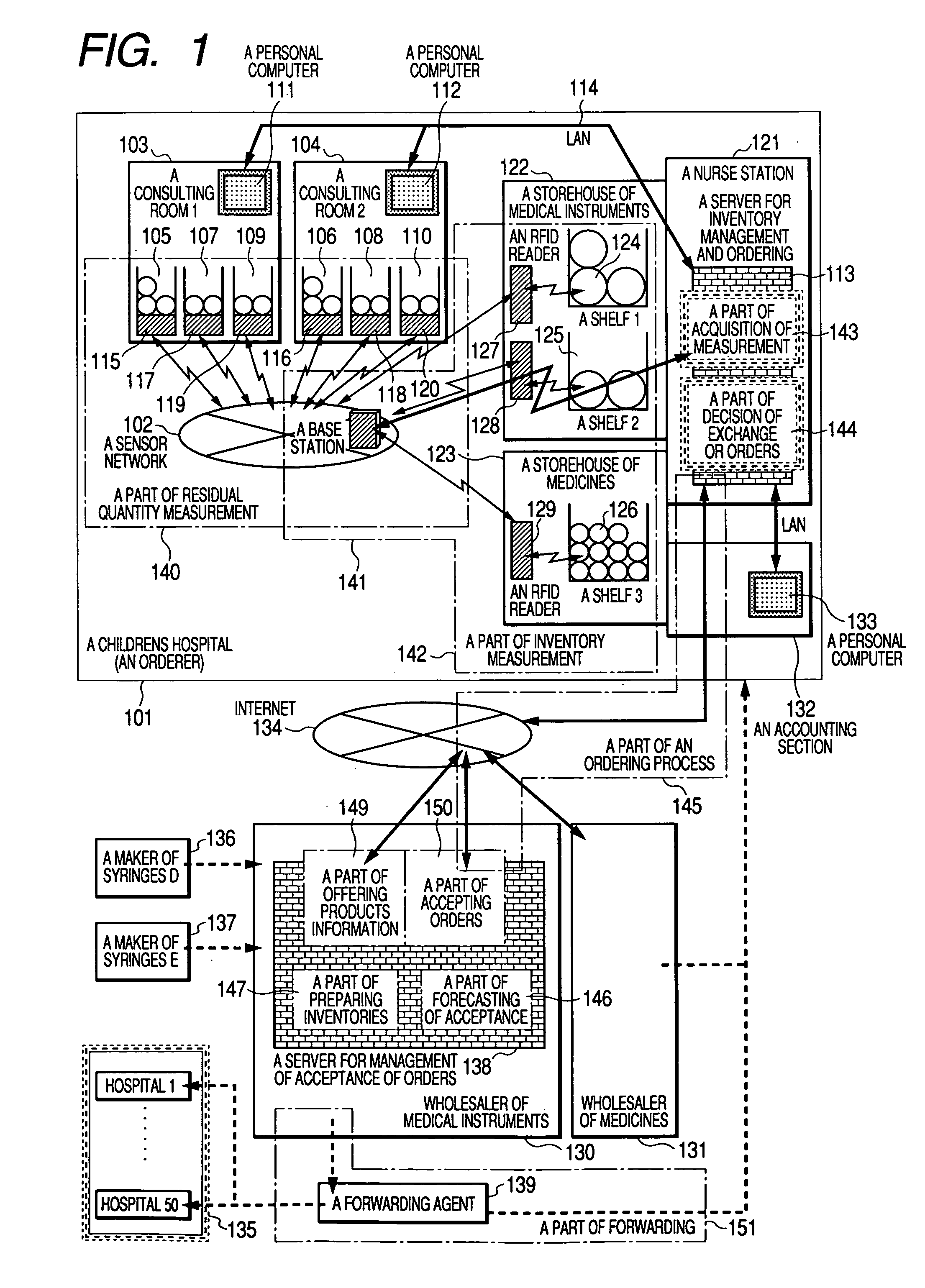

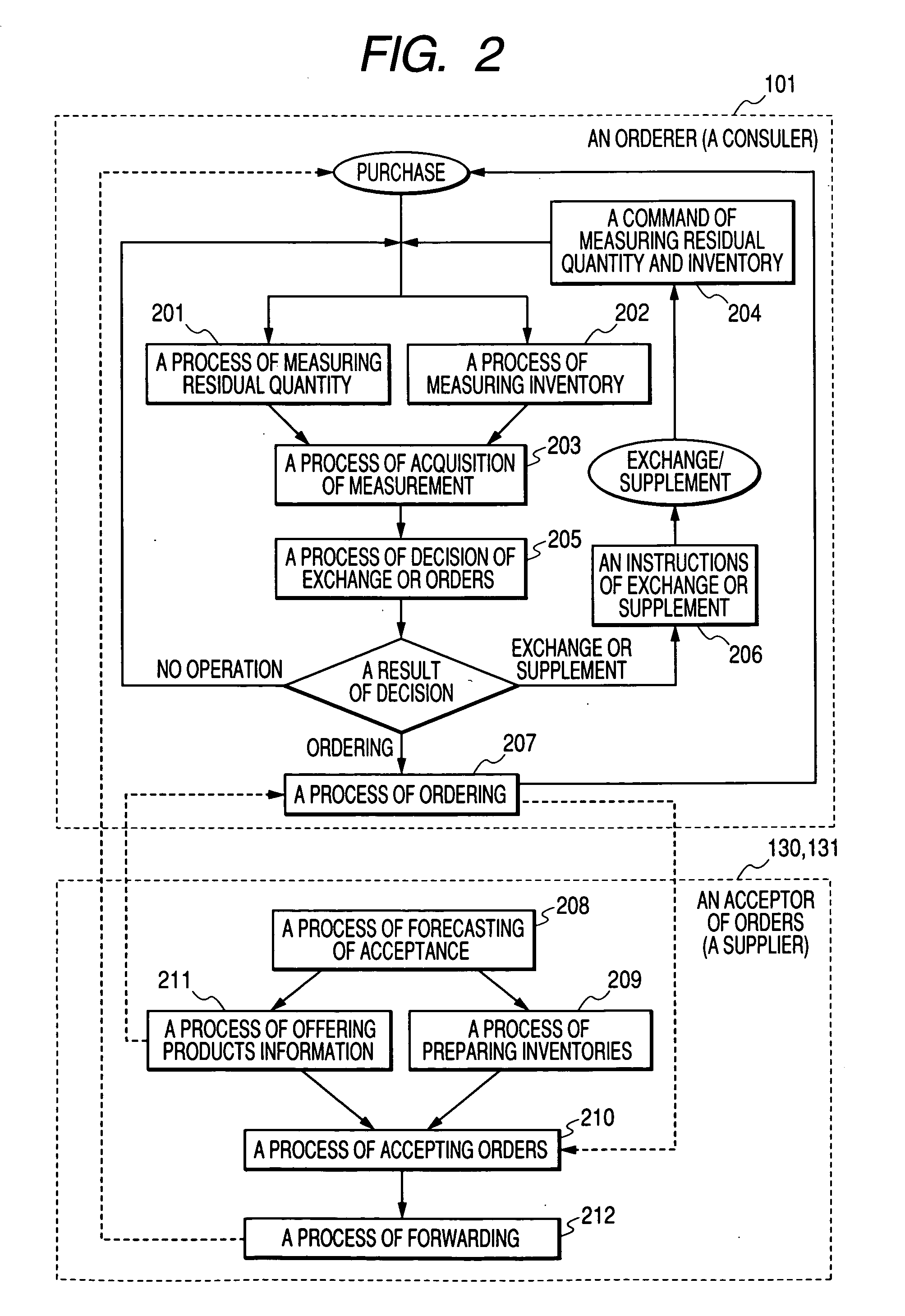

Inventory management and ordering system, and ordering management system using the previous system

InactiveUS20050075954A1Excess inventoryAvoid inventoryBuying/selling/leasing transactionsStacking articlesManagement systemManufacturing engineering

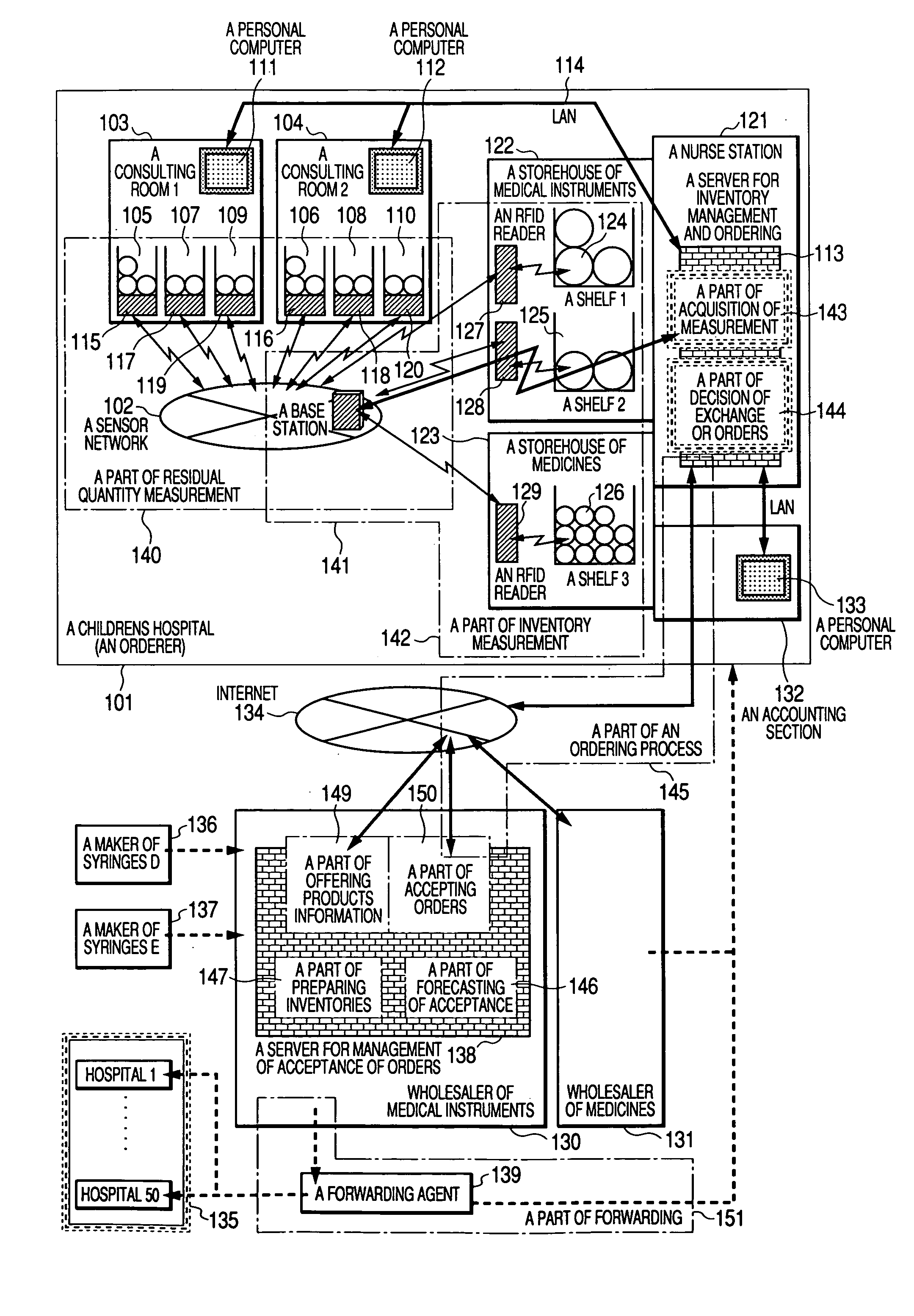

A system which solves the problem of the prior arts that residual quantity cannot be reflected on the inventory and proper inventory management is difficult particularly when the places to use and store the products are different and thoroughly enables processes to the ordering management and support of purchase and moreover the order acceptance management in the order accepting side from residual quantity and inventory management for a plurality of products is provided. In the inventory management and ordering system and the ordering management system, residual quantity of products which changes with use and inventory of products to always keep the products in the available condition are placed under the management, the residual quantity data of products obtained through management of residual quantity is reflected on the inventory management and the ordering is executed on the basis of the inventory management to which the management of residual quantity is reflected.

Owner:HITACHI LTD

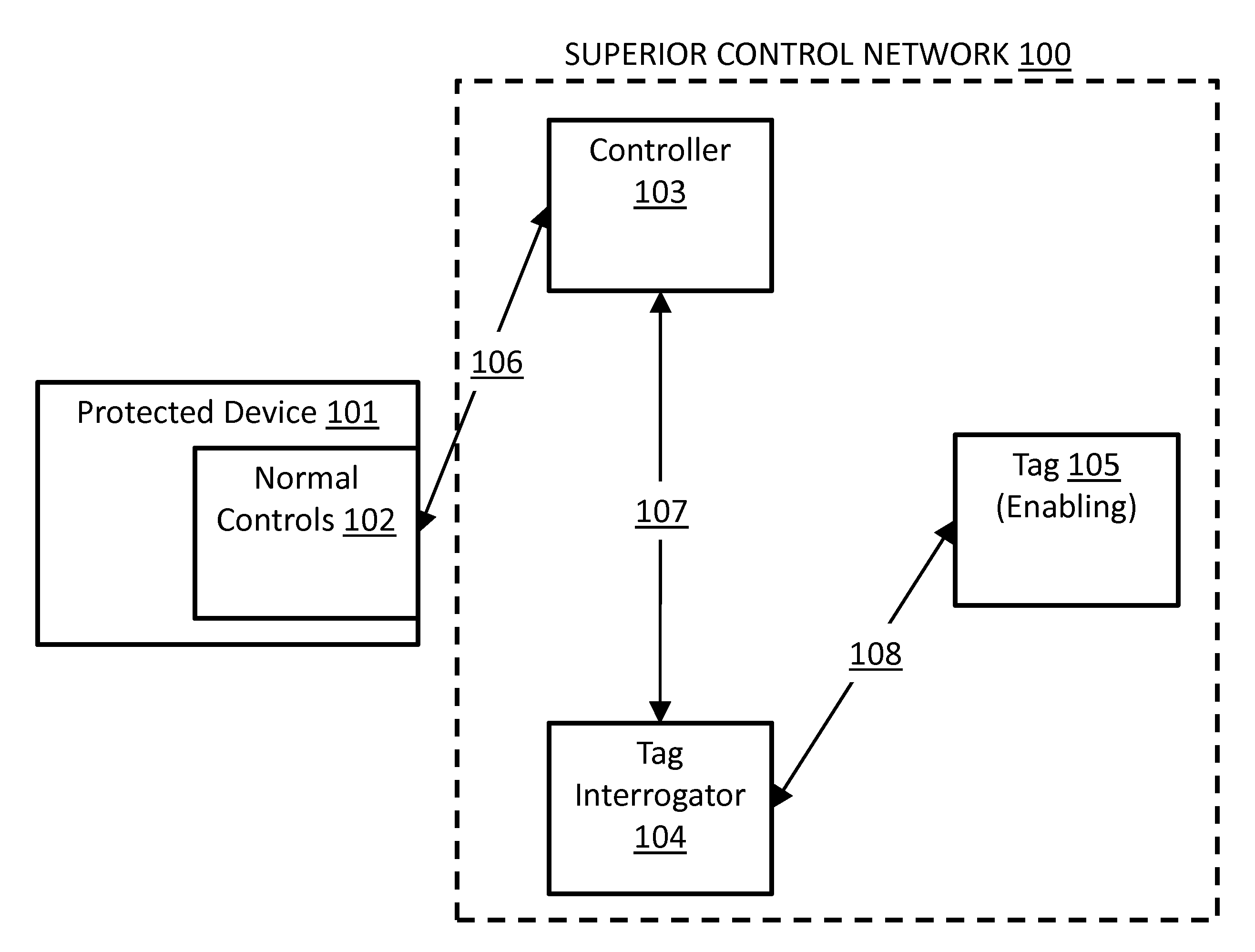

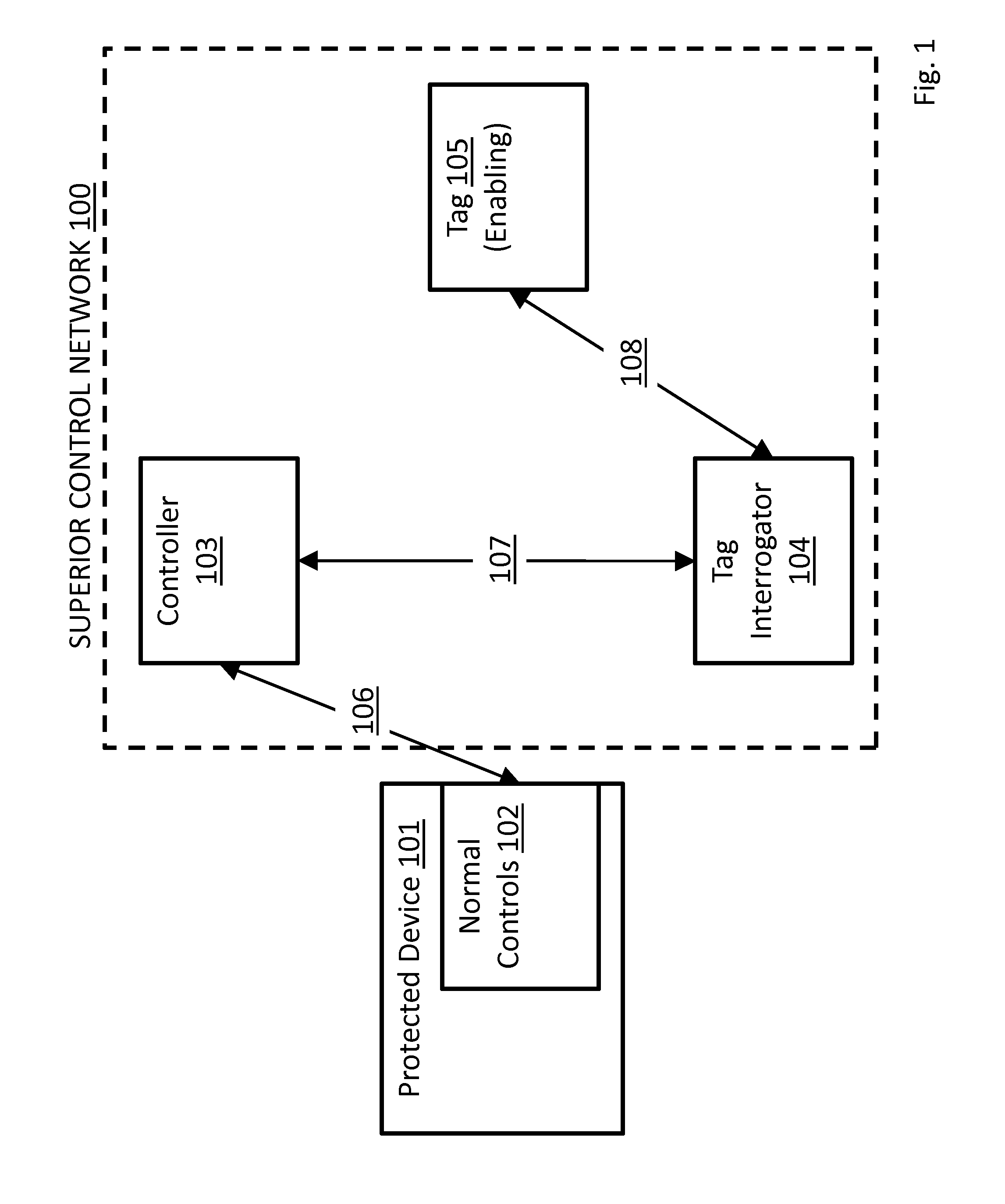

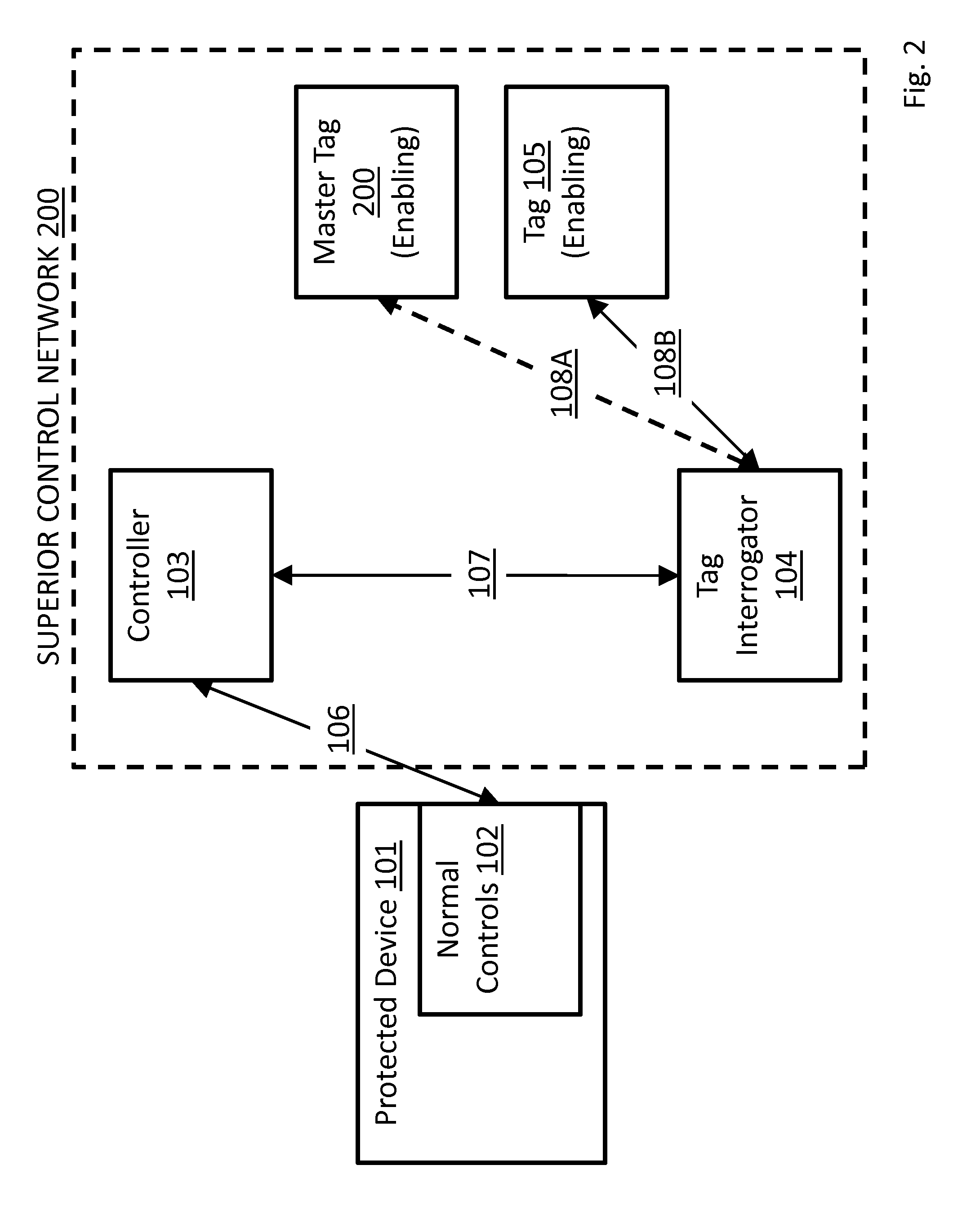

System, method, and apparatus for RFID, emulated RFID and RFID-like based enablement and privilege allocation

InactiveUS20110241838A1Increase costHigh cost of misuseSensing detailsDigital data authenticationComputer hardwareComputer science

A method of emulating a physical RFID tag includes storing in a machine readable memory an RFID tag encoding, communicating the RFID tag encoding to a system, and using the RFID tag encoding at the system to emulate the physical RFID tag and perform a function without emulating an RFID transponder signal.

Owner:WISCHMEYER CARL EDWARD

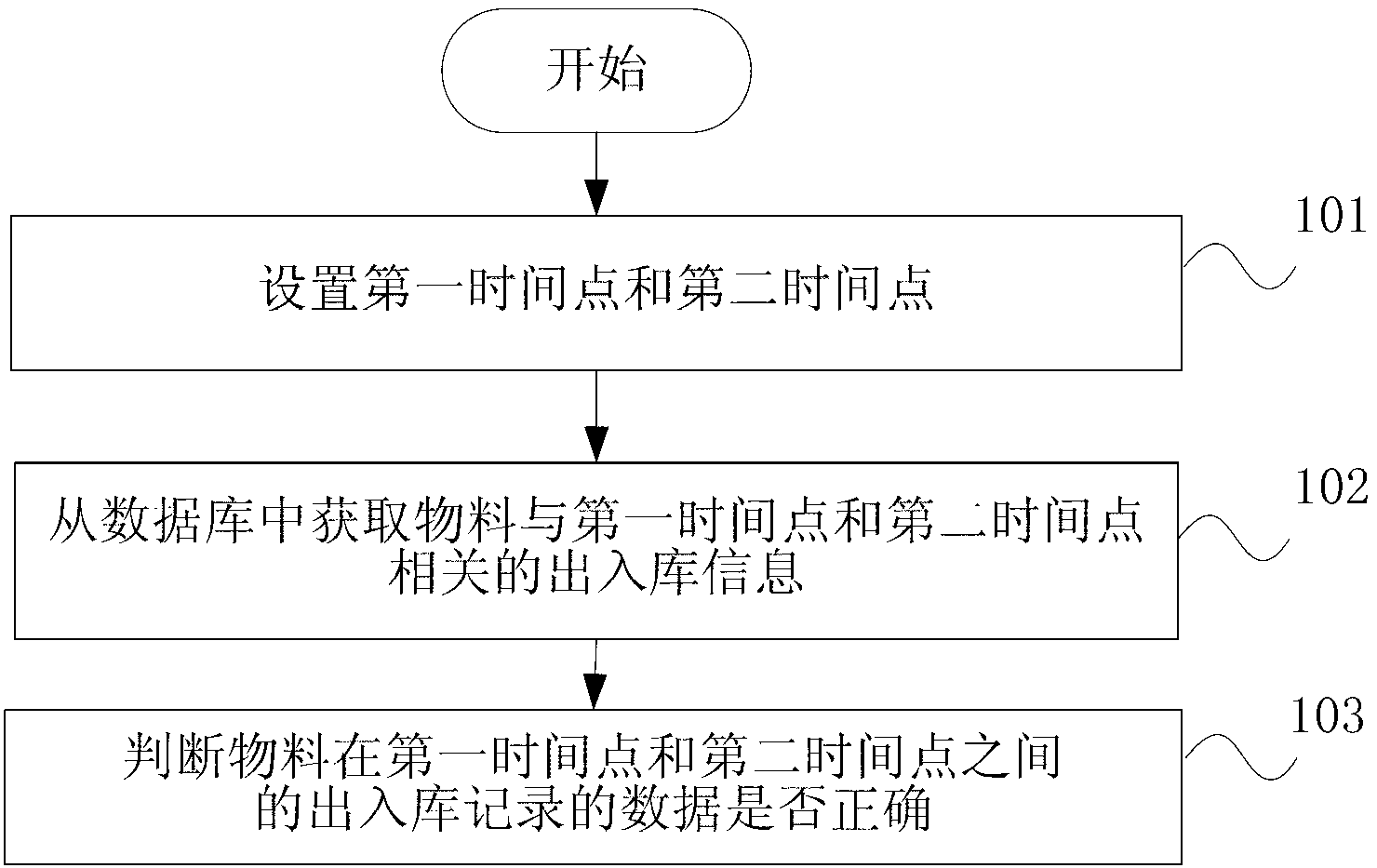

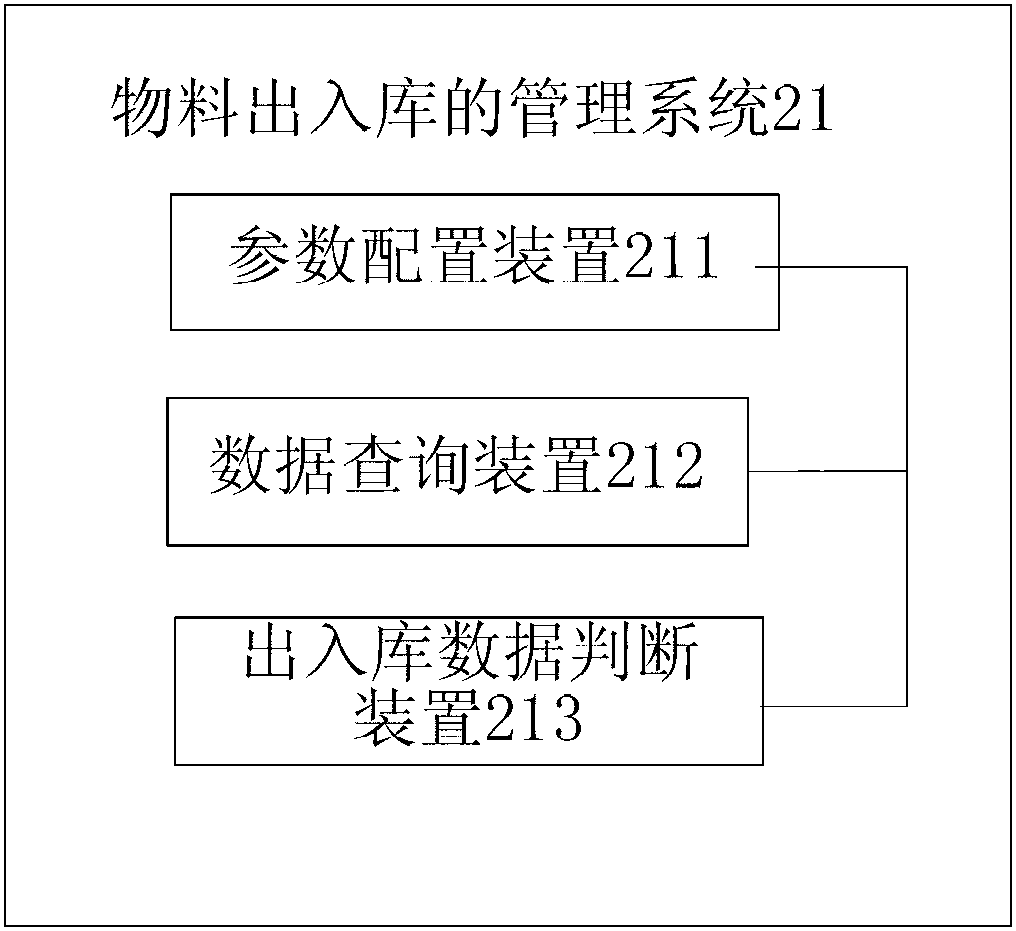

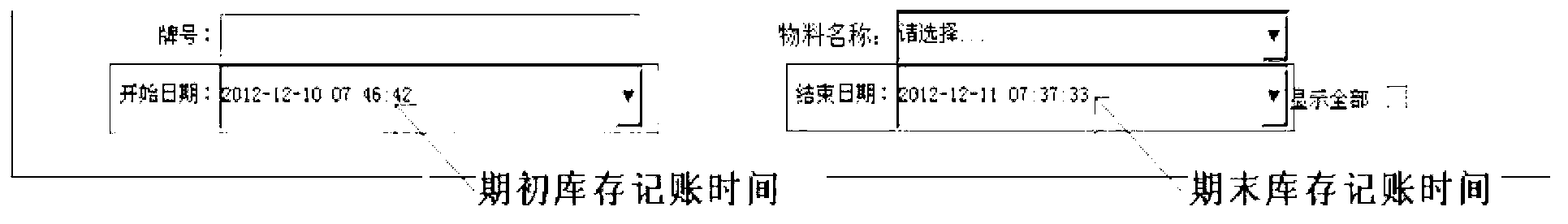

Warehouse management method and system

InactiveCN103295118APrecise positioningAvoid wide-ranging inventoryLogisticsData warehouseComputer science

The invention discloses a warehouse management method and system. The warehouse management method includes that first timing point and second timing point are set up, and data of warehouse records of materials between the first timing point and the second timing point are correct when a warehouse record difference is judged to be zero; the warehouse record difference = material warehoused in the first timing point + total number of the materials warehoused between the first timing point and the second timing point - total number of the material ex-warehoused between the first timing point and the second timing point + total number of the material warehoused from the second timing point to current timing point - total number of the material ex-warehoused from the second timing point to the current timing point - current warehouse of the materials. By the aid of the warehouse management method and system, warehouse information at any timing points can be recorded, all warehouse situations from any two optional timing points to the current timing point and the warehouse information of the two timing points can be inquired at the same time, errors leading to warehouse mistakes can be accurately allocated, so that a wide range of blind checking can be avoided, and checking efficiency can be improved.

Owner:LONGYAN CIGARETTE FACTORY

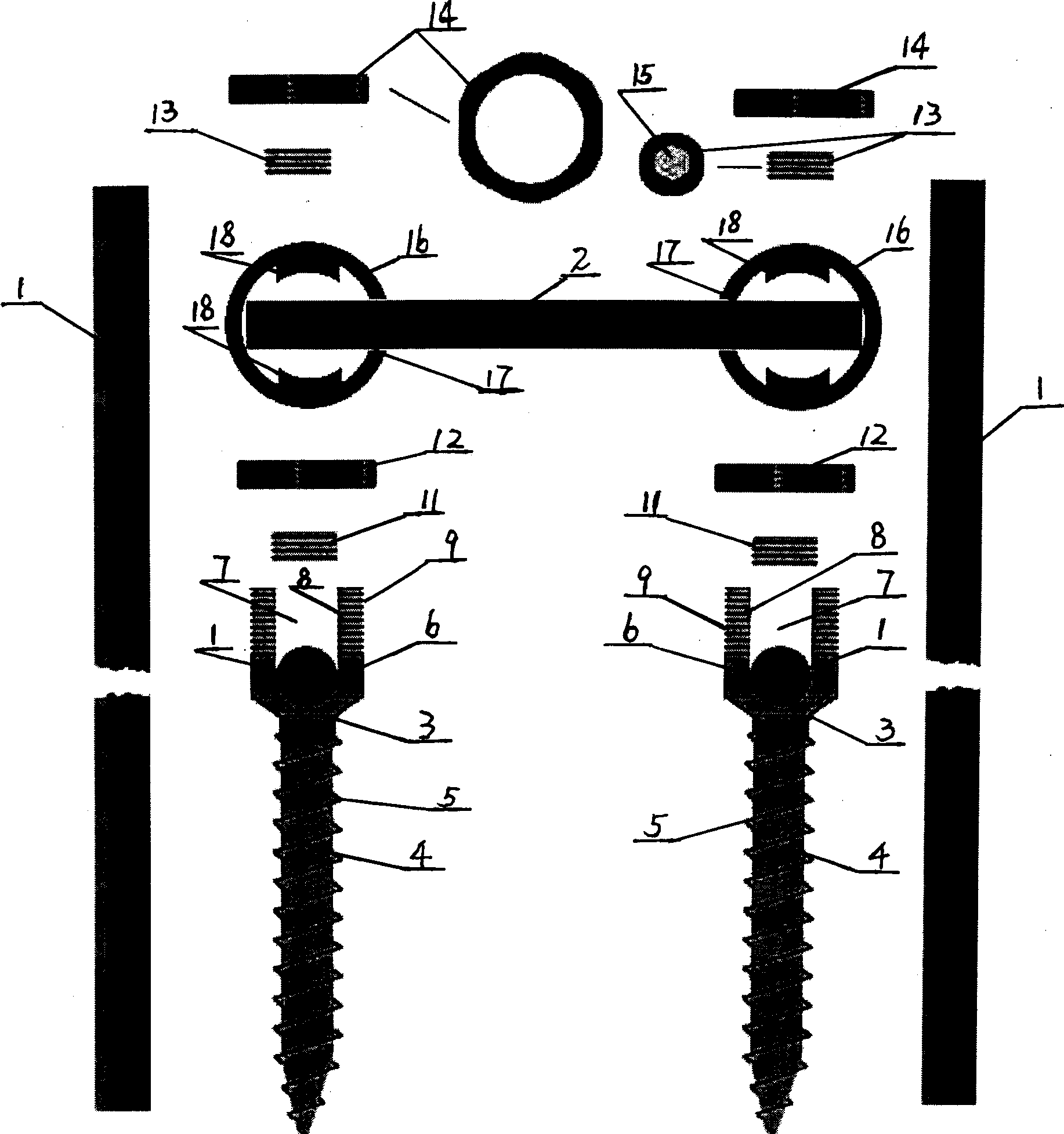

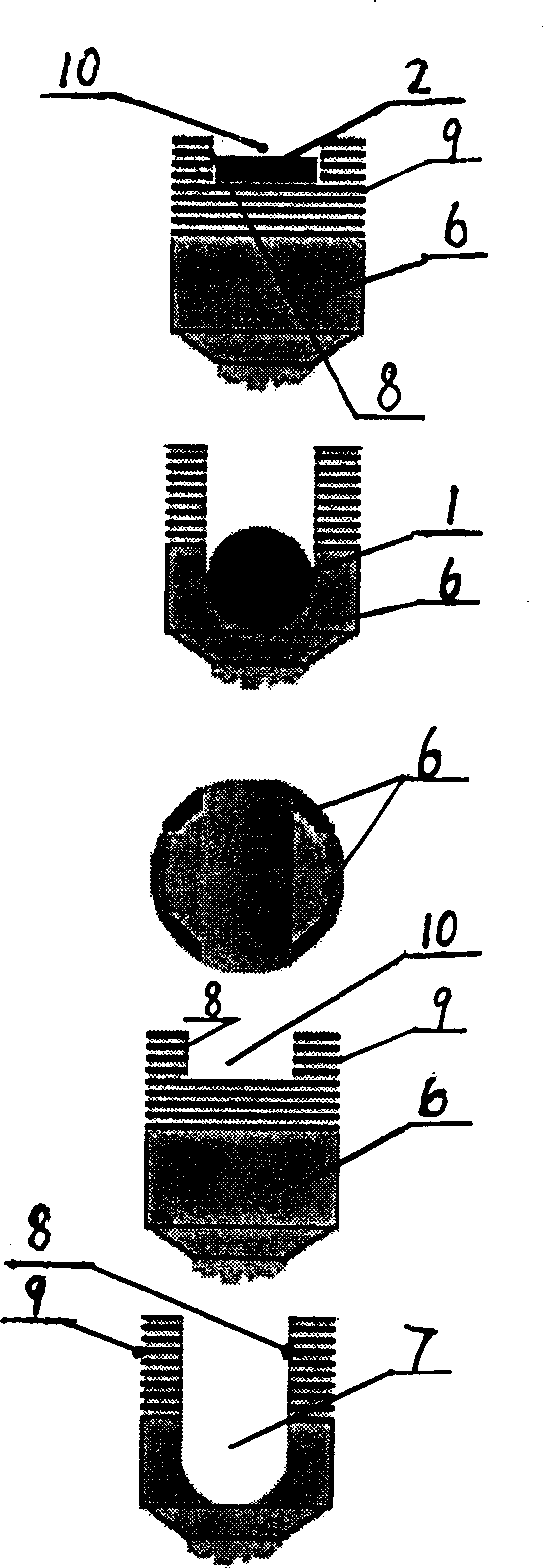

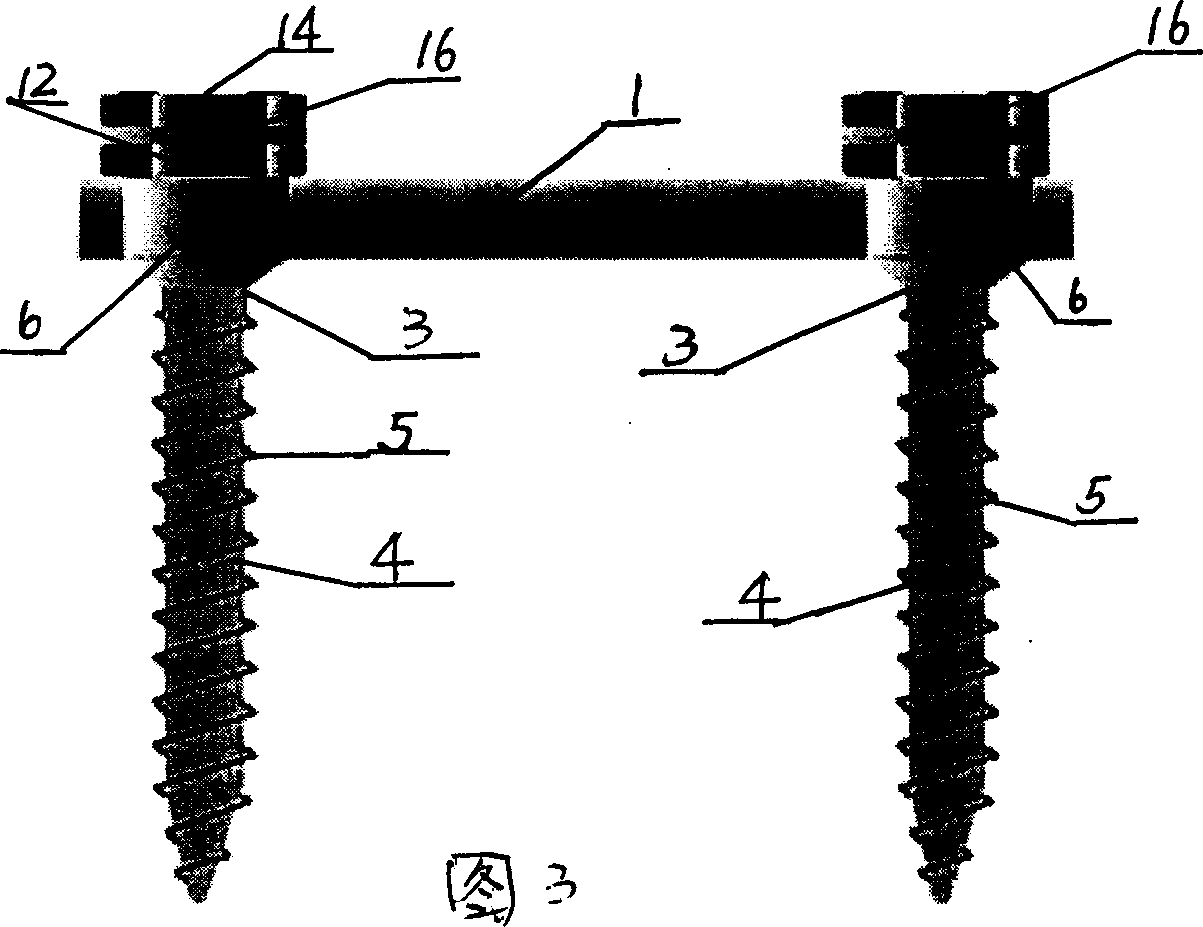

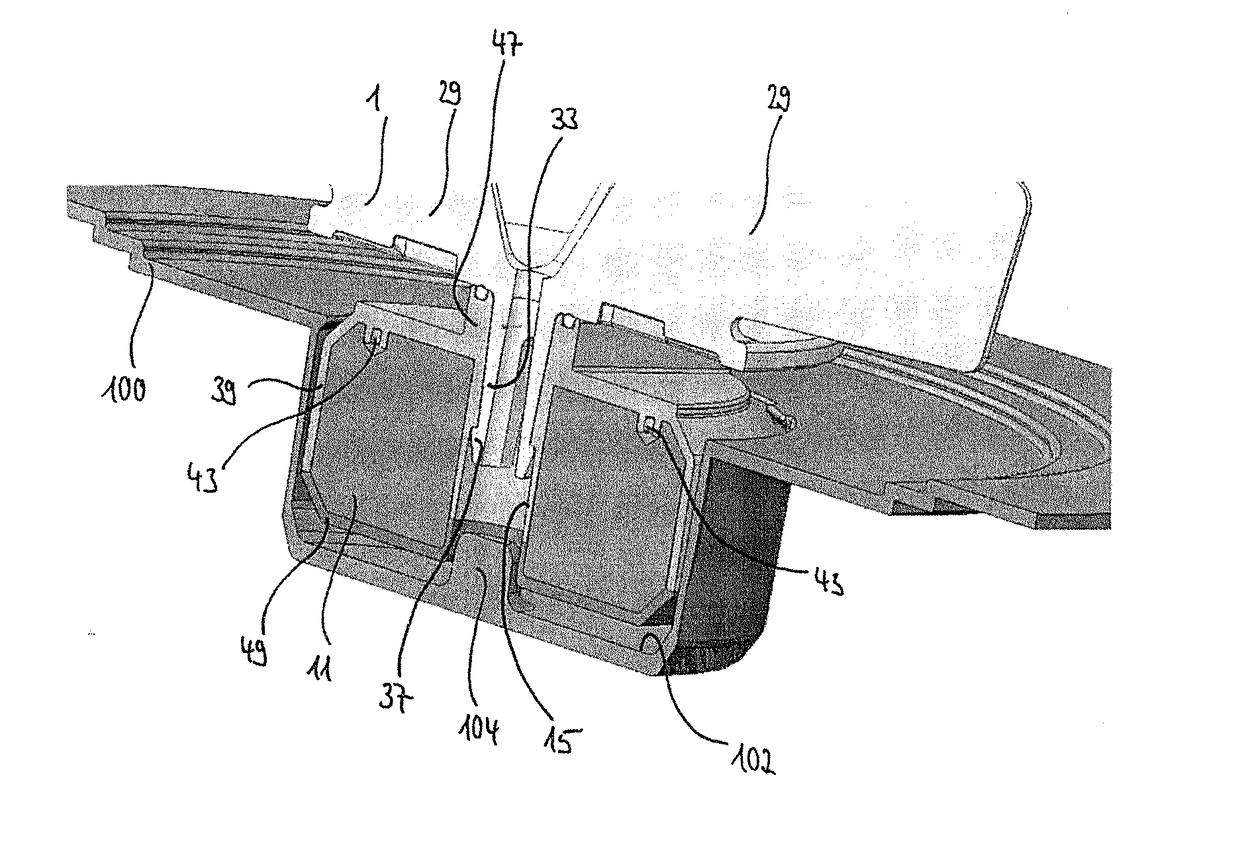

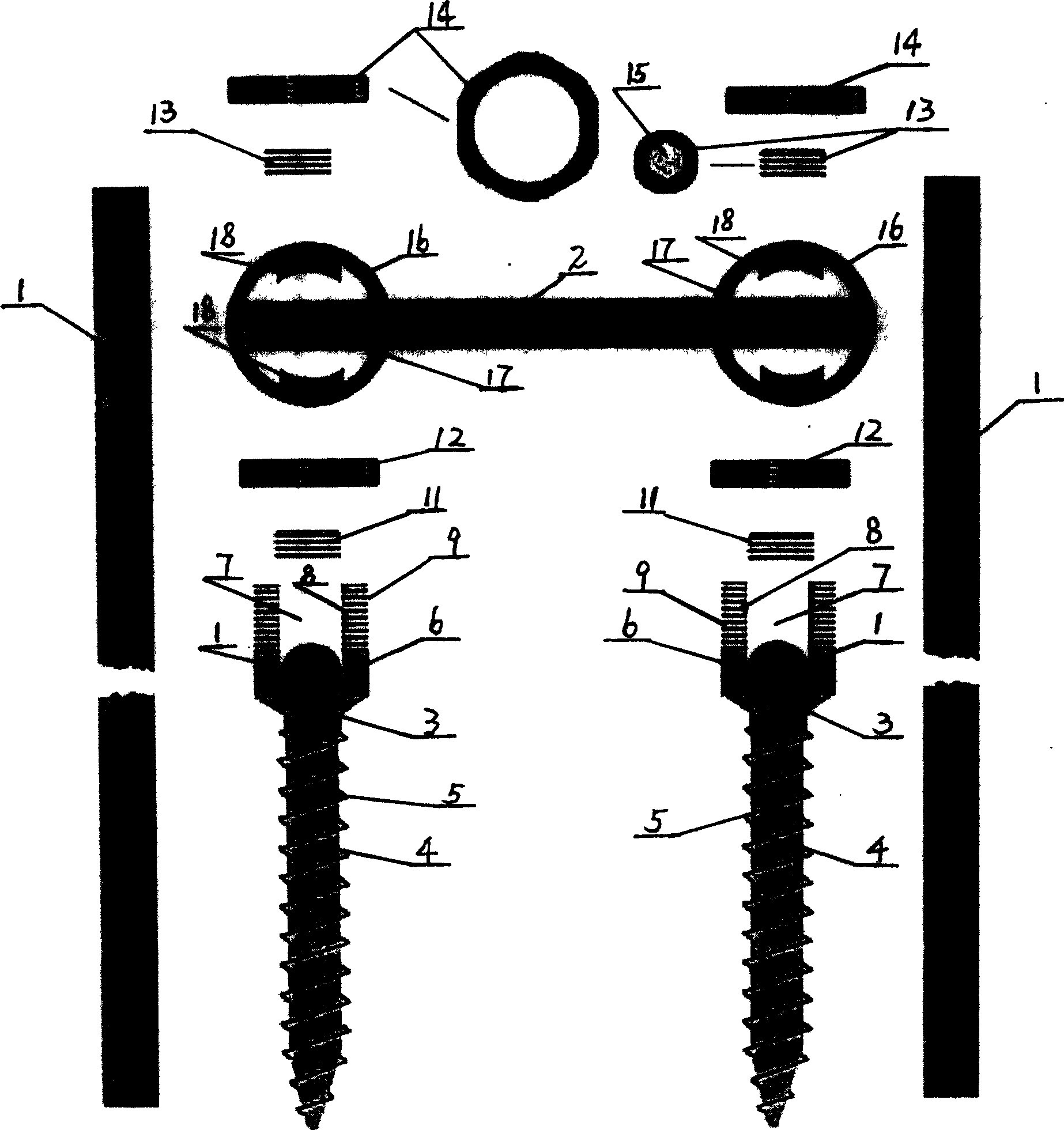

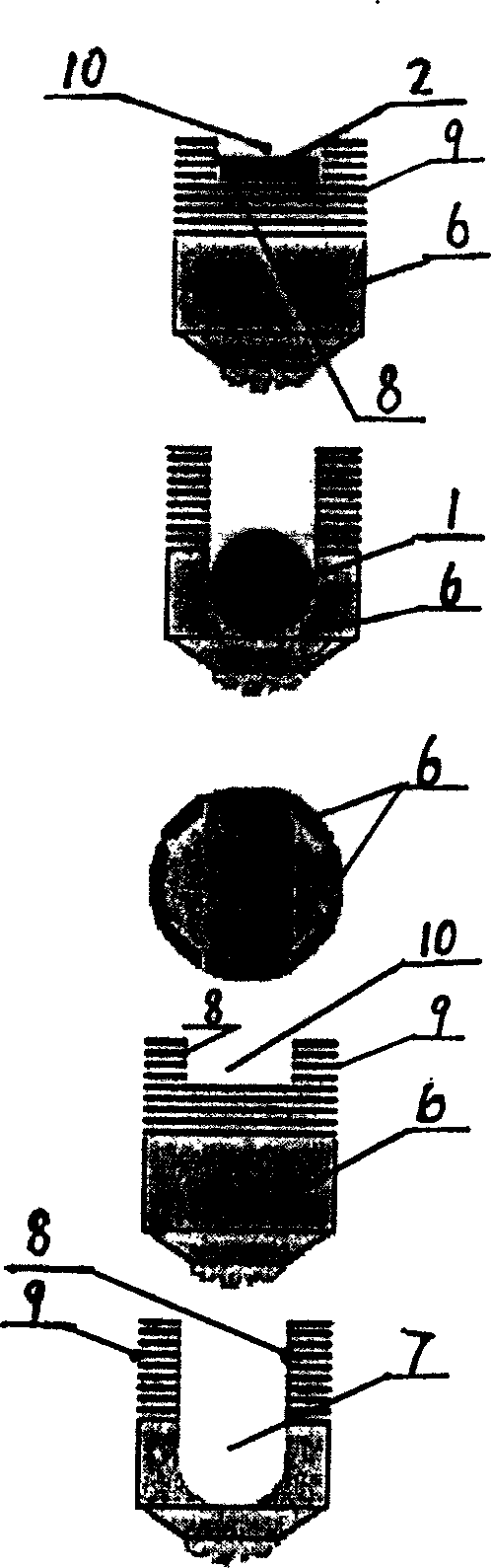

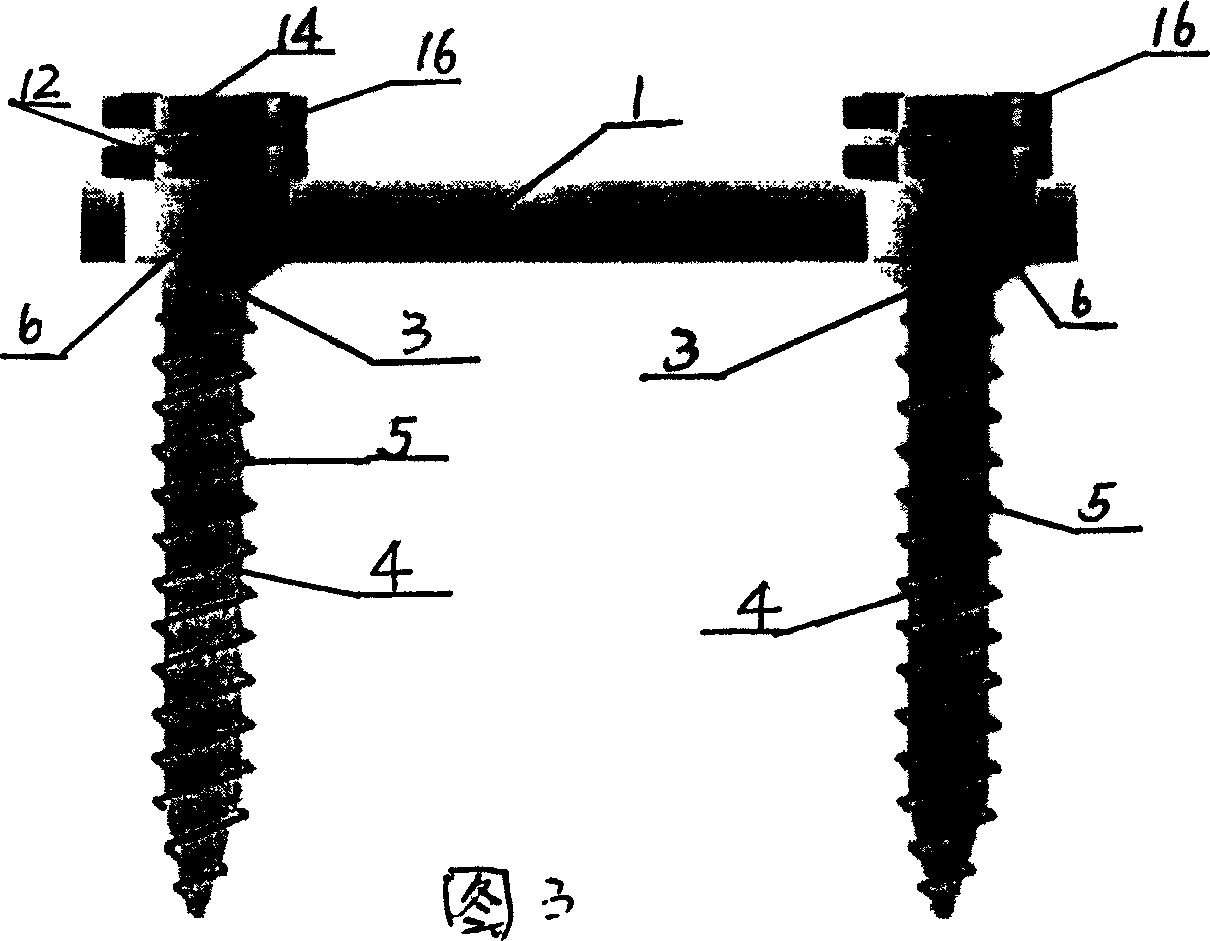

Pier bridge style screw system for vertebral arch pedicle

InactiveCN1424000AImprove stabilityReduce the probability of looseningInternal osteosythesisFastenersScrew systemEngineering

An internal fixator for vertebral arch pedicle is composed of several cylindrical correcting rods, flat square transverse bridge, and several screws for vertebral arch pedicle. Said screw has a screw bolt with external spiral thread on its lower part, and an expanded head with a U-shaped deep slot for recepting said correcting rod and shallow square slots on both side surfaces for recepting said transverse bridges.

Owner:NANJING GENERAL HOSPITAL NANJING MILLITARY COMMAND P L A

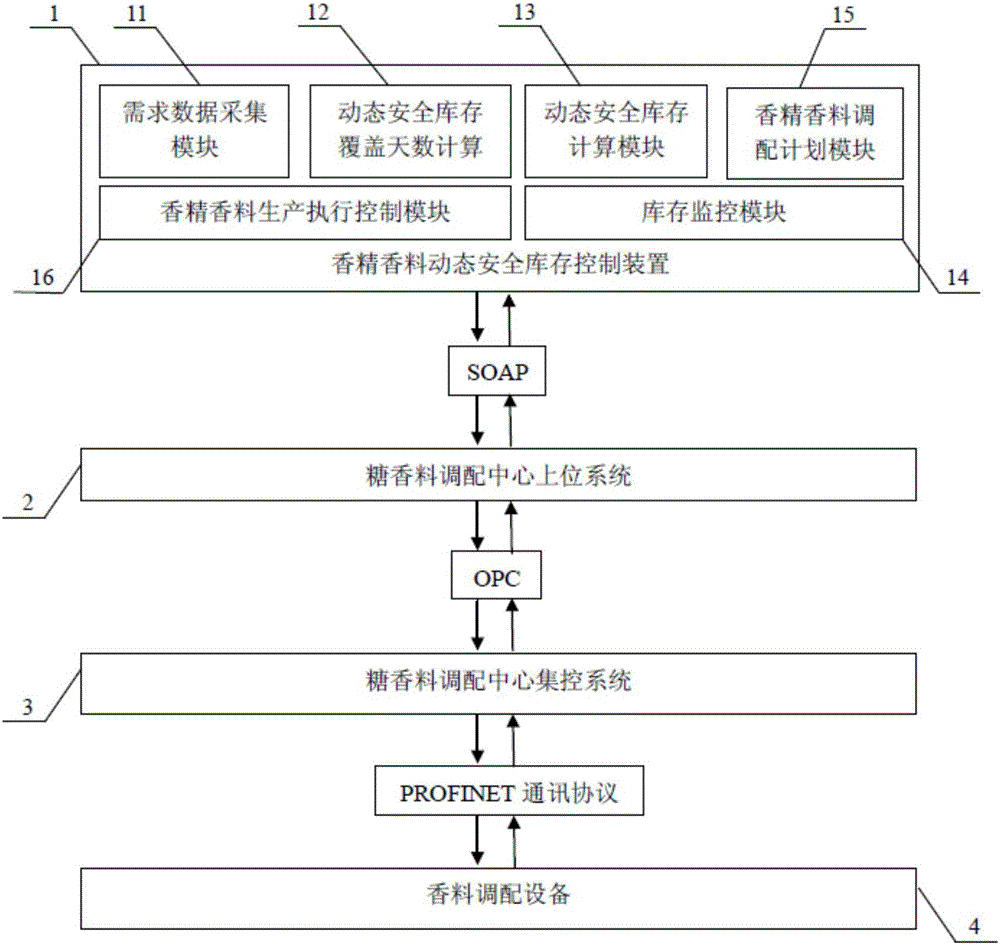

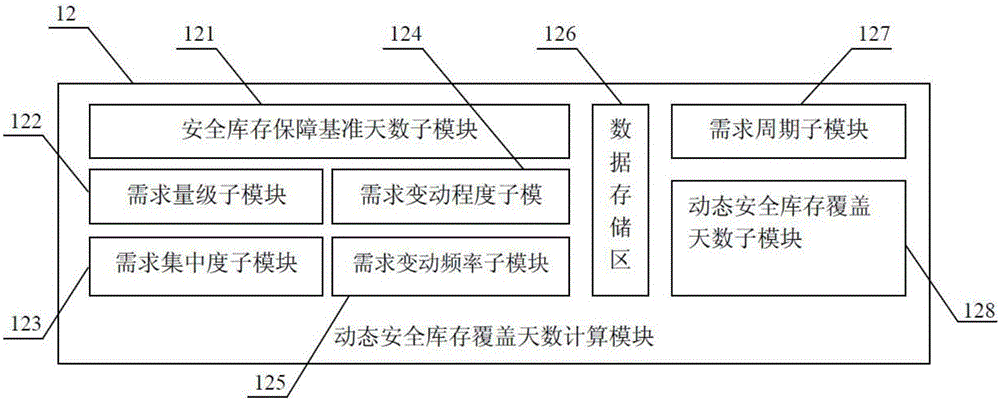

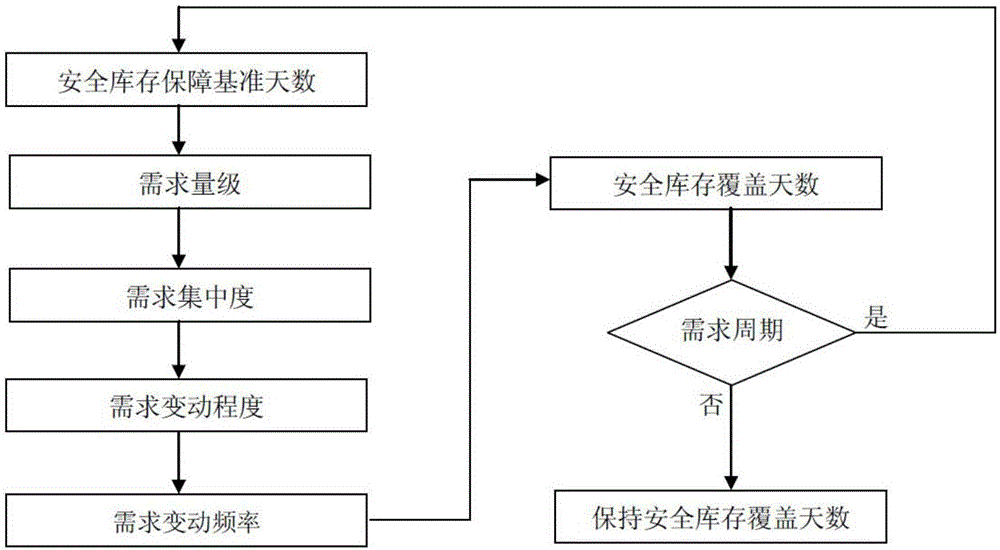

Control device of dynamic safety stock, and regulation and control method of safety stock

InactiveCN106529859AReduce sluggishnessOptimize inventory structureLogisticsData acquisitionExecution control

The invention discloses a control device of dynamic safety stock. The control device of dynamic safety stock includes a demand data acquisition module, a dynamic safety stock duration of dressing calculating module, a dynamic safety stock calculating module, a stock monitoring module, an allocation plan module and a production execution control module. The invention also discloses a dynamic regulation and control method of the control apparatus. The dynamic regulation and control method of the control apparatus can realize real-time control of allocation equipment and control the safety stock to maintain at a reasonably level, and can effectively reduce the stock maintenance cost and improve the stock turnover rate when stock can be supplied continuously.

Owner:CHINA TOBACCO ZHEJIANG IND

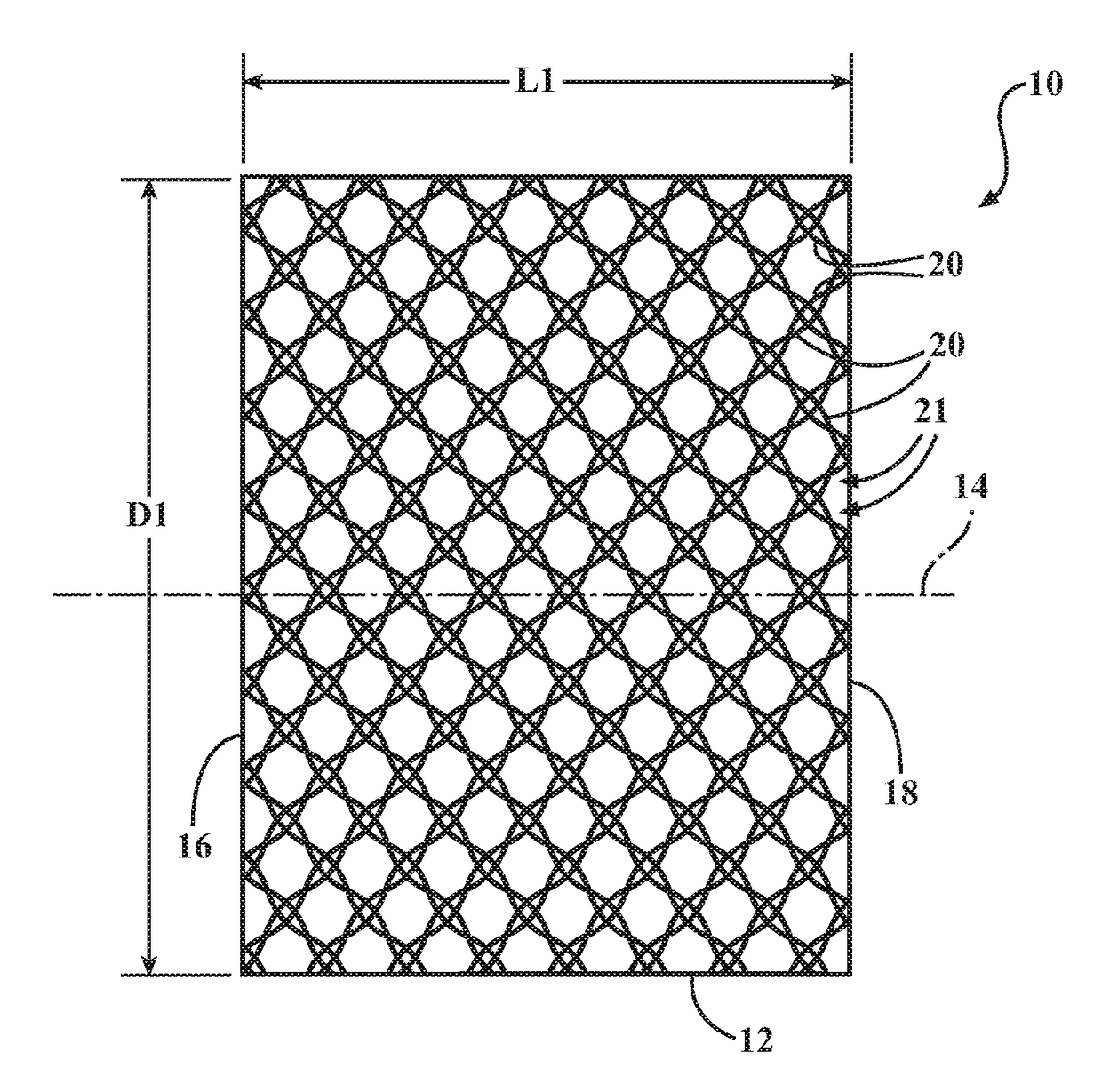

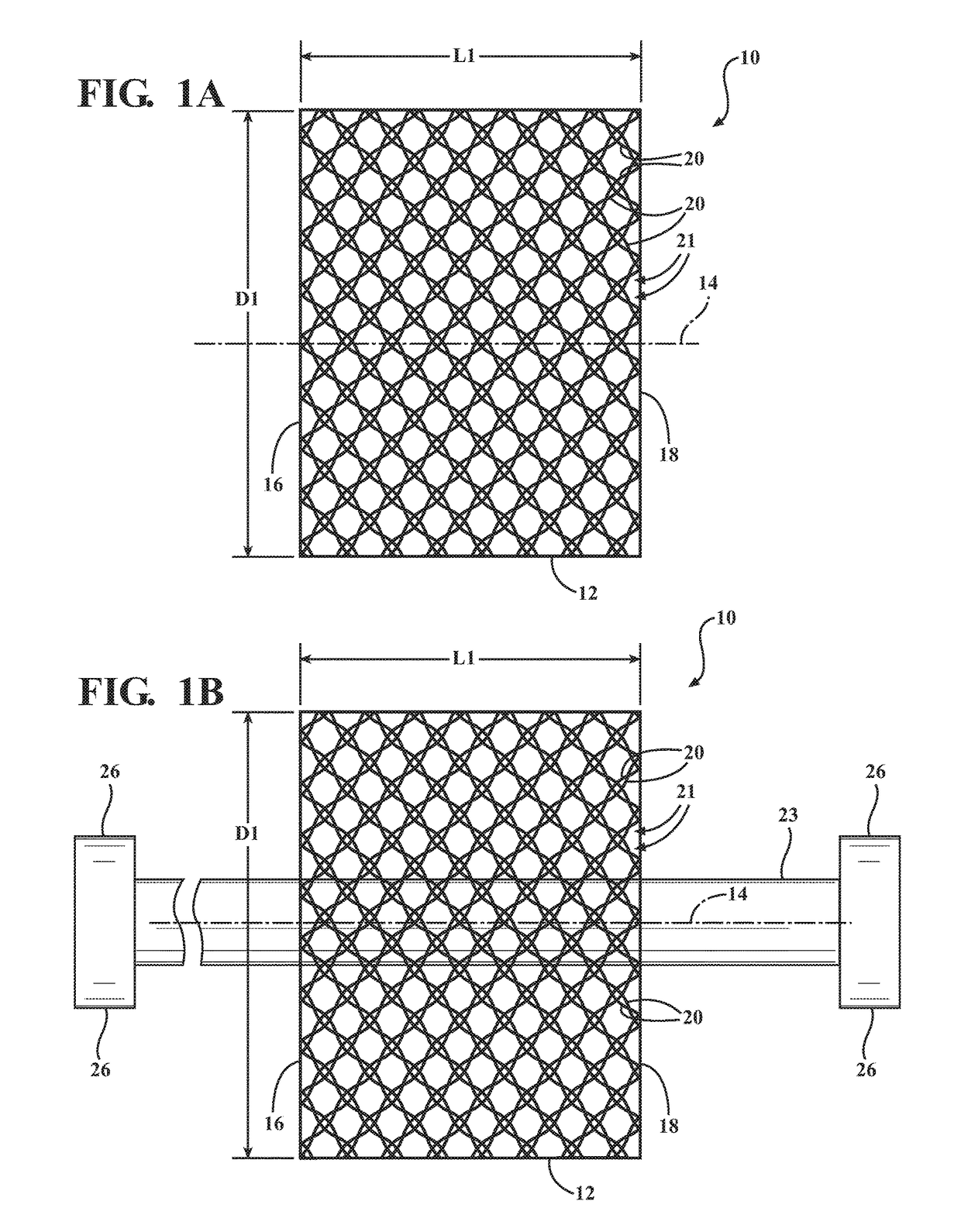

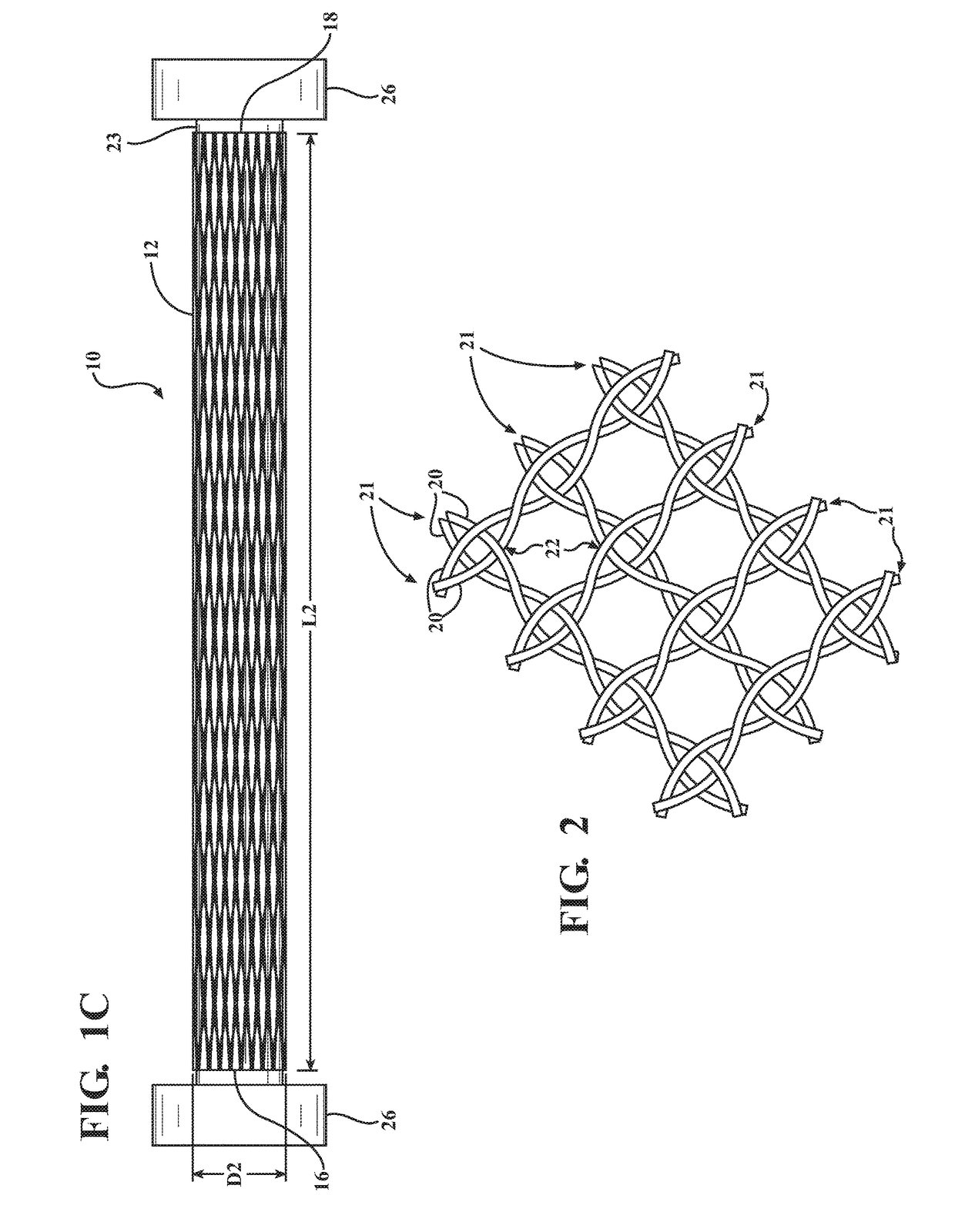

Braided textile sleeve with self-sustaining expanded and contracted states and enhanced "as supplied" bulk configuration and methods of construction and supplying bulk lengths thereof

A bulk supply of a protective textile sleeve and method of construction and supplying thereof is provided. The sleeve includes a braided, tubular wall extending lengthwise along a central longitudinal axis between opposite ends. The wall has a decreased length, increased cross-sectional area first state and an increased length, decreased cross-sectional area second state. The wall has heat-set, braided yarns causing the wall to remain substantially in the first and second states absent some externally applied force. The wall is finish cut having a bulk supply shipping length extending between the opposite ends, and is configured to be subsequently cut into a plurality of discrete use lengths after shipping.

Owner:FEDERAL MOGUL POWERTAIN LLC

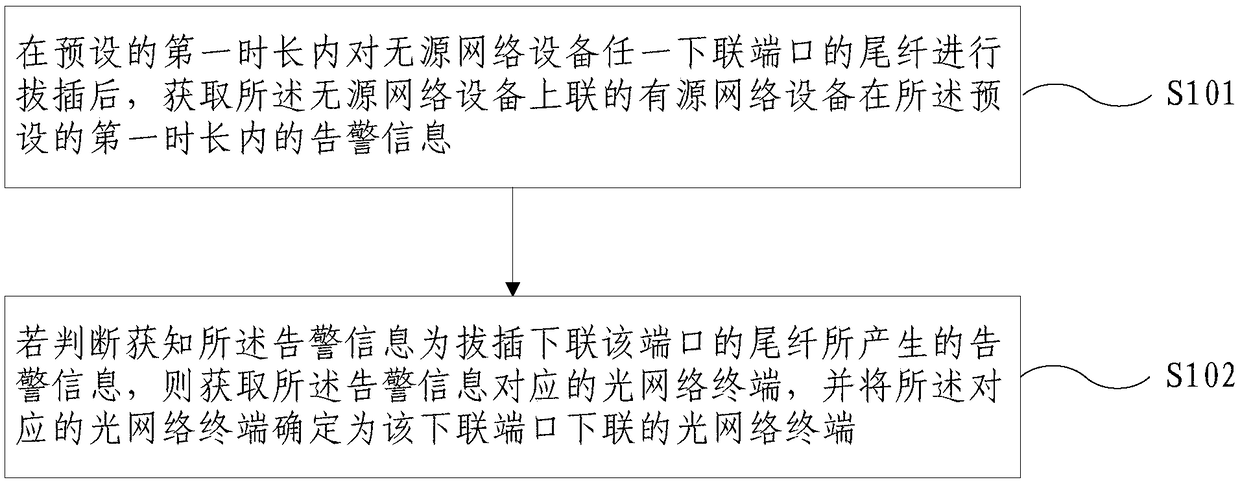

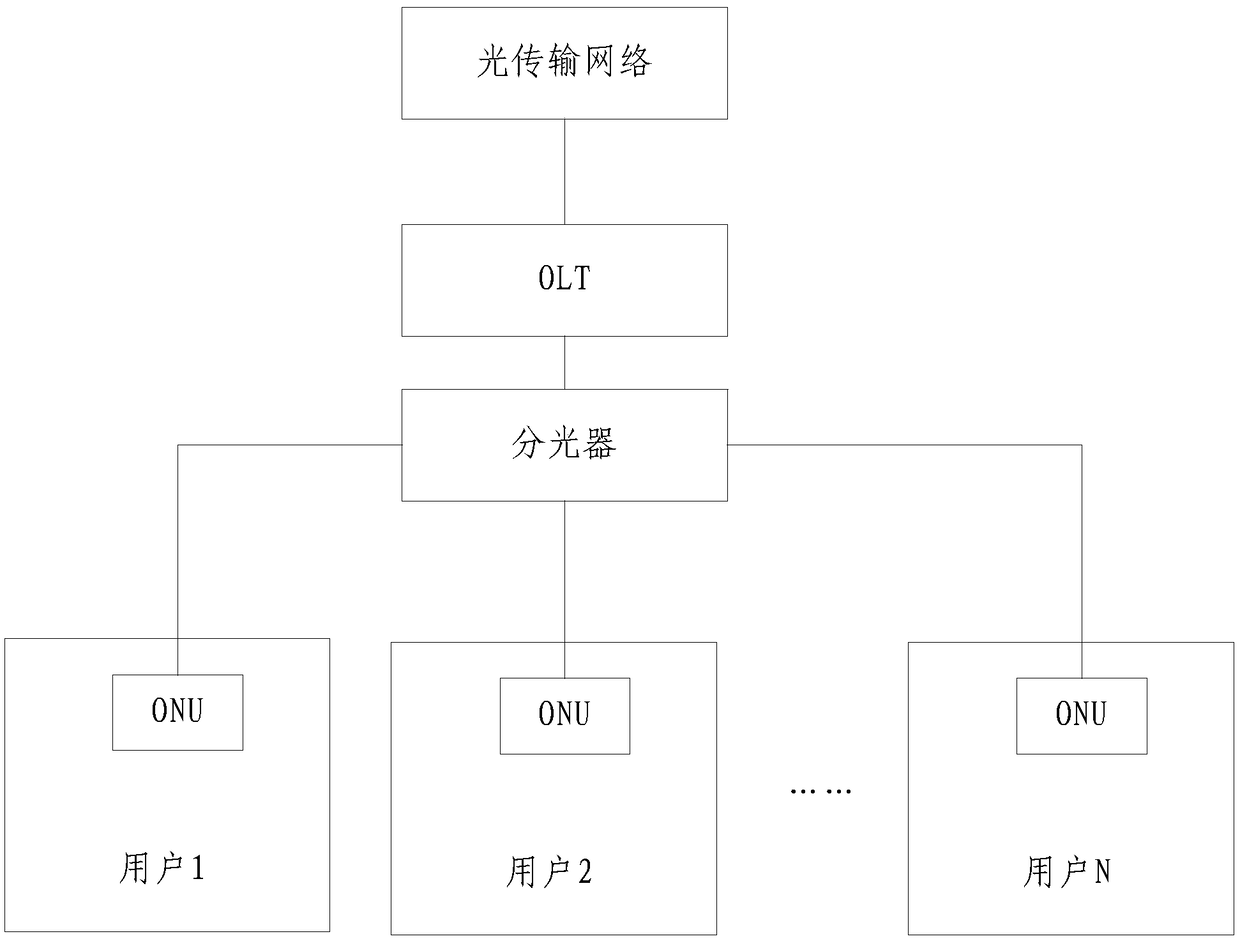

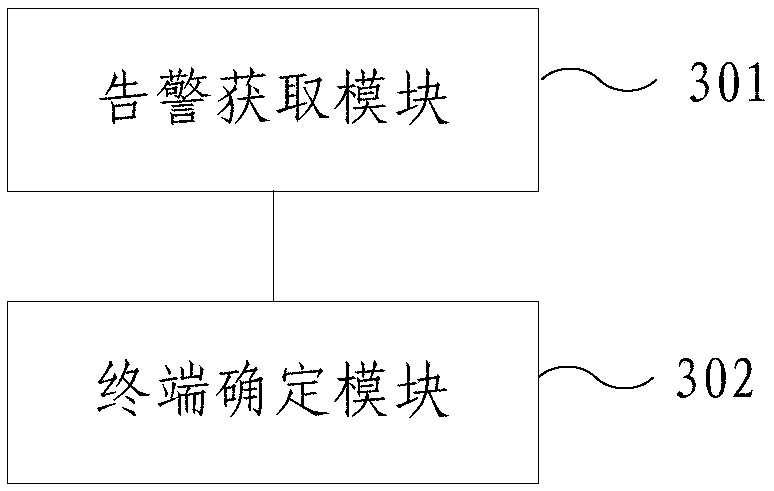

Method and system for detecting port state of network device

ActiveCN109218857AAvoid Resource InventoryImprove detection efficiency and accuracyMultiplex system selection arrangementsElectromagnetic transmissionOptical network terminalNetwork Access Device

The embodiment of the present invention provides a method and system for detecting the port state of a network device. The method includes: acquiring the alarm information of an active network deviceconnected to a passive network device within a preset first time period after the tail fiber of any downlink port of the passive network device is plugged in and out within the preset first time period; if it is determined that the alarm information is the alarm information generated by plugging in and out the tail fiber of the downlink port, acquiring an optical network terminal corresponding tothe alarm information and determining the corresponding optical network terminal as an optical network terminal connected to the downlink port. The method and system for detecting the port state of the network device provided by the embodiment of the present invention can quickly and accurately obtain a corresponding relationship between the downlink port of the passive network device and the optical network terminal, and improve the detection efficiency and accuracy of the port state of the network device.

Owner:BEIJING MATARNET TECH

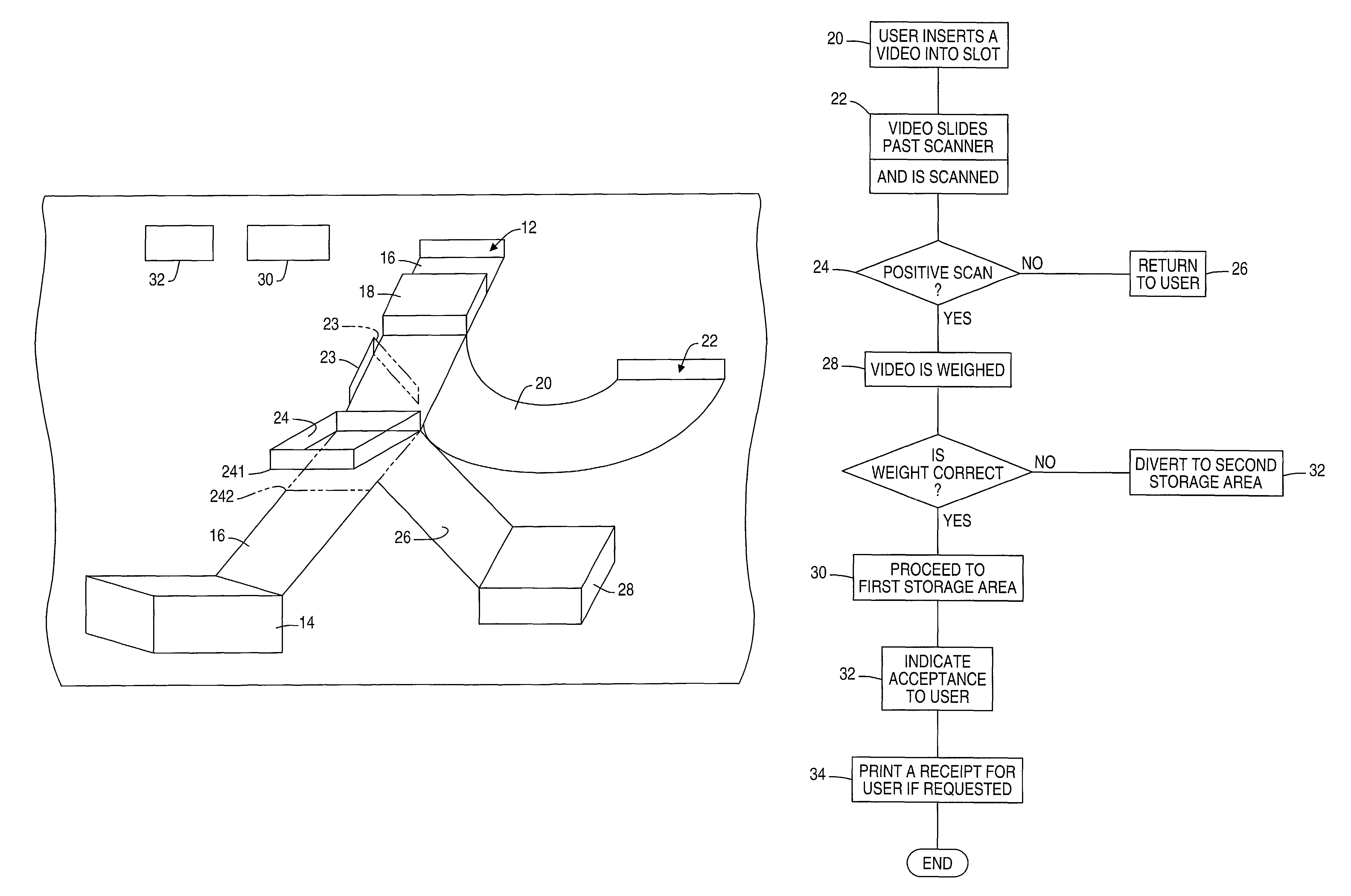

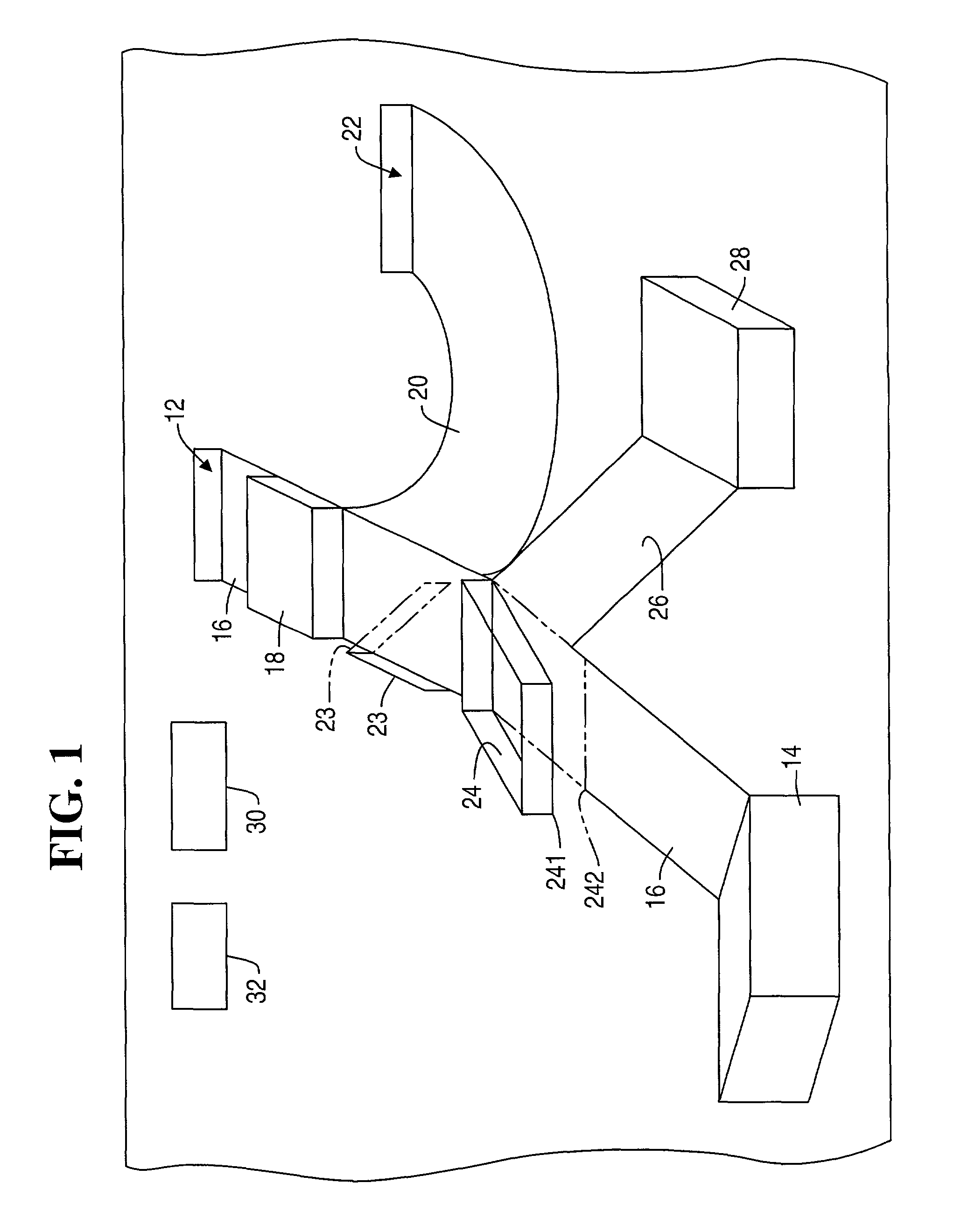

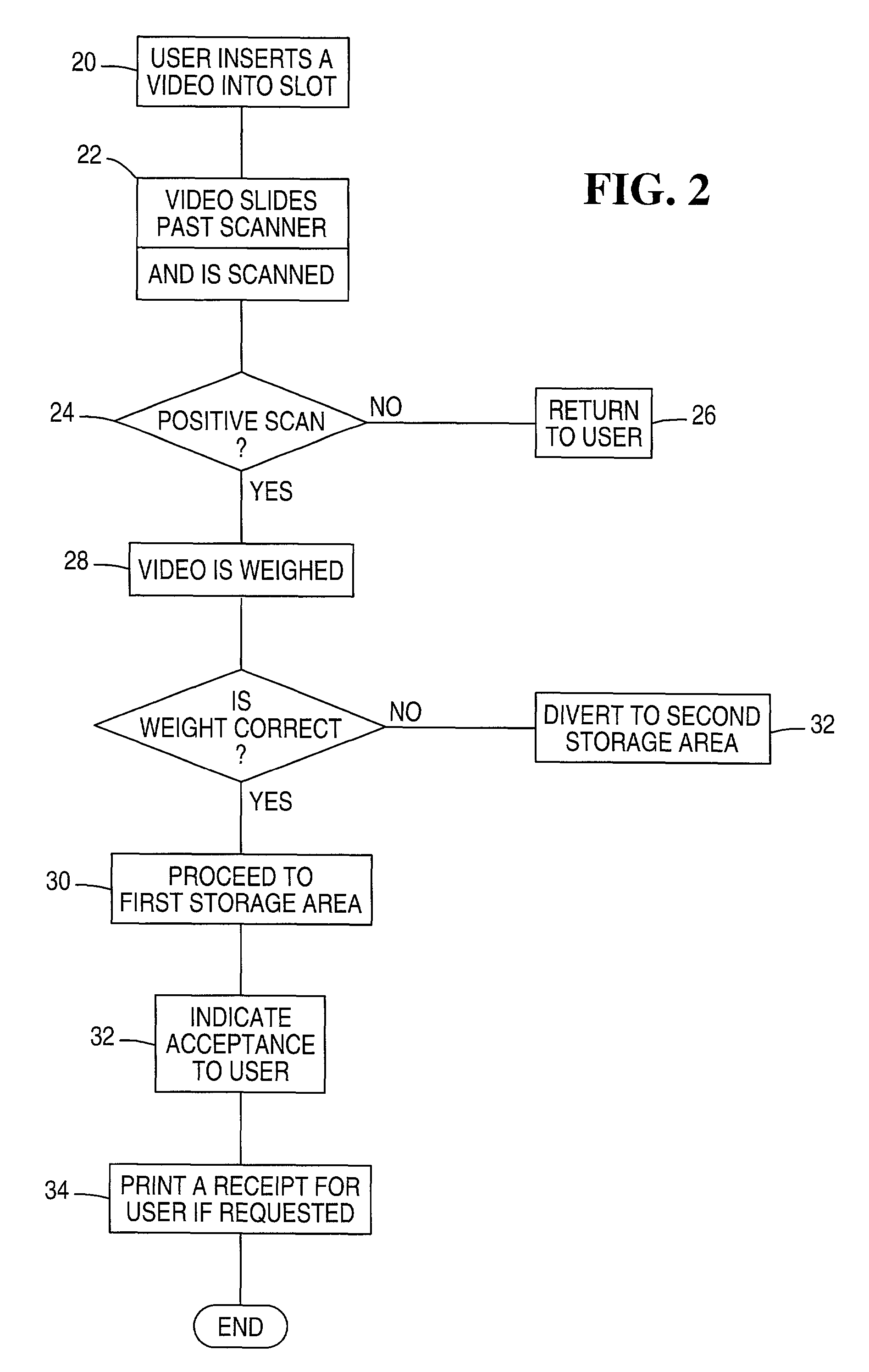

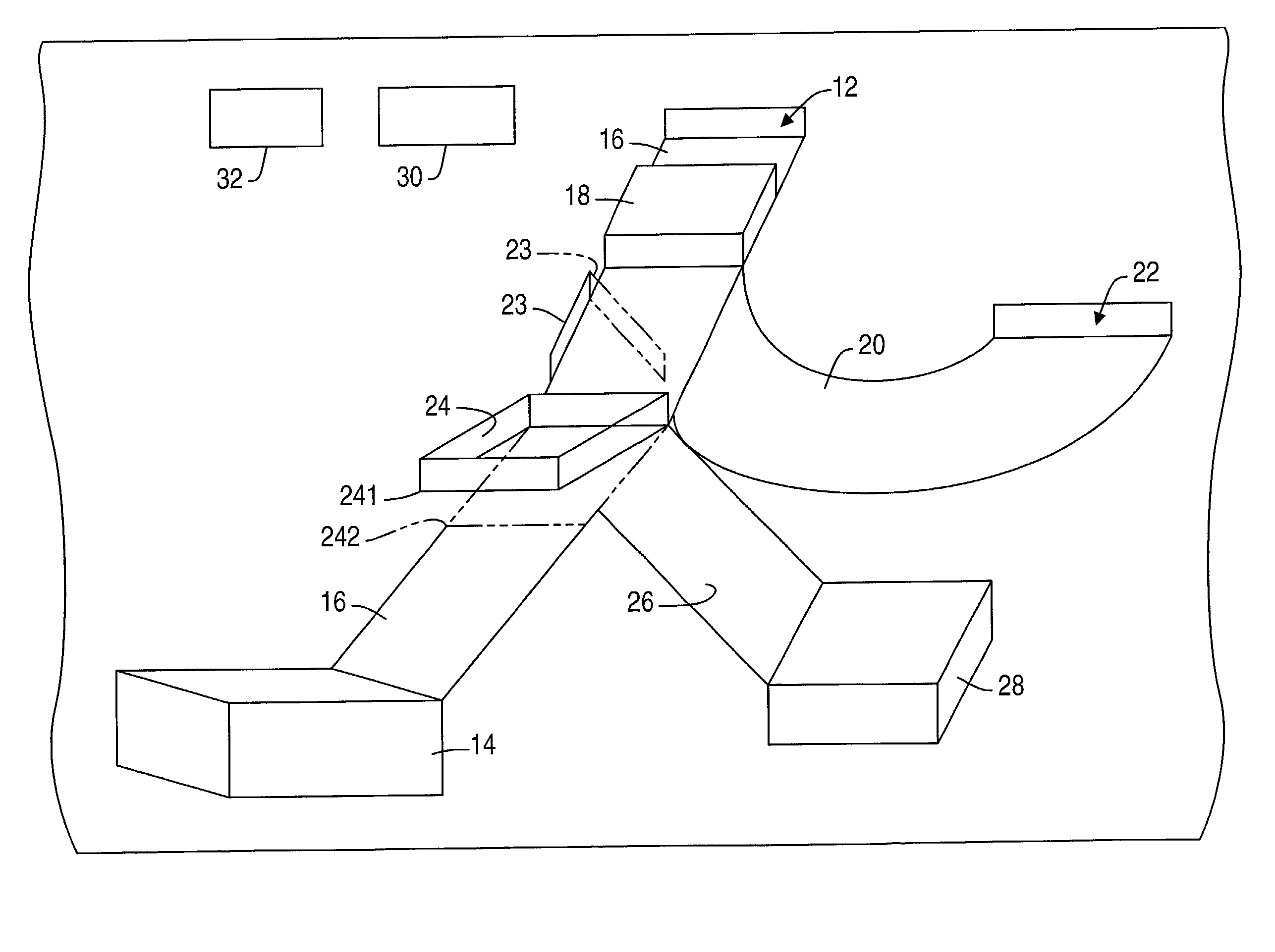

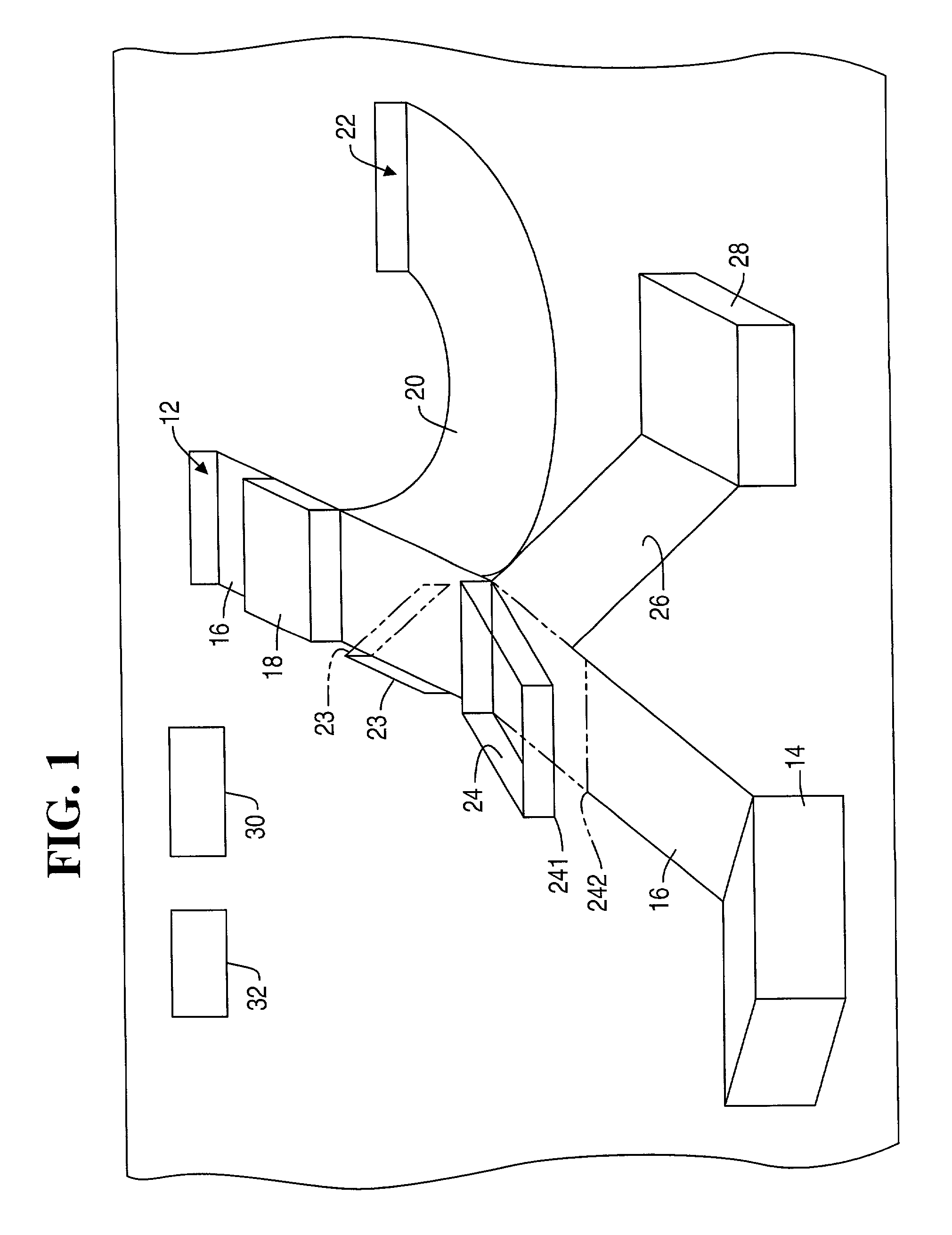

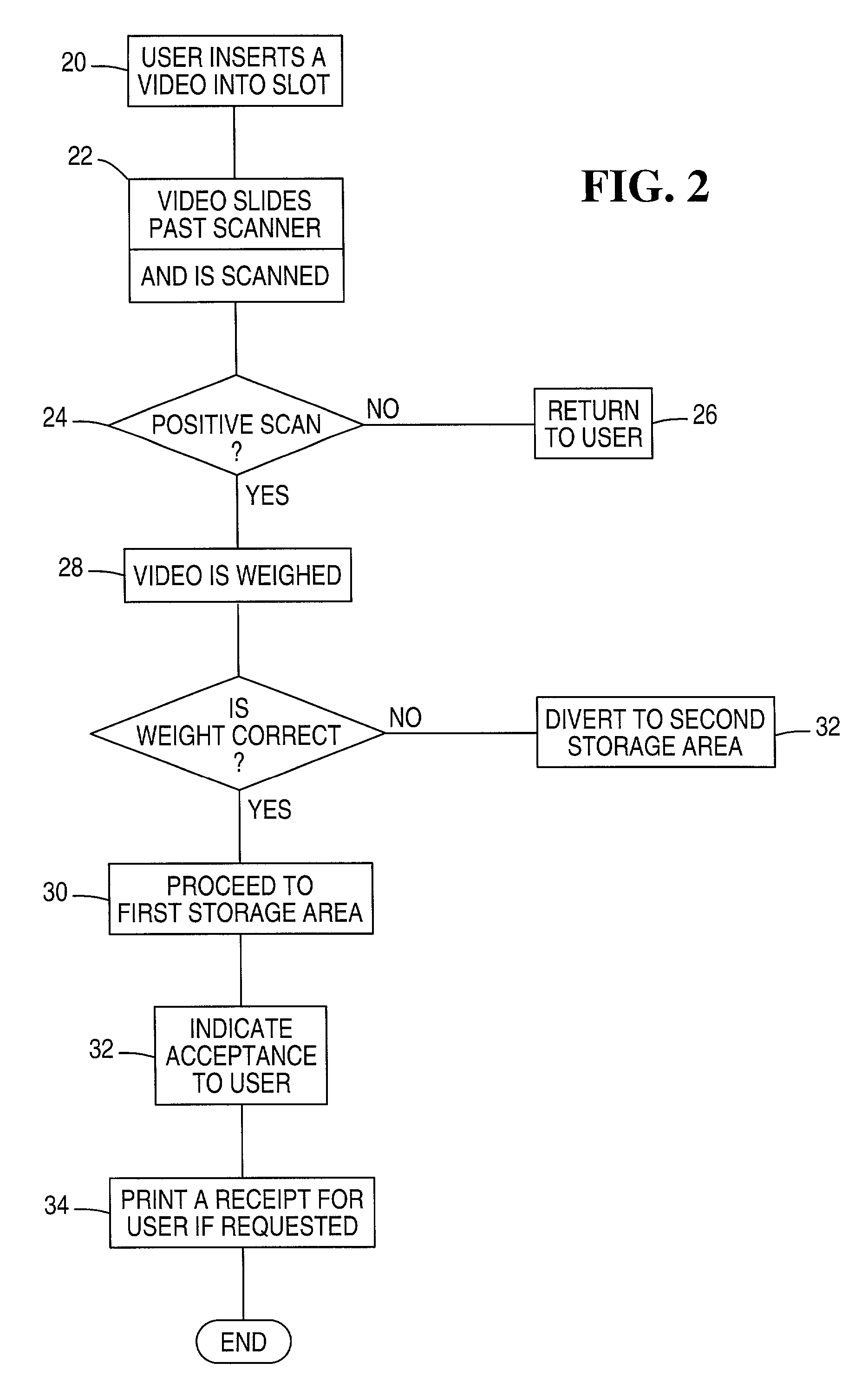

Rental return method and apparatus

Owner:NCR VOYIX CORP

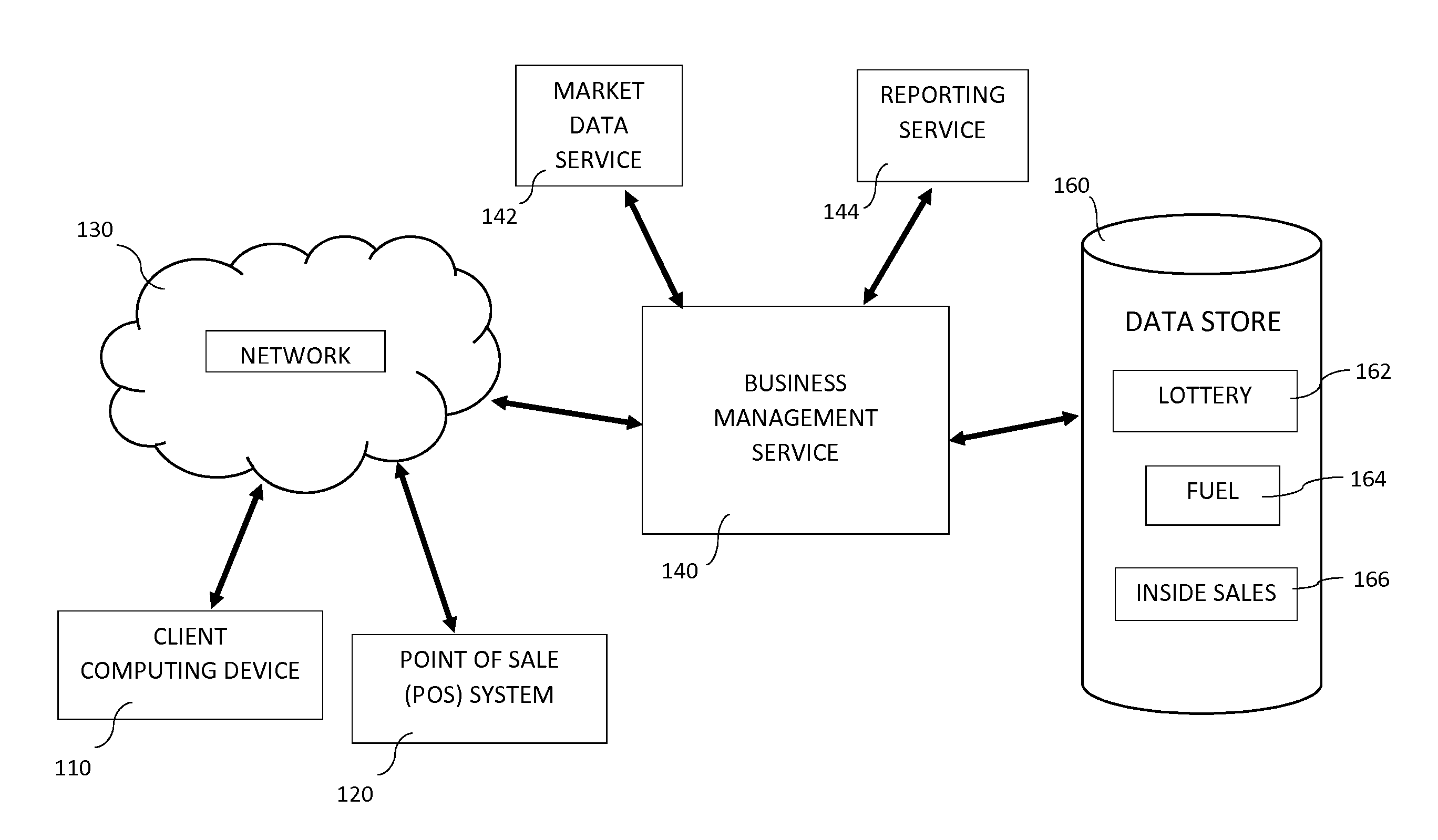

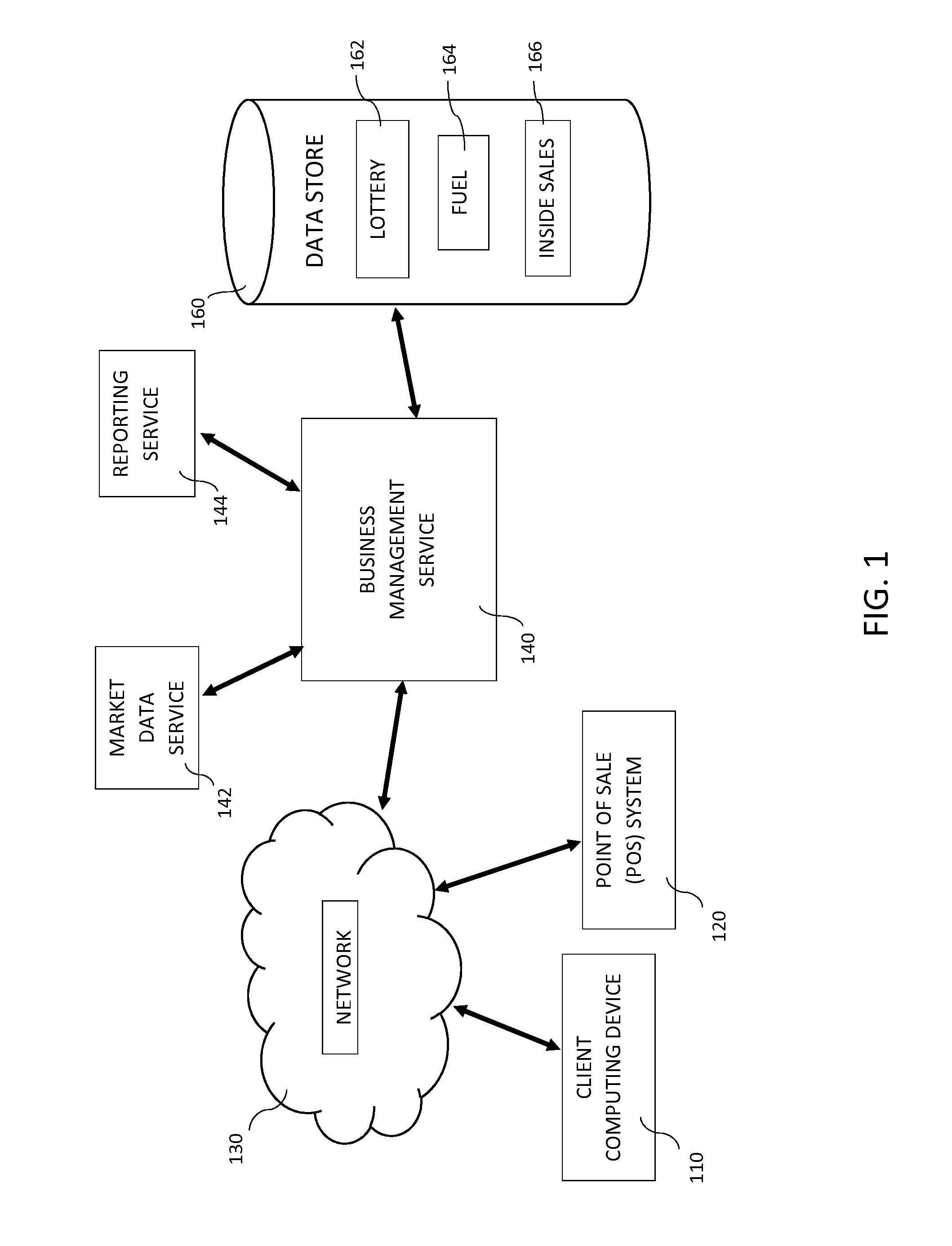

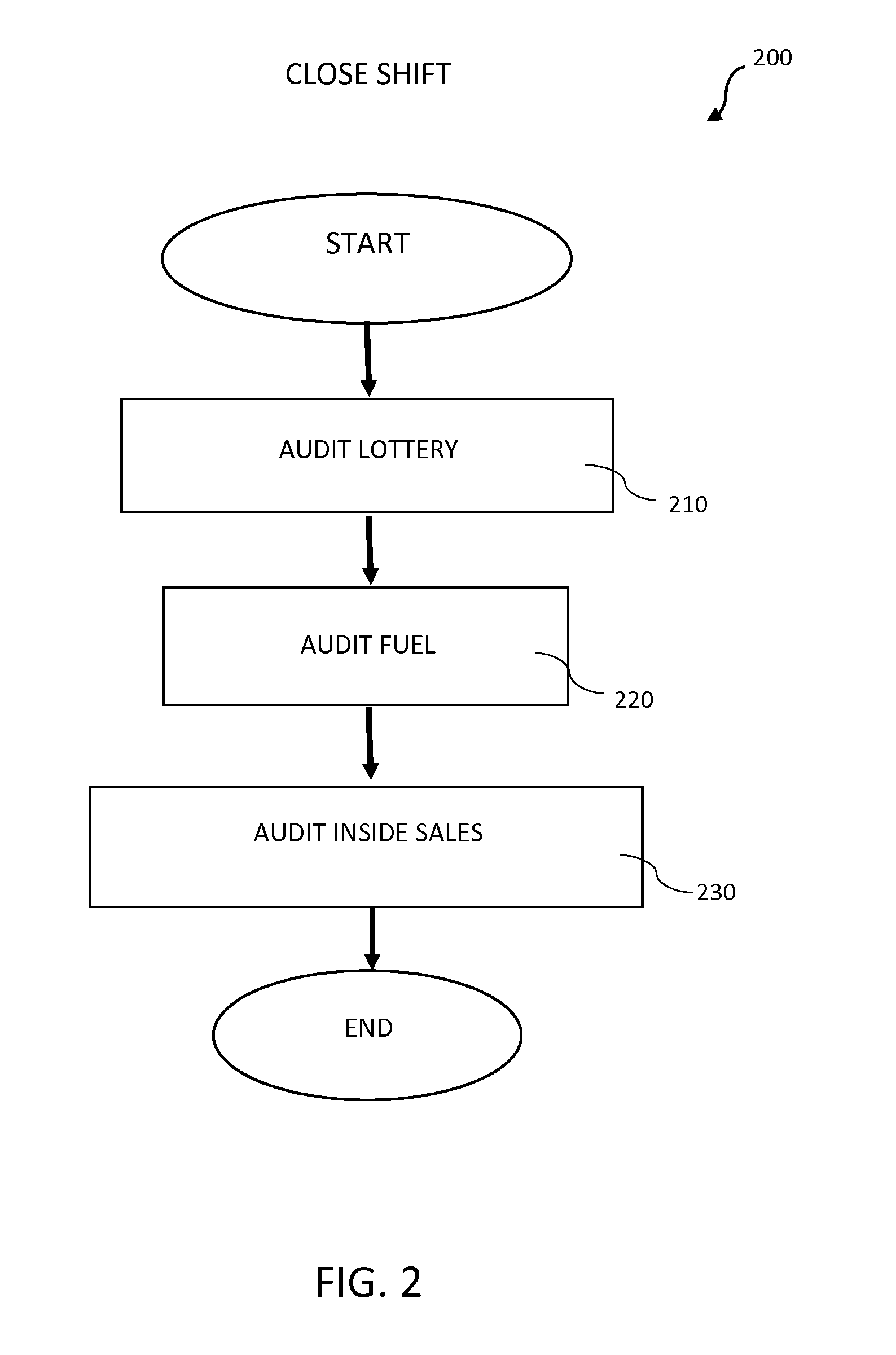

Business Process Management System

InactiveUS20140304096A1Improve efficiencyEasy to manageHand manipulated computer devicesLogisticsBusiness enterpriseKnowledge management

Systems and methods for providing improved efficiency and management of business processes are provided. The management of business enterprises such as convenience stores is improved by tracking and verifying shift data as relates to tracking fuel availability, settling and tracking inventory, and auditing lottery information.

Owner:DEVINENI UDAYA

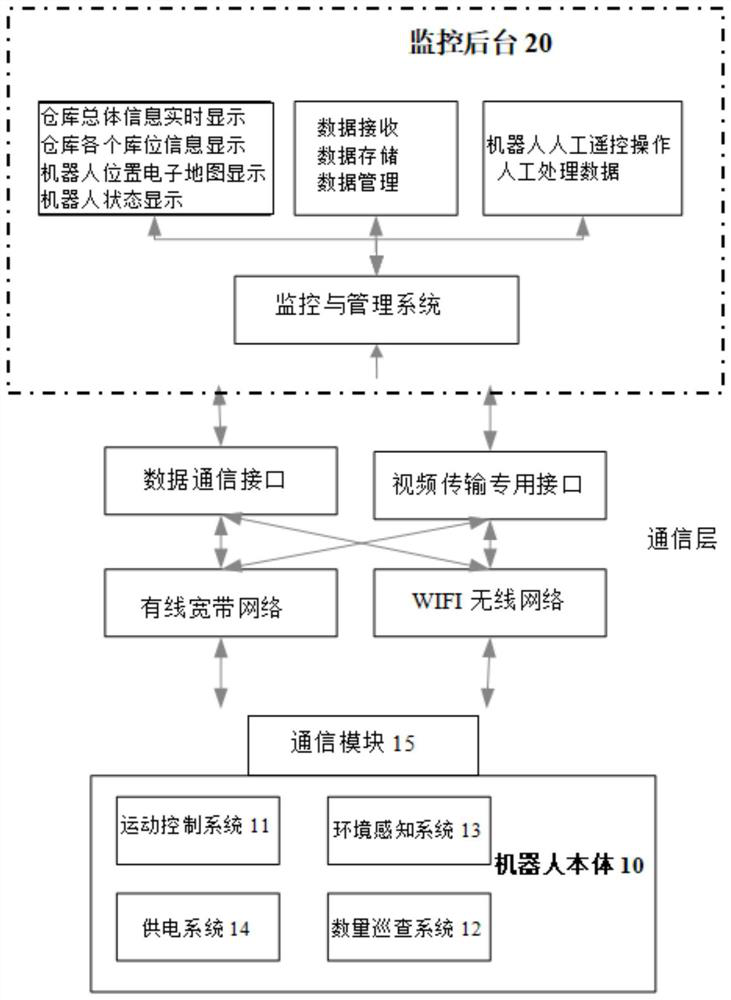

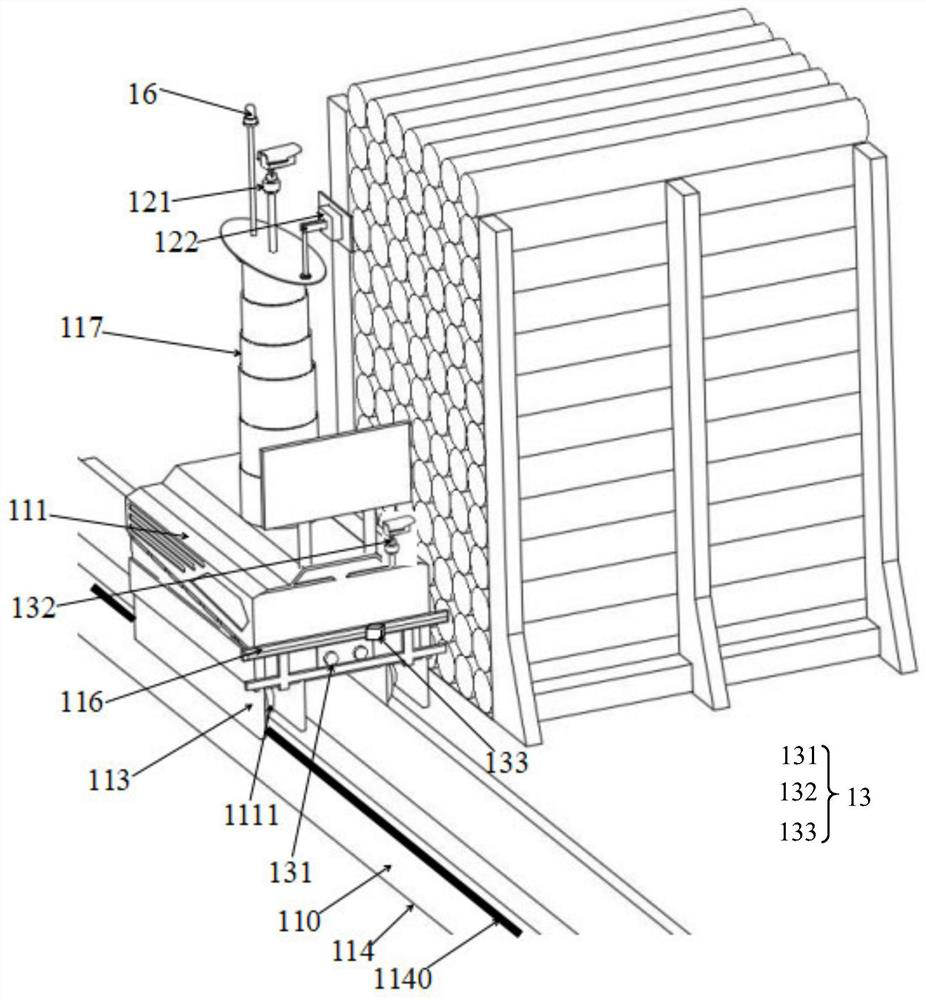

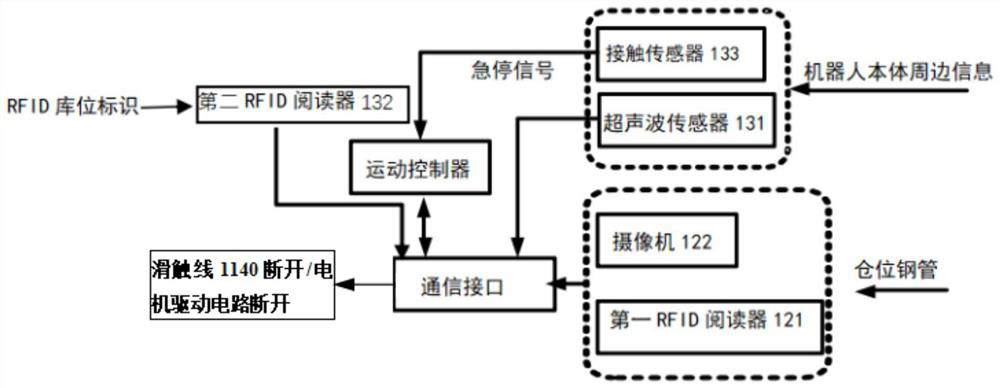

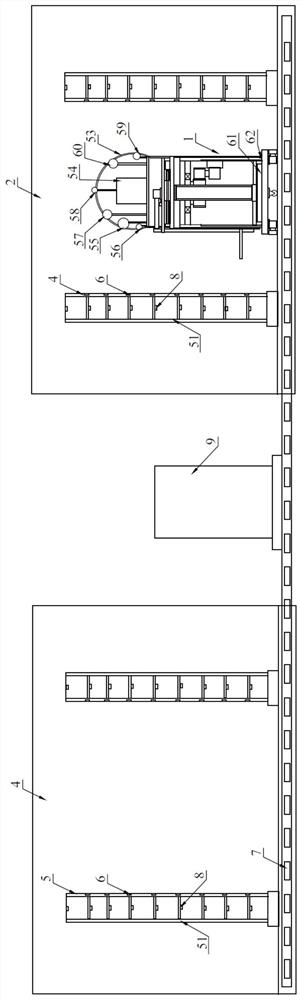

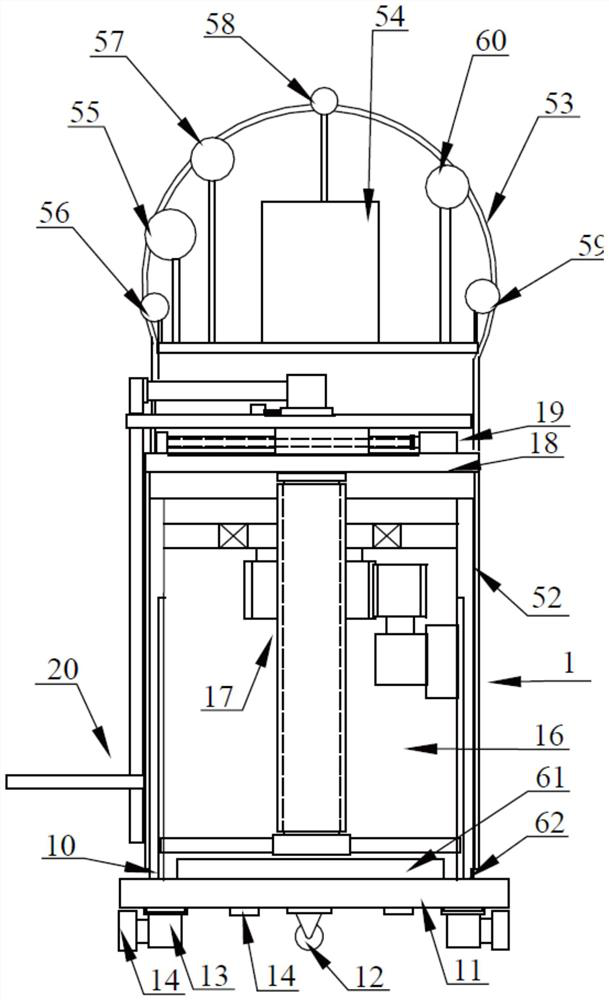

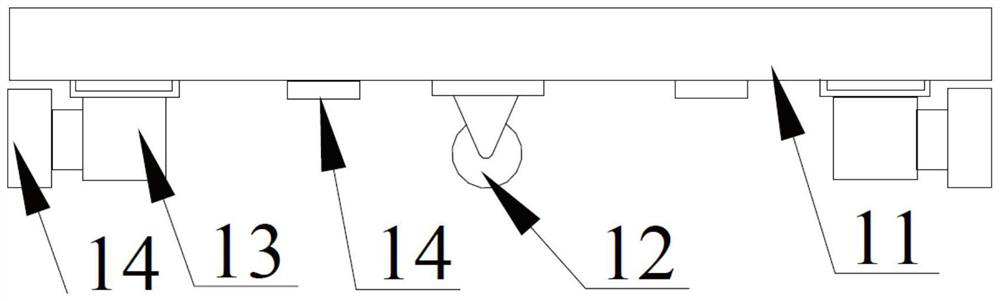

Warehouse-in and warehouse-out management guiding system for steel pipe warehouse, and ground rail type patrol robot

PendingCN112520299AAvoid inventoryHigh degree of intelligenceConveyorsStorage devicesImaging processingImage manipulation

The invention relates to the technical field of warehouse management, in particular to a warehouse-in and warehouse-out management guiding system for a steel pipe warehouse, and a ground rail type patrol robot. The identities of steel pipes are identified through a radio frequency identification device (RFID) technology, the number of the steel pipes is identified through the RFID technology and an image processing technology, the mobile patrol robot is used to conduct patrol on storage locations at regular time, the inventory condition of each storage location is read, and a database is corrected. The ground rail type patrol robot is used for replacing manpower to patrol in the steel pipe warehouse, reading the inventory condition of each storage location and correcting the database, so that the situation that the inventory of the database is inconsistent with the actual situation is avoided, and the labor intensity of workers is reduced. According to the warehouse-in and warehouse-out management guiding system for the steel pipe warehouse provided by the invention, a displayer is installed in a cab of a bridge crane, information such as warehouse-in and warehouse-out steel pipe warehouse location positions (combined with an electronic map of the warehouse) and the number of warehouse-in and warehouse-out steel pipes can be displayed on the displayer to a driver, and the driver can rapidly find out target warehouse locations according to prompts, so that the problem of misinformation transmission caused by shouting is prevented, and the working efficiency is improved.

Owner:SHANDONG JIANZHU UNIV

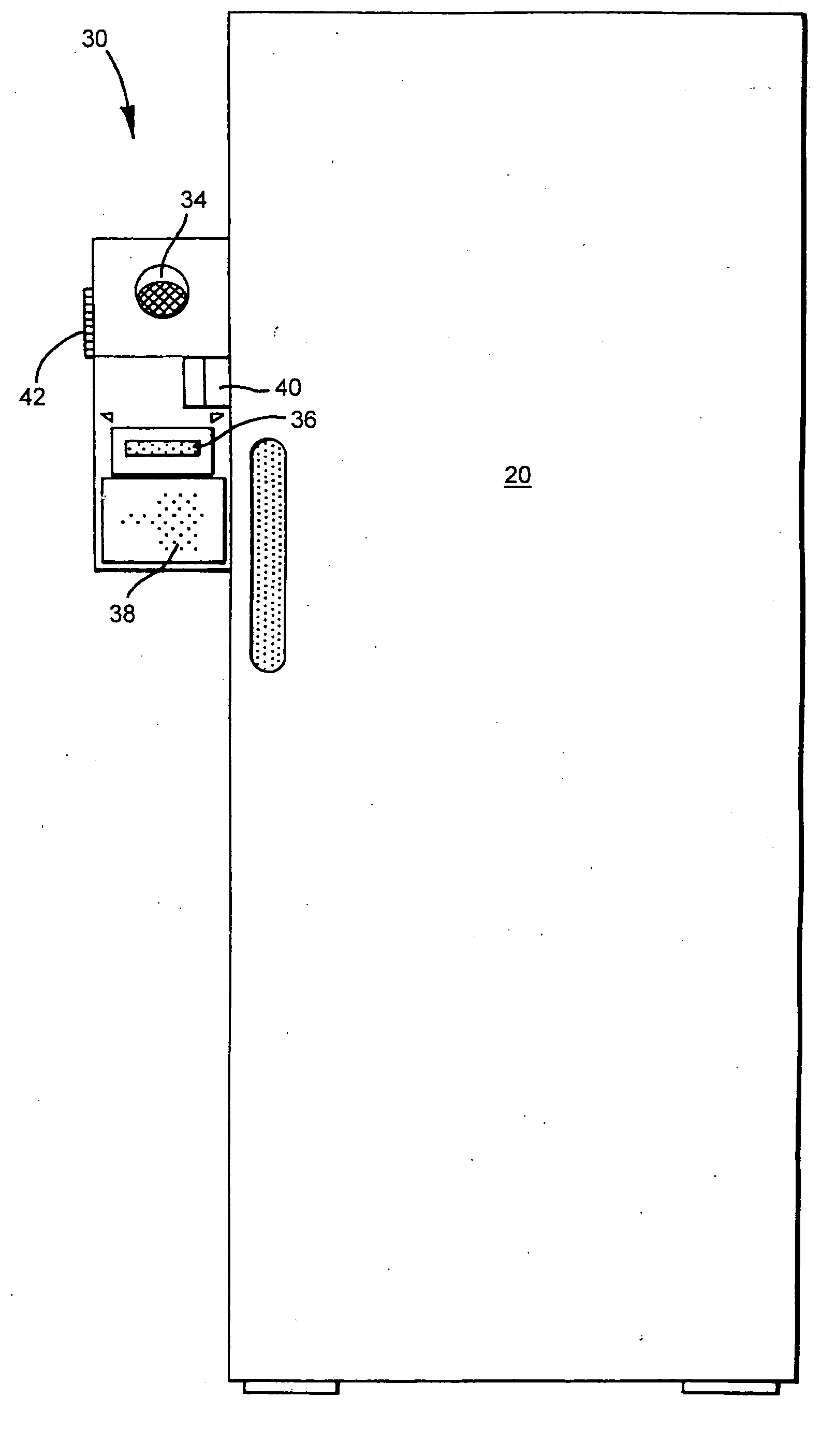

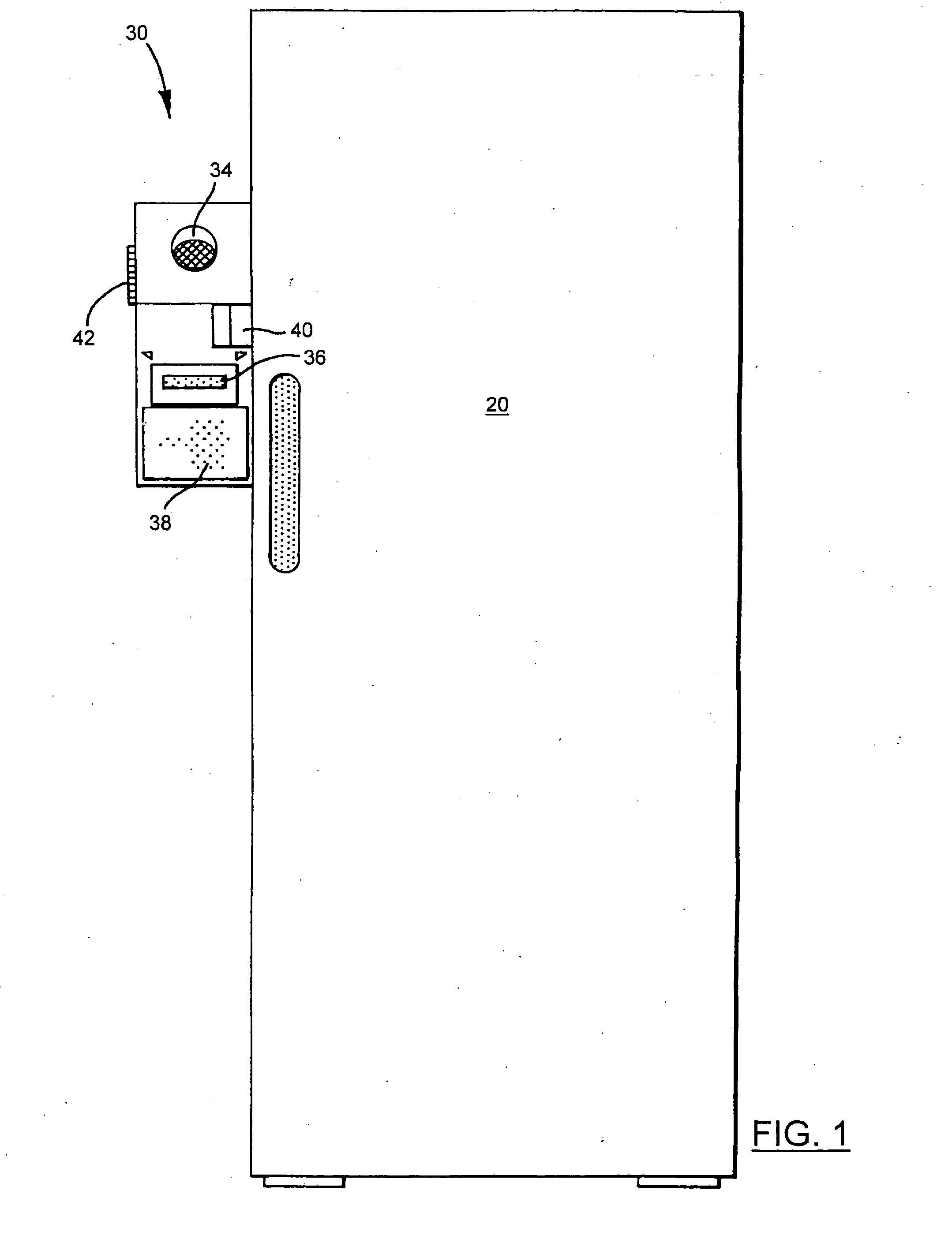

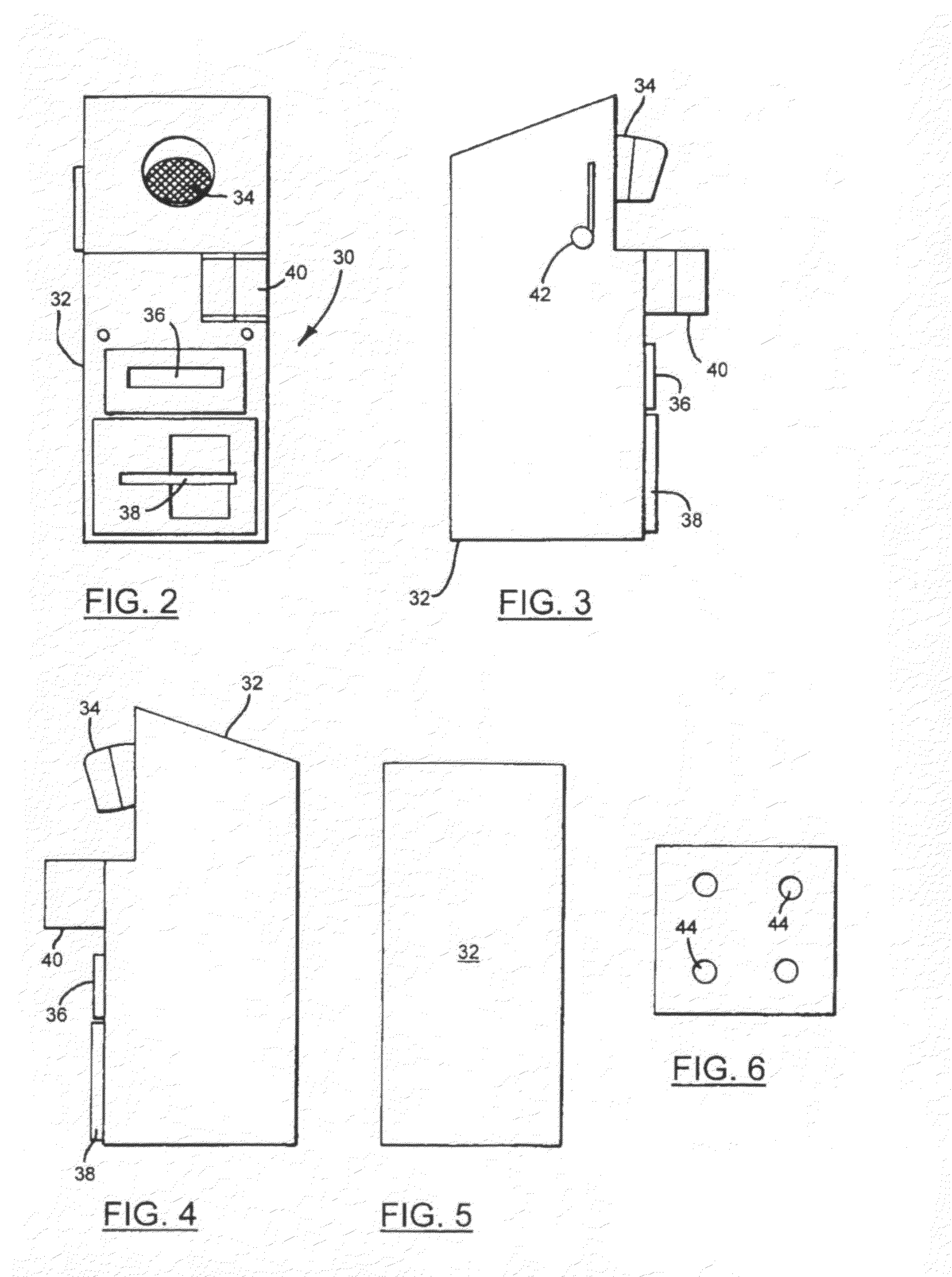

System and method for tracking inventory

ActiveUS20110000964A1Easy to modifyAvoid inventoryOral administration deviceHealthcare resources and facilitiesCommunication interfaceCard reader

Owner:CSTAR TECH

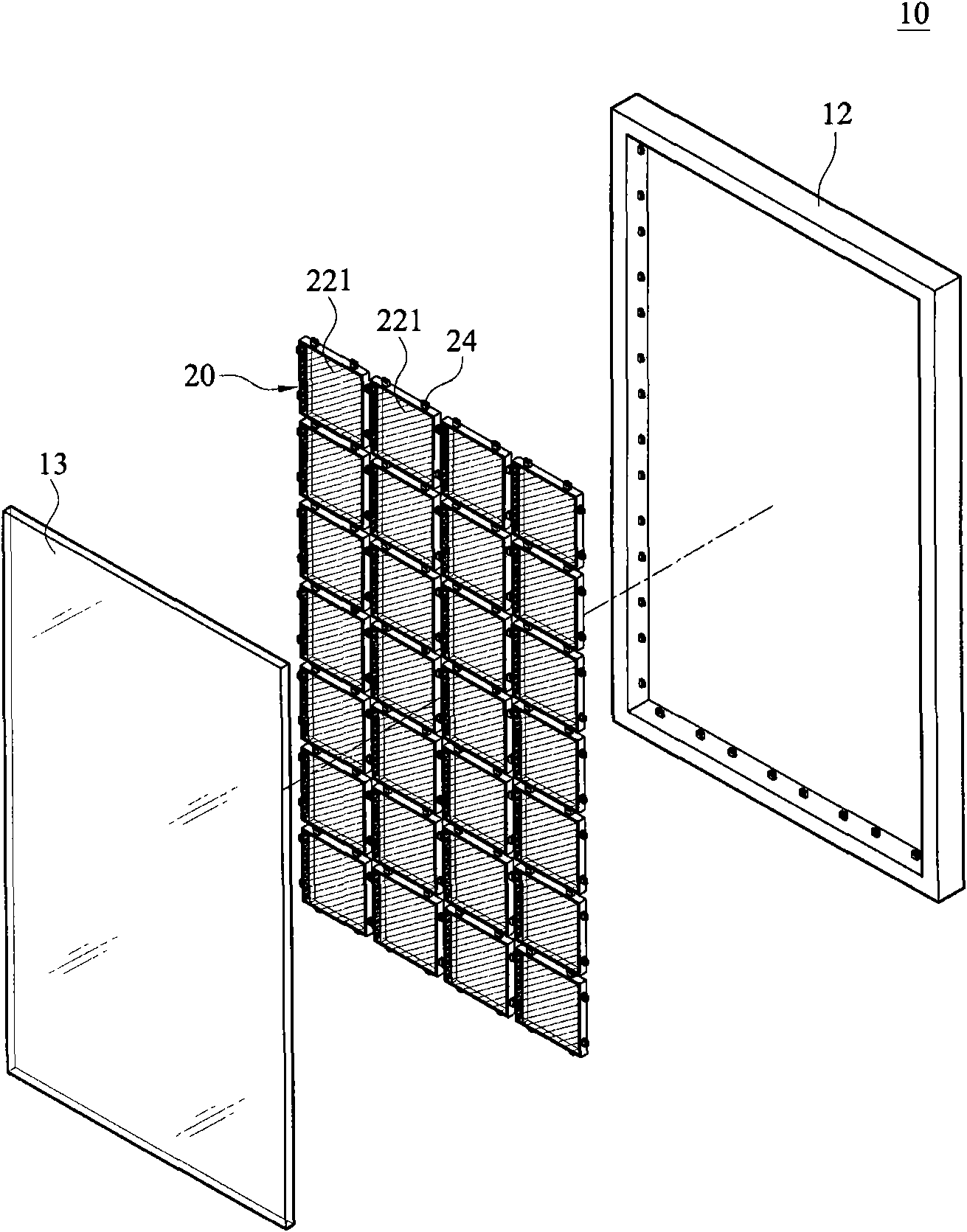

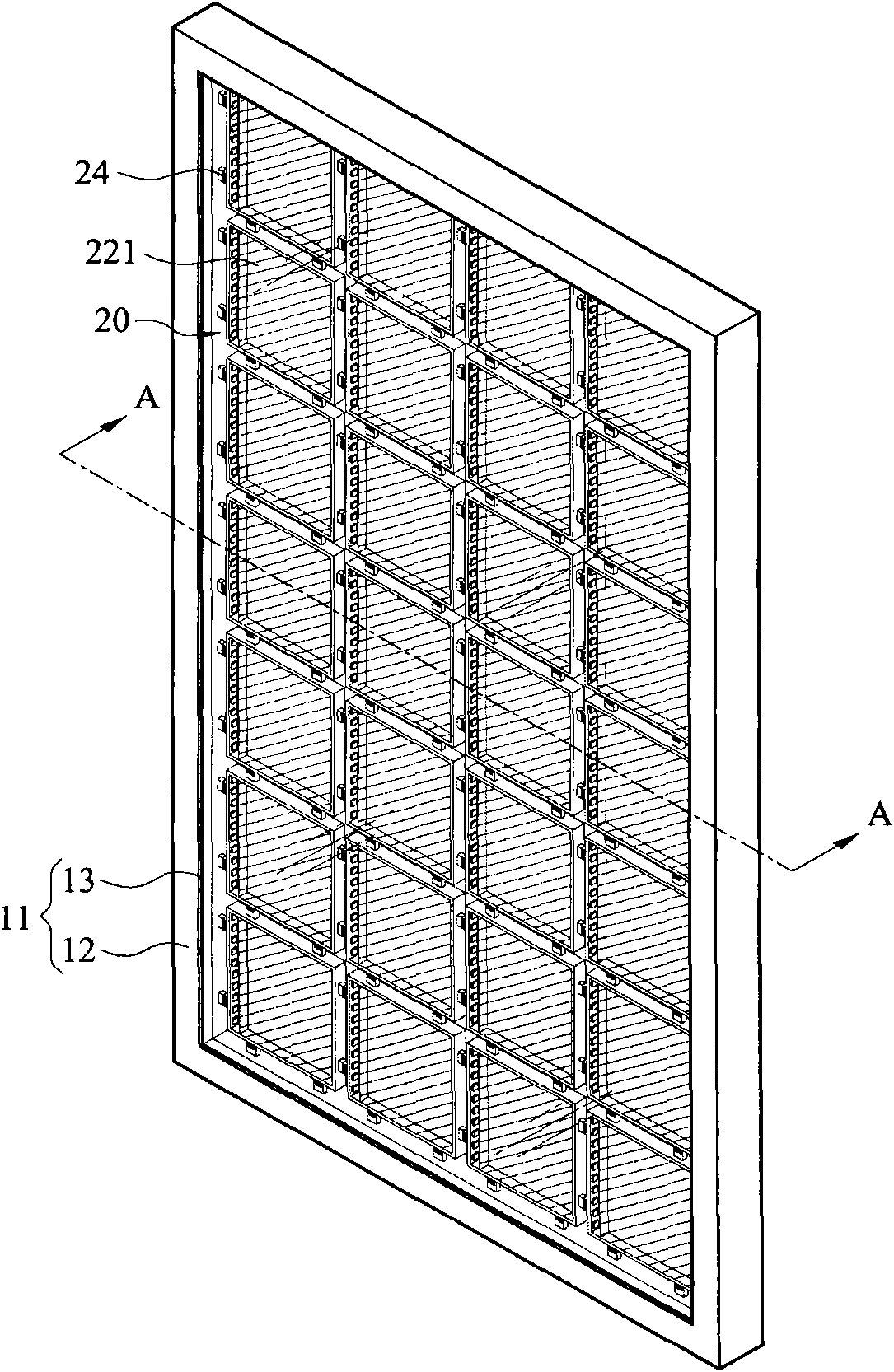

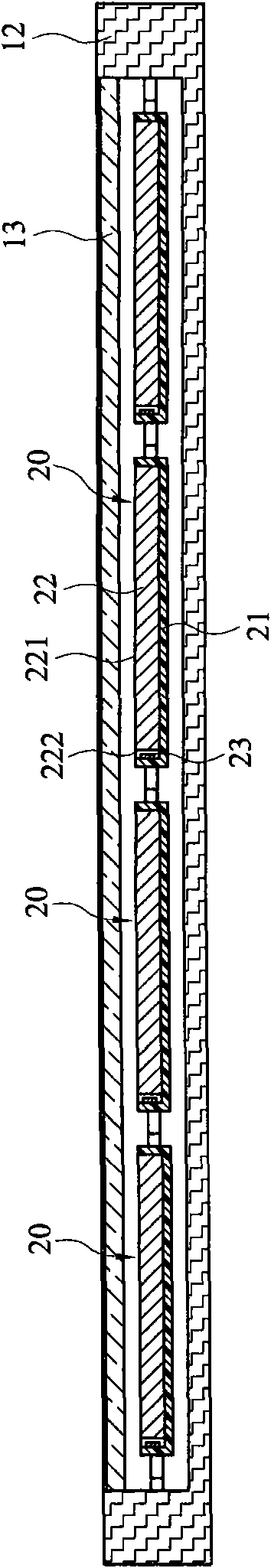

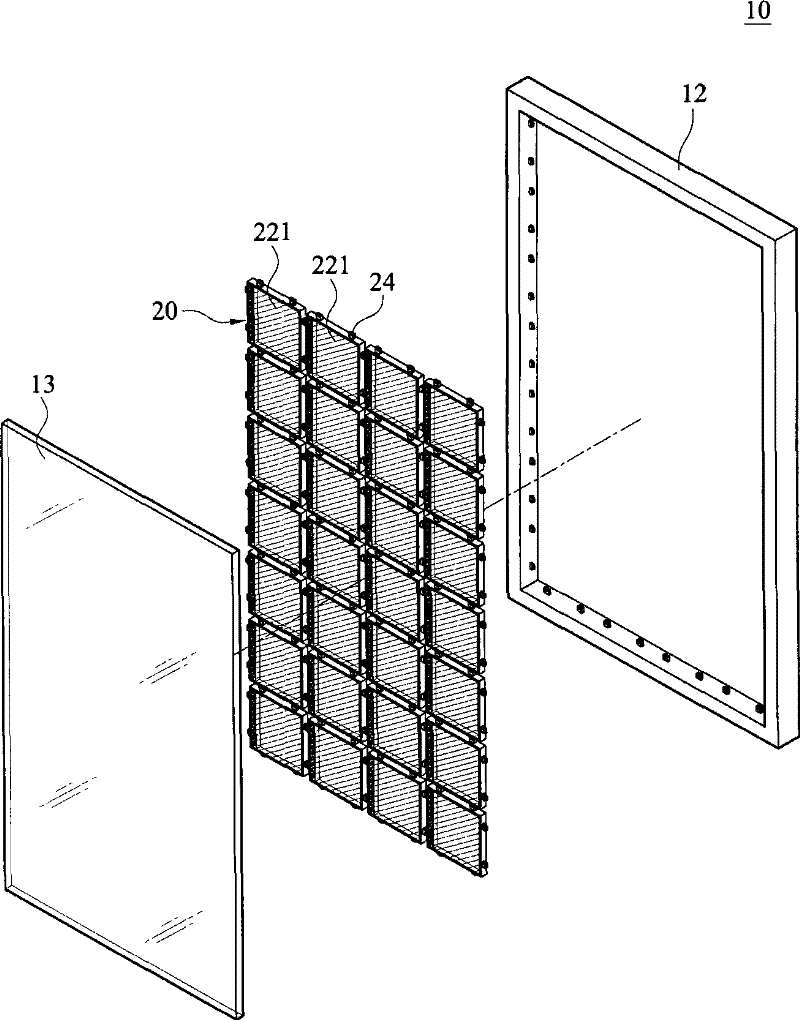

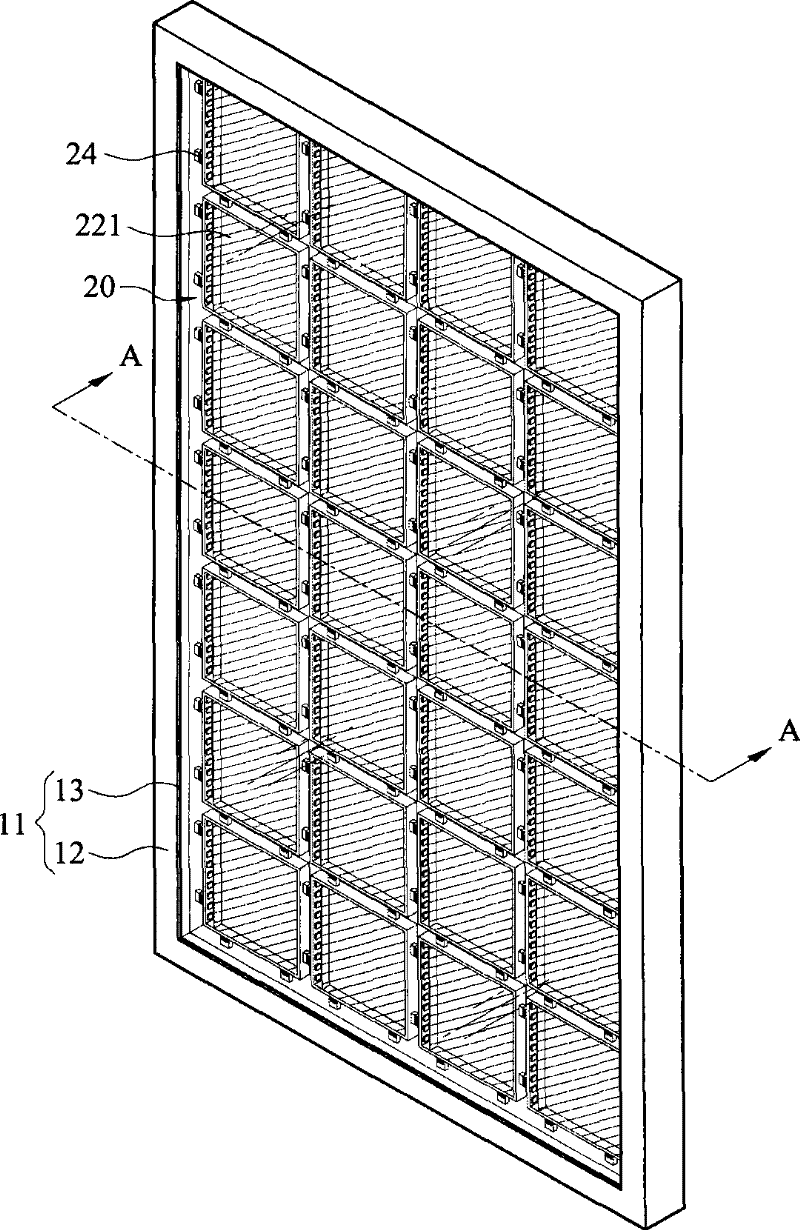

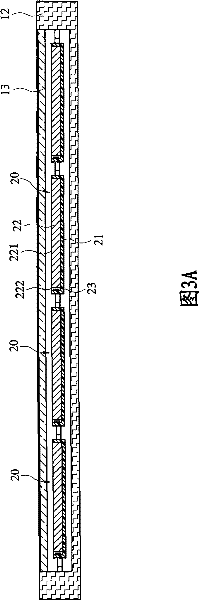

Light box structure with modular light source and modular light source structure thereof

ActiveCN101684928AReduce manufacturing costAvoid inventoryPlanar light sourcesMechanical apparatusLight guideOptical coupling

The invention relates to a light box structure with a modular light source and a modular light source structure thereof, wherein the light box structure comprises a light box body and a plurality of modular light sources. Each modular light source is fixedly arranged in a frame of the light box body and provided with a shell, a light guide plate, a light-emitting unit and a plurality of electrically connecting parts. The light guide plate is combined with the shell, the light-emitting unit is combined in a light incident surface of the light guide plate in an optical coupling mode and the electrically connecting parts are arranged on at least one side of the shell. Light-emitting units of each modular light source are mutually and electrically connected through the electrically connectingpart, thus light sources with various sizes can be formed and used for various advertisement light boxes and the modular light source structure can replace a light source structure with single size. The invention can reduce the using amount of light emitting diodes, is easy to radiate, reduces the manufacturing cost of the light sources, avoids the stock and can enlarge the application range.

Owner:SINOLOGY ENTERPRISE

Method for making light-blocking decorative articles

ActiveUS11181247B2Avoid inventorySimple working processNon-electric lightingPoint-like light sourcePolymer scienceNonwoven fabric

Laminated light-blocking decorative articles are prepared by applying an aqueous foamed opacifying composition to a decorative fabric, drying, laminating a non-woven fabric to the resulting dry foamed opacifying layer, and densifying that layer to have a thickness that is at least 20% less than before densifying. This operation can be carried out so that non-woven fabric, decorative fabric, and aqueous foamed opacifying composition are supplied in a single-pass, in-line operation to make any quantity of laminated light-blocking decorative article. The applied aqueous foamed opacifying composition has 35%-70% solids and a foam density of 0.1-0.5 g / cm3. It is composed of (a) porous particles, (b) a binder material, (c) two or more additives comprising at least one foaming surfactant and at least one foam stabilizer, (d) an aqueous medium, and (e) at least 0.0001 weight % of an opacifying colorant that absorbs electromagnetic radiation having a wavelength of 380-800 nm.

Owner:EASTMAN KODAK CO

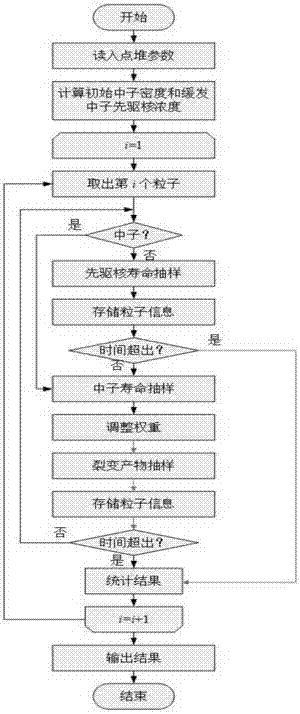

Weighted Monte Carlo calculation method for neutron kinetics

ActiveCN107092732AAvoid the problem of missing countsAvoid inventoryDesign optimisation/simulationSpecial data processing applicationsMonte carlo computationNeutron kinetics

The invention discloses a weighted Monte Carlo calculation method for neutron kinetics. The method comprises the following steps that: 1: establishing an initial particle source library, simulating initial particles, if the initial particles are neutrons, jumping to 2, and if the initial particles are delayed neutron precursors, jumping to 4; 2: sampling time for the neutrons to generate nuclear reaction, if the time exceeds transient process time t, jumping to 5, and otherwise, jumping to 3; 3: sampling to determine a type for the neutron to generate the nuclear reaction, if scattering reaction happens, keeping particle weight to constant, jumping to 2, if adsorption reaction happens, changing the weight of a descendant particle, sampling to determine the existence state of the descendant particle, if the descendant particle is the neutron, jumping to 2, and if the descendant particle is the precursor, jumping to 4; 4: sampling precursor decay time, if the time exceeds the transient process time, jumping to 5, otherwise, changing a particle state into the neutron, and jumping to 3; and 5: carrying out statistics on the contribution of the particle, if particles which are not simulated are still in the presence in the source library, jumping to 1, and otherwise, ending to output a result.

Owner:XI AN JIAOTONG UNIV

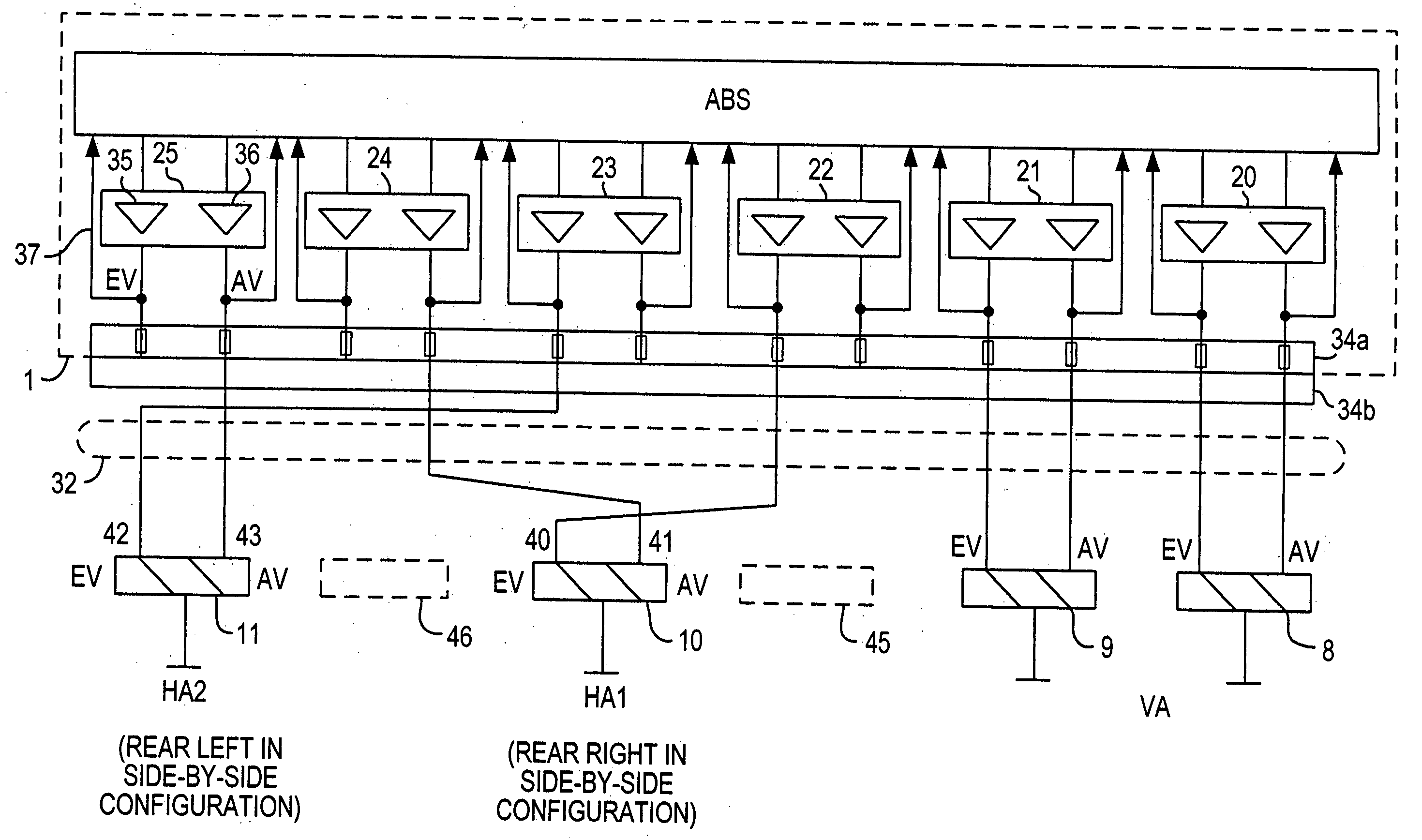

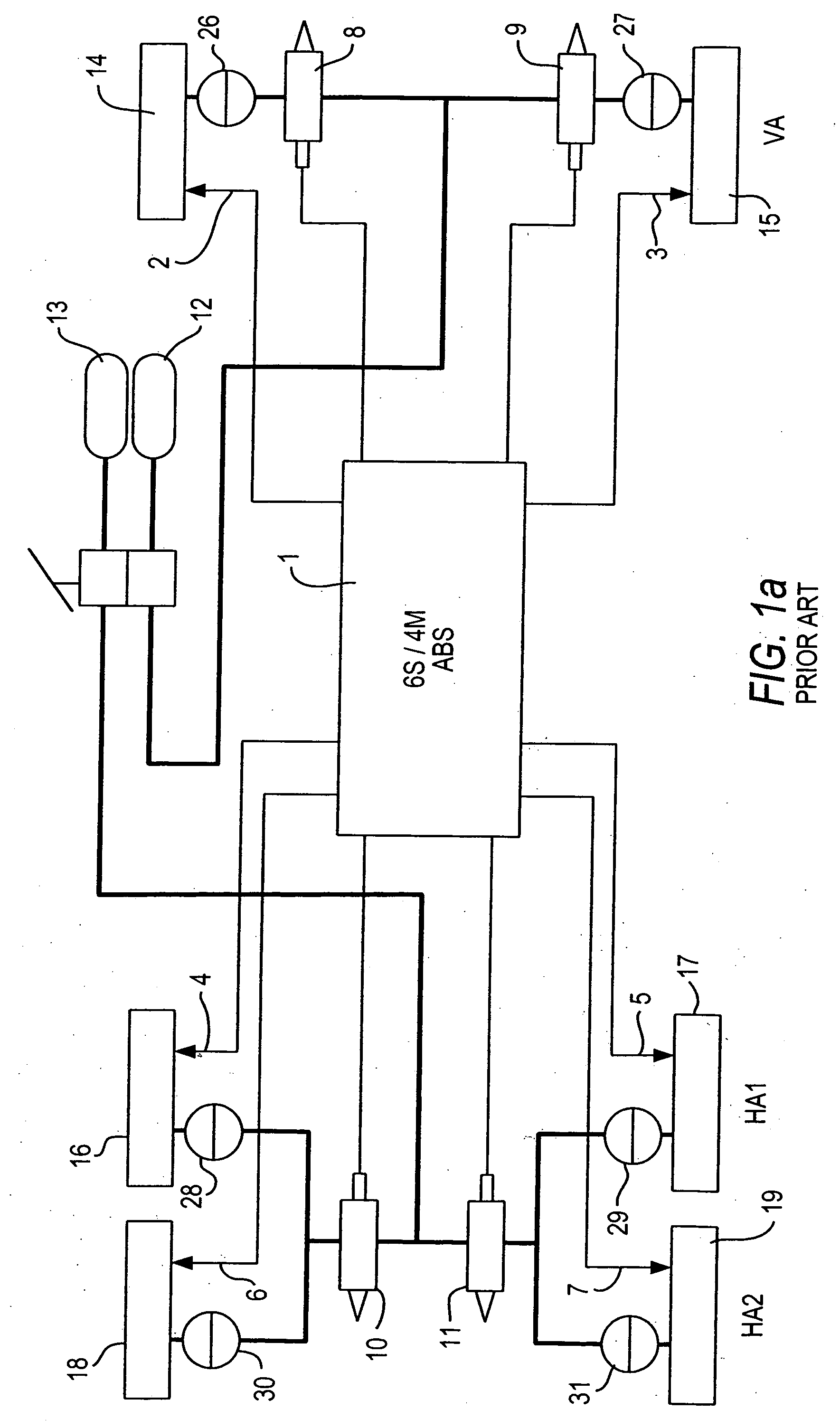

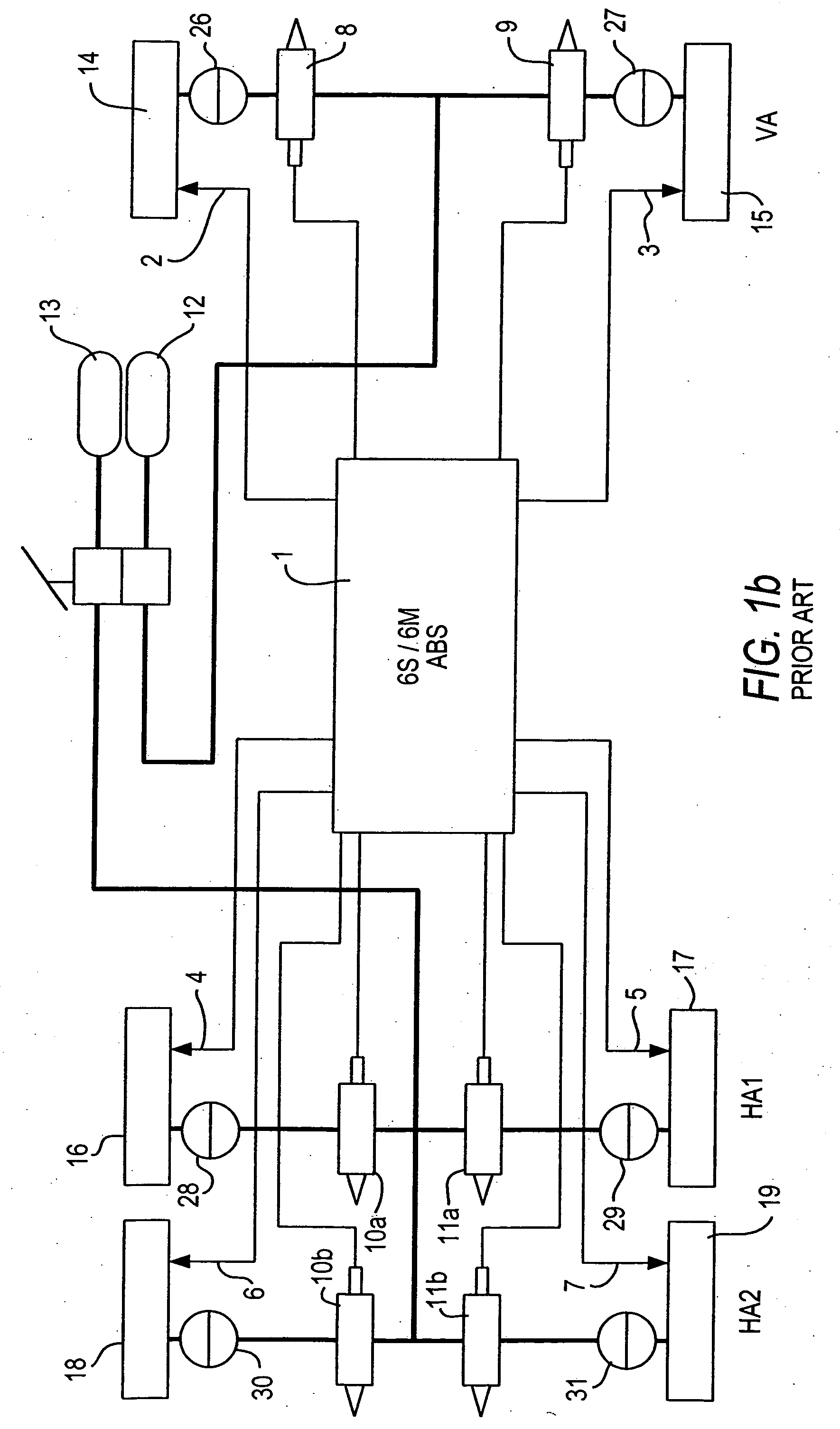

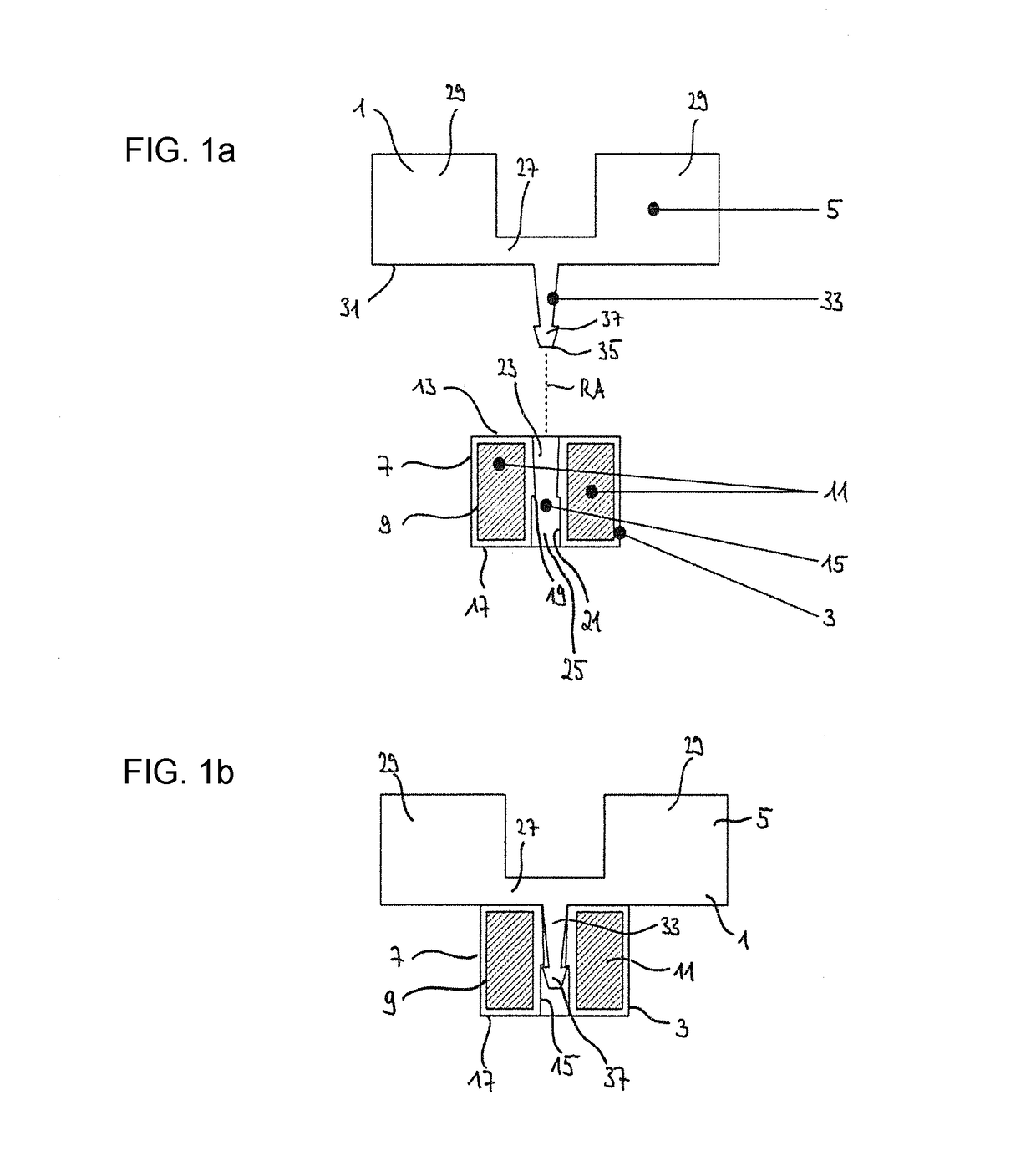

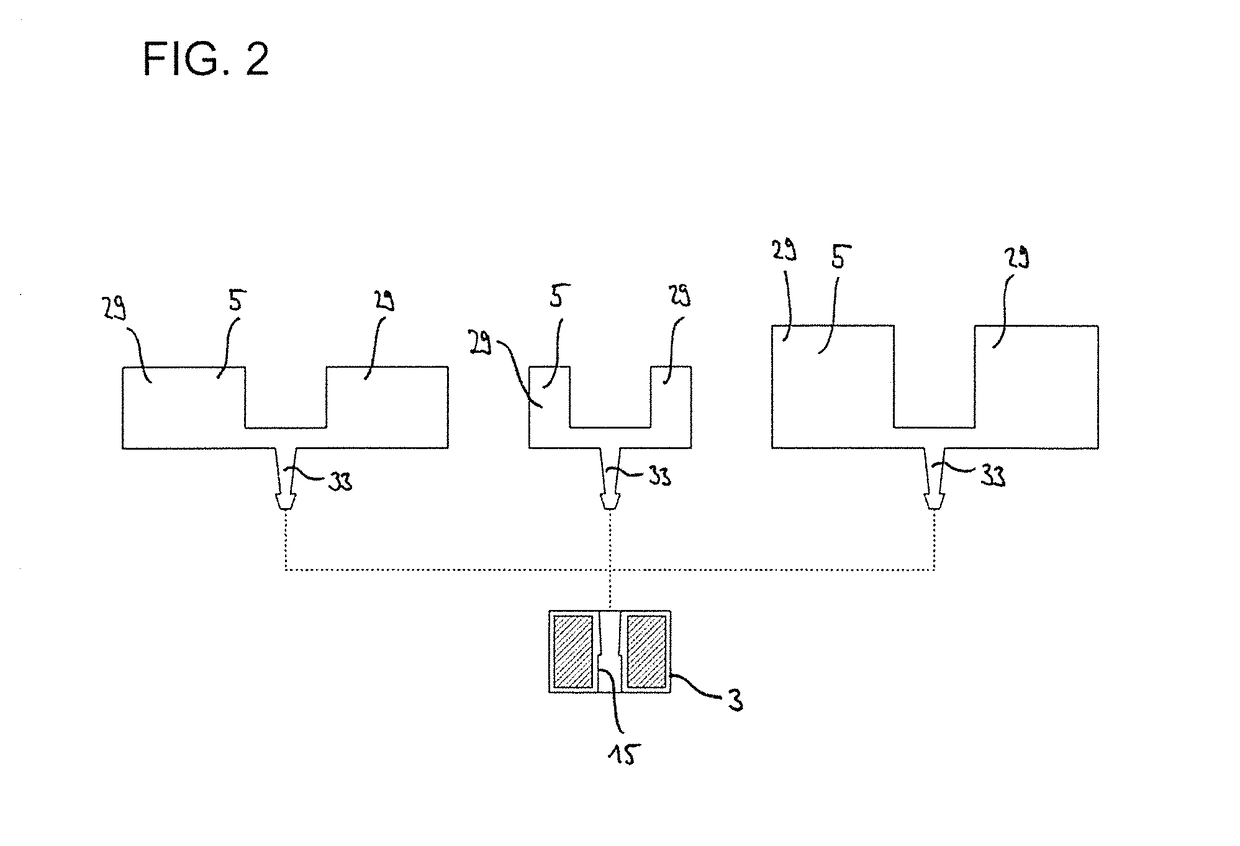

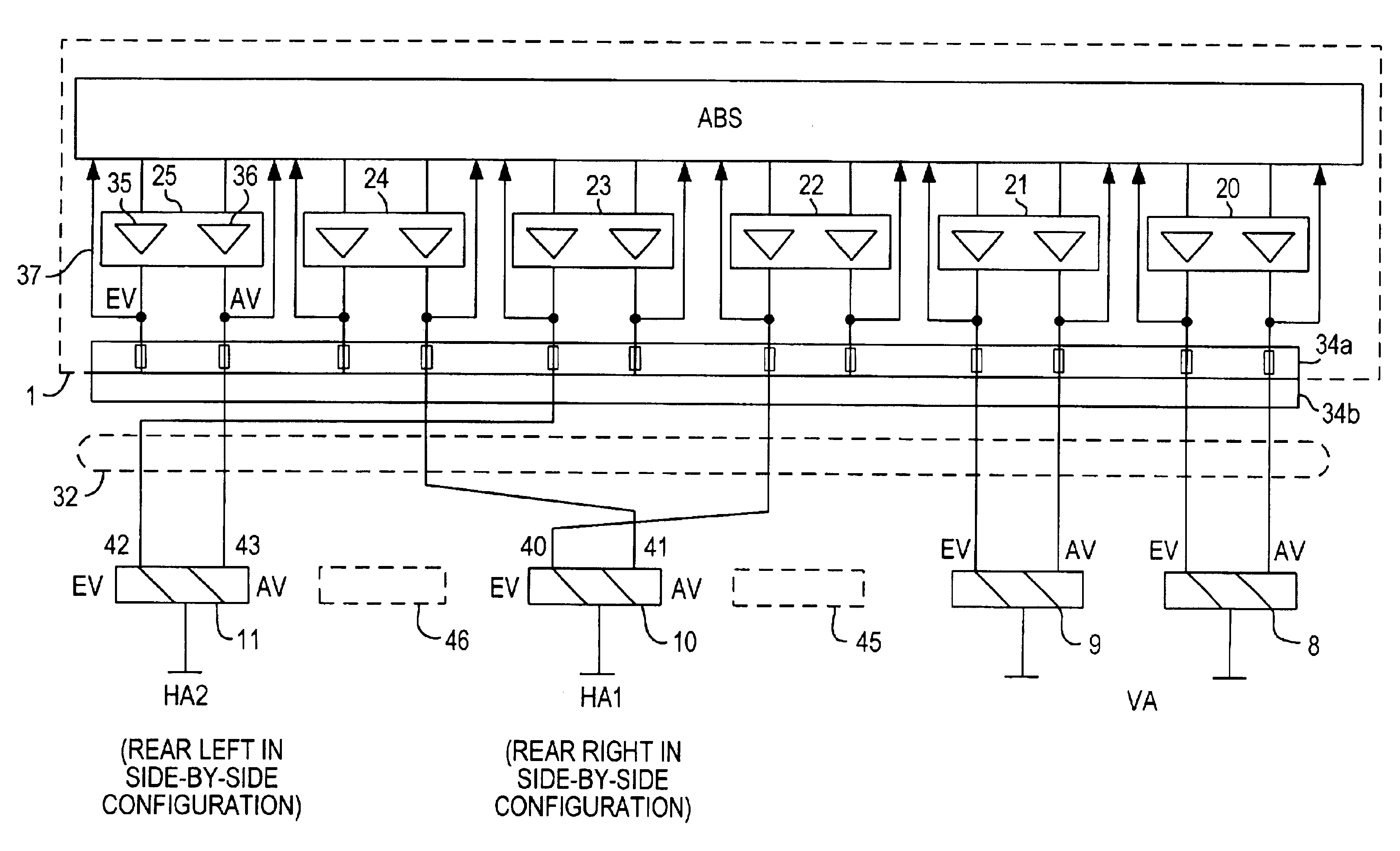

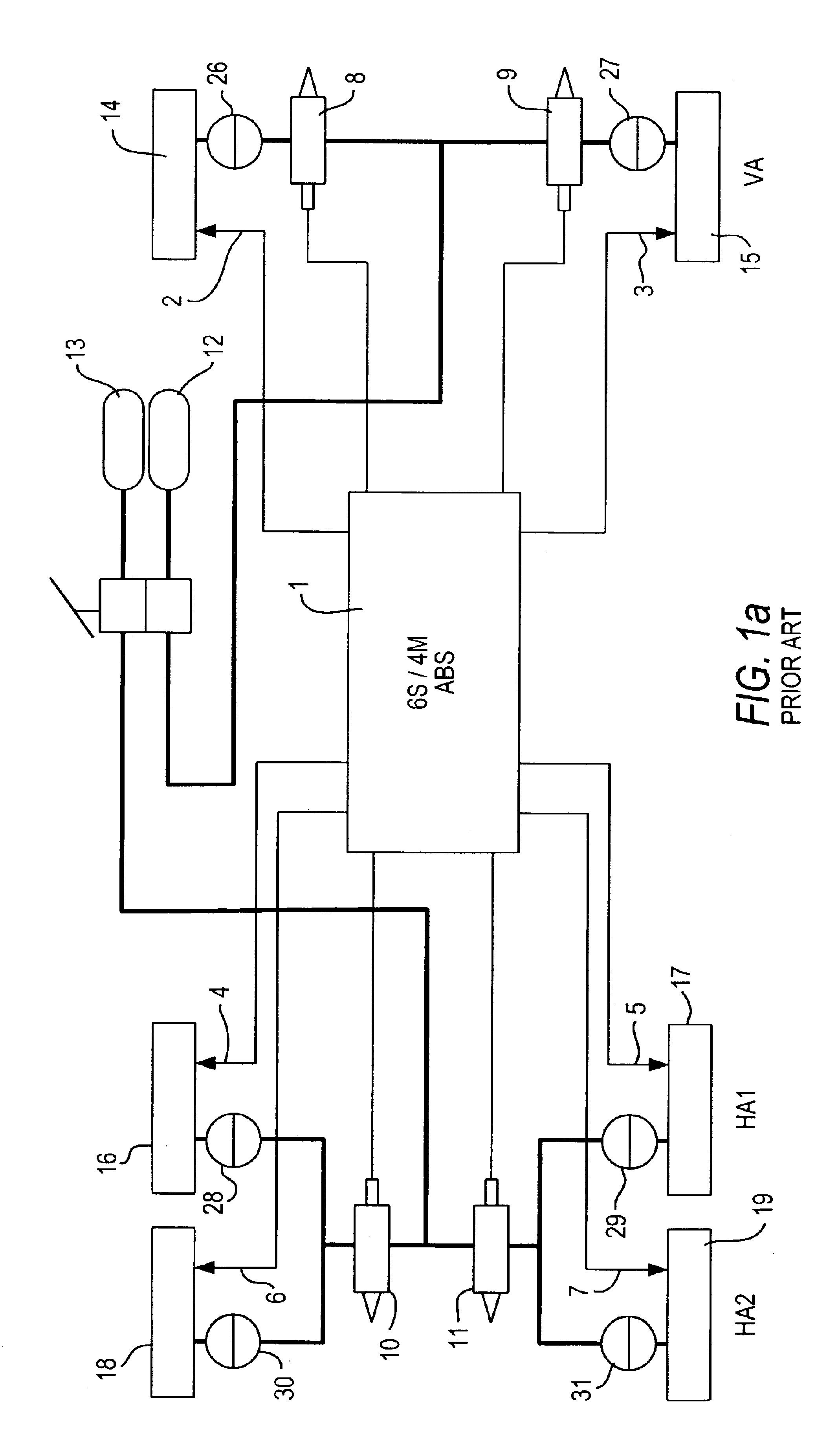

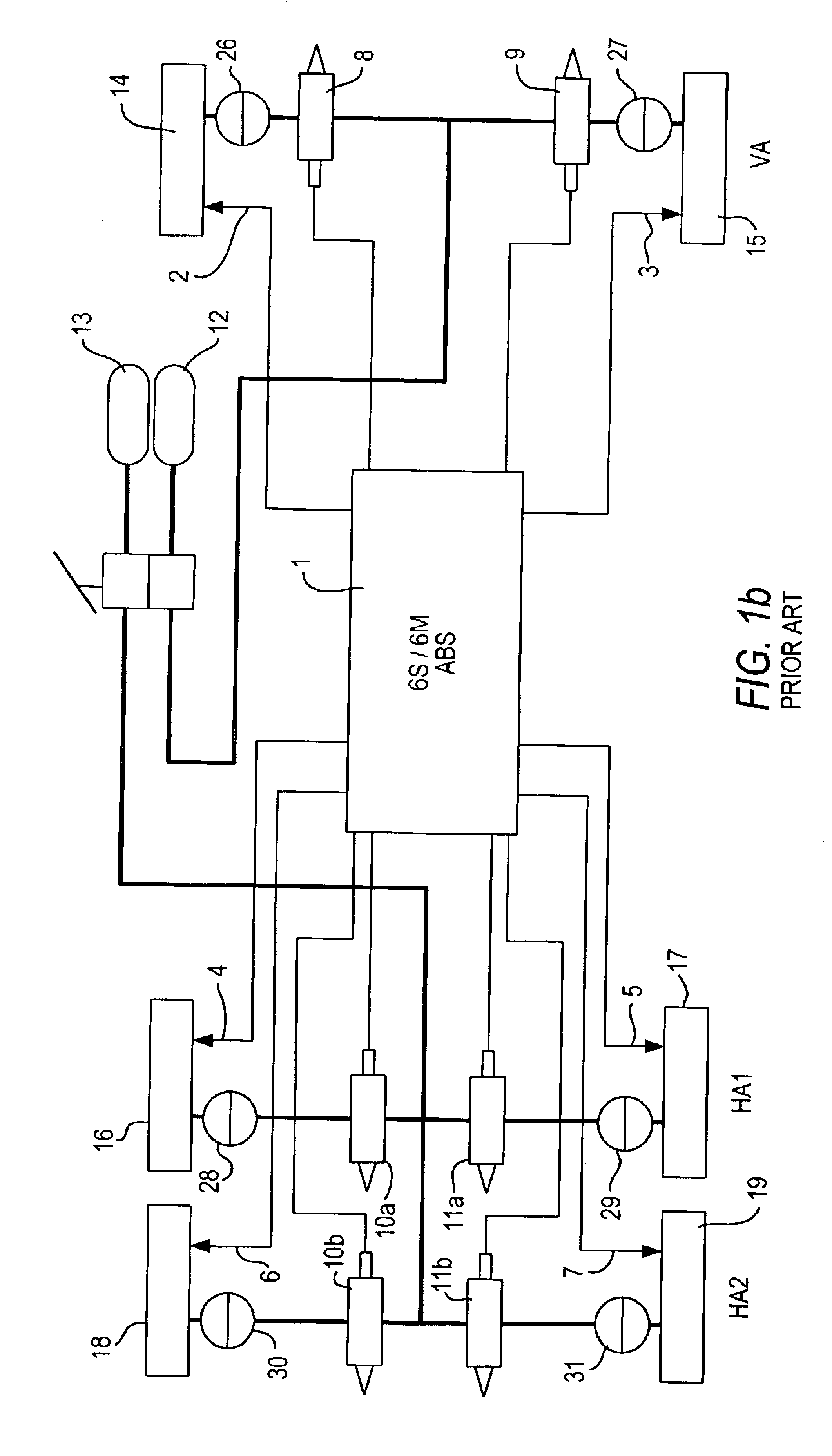

Vehicle anti-lock brake system and method

InactiveUS20050134109A1Low costAvoid inventoryBraking action transmissionApplication and release valvesEnd stagesWheel speed sensor

An anti-lock brake system for a tri-axle wheeled vehicle equipped with wheel speed sensors and modulators for adjusting brake pressure. The modulators are actuated by a six-channel electronic control unit. The modulators associated with the front axle of the vehicle are individually actuated. The modulators associated with the two rear axles of the vehicle are side-by-side or axle modulators, each actuated jointly by respective end stages of the six channels. The electronic control unit detects whether the anti-lock brake system in which it is installed is a compatible anti-lock brake system. An error signal indicating improper installation is delivered.

Owner:WABCO GMBH

Rental return method and apparatus

Owner:NCR CORP

Mixing impeller, method of manufacturing a first subassembly of the mixing impeller and method of assembling the mixing impeller

ActiveUS20170216789A1Reduce manufacturing costAvoid inventoryRotary stirring mixersTransportation and packagingImpellerMagnet

Owner:SARTORIUS STEDIM BIOTECH GMBH

A kind of dyeing method of denim fabric

The invention discloses a dying method of jeans fabric which relates to a pre-spinning dying process of the fiber materials of jeans fabric. The dying process comprises the steps of pretreating, dying and post-treating steps. The fiber materials of the jeans fabric is the high strength low stretch viscose fiber with dry breaking strength of 2.8 to 3.1 CN / DTEX and dry elongation rate of 11% to 15%. The method provided by the invention is the dying process of the fiber materials for the jeans fabric manufacturing which uses the high strength low stretch viscose fiber with dry breaking strength of 2.8 to 3.1 CN / DTEX and dry elongation rate of 11% to 15% as the fiber materials. The materials undergo the fiber dying process and spinning process and the like to become the jeans fabric. The method is helpful to solve the problems of low yielding rate and non-fulfillment of environment protection requirements which at present is prevailing in the prior art of jeans fabrics manufacturing process. The method can be widely applied and promoted.

Owner:YIBIN SPARK NEW FIBER CO LTD

Jeans fabric and dying method thereof

The invention discloses a dying method of jeans fabric which relates to a pre-spinning dying process of the fiber materials of jeans fabric. The dying process comprises the steps of pretreating, dying and post-treating steps. The fiber materials of the jeans fabric is the high strength low stretch viscose fiber with dry breaking strength of 2.8 to 3.1 CN / DTEX and dry elongation rate of 11% to 15%. The method provided by the invention is the dying process of the fiber materials for the jeans fabric manufacturing which uses the high strength low stretch viscose fiber with dry breaking strength of 2.8 to 3.1 CN / DTEX and dry elongation rate of 11% to 15% as the fiber materials. The materials undergo the fiber dying process and spinning process and the like to become the jeans fabric. The method is helpful to solve the problems of low yielding rate and non-fulfillment of environment protection requirements which at present is prevailing in the prior art of jeans fabrics manufacturing process. The method can be widely applied and promoted.

Owner:YIBIN SPARK NEW FIBER CO LTD

Vehicle anti-lock brake system and method

InactiveUS6935707B2Low costAvoid inventoryDigital data processing detailsAutomatic initiationsEnd stagesWheel speed sensor

An anti-lock brake system for a tri-axle wheeled vehicle equipped with wheel speed sensors and modulators for adjusting brake pressure. The modulators are actuated by a six-channel electronic control unit. The modulators associated with the front axle of the vehicle are individually actuated. The modulators associated with the two rear axles of the vehicle are side-by-side or axle modulators, each actuated jointly by respective end stages of the six channels. The electronic control unit detects whether the anti-lock brake system in which it is installed is a compatible anti-lock brake system. An error signal indicating improper installation is delivered.

Owner:WABCO GMBH

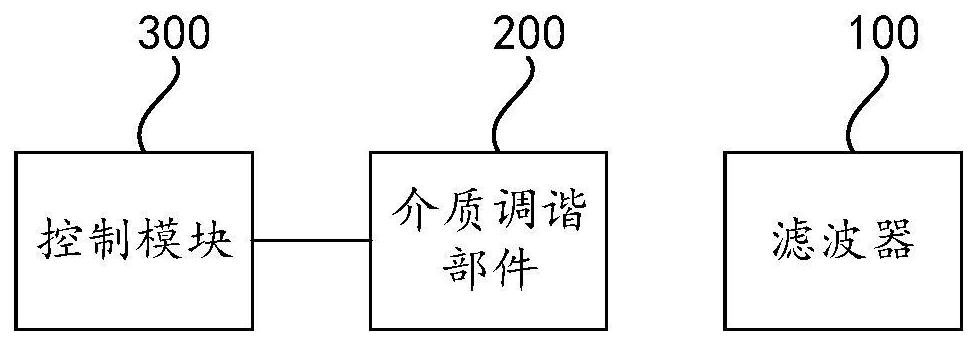

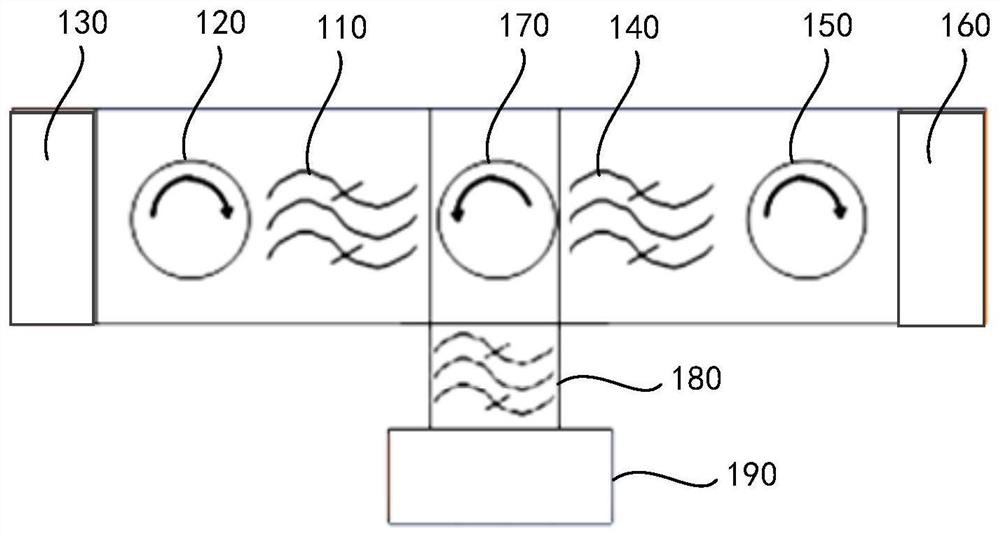

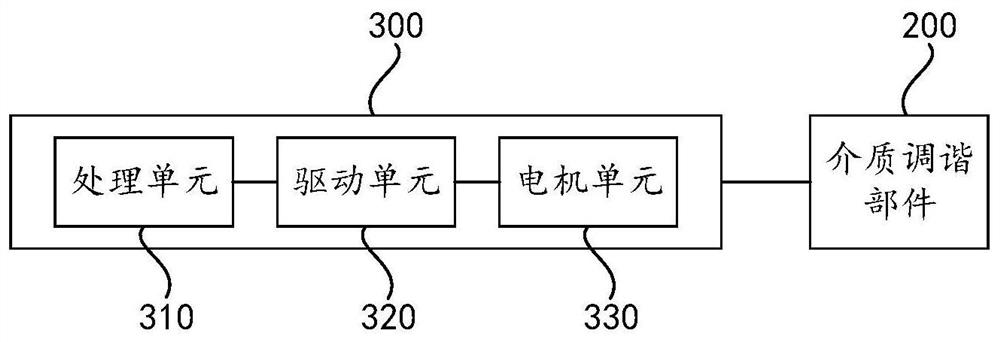

Duplexer, network equipment, control method, electronic equipment and storage medium

PendingCN114079439AAdjust working frequencyIncrease flexibilityActive element networkWaveguide type devicesControl theoryOperating frequency

The invention discloses a duplexer, network equipment, a control method, electronic equipment and a storage medium, and belongs to the technical field of communication. The duplexer includes: a filter; a dielectric tuning component; and a control module which is connected with the dielectric tuning component and is used for controlling the relative position of the dielectric tuning component and the filter so as to adjust the working frequency of the duplexer. According to the duplexer, the relative position of the dielectric tuning component and the filter is controlled, and the reactance parameter of the equivalent circuit of the filter is changed, so that the attribute parameter of the filter is changed, and the purpose of adjusting the working frequency of the duplexer is achieved. When a diplexer with various frequencies is needed, the flexibility and the application range of the diplexer can be improved by adjusting the relative position of the dielectric tuning component and the filter and adjusting the working frequency of the diplexer, so that the problem that a certain amount of diplexer spare part inventory needs to be prepared for different sub-bands is avoided, and the inventory pressure of manufacturers is reduced.

Owner:ZTE CORP

Automatic loading system used in shopping mall

ActiveCN112079029AHigh degree of automationReduce volumeStorage devicesReal-time computingSystems engineering

The invention discloses an automatic loading system used in a shopping mall. The system comprises a cargo carrying robot, wherein the cargo carrying robot takes out cargoes from a storage shelf of a warehouse, and then the cargo carrying robot conveys the cargoes to a selling shelf of a shopping mall selling place; and corresponding codes are arranged on each cargo placement position of the storage shelf and the selling shelf, guide sensors of a running route of the cargo carrying robot are buried under the ground between the storage shelf and the selling shelf, cargo remaining state monitoring sensors are arranged on the storage shelf and the selling shelf respectively, the cargo carrying robot is wirelessly connected with a shopping mall central controller through a wireless communication module, and the shopping mall central controller is further connected with the monitoring sensors and the guide sensors respectively. The automatic loading system used in the shopping mall has the advantages that the automation degree is high, the size of the selling shelf can be reduced, the occupied area of the shelf in the shopping mall is saved, commodities on the shelf are fresh and sufficient, and salesmen are saved.

Owner:北京多采多宜网络科技有限公司

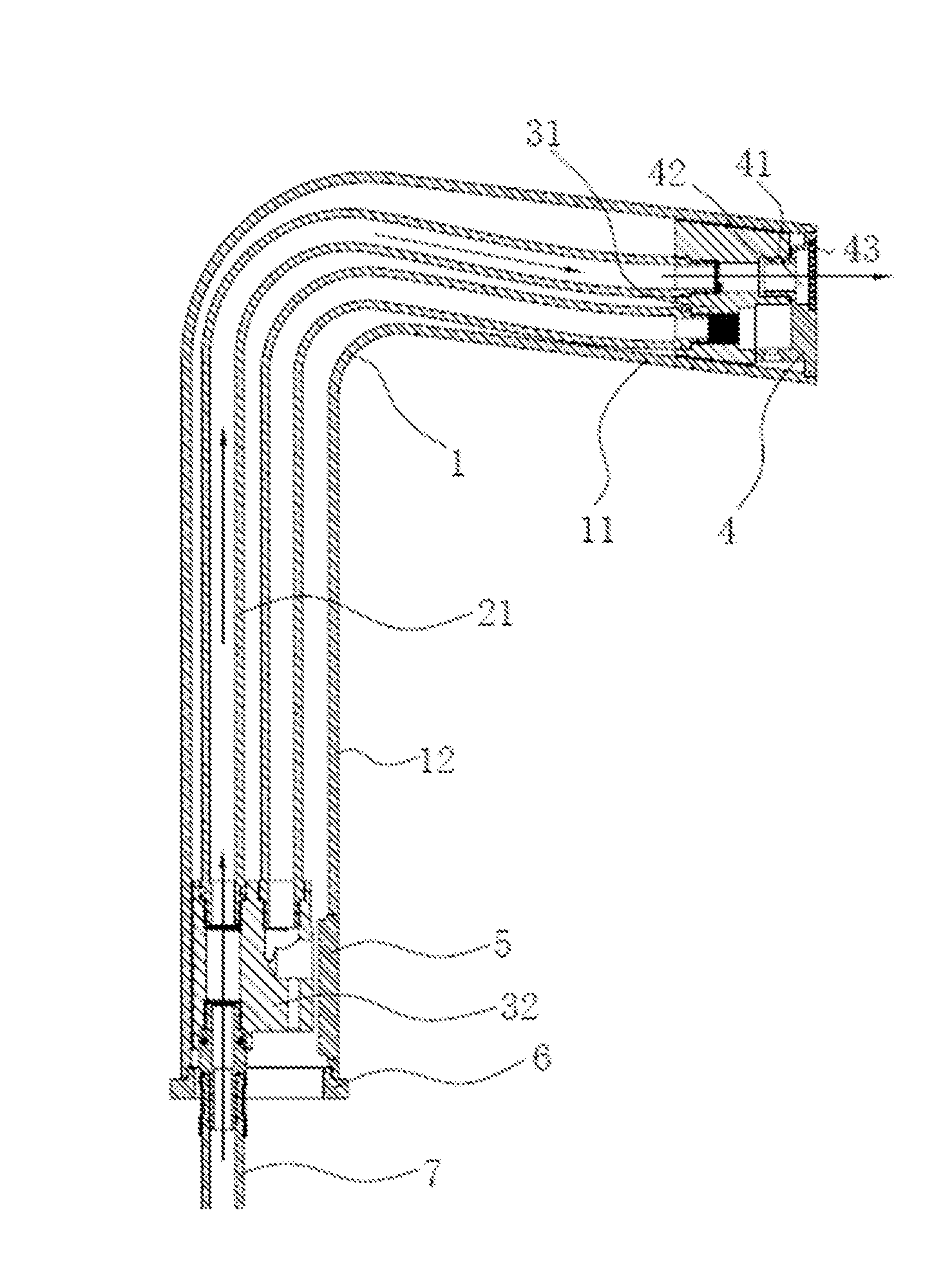

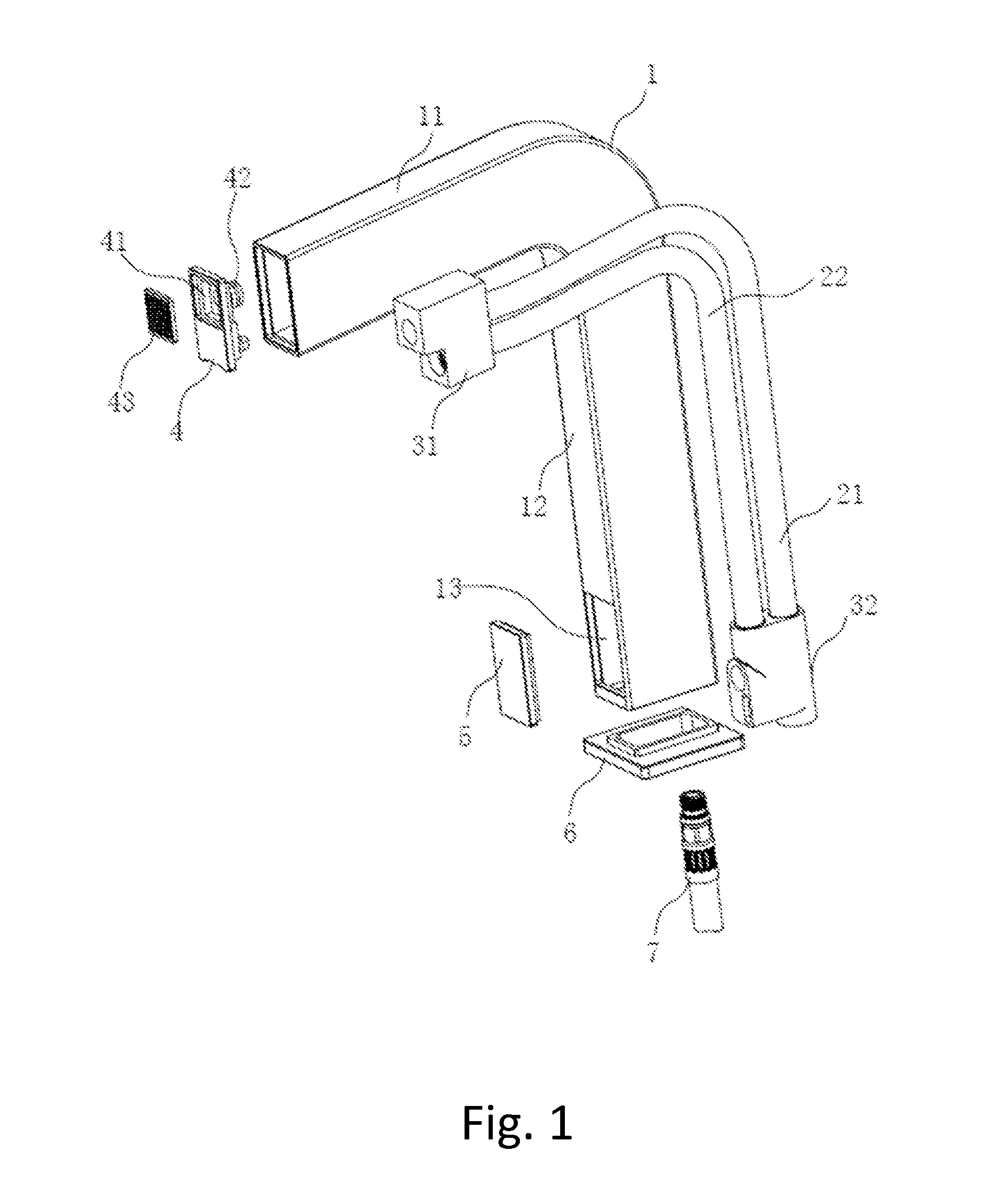

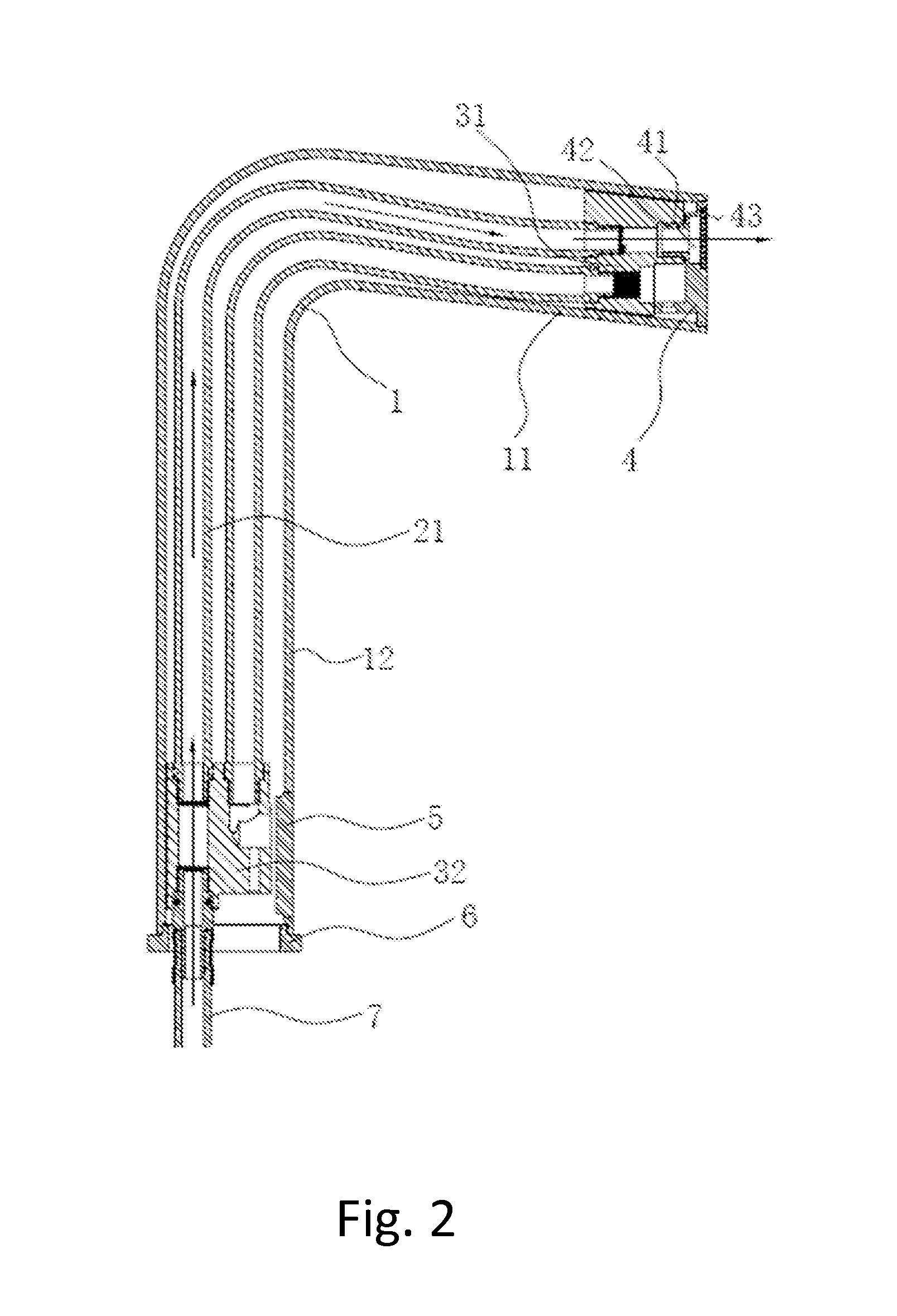

Faucet Water Output Structure

InactiveUS20150345117A1Saving and convenienceFast and convenient mannerServomotor componentsDomestic plumbingEngineering

A faucet water output structure includes an L shape housing including a short tube and a long tube, wherein one end of the short tube is connected to one of the long tube, and on a wall of other end of the long tube is provided with an opening; a first water passage channel and a second water passage channel, both of which are located inside the L shape housing; and a first water route interface and a second water route interface, wherein, on the first water route interface is sleeved a water output end of the first water passage channel and a water input end of the second water passage channel, and on the second water route interface is sleeved a water input end of the first water passage channel and a water output end of the second water passage channel.

Owner:XIAMEN RUNNER IND CORP

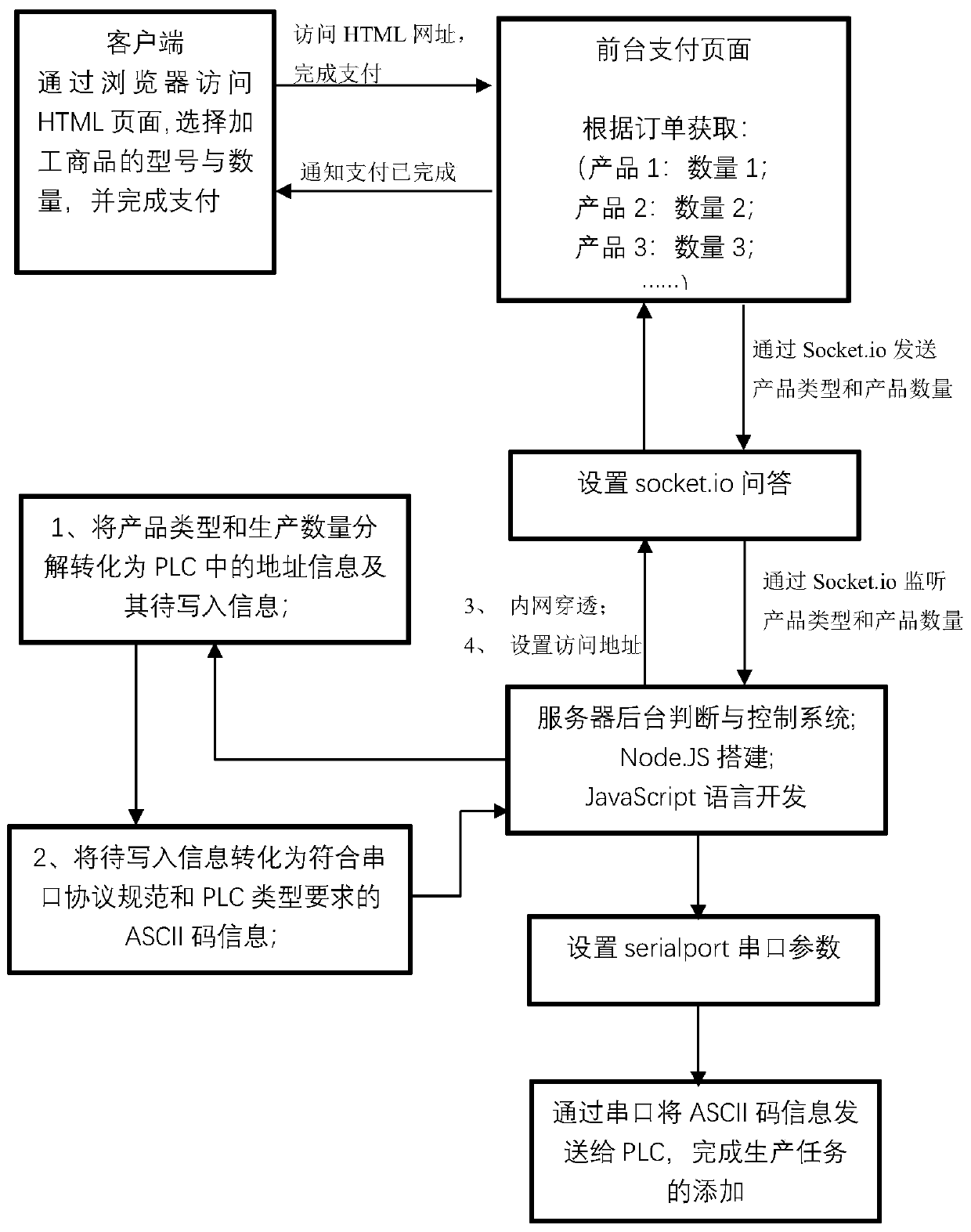

Small online processing production line controlling method and system

InactiveCN110209108ASolve the problem that real-time order response cannot be achievedAvoid inventoryProgramme control in sequence/logic controllersASCIIProduct processing

The invention discloses a small online processing production line controlling method and system. The method comprises the steps of accessing an HTML (Hypertext Markup Language) payment website serverof an intranet through a public network and a link address by a client to carry out online product selection and payment and realizing the conversion between the public network and the intranet through route setting of the link address and related software; analyzing a callback function of an HTML payment website of the intranet to judge the validity of payment information and screening out validpayment information to obtain ordinary string information comprising product processing data; and decomposing the ordinary string information comprising the product processing data into ASCII (American Standard Code For Information Interchange) code strings and reorganizing the decomposed ASCII code strings according to a corresponding communication protocol to obtain reorganized ASCII code strings; and converting the reorganized ASCII code strings into a ladder diagram program of a PLC (Programmable Logic Controller), sending to the PLC to complete the processing of a corresponding order according to the ladder diagram program of the PLC through the PLC of a small online processing production line, thereby realizing the real-time processing of online orders and the synchronous completionof processing tasks of automatic production lines.

Owner:武汉软件工程职业学院

Method for making light-blocking decorative articles

ActiveUS20210190289A1Soft touchAvoid lightNon-electric lightingPoint-like light sourcePolymer scienceNonwoven fabric

Laminated light-blocking decorative articles are prepared by applying an aqueous foamed opacifying composition to a decorative fabric, drying, laminating a non-woven fabric to the resulting dry foamed opacifying layer, and densifying that layer to have a thickness that is at least 20% less than before densifying. This operation can be carried out so that non-woven fabric, decorative fabric, and aqueous foamed opacifying composition are supplied in a single-pass, in-line operation to make any quantity of laminated light-blocking decorative article. The applied aqueous foamed opacifying composition has 35%-70% solids and a foam density of 0.1-0.5 g / cm3. It is composed of (a) porous particles, (b) a binder material, (c) two or more additives comprising at least one foaming surfactant and at least one foam stabilizer, (d) an aqueous medium, and (e) at least 0.0001 weight % of an opacifying colorant that absorbs electromagnetic radiation having a wavelength of 380-800 nm.

Owner:EASTMAN KODAK CO

Pier bridge style screw system for vertebral arch pedicle

InactiveCN1193712CImprove stabilityReduce the probability of looseningInternal osteosythesisFastenersScrew systemEngineering

An internal fixator for vertebral arch pedicle is composed of several cylindrical correcting rods, flat square transverse bridge, and several screws for vertebral arch pedicle. Said screw has a screw bolt with external spiral thread on its lower part, and an expanded head with a U-shaped deep slot for recepting said correcting rod and shallow square slots on both side surfaces for recepting said transverse bridges.

Owner:NANJING GENERAL HOSPITAL NANJING MILLITARY COMMAND P L A

Dyeing method for preparing jean fabric from cotton fiber

ActiveCN106337289AHigh coloring rateImprove pass rateBiochemical treatment with enzymes/microorganismsDyeing processCotton fibreEngineering

The invention discloses a dyeing method for preparing a jean fabric from cotton fiber. The method includes the process for dyeing oxygen-bleached cotton fiber before spinning. The dyeing process includes the steps of preprocessing, dyeing and post-processing. By means of the method, in the preparation process of the jean fabric with the cotton fiber as the raw material, the oxygen-bleached cotton fiber is dyed, the jean fabric is prepared through spinning and other procedures after the oxygen-bleached cotton fiber is dyed through a fiber dyeing method, the problems that in the jean fabric production process, the yield is low and environment protection does not reach the standard are solved easily, and the method is suitable for wide use and popularization.

Owner:YIBIN SPARK NEW FIBER CO LTD

A kind of method for preparing denim fabric

ActiveCN106222906BNo impuritiesEasy to shapeDyeing processLiquid/gas/vapor yarns/filaments treatmentBreaking strengthEngineering

Owner:YIBIN SPARK NEW FIBER CO LTD

Light box structure with modular light source and modular light source structure thereof

ActiveCN101684928BReduce manufacturing costAvoid inventoryPlanar light sourcesMechanical apparatusLight guideEngineering

The invention relates to a light box structure with a modular light source and a modular light source structure thereof, wherein the light box structure comprises a light box body and a plurality of modular light sources. Each modular light source is fixedly arranged in a frame of the light box body and provided with a shell, a light guide plate, a light-emitting unit and a plurality of electrically connecting parts. The light guide plate is combined with the shell, the light-emitting unit is combined in a light incident surface of the light guide plate in an optical coupling mode and the electrically connecting parts are arranged on at least one side of the shell. Light-emitting units of each modular light source are mutually and electrically connected through the electrically connectingpart, thus light sources with various sizes can be formed and used for various advertisement light boxes and the modular light source structure can replace a light source structure with single size. The invention can reduce the using amount of light emitting diodes, is easy to radiate, reduces the manufacturing cost of the light sources, avoids the stock and can enlarge the application range.

Owner:SINOLOGY ENTERPRISE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com