Elevator

An elevator and elevator car technology, which is applied in the field of elevator speed monitoring, can solve the problems such as the deterioration of the coating performance of the lifting rope, the deterioration of the coating performance of the traction sheave, the insufficient grease of the steel wire rope, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

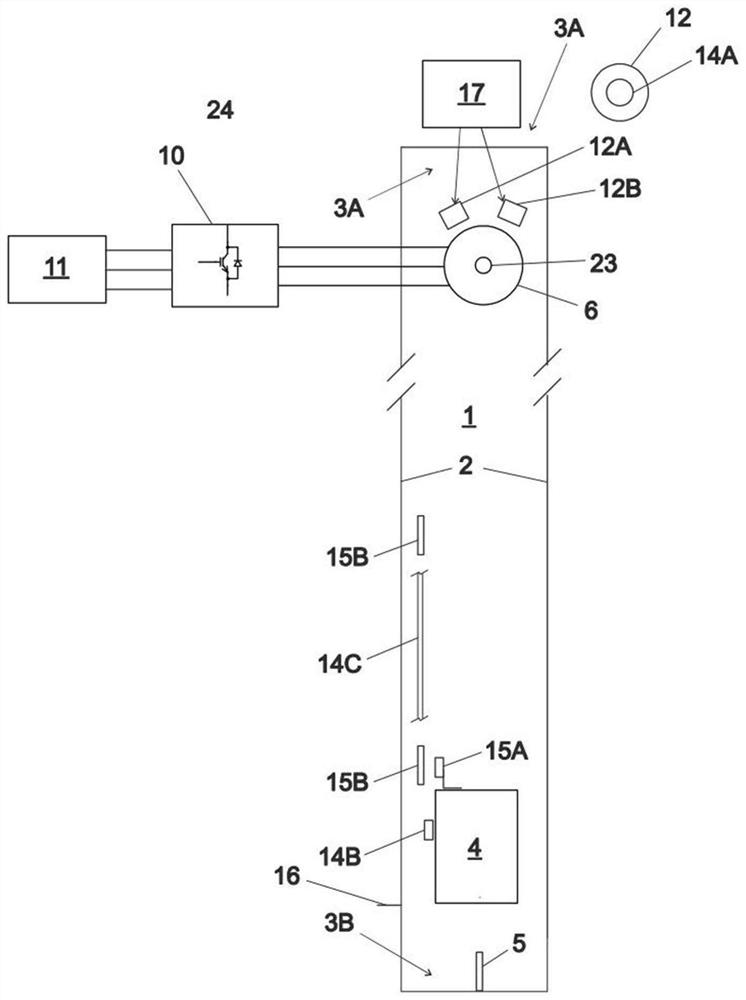

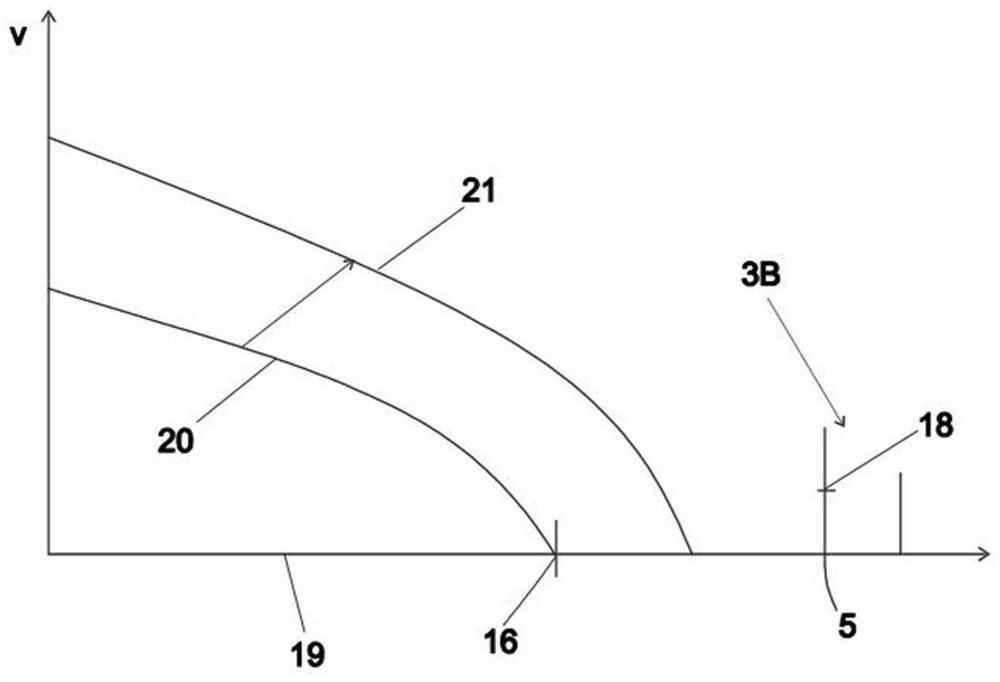

[0029] The following description illustrates a solution for monitoring the movement of the elevator car near the end of the elevator shaft. In the event of failure of the elevator car to decelerate, an emergency stop can be performed to bring the elevator into a safe state. The solution can constitute an ETSL (Emergency Terminal Speed Limiter) safety function as required by the Lift Safety Regulations (EN 81-20 2014 para 5.12.1.3; A17.1 2016 para 2.25.4.1).

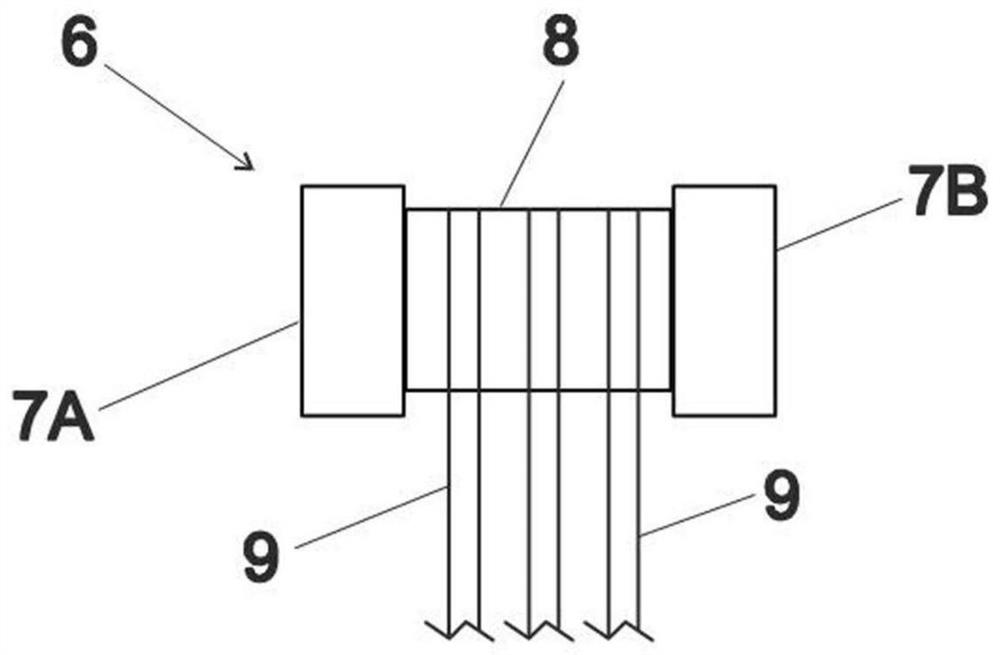

[0030] Figure 1A An elevator is shown with an elevator car 4 and a counterweight arranged to move vertically in an elevator shaft 1 consisting of a surrounding wall 25 and a top end 3A and a bottom end 3B limited. The elevator comprises a hoist 6 comprising a traction sheave 8 . The hoisting ropes 9 of the elevator car 4 engage with and run through the traction sheave 8 . The hoisting rope 9 can be a round rope or a belt. Their load-bearing parts can be made of steel and / or synthetic fibers, such as glass fibers or c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com