Light salt brine concentration system and process

A concentration system and light brine technology, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of high energy consumption in the evaporation and crystallization process, achieve less public works, less total project investment, running smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

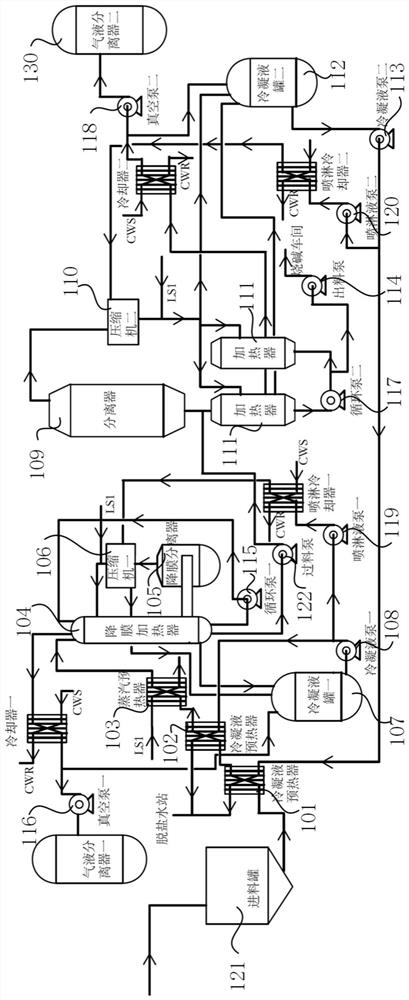

[0028] Embodiment 1, a kind of light brine concentration system of the present embodiment, refer to figure 1 As shown, it includes: a first condensate preheater 101, a second condensate preheater 102, a steam heat exchanger 103, a falling film heater 104, a falling film separator 105, a first compressor 106, a first condensing Liquid tank 107, first condensate pump 108, forced circulation separator 109, second compressor 110, second stage heater 111, second condensate tank 112, second condensate pump 113, discharge pump 114, first A circulation pump 115 , a first vacuum pump 116 , a second circulation pump 117 , a second vacuum pump 118 , a first spray pump 119 , a second spray pump 120 , a feed tank 121 , and a feed pump 122 .

[0029] The connection relationship and workflow of the above devices are as follows:

[0030]The dechlorinated light brine from caustic soda first enters the feed tank 121 and is transported to a number of equipment for evaporation. The feed liquid ...

Embodiment 2

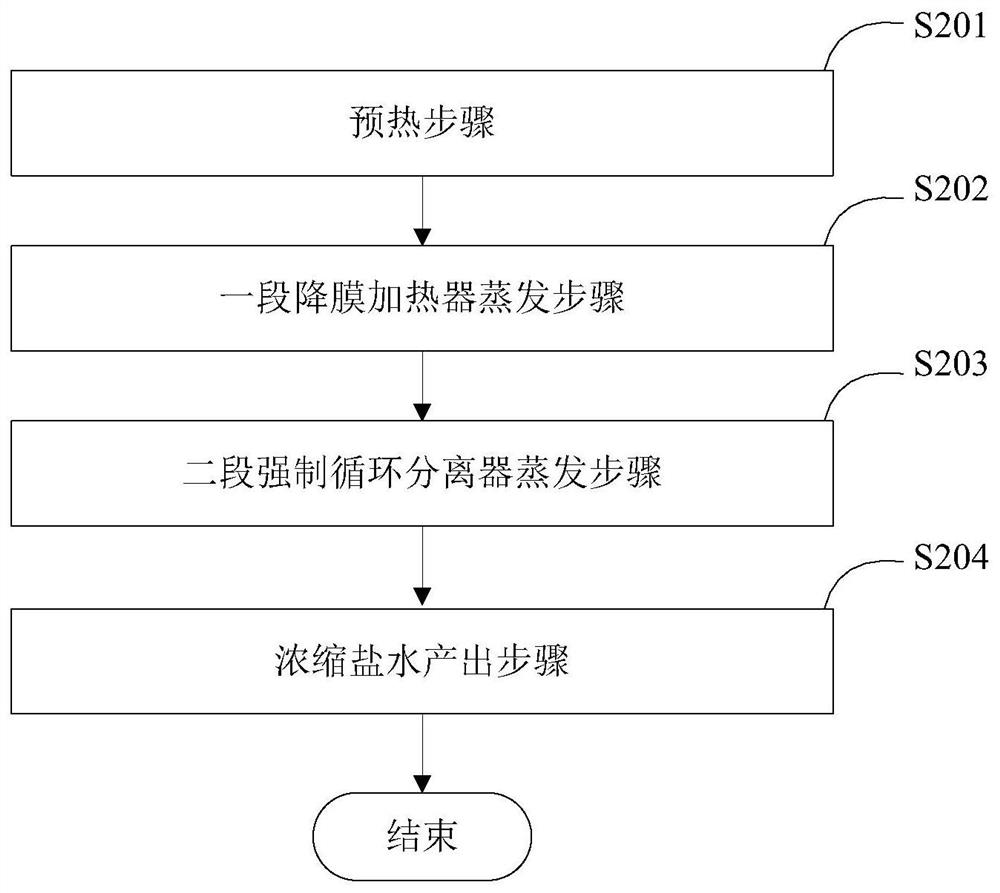

[0057] Embodiment 2, the light brine concentration process of this embodiment is implemented by using the light brine concentration system of the above embodiment, see figure 2 shown, including the following main steps:

[0058] S201, preheating step

[0059] After the feed liquid is preheated, it enters the falling film heater.

[0060] S202, step of evaporating a falling film heater

[0061] The feed liquid is evaporated in the falling film heater, and after separation, the first section of secondary steam and the first section of concentrated liquid are generated; the first section of secondary steam is compressed; the compressed first section The secondary steam heats the feed liquid; during the heating process, the secondary steam condenses into water in the first stage, and the condensed water participates in the preheating of the feed liquid.

[0062] S203. Second-stage forced circulation separator evaporation step

[0063] The first-stage concentrated liquid enter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap