Rotor blade for wind turbine

A technology of wind turbines and rotor blades, applied to wind power engines, wind power generators consistent with the wind direction, engines, etc., can solve the problems of production and transportation of rotor blades, achieve easy alignment and assembly, simplify transportation and transportation, The effect of a mechanically secure connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] figure 1 An inventive wind turbine 1 is shown comprising a tower 2 together with a nacelle 3 and a hub 4 where in this embodiment three inventive rotor blades 5 are attached. As is well known, the rotor blades 5 interact with the wind, causing the hub 4 to rotate. This rotation drives a generator arranged in the nacelle 3 for generating electrical energy.

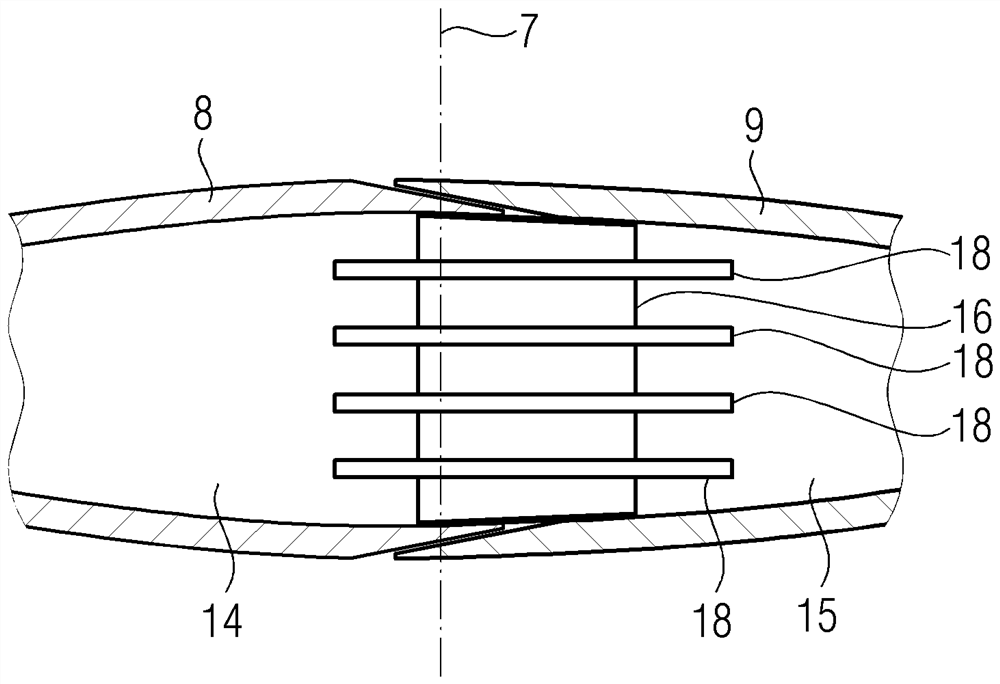

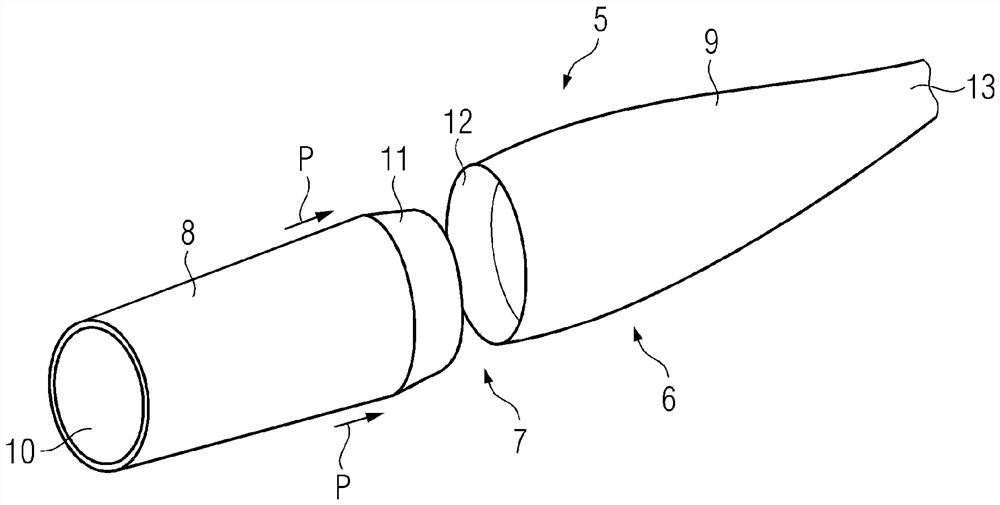

[0028] figure 2 A schematic sketch is shown in the form of an exploded view of a rotor blade 5 according to the first embodiment. In the following, a number of embodiments are described. The same reference numerals will be used for the same or comparable parts of the corresponding embodiments.

[0029] Such as figure 2 The rotor blade 5 shown in comprises a hollow blade body 6 which is divided along a division plane 7 into two body parts 8, 9 which, as indicated by the arrow P, can be pushed into in or connected to each other. The first blade body 8 extends from the root 10 to the first connection section 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com