A kind of steel bar on-site detector for project management

A technology of engineering management and detectors, applied in the field of detectors, can solve problems such as heavy, troublesome, and difficult to align with the center of the circle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

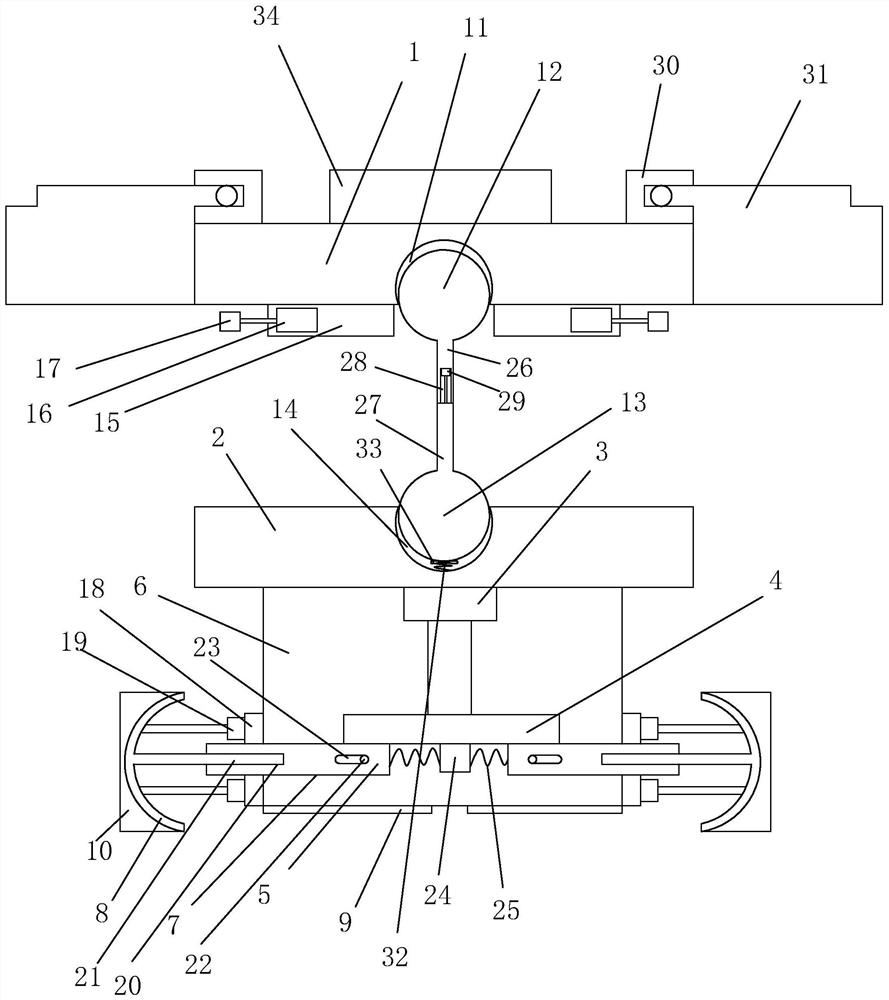

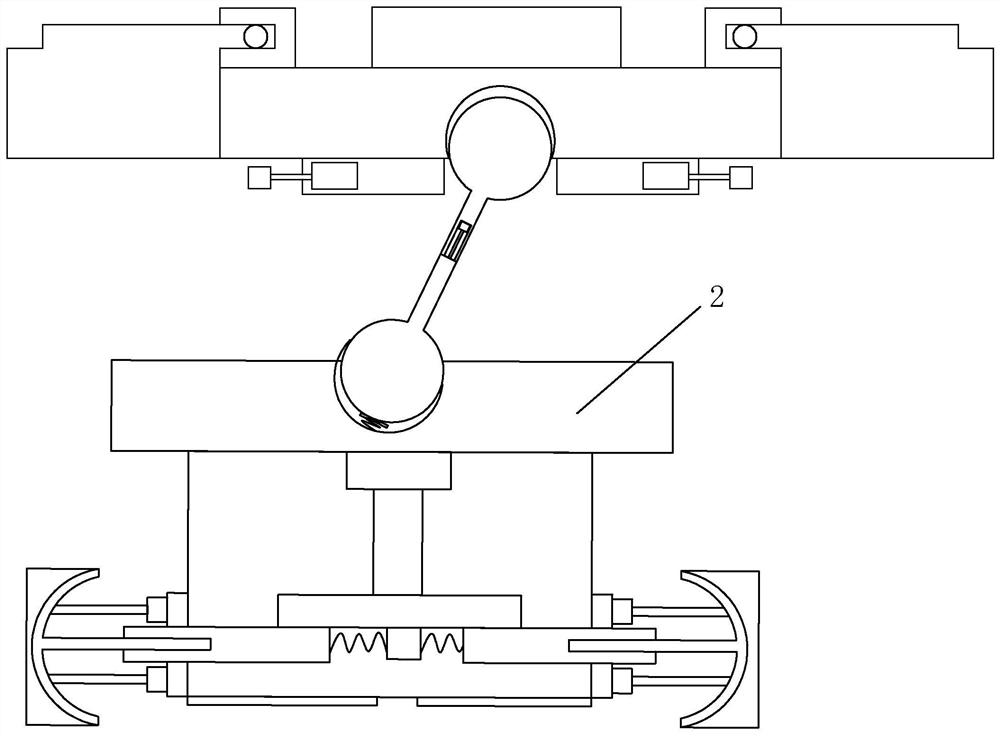

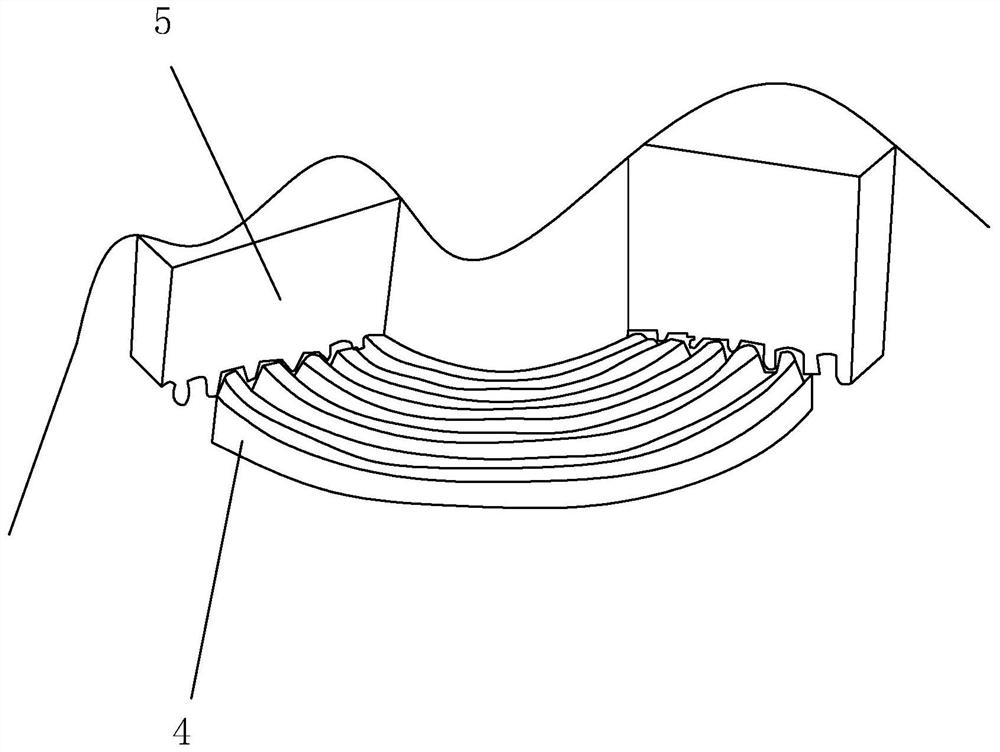

[0026] The present invention will be further described with reference to the accompanying drawings.

[0027] A steel bar field detector for engineering management, such as Figure 1-Figure 3As shown, a first positioning plate 1 is included, a second positioning plate 2 is connected under the first positioning plate 1, a rotating motor 3 is arranged on one side of the second positioning plate 2, and a rotating motor 3 is connected to the rotating motor 3. Drive disc 4, one side of the drive disc 4 is integrally connected with thread stripes, one side of the drive disc 4 is provided with three drive blocks 5 matching the thread stripes, and the three drive blocks 5 are connected to the drive disc 4 The center of the symmetrical distribution, the second positioning plate 2 is connected with the third positioning plate 6 sleeved on the outside of the driving disk 4, the third positioning plate 6 is provided with a driving slot 7 for driving the block 5 to move, the driving One si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com