Multi-degree-of-freedom macro-micro driving platform for testing mechanical properties of irregular cartilage surface

A technology with a degree of freedom and irregularity, which is applied in the direction of testing material hardness, testing wear resistance, measuring devices, etc., can solve the problems of large size limitation, difficulty in clamping irregular shapes, inconvenient testing of cartilage micromechanical properties, etc., and achieves the goal of using The effect of convenience, novel idea and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

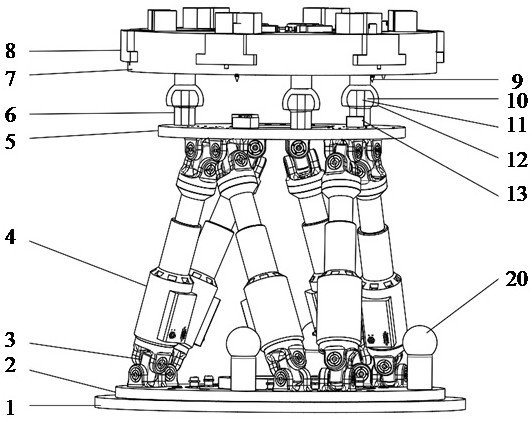

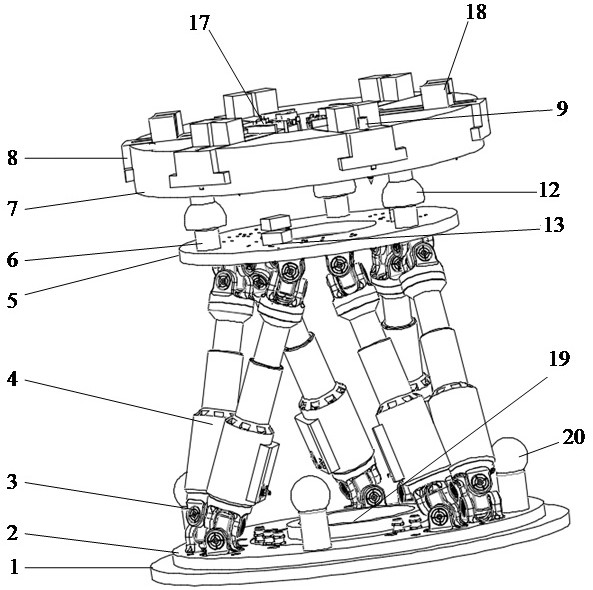

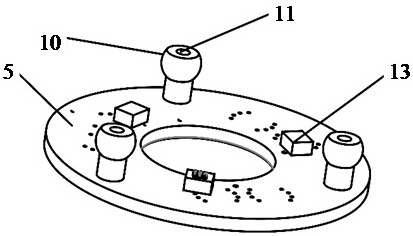

[0039] The miniaturized multi-degree-of-freedom macro-micro-drive platform for testing the mechanical properties of the irregular surface of cartilage, which combines the macro-micro drive and the cartilage placement and clamping device, is mainly divided into three modules: macro-micro drive module, clamping module, The sensing and detection module has three parts. The drive module is a macro-micro-rigid-flexible coupling drive. It consists of a six-degree-of-freedom macro-rigid drive and a three-degree-of-freedom micro-flexible drive. The macro drive is realized by using the compound linkage of parallel rigid telescopic rods, and the inverse piezoelectric effect of the piezoelectric ceramic material is used. Three-degree-of-freedom microscopic flexible drive. The clamping module is mainly a special fixture designed according to the structural characteristics of the irregular curved surface of cartilage. The characteristics of the fixture can clamp irregular curved surface ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com