Servo type soil frost heaving and thaw collapse test device and test method thereof

A test device and servo-type technology, which is applied in the field of thawing test device, soil frost heave, and servo-type soil frost heave, can solve the problems of inability to provide convenience for scientific research, achieve a high degree of simulation, and improve the effect of test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

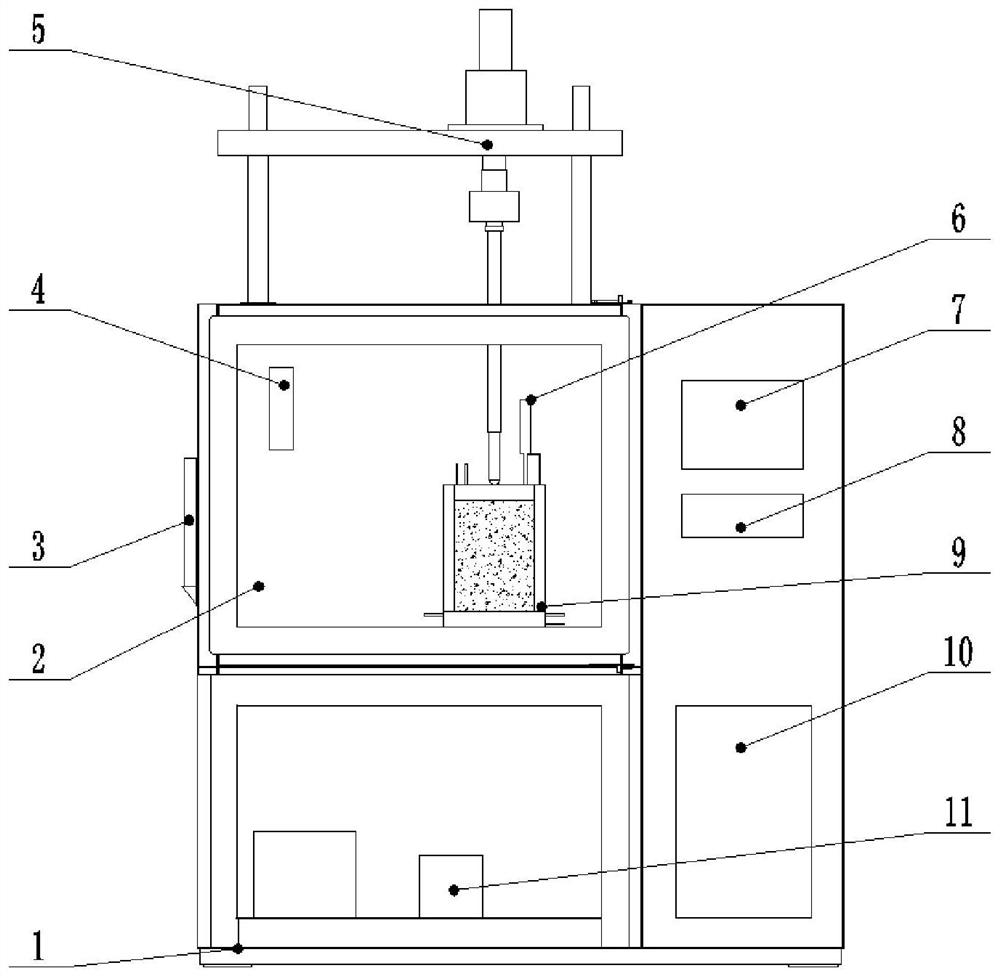

[0028] Specific implementation mode one: combine Figure 1 to Figure 2 Describe this embodiment, a kind of servo-type soil frost heaving and thawing test device of this embodiment, it comprises base 1, test cabin 2, replenishing water device 3, heating device 4, pressurizing device 5, displacement sensor 6, control System 7, data acquisition module 8, sample mold 9, water bath system 10 and refrigeration system 11, refrigeration system 11 is installed on the base 1, test chamber 2 is installed on the refrigeration system 11, heating device 4 is installed in the test chamber 2, And the heating device 4 is located at the top of the test chamber 2, the sample mold 9 is installed in the test chamber 2, the displacement sensor 6 is installed on the sample mold 9, the pressurizing device 5 is installed at the upper end of the test chamber 2, and the pressurizing device 5 The pressurizing rod passes through the upper end of the test chamber 2 and contacts with the upper end of the sa...

specific Embodiment approach 2

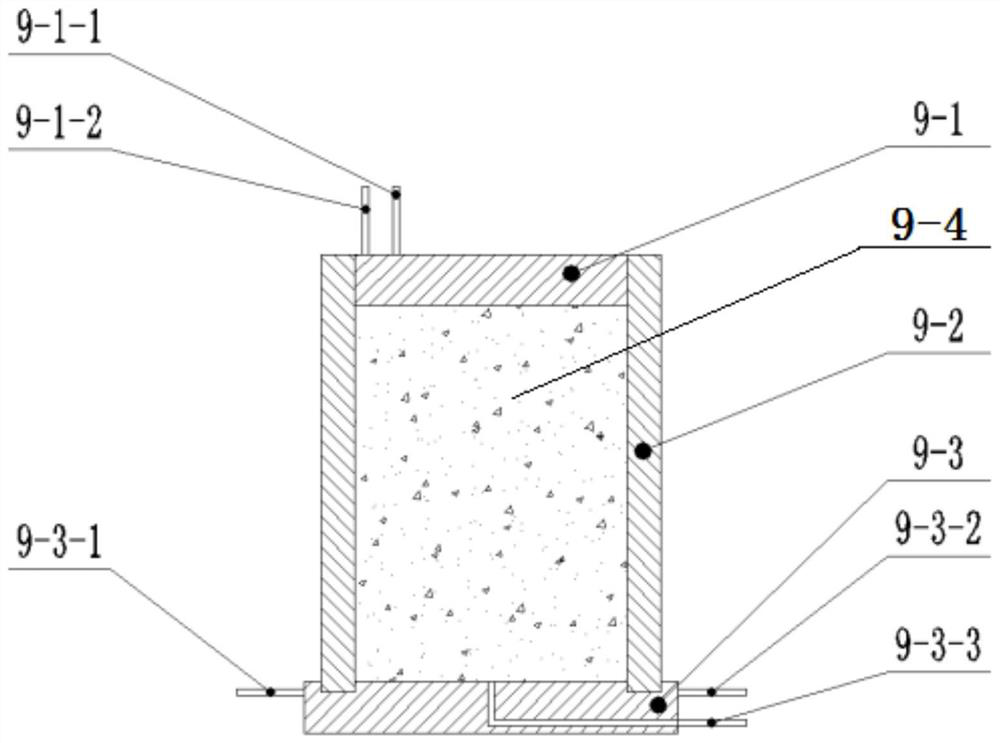

[0038] Specific implementation mode two: combination figure 2 Describe this embodiment, the sample mold 9 of this embodiment comprises mold top plate 9-1, casing 9-2, mold bottom plate 9-3 and sample 9-4, and casing 9-2 is installed on mold bottom plate 9-3 Above, the sample 9-4 is installed in the casing 9-2, and the mold top plate 9-1 is installed on the sample 9-4. With such arrangement, it is convenient to make and fix the sample. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Specific implementation mode three: combination figure 2To illustrate this embodiment, the sample mold 9 of this embodiment also includes a top plate circulating liquid inlet pipe 9-1-1 and a top plate circulating liquid outlet pipe 9-1-2, a top plate circulating liquid inlet pipe 9-1-1 and a top plate circulation The liquid outlet pipe 9-1-2 is vertically inserted on the mold top plate 9-1. In this way, it is connected to the sample mold through a hose, and its circulating medium circulates on the top plate and bottom plate of the mold through the temperature required by the test, so as to realize different freezing methods and freezing temperatures. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com