Stranding and cabling device for optical cable production

A technology for optical cables and racks, applied in the field of optical cable production, can solve the problems of poor tensile resistance, larger pitch of optical cables, and increased production costs of optical cables, so as to prevent self-rotation, good anti-rotation effect, and convenient loading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

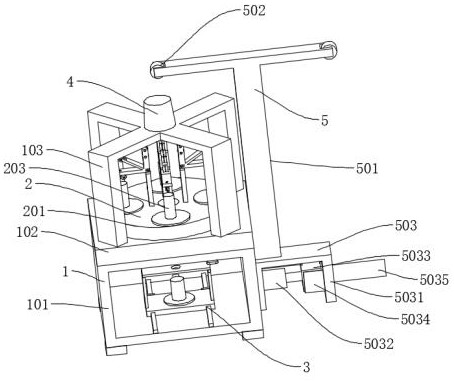

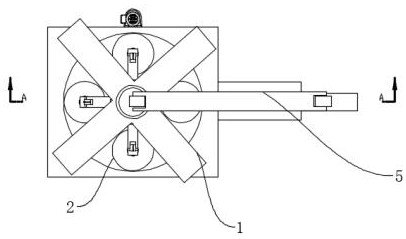

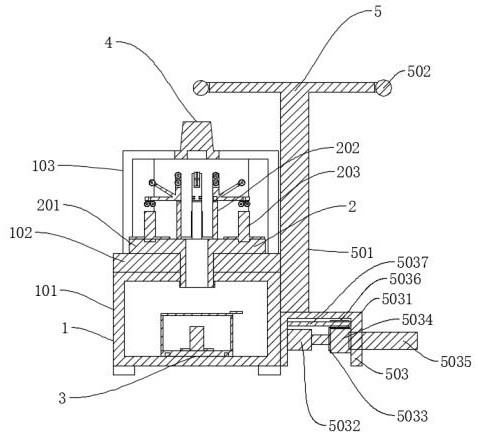

[0035] Such as Figure 1-7 As shown, a stranding device for optical cable production includes a support mechanism 1 and a winding mechanism 5. The support mechanism 1 is mainly composed of a support frame 101, a working plate 102, and a frame 103, and also includes a stranding mechanism 2, Placement mechanism 3, anti-retraction mechanism 4, twisting mechanism 2 includes a rotating plate 201, a guide frame 202, a first placement frame 203, the center of the rotating plate 201 is provided with a through-wire hole 1, and the rotating plate 201 is rotatably connected to the top of the working plate 102 , and the bottom of the rotating plate 201 is provided with a bump, which runs through the working plate 102 and is connected to the motor through a chain. The top of the rotating plate 201 is rotatably connected to the first placement frame 203, and the inside of the first placement frame 203 is provided with a guide frame. 202, such setting can drive the rotating plate 201 to rota...

Embodiment 2

[0038] Such as Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that: the end of the guide bracket 2023 close to the rotating seat 2022 is provided with a mounting groove 2027, and a locking screw 20201 is arranged under the mounting groove 2027, and the lower end of the locking screw 20201 passes through the guide The bracket 2023 extends into the rotating base 2022 and is threadedly connected with the rotating base 2022. In this way, the locking screw 20201 can be rotated so that the locking screw 20201 can extend into the rotating base 2022 to realize the function of fixing the guide bracket 2023.

[0039]In the above structure, when in use, the cylinder 303 is first activated, the cylinder 303 drives the slide plate 302 to slide outside the slide rail 301, and the slide plate 302 drives the second placement frame 304 to move, so that the slide plate 302 moves out of the support frame 101, and the top plate 306 can also be flipped, Make the top pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com