Hard disk data interface pitch conversion connector

A data interface and connector technology, which is applied in the direction of connection, parts of the connection device, contact parts, etc., can solve problems such as inability to disassemble, a large amount of harmful gas, and complicated welding processing methods, so as to improve convenience, save welding process, The effect of convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

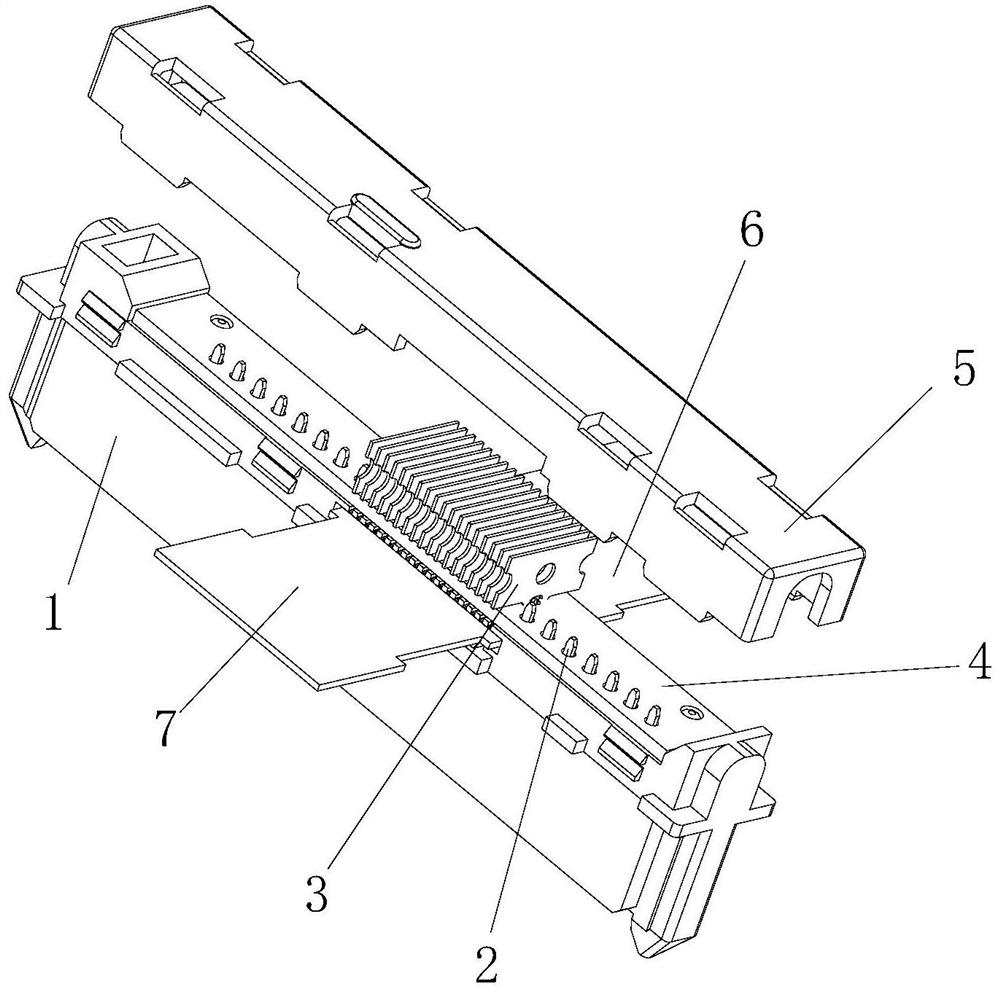

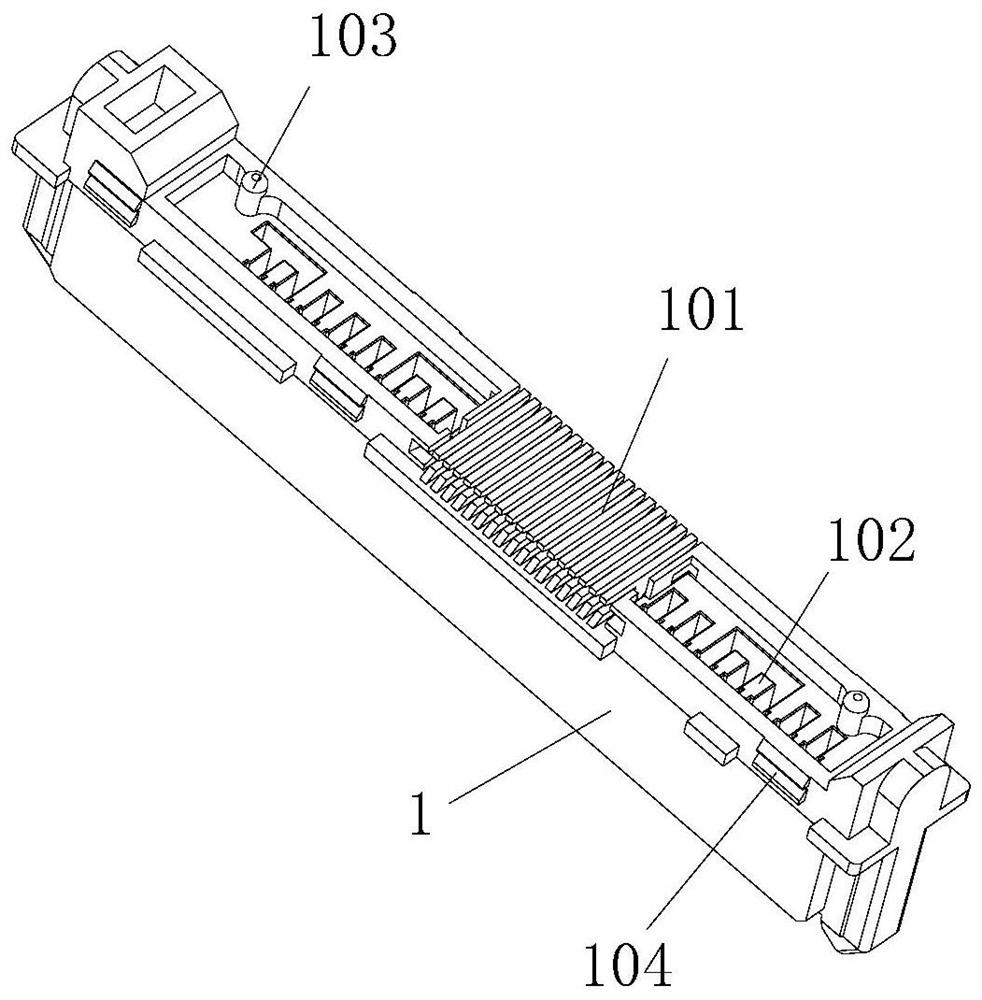

[0032] Embodiment 1: A hard disk data interface pitch conversion connector, including a main rubber core 1, a hard disk contact terminal 2, an FFC transfer terminal 3, a PCB board 4 and a cover body 5, and the PCB board 4 passes through several hard disk contact terminals 2 is connected to the main rubber core 1, and an FFC transfer terminal 3 is provided between the PCB board 4 and the main rubber core 1, and an FFC is connected to the FFC transfer terminal 3;

[0033] The outer side of the PCB board 4 is provided with a cover body 5, and the cover body 5 is connected to the rubber core 1 of the main body;

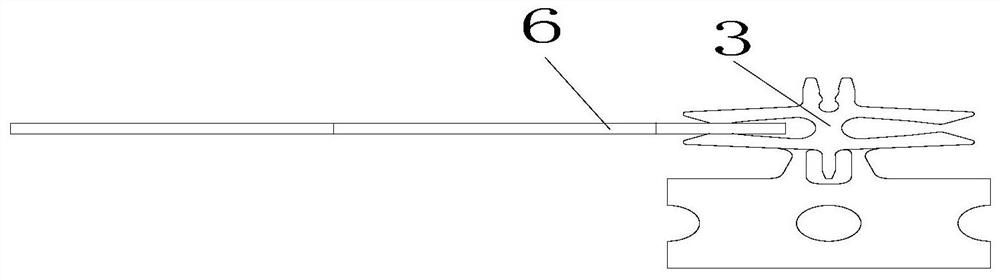

[0034] The FFC transfer terminal 3 includes a first socket 301, a second socket 302, a first connecting body 303 and a second connecting body 304, the first connecting body 303 is connected to the PCB board 4, and the second connecting body 304 Connected to the main rubber core 1, the first socket 301 and the second socket 302 are distributed on both sides of the PCB boar...

Embodiment 2

[0040] Embodiment 2: A hard disk data interface pitch conversion connector, including a main body rubber core 1, a hard disk contact terminal 2, an FFC transfer terminal 3, a PCB board 4 and a cover body 5, and the PCB board 4 passes through several hard disk contact terminals 2 is connected to the main rubber core 1, and an FFC transfer terminal 3 is provided between the PCB board 4 and the main rubber core 1, and an FFC is connected to the FFC transfer terminal 3;

[0041] The outer side of the PCB board 4 is provided with a cover body 5, and the cover body 5 is connected to the rubber core 1 of the main body;

[0042] The FFC transfer terminal 3 includes a first socket 301, a second socket 302, a first connecting body 303 and a second connecting body 304, the first connecting body 303 is connected to the PCB board 4, and the second connecting body 304 Connected to the main rubber core 1, the first socket 301 and the second socket 302 are distributed on both sides of the PCB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com