Woven Barcode made of smeltable yarn material

A label and yarn technology, applied in the cutting of textile materials, textiles and papermaking, auxiliary equipment for weaving, etc., can solve problems such as complex costs, and achieve the effect of improving wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

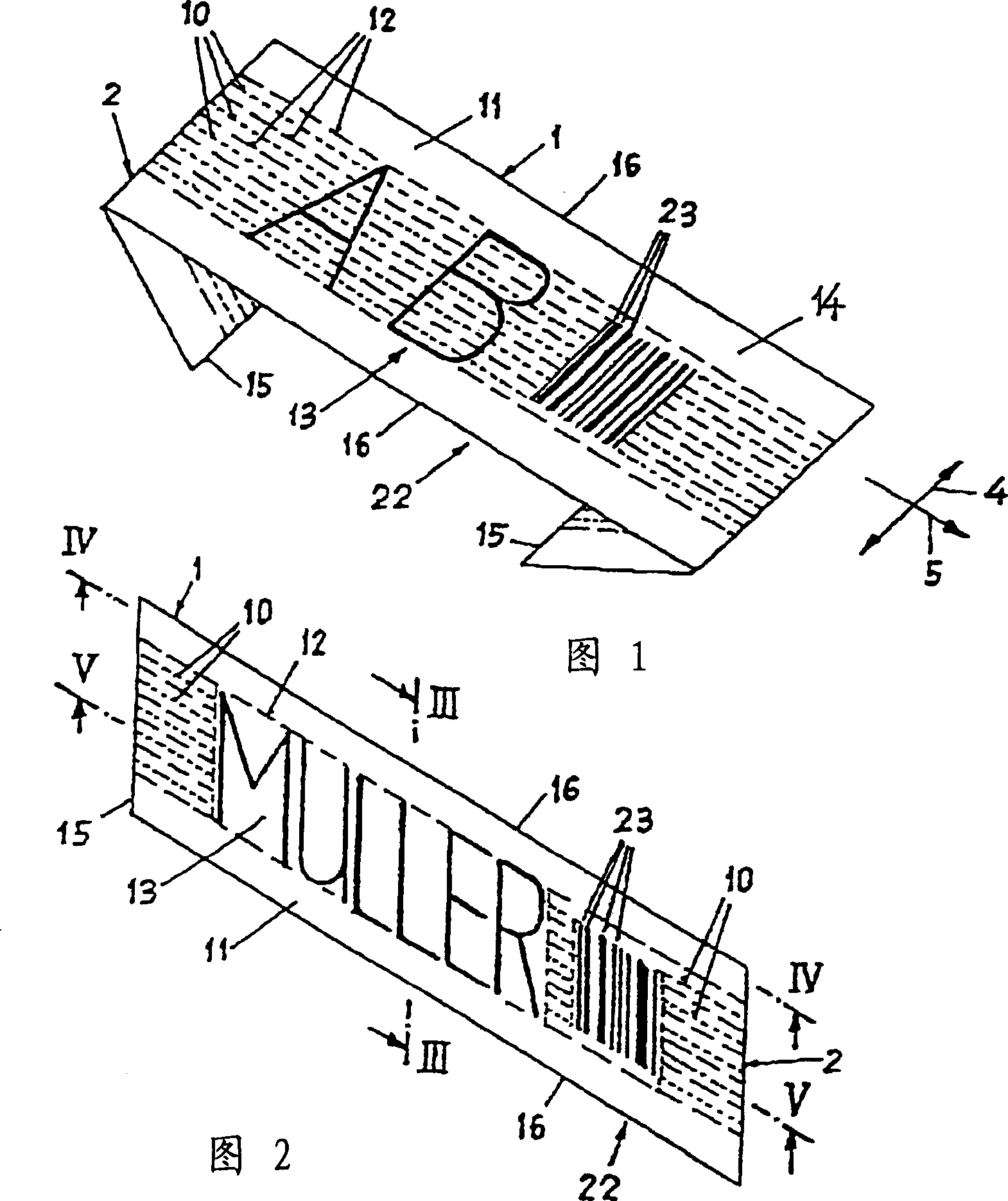

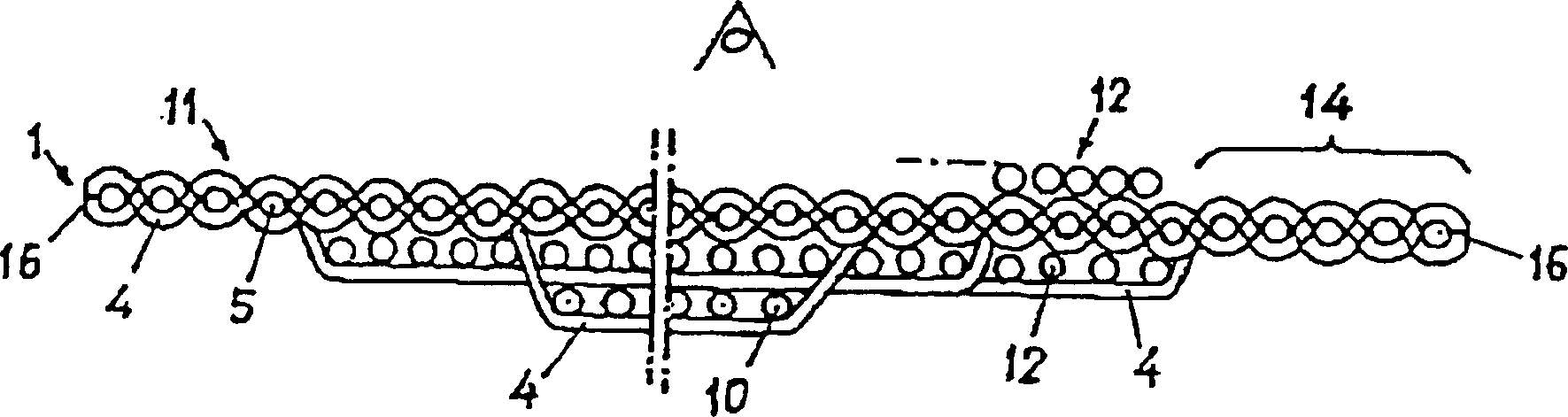

[0024] Figure 1 shows a label 22 according to the invention, from which the differences with known labels in the warp and weft directions are clearly seen and explained by the following description with reference to Figures 2 to 5.

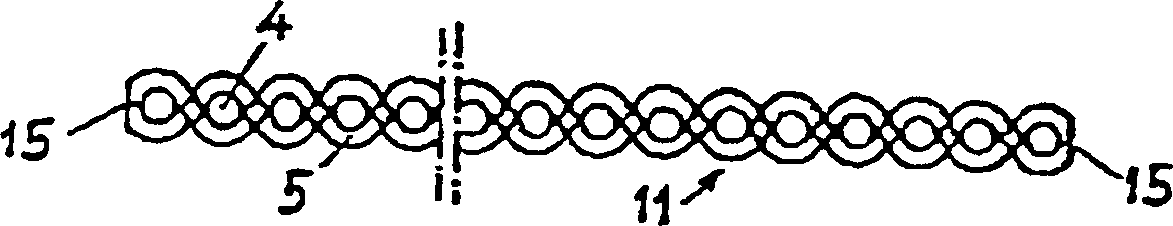

[0025] The label 22 is conventionally in the shape of a quadrilateral with two non-folding longitudinal sides 1 and two foldable transverse sides 2 which, as shown, are designed as narrow sides. The label 22 is made of a backing fabric 11 and a plurality of decorative weft yarns 12 and a plurality of coded weft yarns 10, the backing fabric 11 is formed by the backing warp yarns 4 and the backing weft yarns 5, and the decorative weft yarns 12 form a pattern in the region 13 of the label, many The root coded weft yarn 10 forms in the region 13 a coded pattern in the form of a bar code, which is "invisible" when viewed under visible light and, in each case, by extending in the warp direction and one after the other in the weft direction. Strips 23 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com