A fixed clamping extension type auto parts processing machine tool

A technology for auto parts and processing machine tools, which is applied in metal processing machinery parts, metal processing equipment, large fixed members, etc., and can solve the problems of high cost, low use value, and reduced positioning accuracy of machining centers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

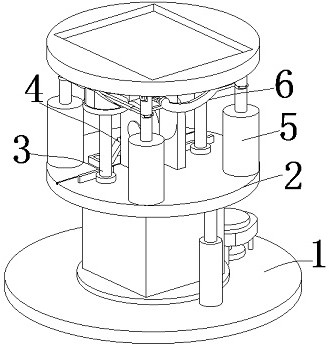

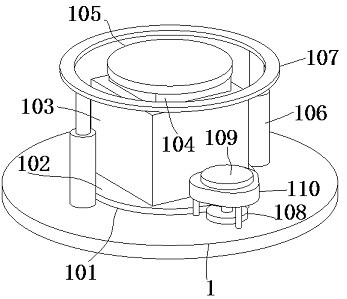

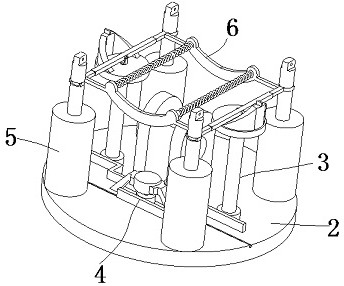

[0028] Embodiment one, such as Figure 1-9As shown, the bottom plate 1 is included, and the center of the upper surface of the bottom plate 1 is provided with a groove 101. The inside of the groove 101 is connected with the main shaft gear 102 for rotation. The upper half of the main shaft gear 102 is located above the groove 101. The surface is fixedly connected with a fixed sleeve 103 , and the inside of the fixed sleeve 103 is slidably connected with a central shaft 104 . The shape of the fixed sleeve 103 is rectangular, and the cross-sectional shape of the central shaft 104 is rectangular. It can be guaranteed to be able to rotate as well as telescopic by such arrangement. The top end of the central shaft 104 is fixedly equipped with a rotating plate 105, and the upper surface of the base plate 1 is fixedly installed with a telescopic sleeve 106 on both sides of the fixed sleeve 103. The telescopic sleeve 106 It is a hydraulic type, which can control the lifting of the dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com