Negative electrode panel for alkaline dry battery and application of negative electrode panel

A dry battery and negative electrode technology, which is applied to the negative electrode plate for alkaline dry battery and its application field, can solve the problems such as difficulty in maintaining consistent support force, loss of sealing effect, large contact area, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

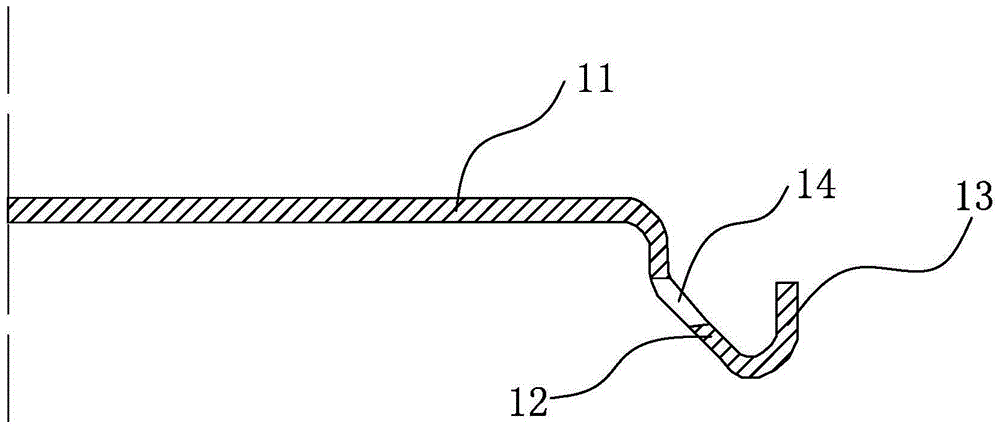

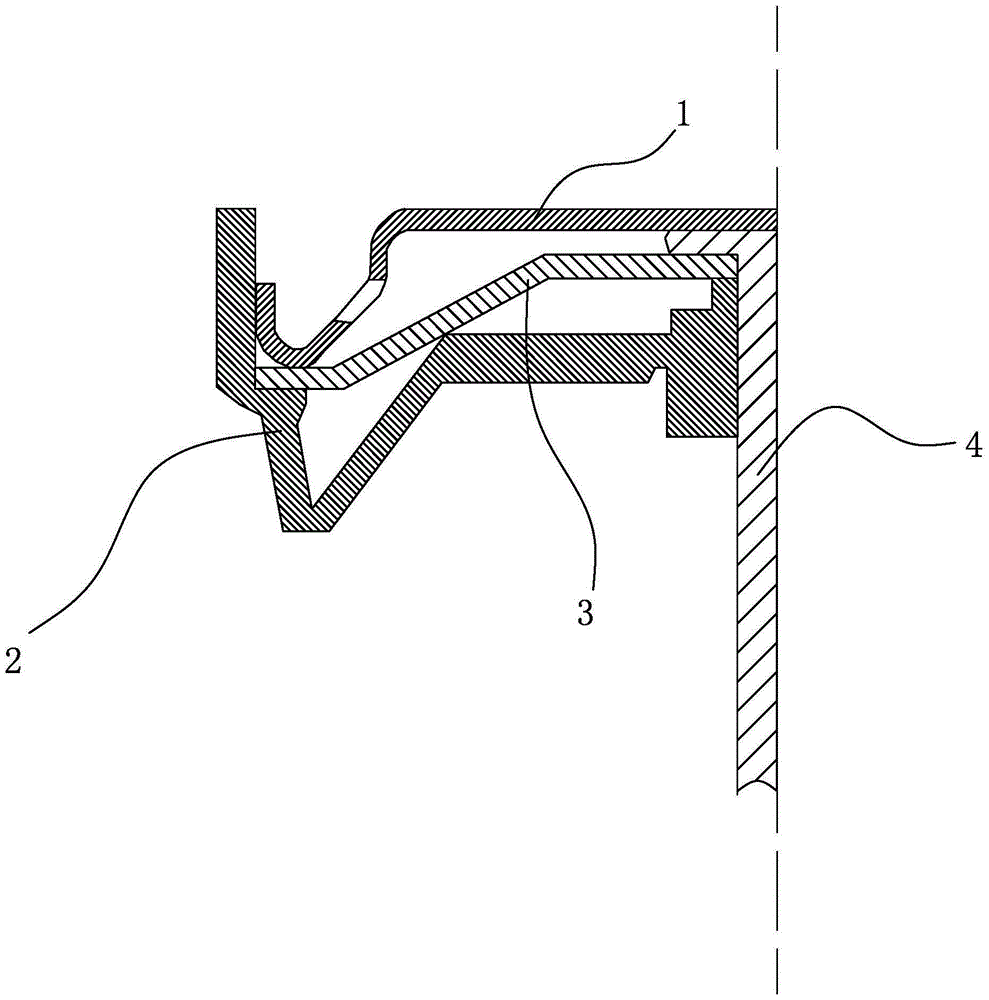

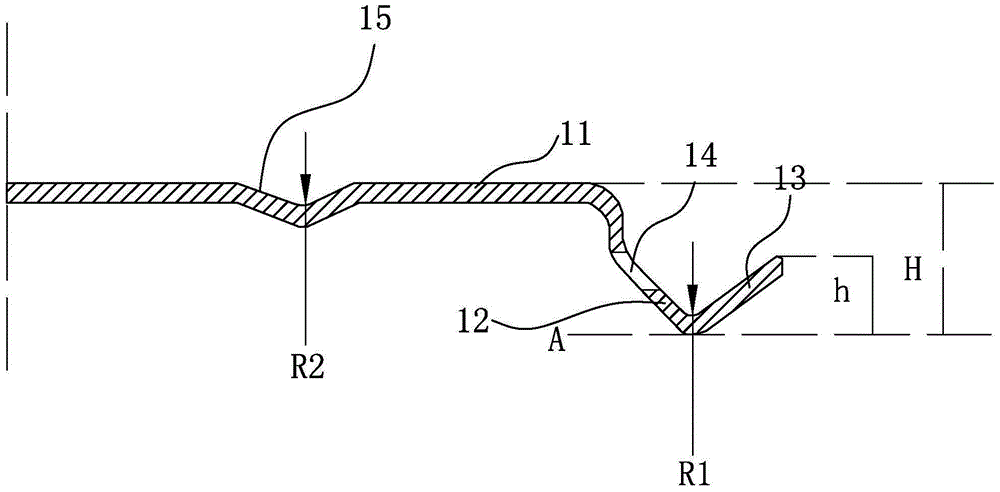

[0034] Such as figure 1 As shown, the alkaline dry battery negative plate 1 of the present invention includes a horizontal portion 11, one end of the horizontal portion 11 extends downwards and is connected with a shoulder for support, the shoulder portion includes a connecting portion 12 and a working portion 13, and one end of the connecting portion 12 is connected to the The horizontal part 11 is connected, and the working part 13 is connected with the other end of the connecting part 12 to form a "V"-shaped angle. Therefore, the contact between the working part 13 and the sealing plate 2 has changed from the original two-plane contact mode to a point-to-plane contact mode, and the improved working part 12 also forms a certain support for the sealing plate 2 effect. The outer side of the sealing plate 2 is in direct contact with the positive electrode casing to form a sealing ring structure, therefore, the cooperation between the sealing plate 2 and the positive electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com