Beverage canning equipment

A technology of canning and equipment, applied in packaging, liquid bottling, transportation and packaging, etc., can solve the problem that there is no way to realize the canning of bottles of different specifications, and achieve the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

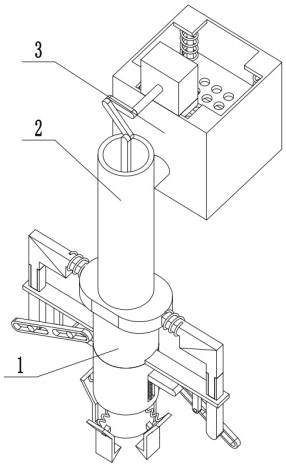

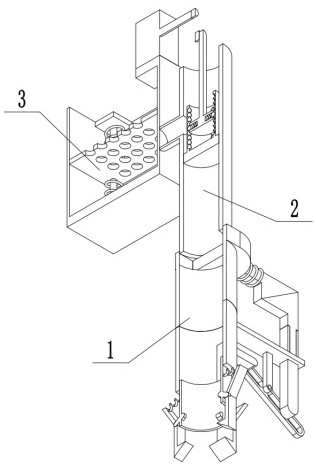

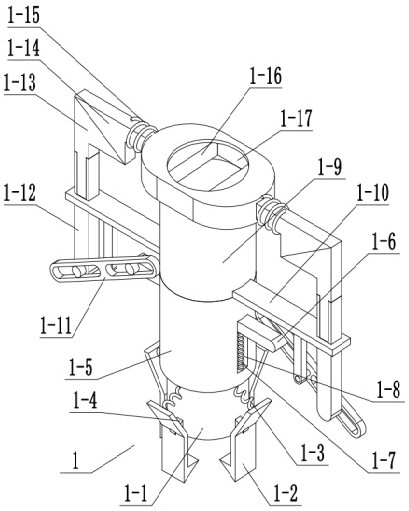

[0028] Combine below Figure 1-9 Describe this embodiment, a beverage canning equipment, including a canning assembly 1, a liquid pumping assembly 2, and a liquid tank assembly 3, the canning assembly 1 is connected to the liquid pumping assembly 2, and the liquid pumping assembly 2 is connected to the liquid tank assembly 3-phase connection;

[0029] The canning assembly 1 includes a slidable sleeve 1-1, a clamping plate 1-2, a clamping plate push spring 1-3, a hinge column 1-4, a fixed sleeve 1-5, a driving slide bar 1-6, a driving Sliding rod sliding column 1-7, driving sliding rod push spring 1-8, upper casing 1-9, outer end bracket 1-10, hinged rotating rod 1-11, driving sliding rod one 1-12, driving sliding rod two 1-13, drive slider three 1-14, drive slider push spring one 1-15, closing plate 1-16, connection cavity 1-17, inner end slot one 1-18, inner end clamp rod one 1- 19. The push spring 1-20 of the inner end clamping rod, the hinged column 1-4 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com