Special liquid fertilizer for cotton

A liquid and cotton technology, applied in the direction of liquid fertilizer, application, nitrogen fertilizer, etc., can solve the problems of reducing workload, heavy workload, and generating a large number of air bubbles, and achieve the effect of improving work efficiency, crushing materials carefully, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A special liquid fertilizer for cotton, the weight ratio of raw materials is as follows: urea 23kg, monoammonium phosphate 171kg, potassium tripolyphosphate 50kg, diammonium phosphate 50kg, seaweed extract 10kg, potassium fulvic acid 60kg, boric acid 3kg, NAM inhibitor 3.5kg , Soft water 852kg.

[0038] A kind of production technology of liquid fertilizer special for cotton, concrete steps are as follows:

[0039] 1) Crushing and dissolving of inorganic raw materials: crush the proportioned solid raw materials including urea, monoammonium phosphate, potassium tripolyphosphate, diammonium phosphate, and boric acid through the raw material crushing device, put them in the reaction kettle, and add the proportioned soft water for dissolution ;

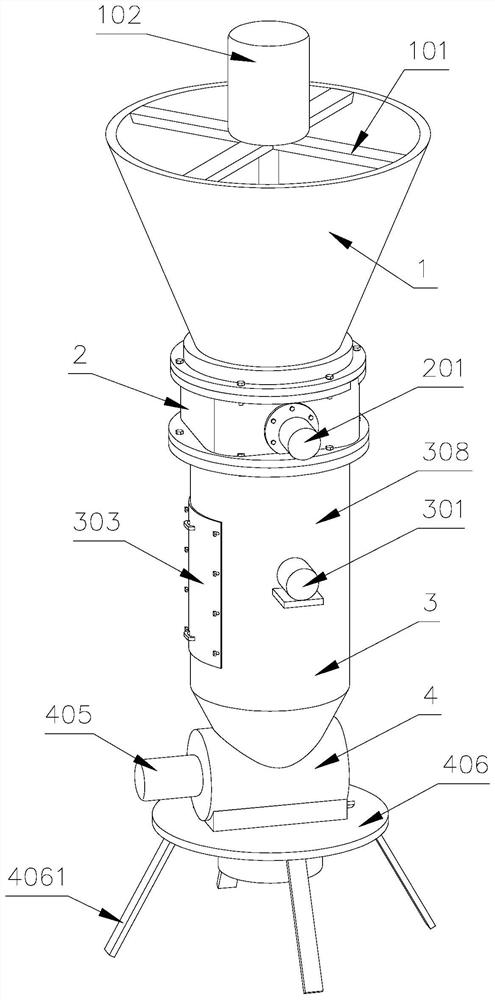

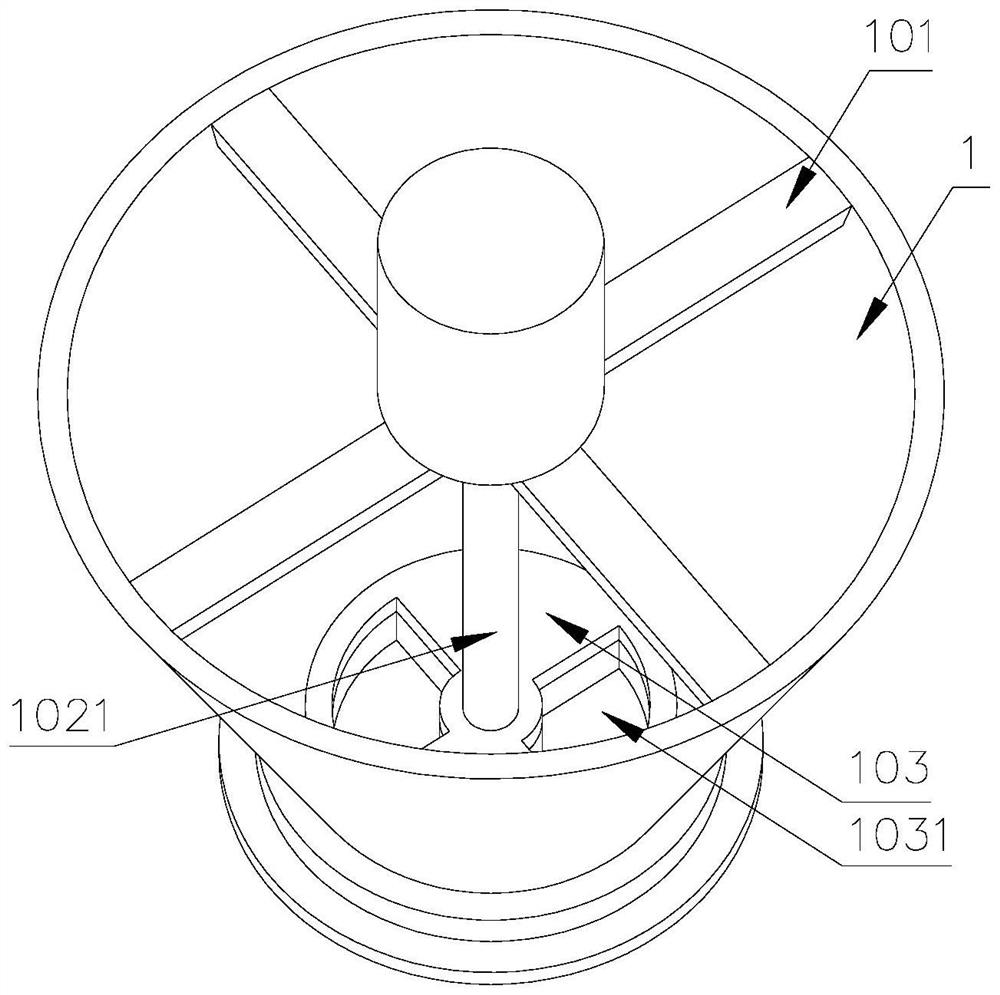

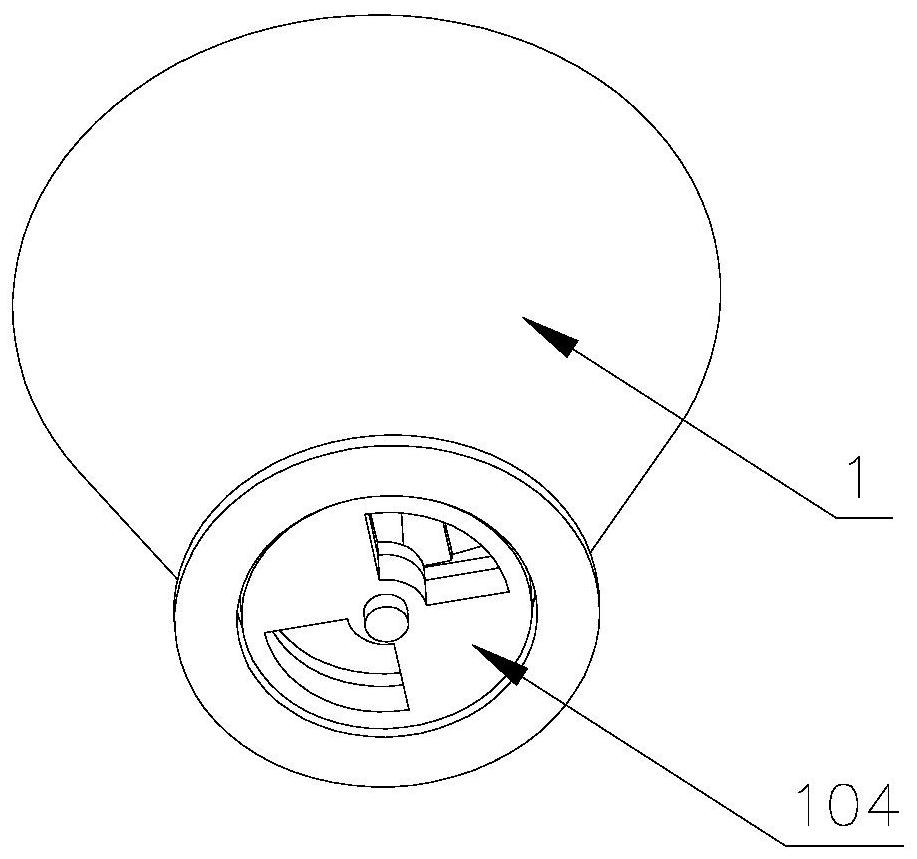

[0040] A raw material crushing device, comprising a feeding hopper 1, a conveying mechanism 2, a crushing mechanism 3, and a screening mechanism 4; the feeding hopper 1 is arranged on the top of the conveying mechanism 2, and the c...

Embodiment 2

[0051] Compared with Example 1, the difference is: a cotton liquid special fertilizer, the raw material weight ratio is as follows: urea 23kg, monoammonium phosphate 171kg, potassium tripolyphosphate 50kg, diammonium phosphate 50kg, fish protein powder 2kg, seaweed extract 10kg, potassium fulvic acid 60kg, boric acid 3kg, soft water 853.5kg.

[0052] In step 2) of the liquid special fertilizer production process, add fish protein powder, seaweed extract, potassium fulvic acid and boric acid into the reaction kettle for dissolution.

Embodiment 3

[0054] Compared with Example 1, the difference is that a cotton liquid special fertilizer has the following weight ratio of raw materials: urea 23kg, monoammonium phosphate 171kg, potassium tripolyphosphate 50kg, diammonium phosphate 50kg, fish protein powder 2kg, seaweed extract 10kg, potassium fulvic acid 60kg, boric acid 3kg, NAM inhibitor 3.5kg, soft water 855kg.

[0055] In step 2) of the liquid special fertilizer production process, add fish protein powder, seaweed extract, potassium fulvic acid, boric acid, and NAM inhibitor into the reaction kettle for dissolution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com