Production switching production channel and switching method for two different steel plate products

A channel switching and switching channel technology, which is applied in the field of production switching production channel structure, can solve the problems of large market demand for hot-dip galvanized products, low production load, and equipment stoppage, etc., to save switching time, high production efficiency, and occupy empty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

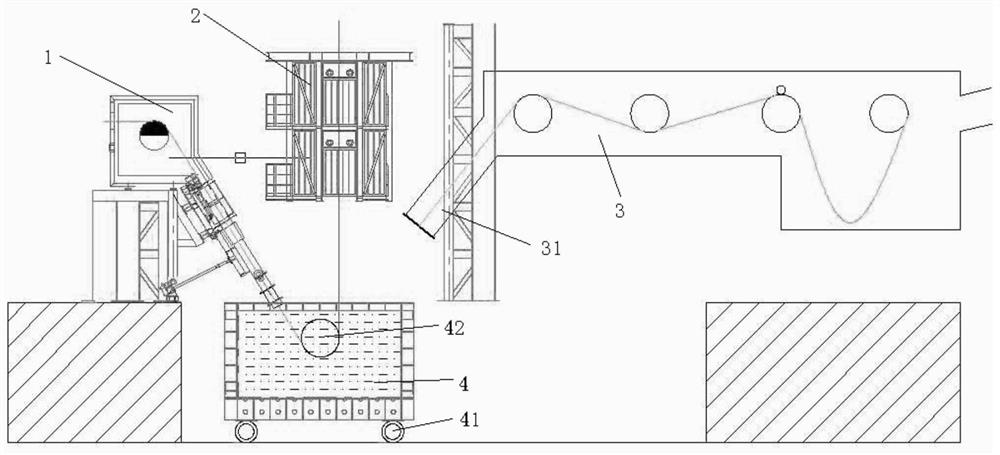

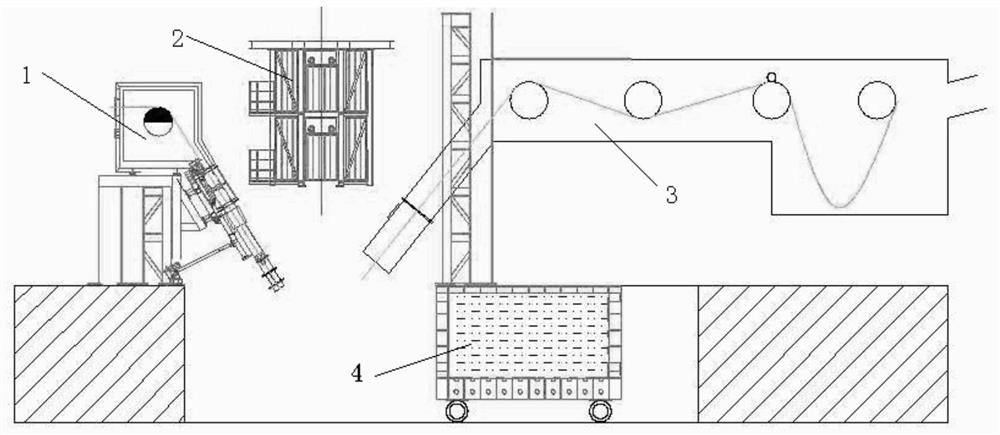

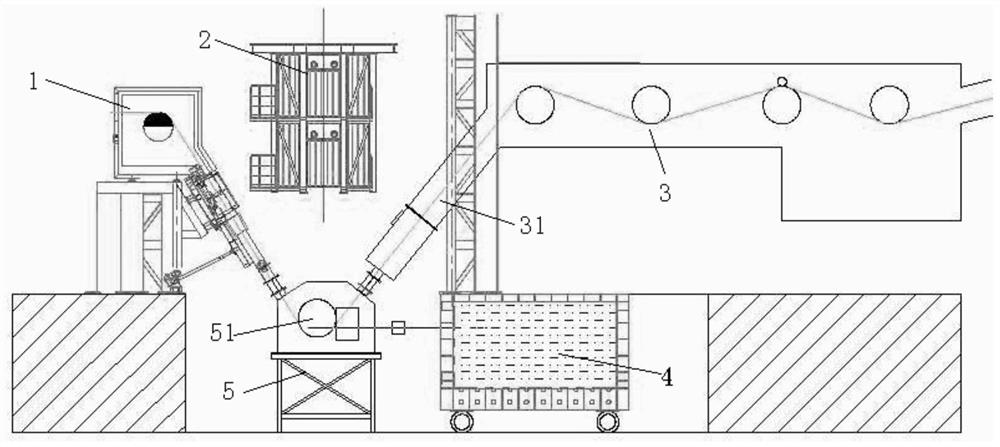

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] like Figures 1 to 3 As shown, the production switching production channel of two different steel plate products includes a continuous annealing furnace 1, a galvanizing process section 2, a continuous annealing aging process section 3, a zinc pot 4 and a switching channel device 5, and the bottom of the zinc pot 4 is provided with There are wheels 41 that are convenient to move, and a switching space for placing the zinc pot 4 and the switching channel device 5 is provided between the continuous annealing furnace 1, the galvanizing process section 2 and the continuous annealing aging process section 3; the zinc pot 4 The steel plate installed with the continuous annealing furnace 1 is transported to the sinking roller 42 of the galvanizing process section 2, the front end of the continuous annealing aging process section 3 is connected with a switching channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com