Novel rice noodle machine

A rice noodle machine, a new type of technology, is applied in food forming, food science, application, etc. It can solve the problems of product contamination, reduce labor costs, and the elasticity is not as good as natural air cooling, so as to reduce manual participation and realize automatic production , easy and fast maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention and its beneficial technical effects will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

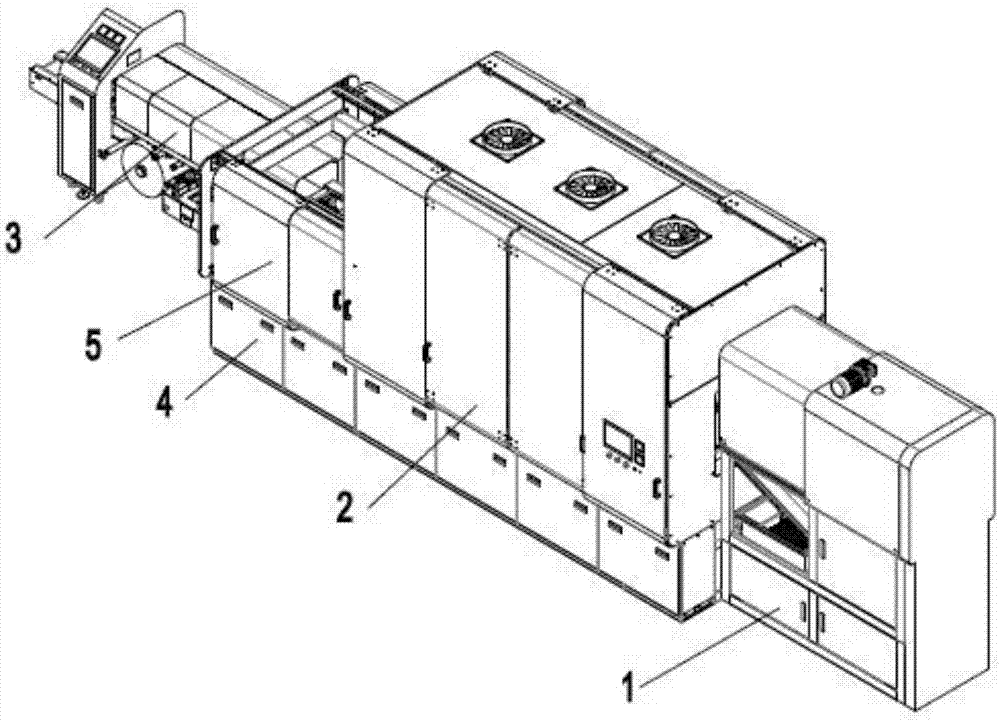

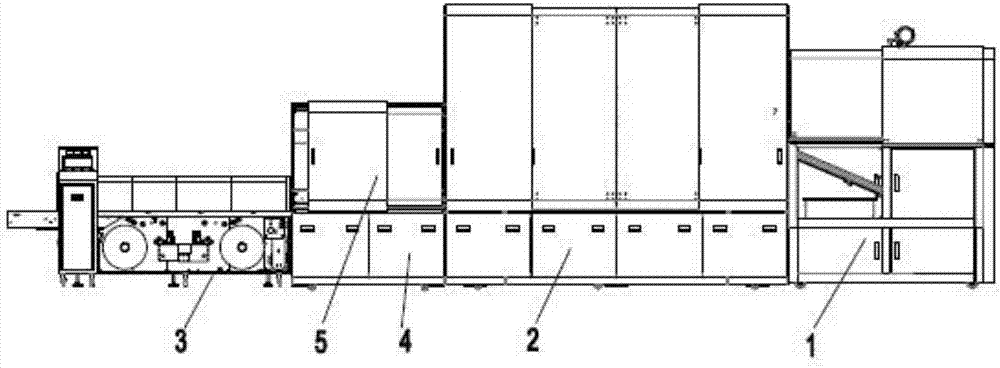

[0051] see Figure 1 to Figure 15 , the novel rice noodle machine comprises the following rice noodle making device 1, conveying and cooling device 2, stacking device 4 and packaging device 3 arranged end to end; wherein,

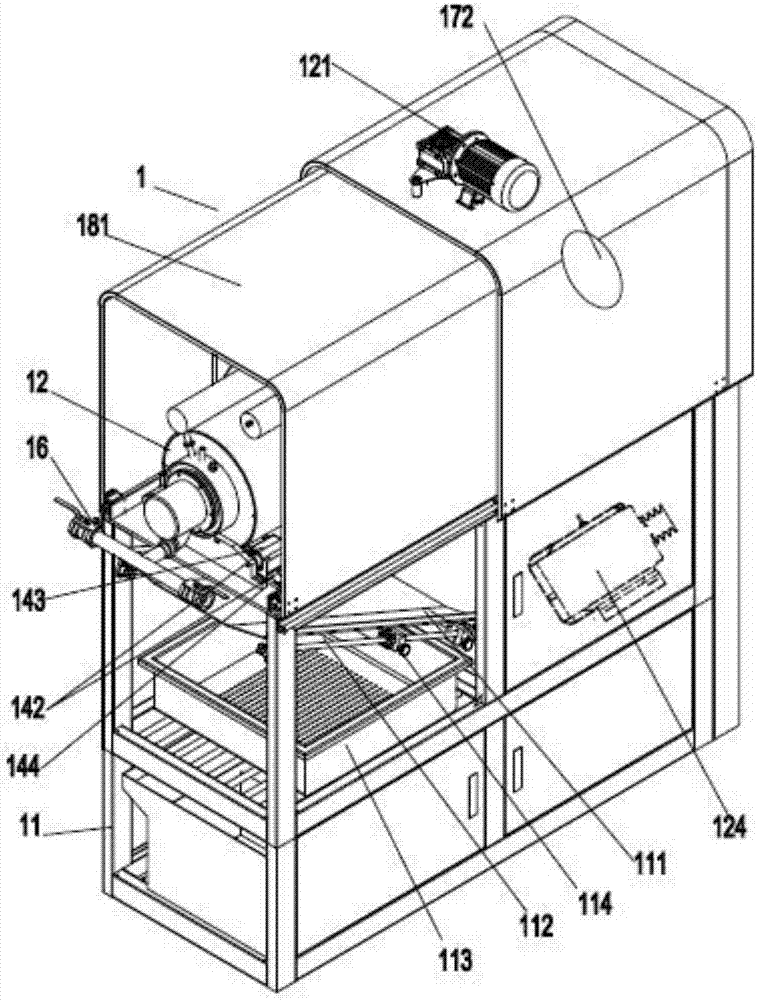

[0052] see Figure 3 to Figure 9 , the rice flour making device 1 comprises a milling cabinet 11 and a milling device 12 located on the milling cabinet 11, and the milling device 12 includes a feeding mechanism 121, a material extruding mechanism 122 for unidirectionally extruding the slurry, and The slurry in the extruding mechanism 122 heats the heating device 123 of clinker, the clinker extruded by the extruding mechanism 122 is extruded into the rice noodle forming assembly 16 of rice vermicelli, and the power mechanism 124 that provides driving force for the extruding mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com