Aluminum template for building

A technology for aluminum formwork and construction, applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of large wood consumption, poor structural strength, unfavorable environmental protection, etc., to increase the occlusal contact surface and occlusal force , Improve the structural strength and compression resistance, and improve the effect of building efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

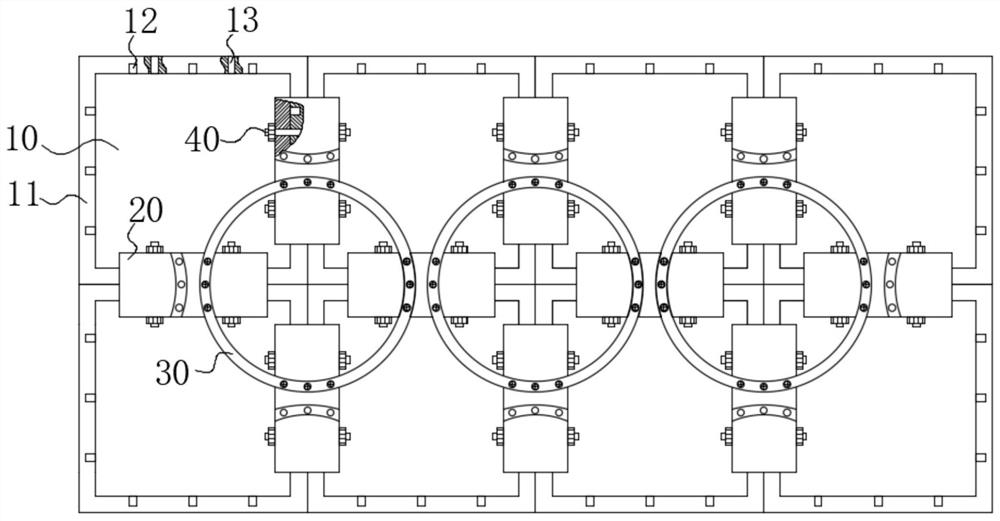

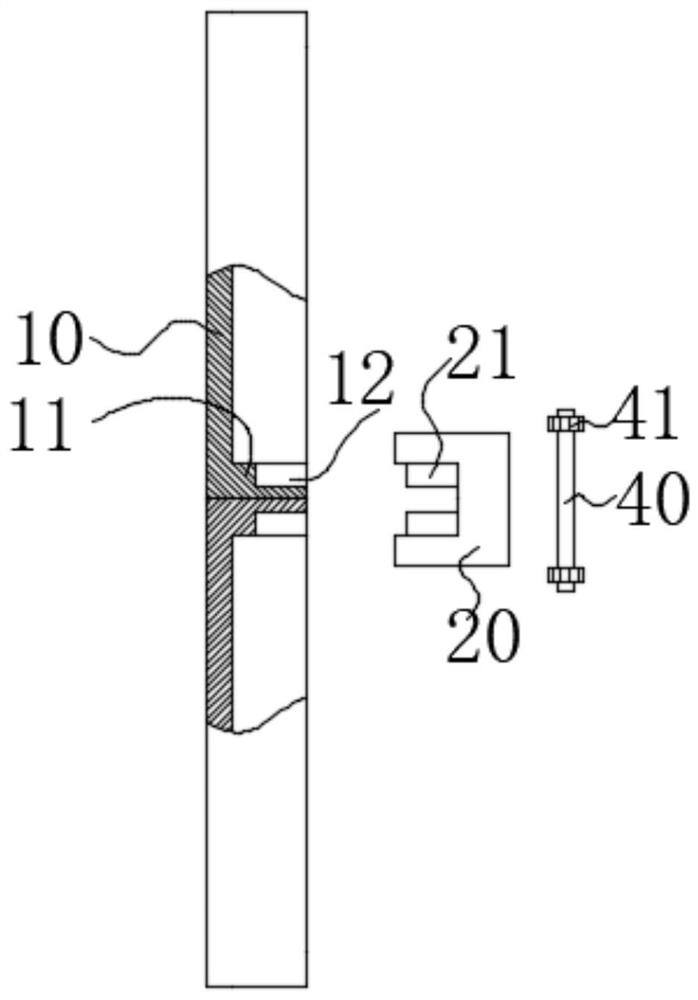

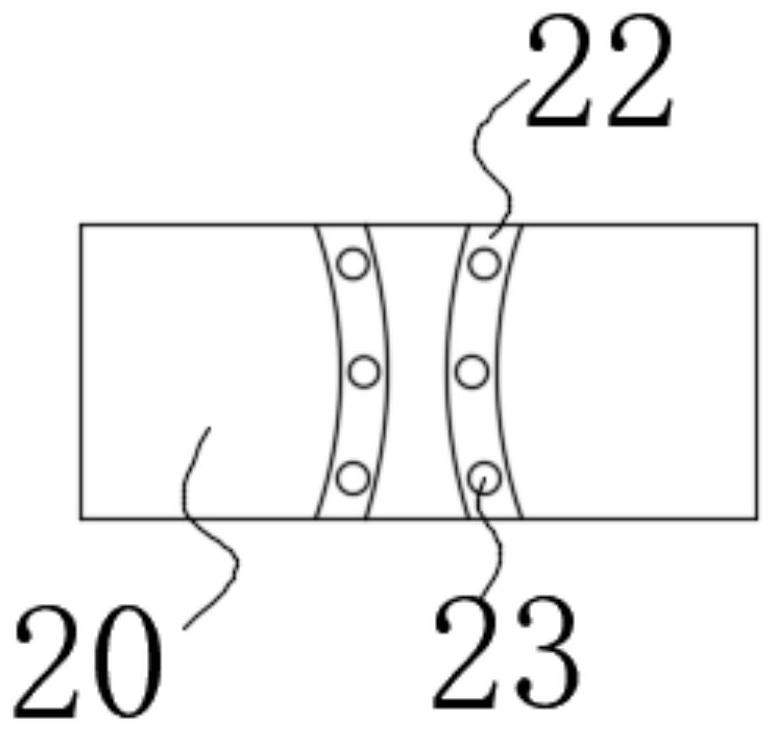

[0021] see figure 1 In this embodiment, an aluminum formwork for construction includes a base plate 10, preferably, the base plate 10 is a square base plate 10, and one side of the base plate 10 has a frame 11, and the frame 11 is surrounded by four side bars. The airtight frame body formed, a fastener 20 is fastened between two adjacent bottom plates 10, and one side of the fastener 20 has a fastening groove (not shown in the figure), and the fastening groove can be used to connect adjacent The frames 11 of the two bottom plates 10 are snapped into it, in other words, the width of the fastening groove is twice the width of the side strips, the side strips are provided with pin holes 13, and the fasteners 20 are provided with The thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com