Positioning device for embedded steel plate and construction method thereof

A positioning device and pre-embedded steel plate technology, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as the difficulty of fixing steel plates, and achieve the effects of solving the problem of fixing difficulties, ensuring the accuracy of pre-embedding, and avoiding deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

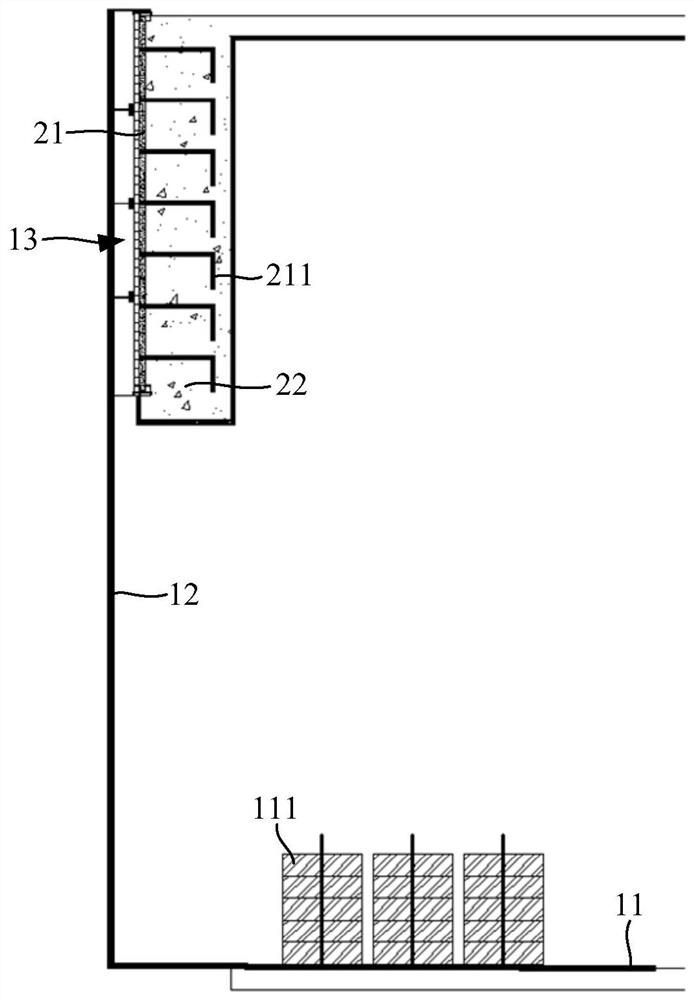

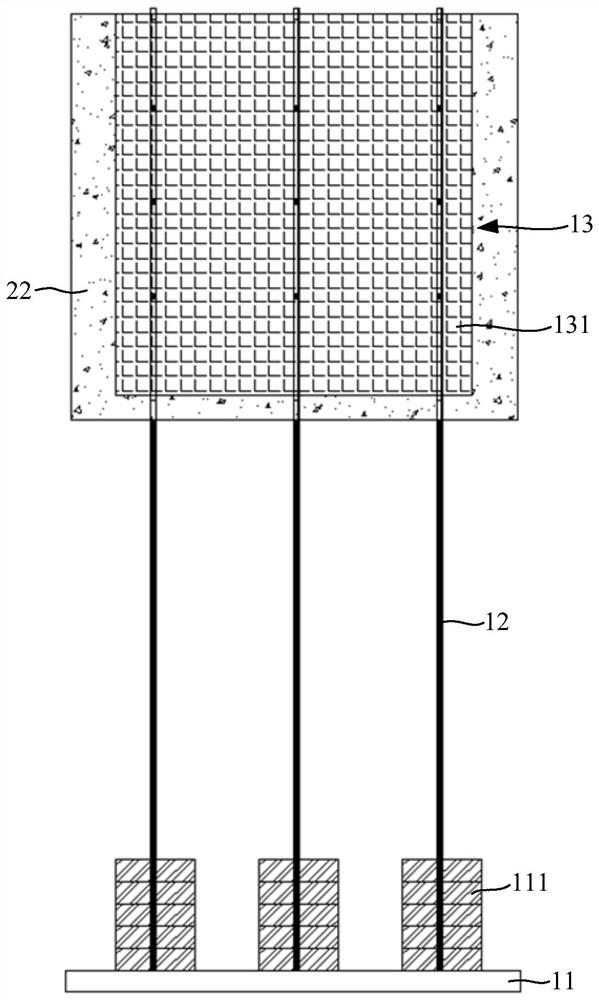

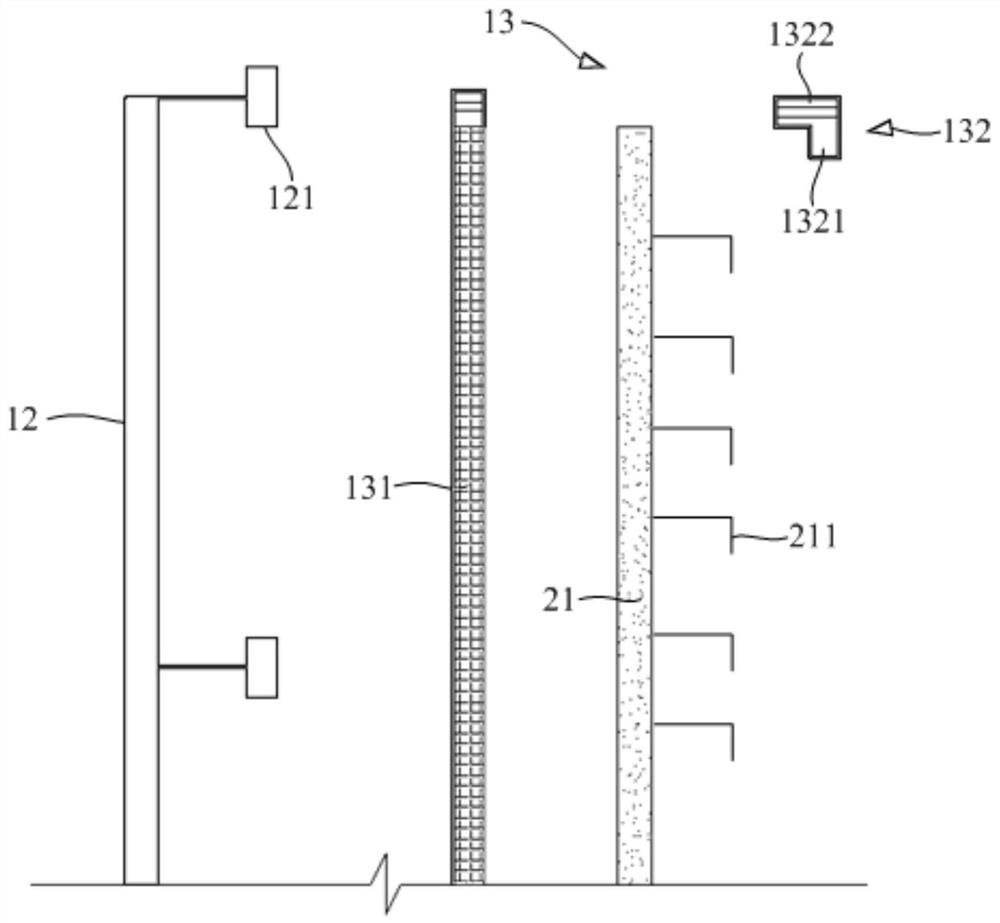

[0032] refer to figure 1 , the present invention provides a positioning device for pre-embedded steel plates and a construction method thereof. The steel plates are fixed by using clamps, and then the steel plates are moved to the position where the concrete structure is to be formed by using telescopic parts, and formwork is supported around the concrete structure to be formed. , and the formwork and the steel plate are close together, and concrete is poured in the area enclosed by the formwork and the steel plate to form a concrete structure. At this time, the fixing bars are buried in the concrete structure, and the steel plate part is exposed to the concrete structure. There is no need to connect the fixing bars with the concrete. The steel bars in the structure are welded, and the expansion parts are directly used to fix the position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com