Electro-hydraulic control pressure suppression system and method for hydraulic support column

A hydraulic support column, electro-hydraulic control technology, applied in the direction of mine roof support, support/support, earthwork drilling, etc. Low work efficiency and other problems, to achieve the effect of improving the success rate of dismantling, solving the problem of safety accidents, and improving the efficiency of dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

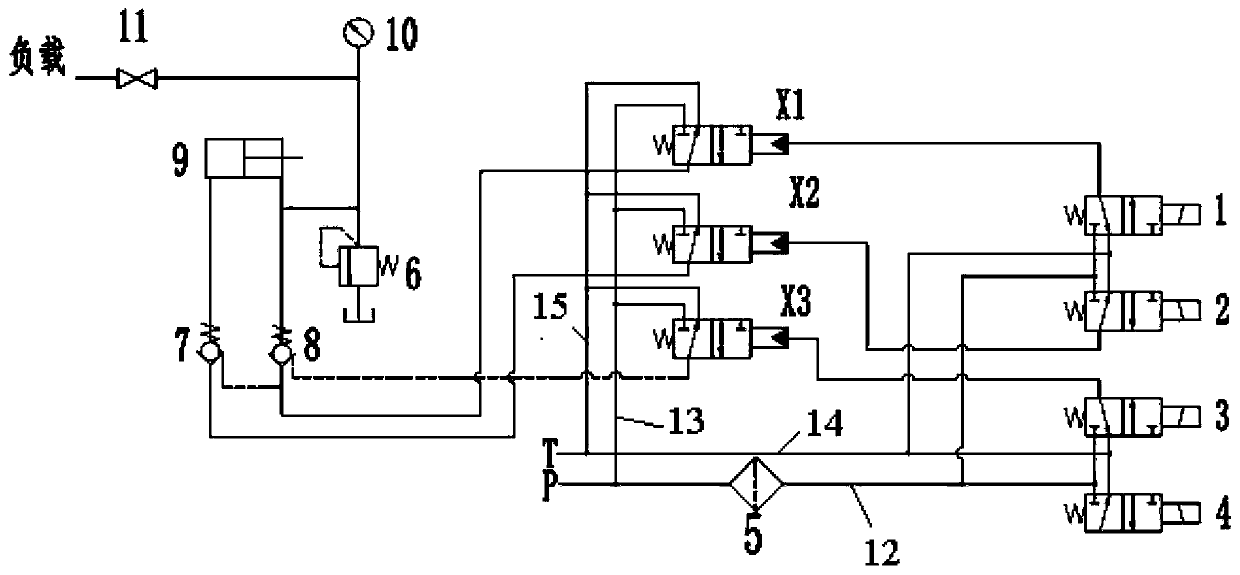

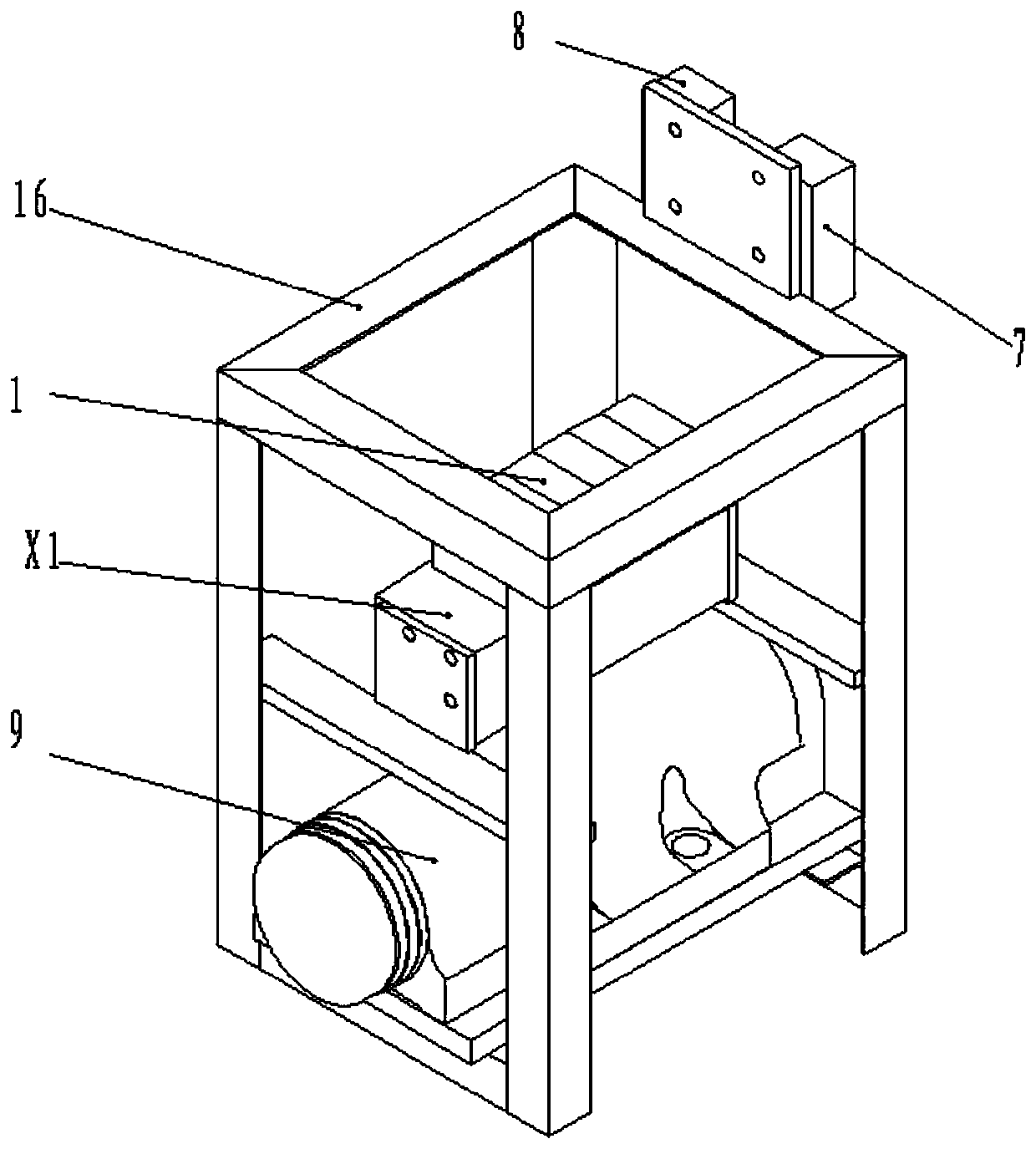

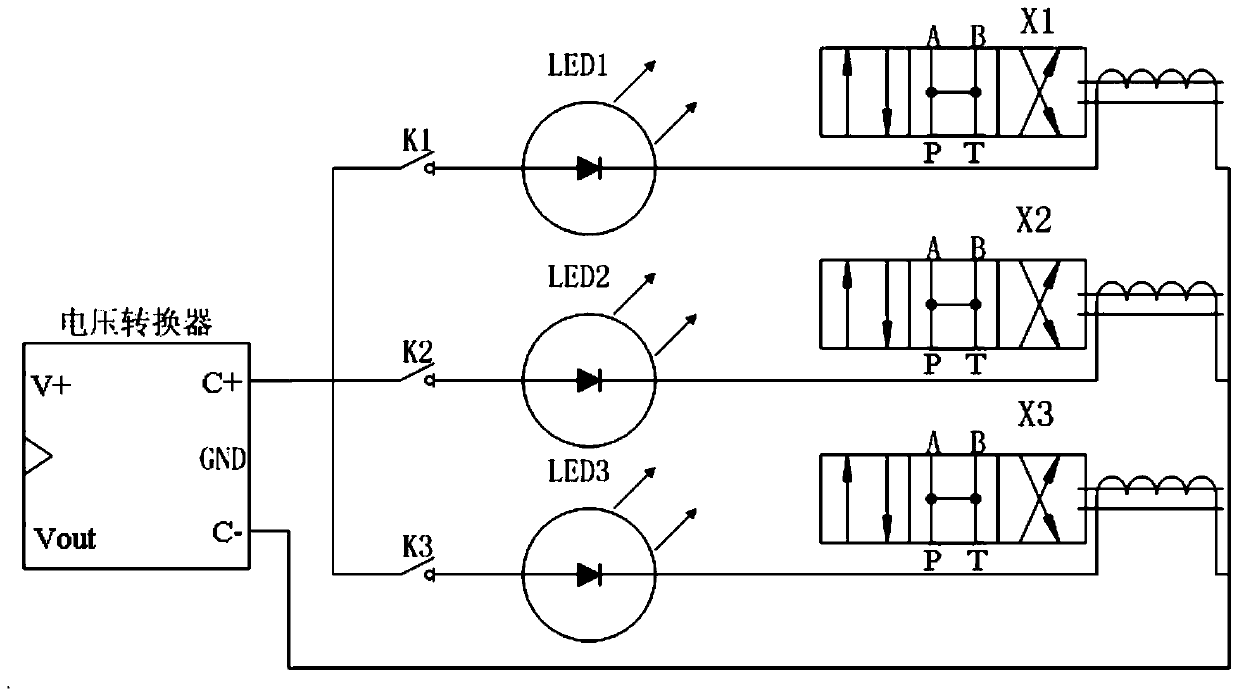

[0021] figure 1 It shows the control principle diagram of the electro-hydraulic control pressure holding system of the embodiment of the present invention, as figure 1 As shown, the electro-hydraulic control pressure holding system includes the main liquid inlet pipeline P, the main liquid return pipeline T, the supercharger 9, the first hydraulic control check valve 8, the second hydraulic control check valve 7, the first hydraulic control two-way One-position three-way reversing valve X1, the second hydraulically controlled two-position three-way reversing valve X2, the first electromagnetic reversing valve 1 and the second electromagnetic reversing valve 2.

[0022] Wherein, the main liquid inlet pipeline P includes a first branch 12 and a second branch 13 . The main liquid return pipeline T includes a third br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com