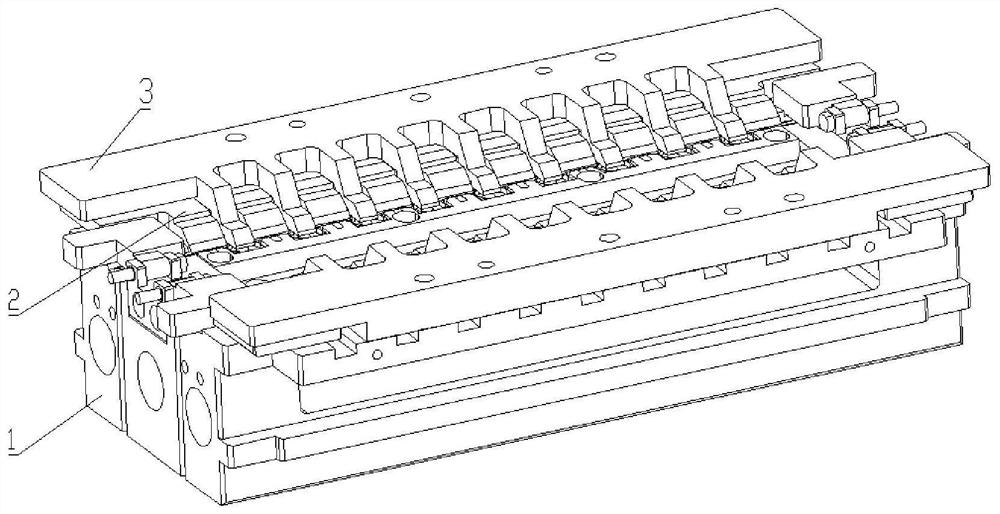

Rapid clamping device for laser tin soldering of electric ignition head

A clamping device and laser welding technology, used in auxiliary devices, welding equipment, metal processing equipment, etc., can solve the problems of control accuracy and service life affecting the fixing effect and accuracy of solder parts, and improve clamping efficiency and synchronization. flexibility, high positional accuracy, high degree of automation and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

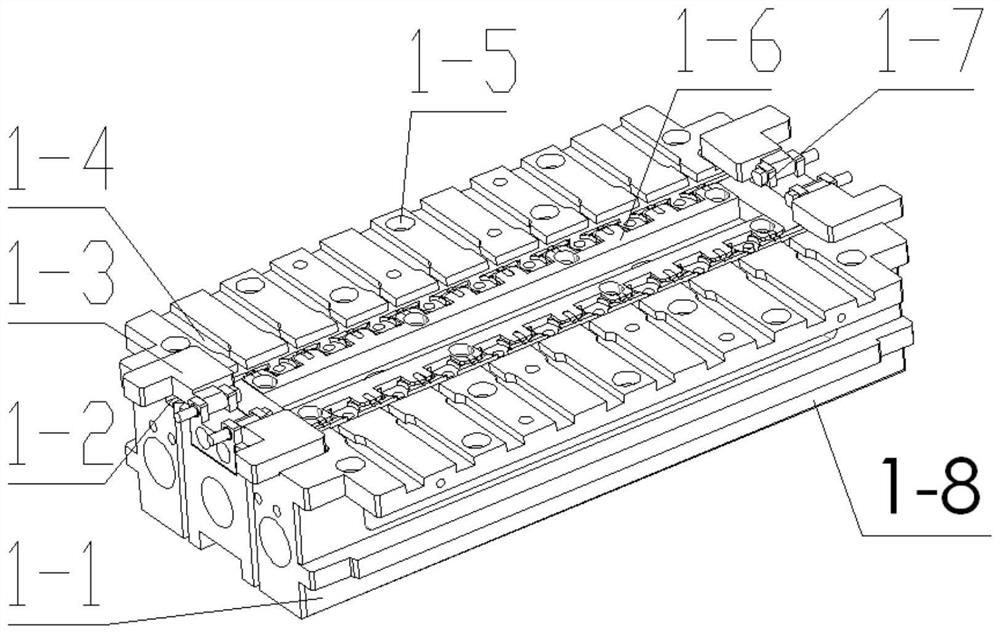

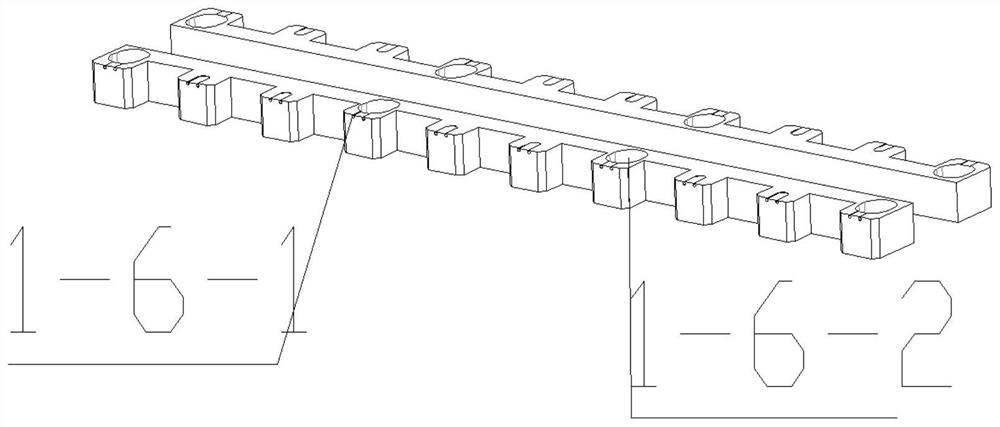

[0054]The base assembly 1 includes: a limiting step 1-1, a bridge drawing tank 1-2, a wire pressure block 1-3, a power-proof head limit fixing groove 1-4, a first magnetic suction hole 1-5 , The wire adjustment baffle 1-6, the wire block rotating shaft 1-7. The base 1-8 is a rectangular structure, the top symmetry distribution two-discharged head limit fixing groove 1-4, on the top surface, the limit fixed groove 1-4 is small, the central to the end is wider The width at the opening is about two wires and the distance is row, and the overall shrinkage is shaped. The limit fixed slot is the first magnetic suction hole 1-5, and the fault is distributed on the surface, and the depth is 3 to 5 mm. The front position of the limit fixed slot is close to the base 1-8 is in the middle position as the wire adjustment baffle 1-6, including wire core limit apertures 1-6-1, wire adjustment baffle position fixing hole 1-6-2, guide wire core The line limit hole 1-6-1 has a diameter of 0.2 to 1 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com