Wheel type polishing and skid-resisting all-in-one machine for complex road working conditions

A complex working condition, integrated machine technology, applied in the direction of testing wear resistance, using mechanical devices, measuring devices, etc., can solve the problems of low test speed, difficult load loading, low accuracy, etc., to improve test conditions and reliability , Reduce the effect of manual operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

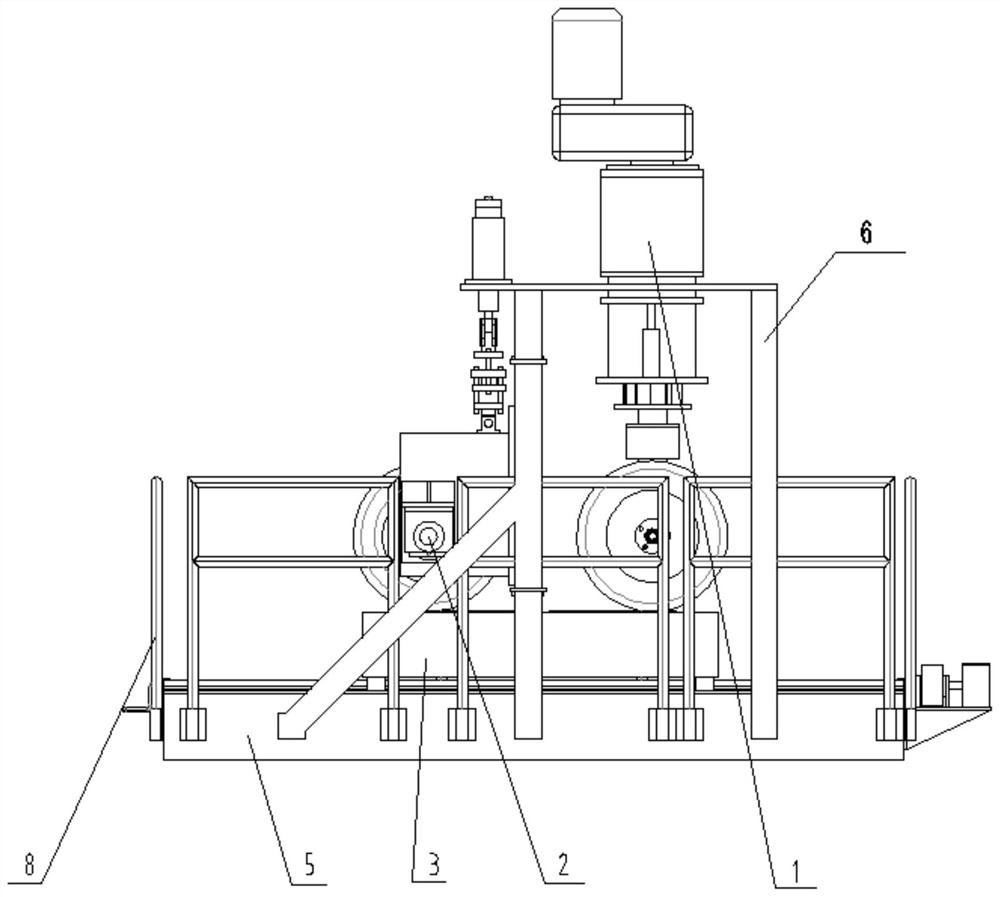

[0036] Specific Embodiment 1: In this embodiment, the wheel-type polishing and anti-skid integrated machine under complex road conditions includes a polishing body 1, an anti-skid performance testing body 2, a mobile workbench 3, a work base 5 and two workbench frames 6 , the mobile workbench 3 slides on the work base 5, two workbench support frames 6 are arranged above the work base 5 at intervals, and the polishing body 1 and the anti-skid performance test body 2 are respectively arranged on the two work support frames 6;

[0037] The polishing body 1 includes a reducer 1-23, a reducer connection sleeve 1-21, a polishing spindle spline jacket 1-1, a polishing spindle turning head 1-12 and a double-wheel mechanism. The mechanism is composed of two grinding machine tires 1-20 connected with a tire shaft 1-17. The grinding machine 1 is sequentially provided with a reducer 1-23, a reducer connecting sleeve 1-21, and a grinding spindle from top to bottom. Spline overcoat 1-1, pol...

specific Embodiment approach 2

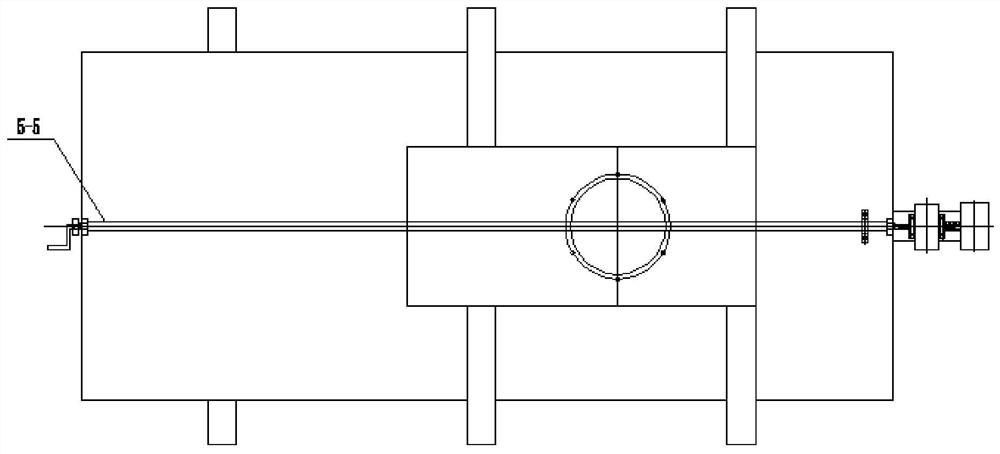

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that two slide rails 4 are provided on the working base 5 , and the mobile workbench 3 is slidably connected within the two slide rails 4 .

specific Embodiment approach 3

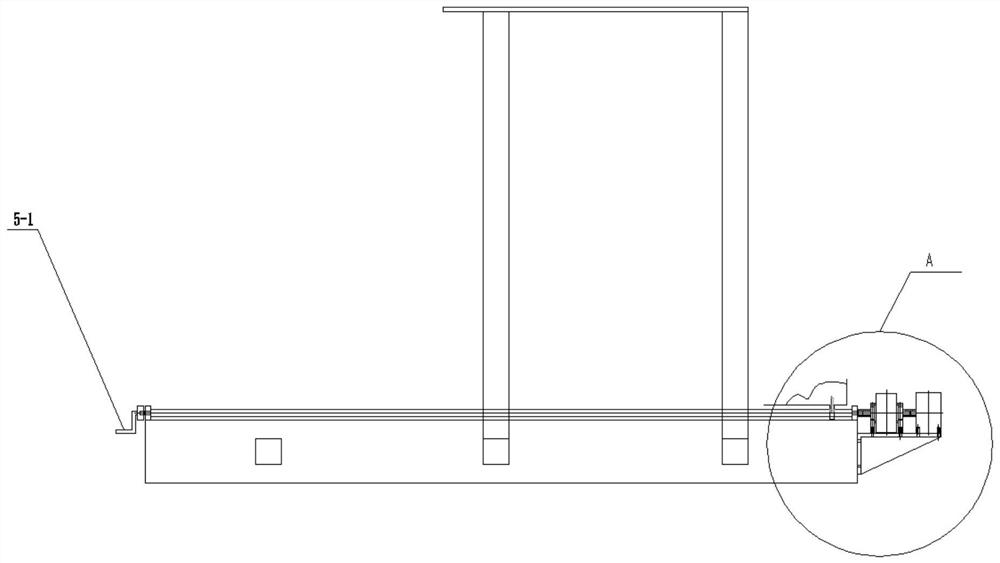

[0042] Specific embodiment three: the difference between this embodiment and specific embodiment two is that a workbench screw 5-5 is also arranged on the working base 5, and the two ends of the workbench screw 5-5 are inserted into the workbench screw bearing seat In 5-6, (at least two) screw nuts 5-4 are sleeved on the workbench screw 5-5, the screw nuts 5-4 are fixedly connected with the mobile workbench 3, and one end of the workbench screw 5-5 passes through The connecting sleeve 5-7 is axially connected with the power output shaft of the motor 5-10.

[0043] In this embodiment, the worktable screw is located between the two slide rails. The other end of the workbench screw 5-5 is provided with a hand handle 5-1, and the power output shaft of the motor 5-10 is also provided with a clutch 5-9, and the clutch 5-9 is fixed by the fixed base plate 5-8 of the clutch .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap