Submicron motion platform and motion control method thereof

A motion platform, sub-micron technology, applied in the direction of AC motor control, control system, connection with control/drive circuits, etc., can solve problems such as poor stability, poor motion control accuracy, complex structure, etc., to improve stability and Motion control accuracy and the effect of improving motion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

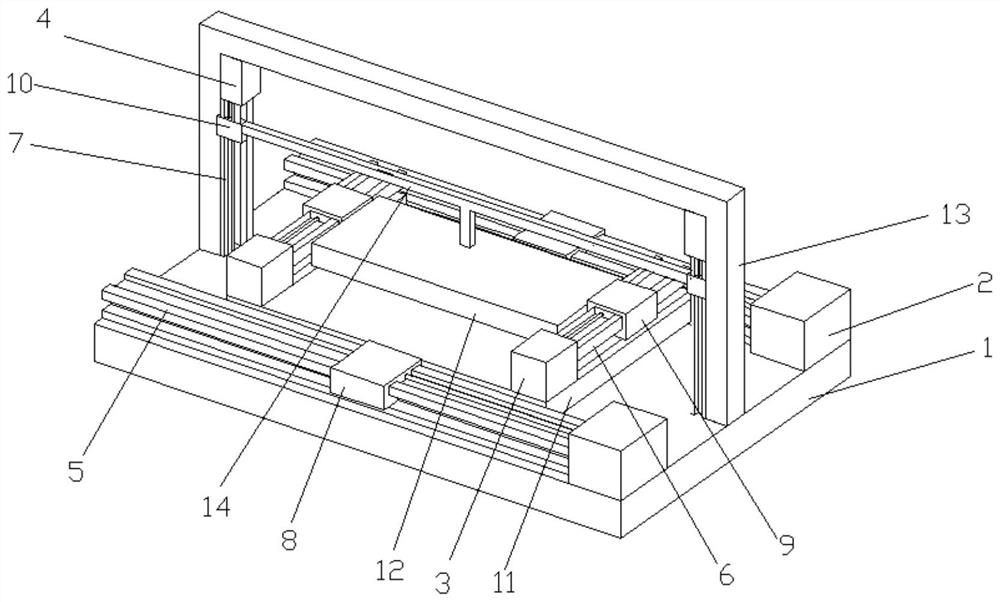

[0032] A sub-micron motion platform comprising a linear motor, an air bearing guide rail, a slider, a grating scale, a granite base plate 1, an X-direction base plate 11, a Y-direction base plate 12, a Z-direction bracket 13 and a drive controller; the linear motor includes X-direction linear motor 2, Y-direction linear motor 3 and Z-direction linear motor 4; the air bearing guide rail includes X-direction air bearing guide rail 5, Y-direction air bearing guide rail 6 and Z-direction air bearing guide rail 7; the slider includes The X-direction slide block 8, the Y-direction slide block 9 and the Z-direction slide block 10, the X-direction slide block 8, the Y-direction slide block 9 and the Z-direction slide block 10 are connected with the X-direction air bearing guide rail 5 and the Y-direction slide rail respectively. The air-floating guide rail 6 is connected to the Z-direction air-floating guide rail 7; the X-direction linear motor 2, the Y-direction linear motor 3 and the...

Embodiment 2

[0034] A sub-micron motion platform, including a linear motor, an air bearing guide rail, a slider, a grating scale, a granite bottom plate 1, an X-direction bottom plate 11, a Y-direction bottom plate 12, a Z-direction bracket 13, a Z-direction operating arm 14 and a drive controller The linear motor includes X-direction linear motor 2, Y-direction linear motor 3 and Z-direction linear motor 4; the air bearing guide rail includes X-direction air bearing guide rail 5, Y-direction air bearing guide rail 6 and Z-direction air bearing guide rail 7 ; The slider includes an X-direction slider 8, a Y-direction slider 9 and a Z-direction slider 10, and the X-direction slider 8, Y-direction slider 9 and Z-direction slider 10 are respectively connected with the X-direction air The floating guide rail 5, the Y-direction air-floating guide rail 6 and the Z-direction air-floating guide rail 7 are connected; the X-direction linear motor 2, the Y-direction linear motor 3 and the Z-direction ...

Embodiment 3

[0037] A motion control method for a submicron-level motion platform. According to the processing procedure of a workpiece, the motion amounts of an X-direction linear motor 2, a Y-direction linear motor 3, and a Z-direction linear motor 4 are set, and the X-direction linear motor is controlled by a drive controller. 2. The Y-direction linear motor 3 and the Z-direction linear motor 4 issue drive commands, the X-direction linear motor 2 receives the drive controller's drive command, drives the X-direction slider 8 to slide on the X-direction air bearing guide rail 5, and the The X-direction bottom plate 11 follows the movement of the X-direction slider 8; the Y-direction linear motor 3 receives the drive command from the drive controller, drives the Y-direction slider 9 to slide on the Y-direction air bearing guide rail 6, and the Y-direction bottom plate 12 follows The Y-direction slider 9 moves; the Z-direction linear motor 4 receives the drive command from the drive controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com