A pcb carrier vehicle and method for improving production efficiency of forming process

A production efficiency, PCB board technology, applied in the direction of printed circuit, electrical components, printed circuit manufacturing, etc., can solve the problems of increasing the probability of product scratches and collisions, increasing product quality hidden dangers, and consuming time and manpower, so as to reduce manual work. The process of framing and unframing reduces hidden dangers of product quality and saves time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

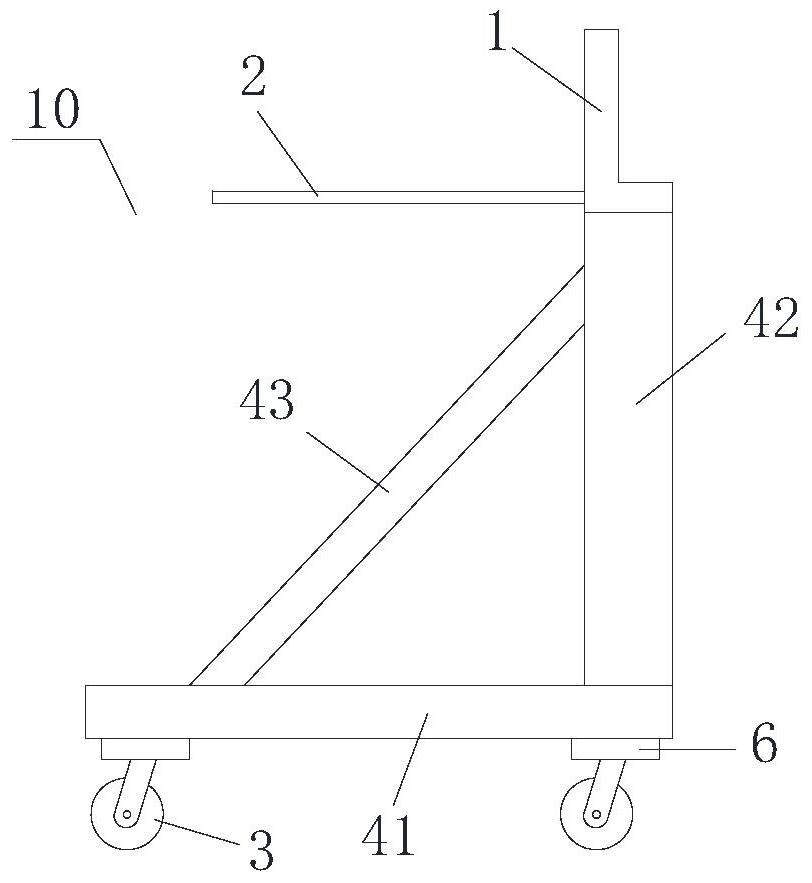

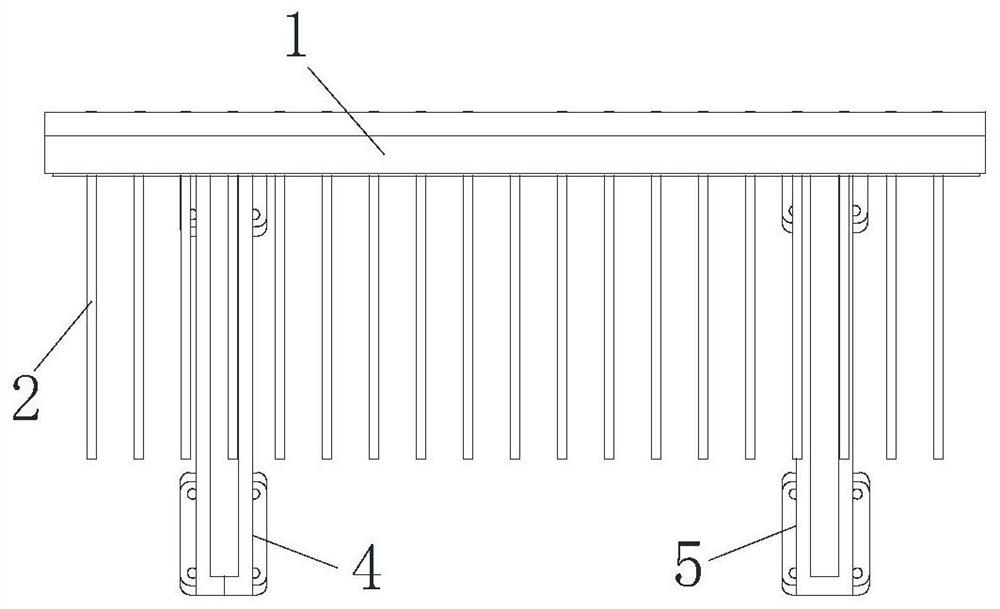

[0031] Such as Figure 1-3 As shown, a PCB carrier vehicle 10 shown in this embodiment includes a bracket, a fixed plate 1 vertically arranged on the upper end of the bracket, and several long strips arranged at the lower end of one side of the fixed plate 1 at intervals in parallel and extending horizontally forward. Rod 2, a plurality of long rods 2 form the placement rack for placing PCB boards, and the fixed plate is used as a baffle plate during transfer, and the lower end of the support is provided with a plurality of rollers 3.

[0032] Specifically, the support includes a first support 4 and a second support 5 symmetrically arranged left and right. There are two rollers 3 distributed front and back.

[0033] Specifically, the first bracket 4 and the second bracket 5 both include a horizontal bar 41 and a vertical bar 42 that is arranged at the rear end of the bar 41 and extends upwards, and the fixed plate 1 straddles the first bracket 4 and the two vertical bars of ...

Embodiment 2

[0036] Such as Figure 1-6 As shown, a method for improving the production efficiency of the molding process shown in this embodiment, adopts the PCB carrier car 10 as described in Embodiment 1 to transfer PCB boards and adopts the retractable board machine 20 used in conjunction with the PCB carrier car For upper board and lower board, the retractable trigger 20 includes a support frame, a transmission roller group movable on the upper end of the support frame, and a cylinder 202 arranged on the support frame and used to drive the transmission roller group to move up and down. The upper end of the side is provided with a plurality of grooves 201 for one-to-one insertion of the long rods between the two rollers; the method for improving the production efficiency of the molding process includes the following steps:

[0037] a. The ends of the upper plate section 31 (conveyor belt) and the lower plate section 32 (conveyor belt) of the V-CUT machine 30 are all docked with a retra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com