Transfer AGV trolley, and intelligent transfer system and intelligent transfer method of printed board

A technology of printed boards and trolleys, which is applied to vehicles used for freight transport, vehicles that carry parallel movements, and motor vehicles, can solve the problems of increasing product quality hidden dangers, wasting manpower, and having a large number of turnover baskets and carrier trolleys. To achieve the effect of reducing the process of framing and framing, reducing the probability of rubbing and collision, and reducing the hidden danger of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

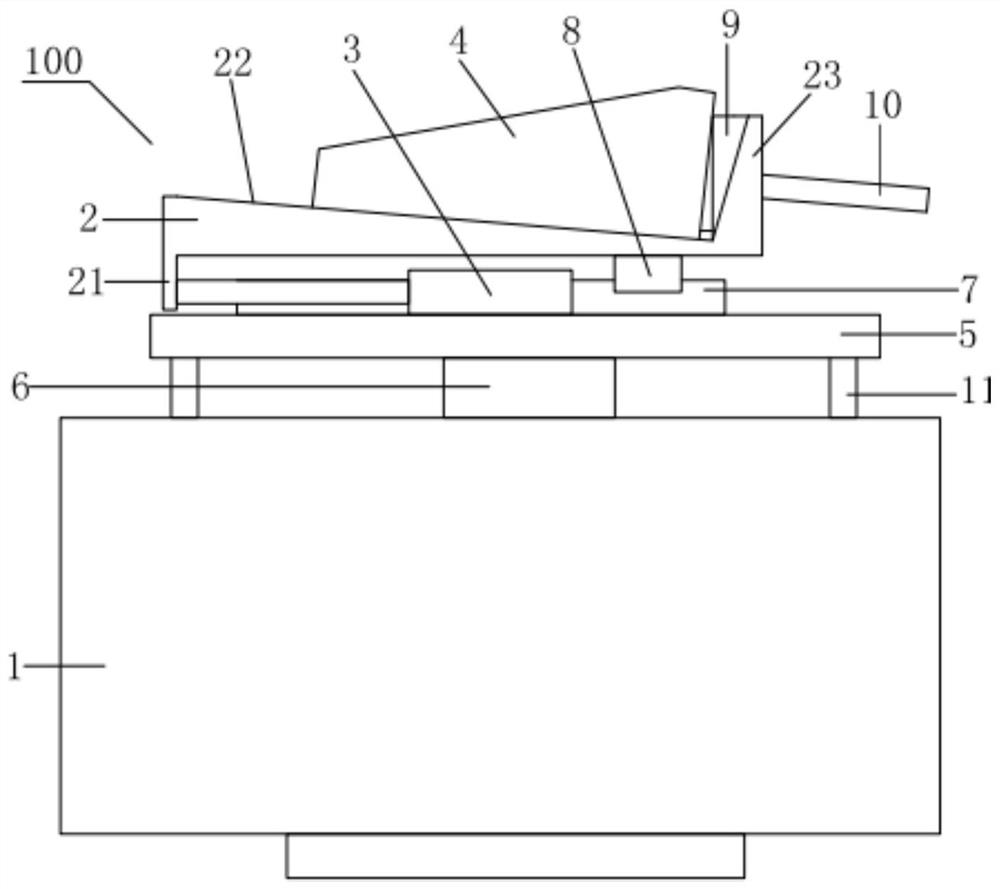

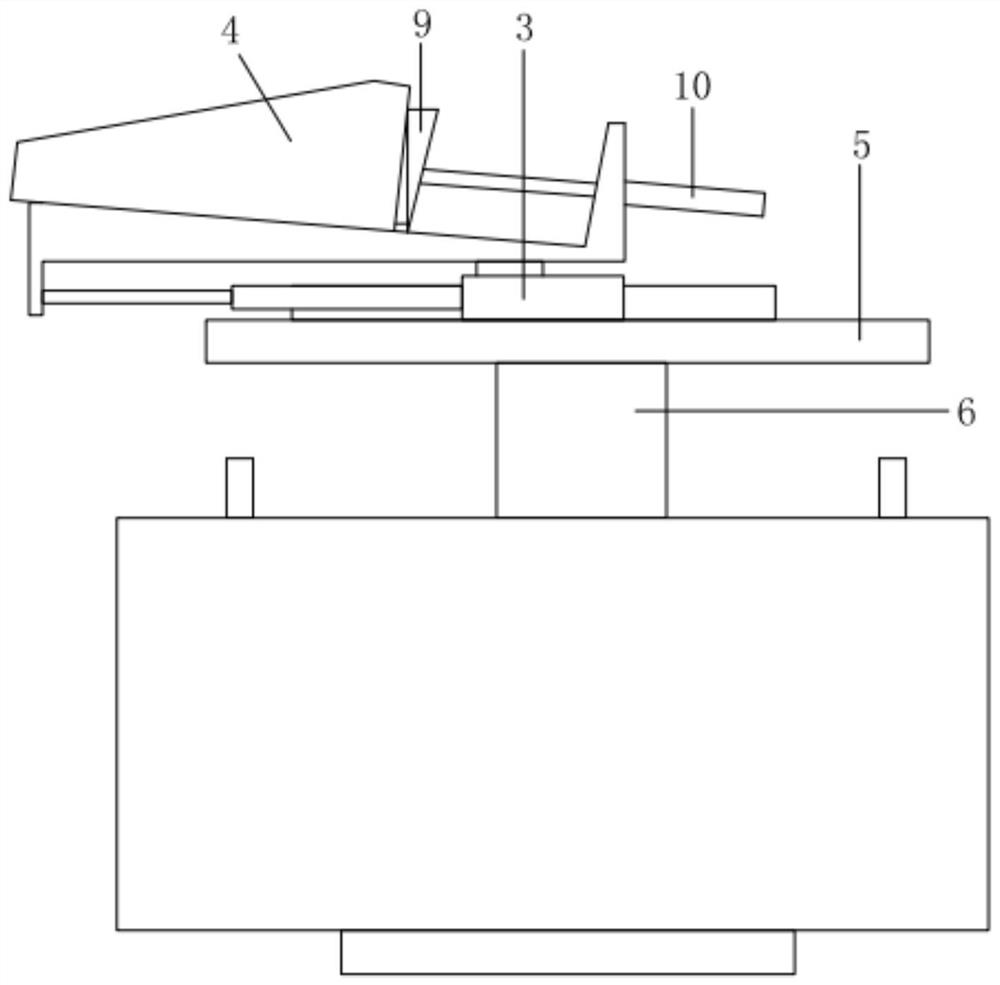

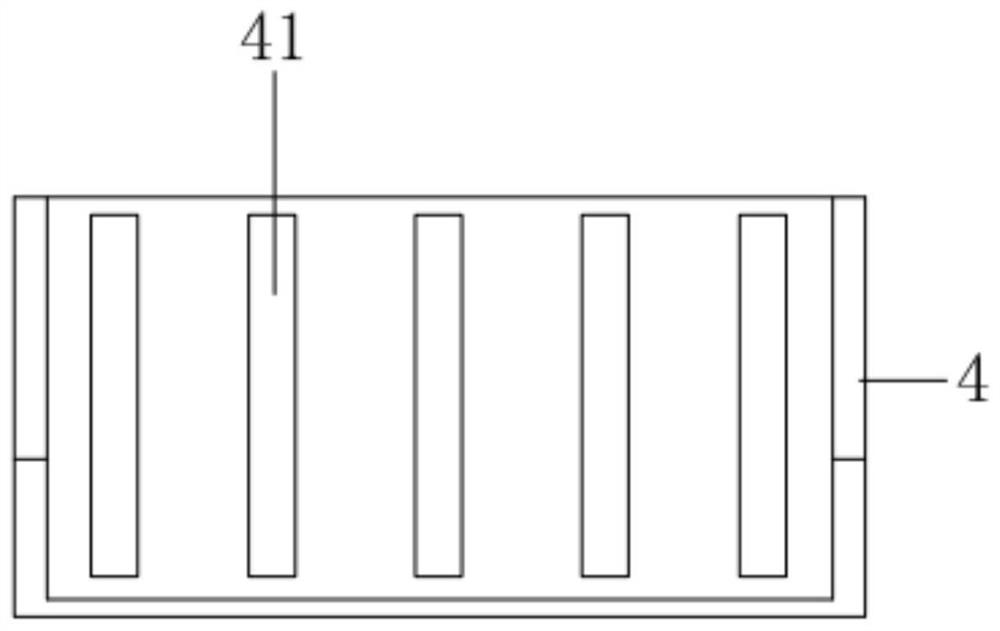

[0044] Such as Figure 1-5 As shown, a transfer AGV trolley 100 shown in this embodiment includes a jack-up AGV trolley 1, a sliding frame 2, a driving device 3, a transfer frame 4 and a push plate mechanism, and the upper end of the AGV trolley 1 has two front and rear Distributed jacking device, the jacking device can move up and down in the longitudinal direction, and a sliding frame 2 is slid on each jacking device; the driving device 3 is arranged on the jacking device and is used to drive the sliding frame 2 to move left and right ; The upper end of each sliding frame is slidingly provided with a transfer frame 4 for loading printed boards; the push plate mechanism is located on the sliding frame and is used to push the transfer frame forward so that the transfer frame moves forward and leaves the sliding frame; Therefore, the functions of lifting, translation and pushing are integrated on the AGV trolley, so that the transfer frame on it can be docked with the board mac...

Embodiment 2

[0054] Such as Figures 1 to 6 As shown, this embodiment provides an intelligent transfer system for printed boards, including:

[0055] The plate placing machine 200 is used for the automatic board unloading operation of the printed board;

[0056] Several gong machines 300 are distributed and arranged on the ground 800 in a square array;

[0057] A plurality of tooling frames 400 are provided with a tooling frame 400 on both sides of each gong machine 300;

[0058] At least one transfer AGV trolley 100 as described in Embodiment 1, which can move horizontally and vertically along the line network preset on the ground 800, and the transfer AGV trolley can move to the trigger or each tooling along the line network the front of the shelf.

[0059] The intelligent transfer system provided above draws on the principle of the sorting system of express delivery, distributes several gongs in a square array, and then arranges a line network around the gongs to guide the direction ...

Embodiment 3

[0067] This embodiment provides an intelligent transfer method for printed boards. The intelligent transfer system for printed boards described in Embodiment 2 is used for transfer. The intelligent transfer method includes the following steps:

[0068] a. At the beginning, the transfer AGV trolley is moved to the lower plate position of the board release machine, and then through the lifting and translation functions of the transfer AGV trolley, the transfer frame is docked with the board release machine, and then the printed boards are automatically placed in sequence through the board release machine in a transfer rack;

[0069] b. Then return the transfer rack to its original position, and control the transfer AGV trolley to automatically move along the line network to the tooling racks on both sides of the corresponding gong machine station;

[0070] c. Then use the jacking device and driving device on the transfer AGV trolley to make the sliding frame dock with the toolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com