Capacitor conveying assembly line

An assembly line and capacitor technology, applied in electrical components, electrical components, etc., can solve the problems of large soft extrusion loss of pin quality, static leakage of pin rods, unqualified pins, etc., to improve the safe storage of terminal stacking materials. Effect, guarantee the effect of quality adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

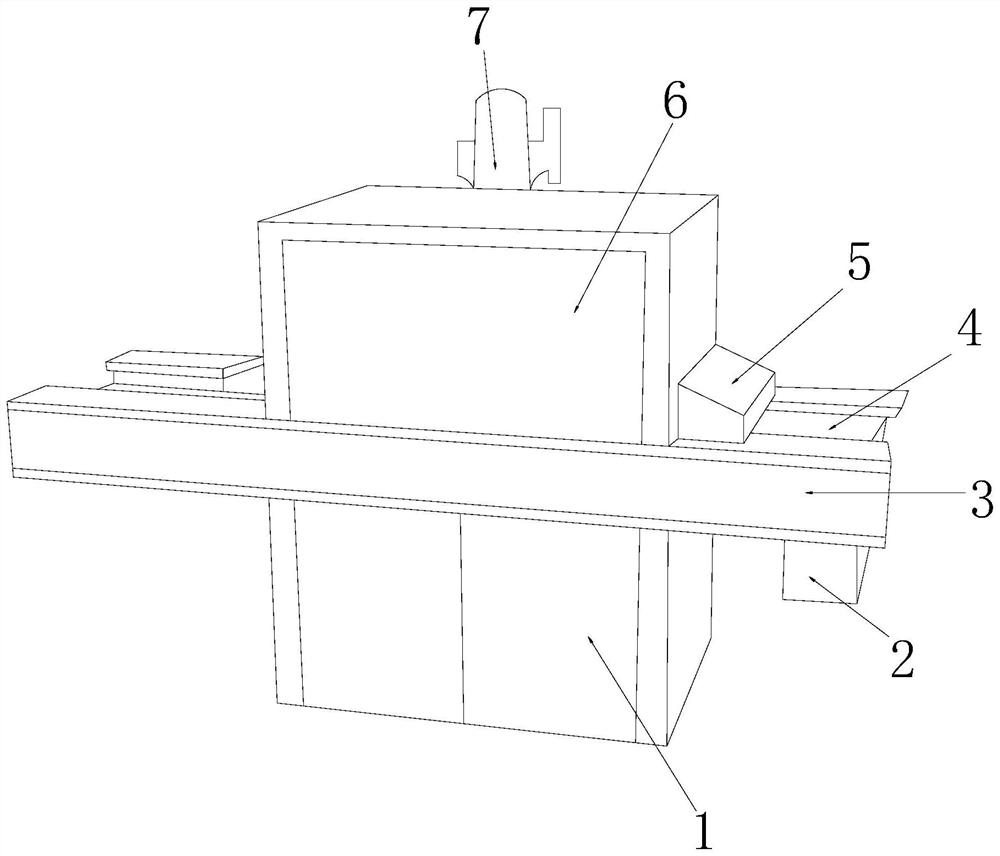

[0032] see Figure 1-Figure 6, the present invention provides a capacitor conveying line, the structure of which includes: a power distribution base box 1, a pin clamp stacking groove 2, a roller side frame plate 3, a conveyor belt 4, a counterweight block 5, and an assembly line cover 6. The cylinder groove 7, the pin clamping stack groove 2 is inserted in the lower right corner of the conveyor belt 4 and is perpendicular to each other, the power distribution base box 1 is nested under the bottom of the assembly line cover 6 and is in the same On the vertical plane, the column groove 7 is inserted on the top of the assembly line cover 6 and is on the same vertical plane, and the counterweight pressing block 5 is close to the lower right corner of the assembly line cover 6 and is on the same vertical plane. On the straight face, there are two roller side frame plates 3 and they are respectively nested on the front and back sides of the conveyor belt 4. The top surface of the ...

Embodiment 2

[0038] see Figure 1-Figure 6 , the present invention provides a pipeline for conveying capacitors, the other aspects are the same as in Embodiment 1, the difference is that:

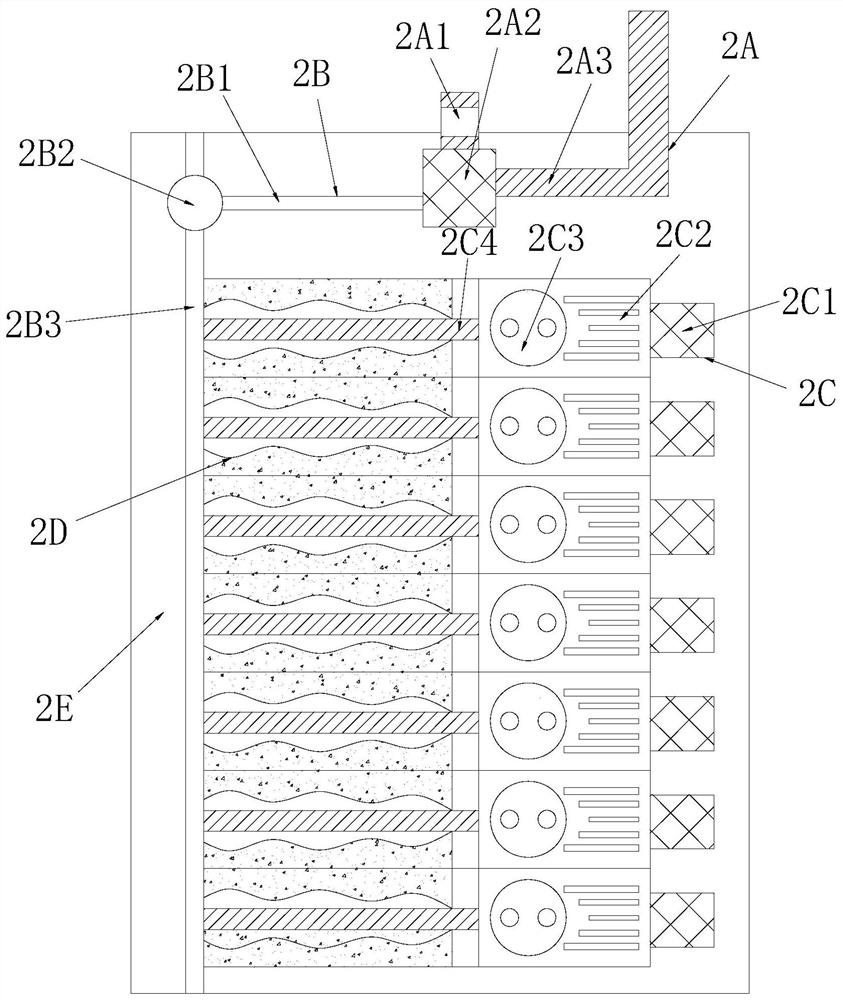

[0039] see figure 2 The storage tank seat 2C is composed of an arc top support rod block 2C1, a ventilating slot seat 2C2, a side-mounted suction cup 2C3, and an electroplating ring rod 2C4. The electroplating ring rod 2C4 is inserted on the left side of the side-mounted suction cup 2C3. The above-mentioned side-attached suction cup 2C3 and the arc-top support rod block 2C1 are respectively closely attached to the left and right sides of the air-permeable slot seat 2C2 and are on the same vertical plane, and the side-positioned arc-top support rod block 2C1 presses the side-attached suction cup 2C3 to form compressed air. The close-to-pad protective clamping effect when the suction capacitor is stored.

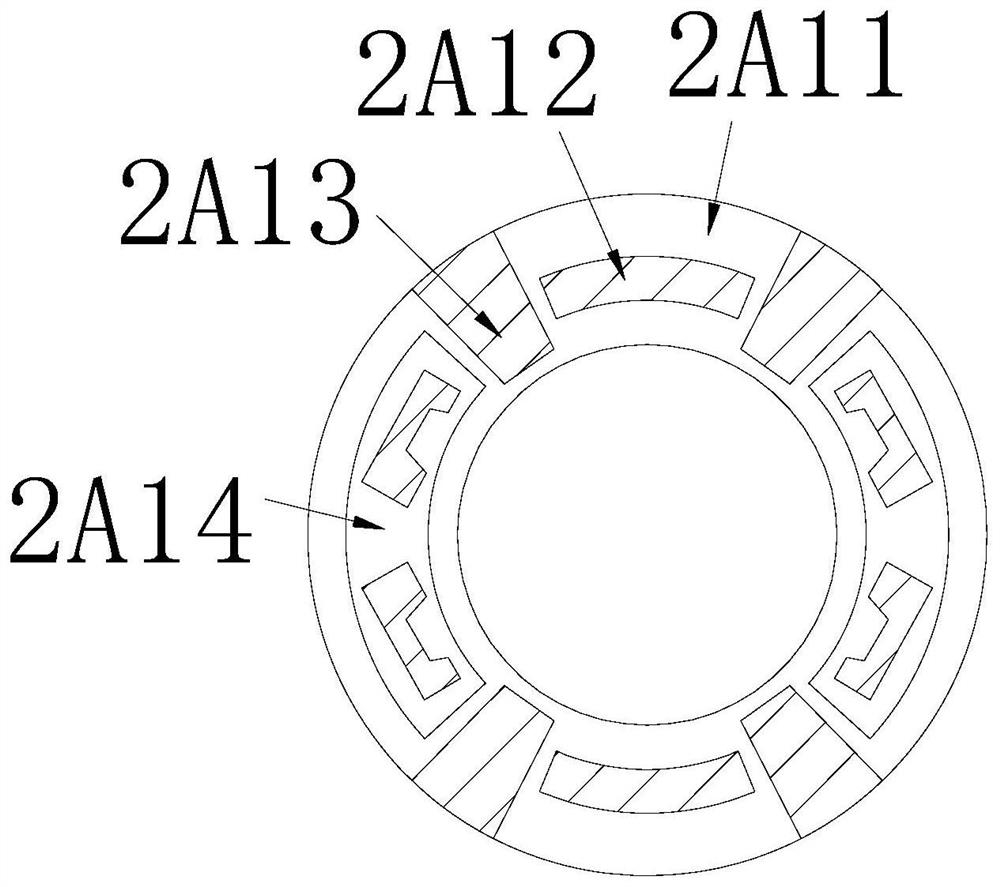

[0040] see Figure 5 , the arc top pole block 2C1 is composed of a double pole ear plate 2C11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com