Efficient crushing device for ore processing

A pulverizing device and ore technology, applied in the field of ore processing, can solve the problems of energy waste, affecting the user's production efficiency, etc., and achieve the effects of convenient use, simple structure and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

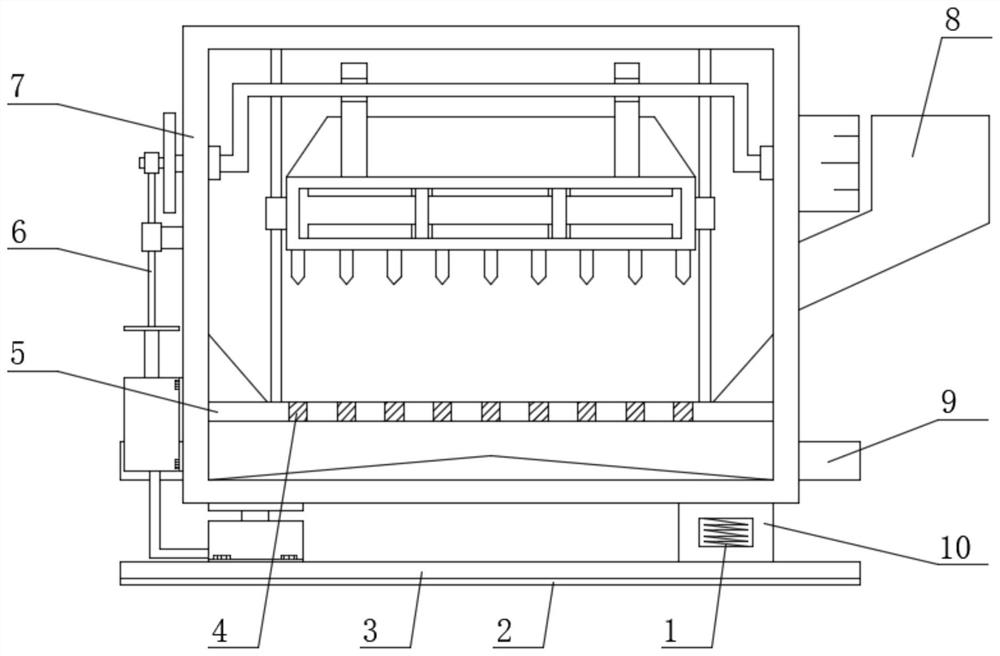

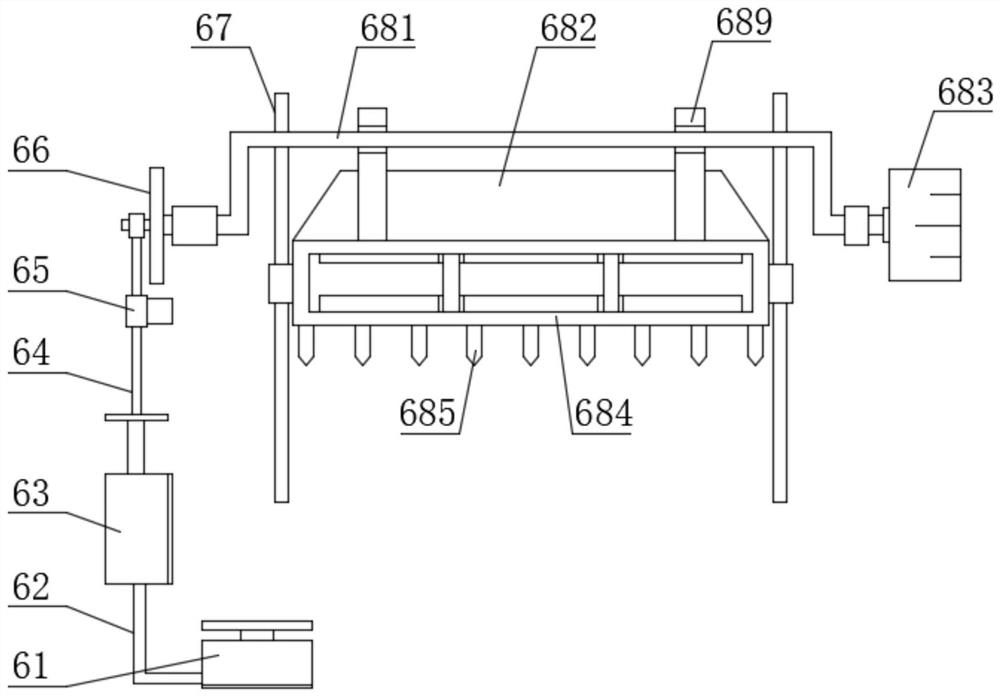

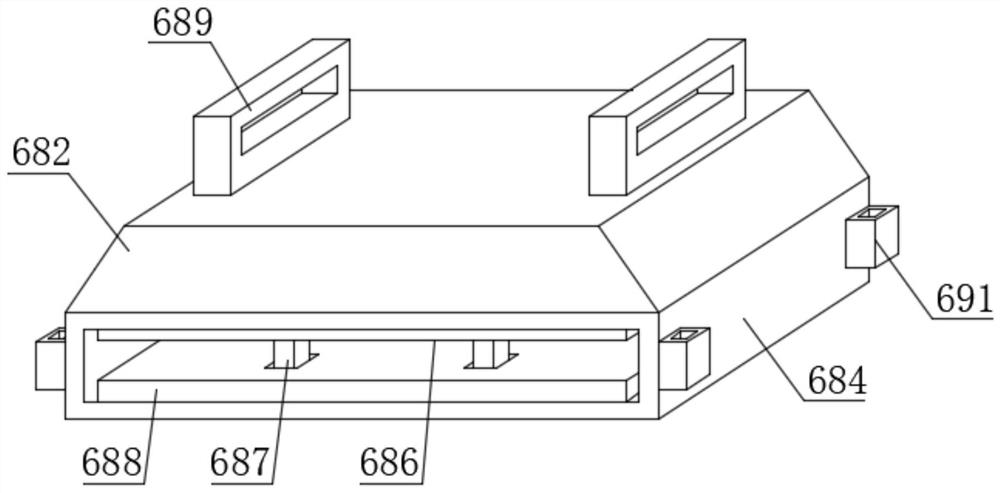

[0023] see Figure 1-Figure 3 , the present invention provides a technical solution: a crushing device for high-efficiency ore processing, including a crushing box 7, a feed hopper 8 is welded to the top of the side of the crushing box 7, a discharge pipe 9 is welded to the bottom of the crushing box 7, and the crushing The bottom end of case 7 is welded with deflector corresponding to discharge pipe 9, and the inside of crushing case 7 is provided with crushing mechanism 6, and crushing mechanism 6 comprises drive motor 683, and the output end of drive motor 683 is provided with drive shaft 681, The two ends of the transmission shaft 681 are provided with limit bearings corresponding to the crushing box 7, and the bottom of the transmission shaft 681 is provided with a crushing hammer 684, and the two ends of the upper surface of the crushing hammer 684 are welded with transmission plates 689 corresponding to the transmission shaft 681. , the two sides of the crushing hammer ...

Embodiment 2

[0030] On the basis of Embodiment 1, in order to make the supporting effect of the rubber support block 10 better, in this embodiment, preferably, the interior of the rubber support block 10 is embedded with a limit spring 1, and the material of the limit spring 1 is stainless steel , during use, the limit spring 1 cooperates with the rubber support block 10 to support, and the limit spring 1 plays a role in vibrating, thereby amplifying the vibration of the crushing box 7;

[0031] In order to prevent the impact plate 688 from colliding with the top of the crushing hammer 684 to cause abnormal noise, in this embodiment, preferably, the interior of the crushing hammer 684 is provided with a cushion plate 686 corresponding to the impact plate 688, and the material of the cushion plate 686 is for rubber;

[0032] The connection mode of the cushioning plate 686 is not limited, in order to make the use of the cushioning plate 686 more reliable, in this embodiment, preferably, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com