A kind of additive manufacturing method and its preparation method and device using powder core wire

A technology of additive manufacturing and powder core wire, applied in the field of additive manufacturing, can solve problems such as difficult to achieve continuous and precise changes in composition, single alloy composition, etc., to achieve the effects of improving composition editing accuracy, avoiding process restrictions, and retaining flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

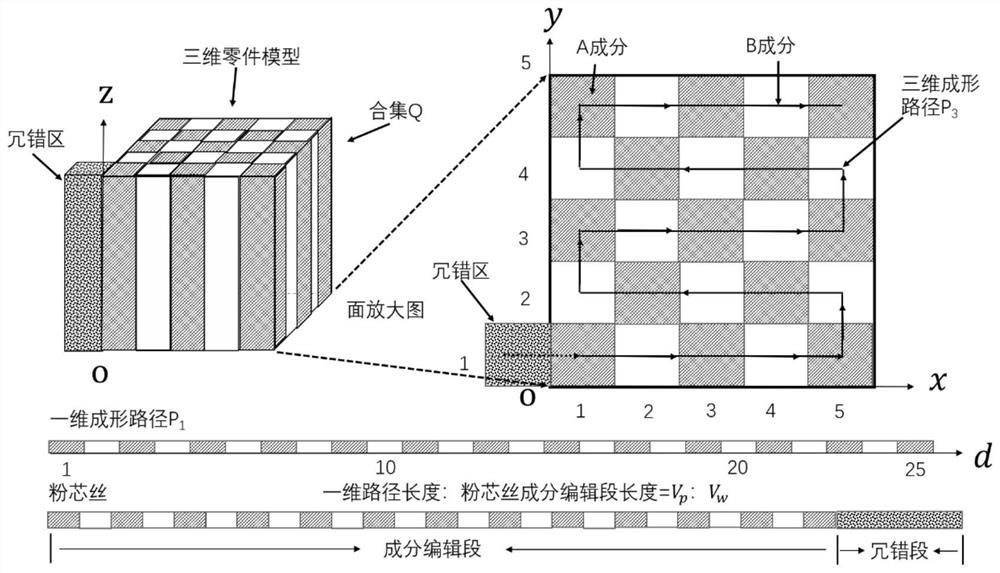

[0085] Such as Figure 1-Figure 3 shown. according to figure 1 , for a given component set Q={x, y, z, C}, it is composed of components A and B intervals, where the functional relationship between components and positions is:

[0086]

[0087] according to figure 1 Planning 3D Forming Paths

[0088] P 3

[0089] ={(1,1,0,C A )...(5,1,0,C A ),(5,2,0,C B )...(1,2,0,C B ),(1,3,0,C A )...(5,3,0,C A ),(5,4,0,C B )...(1,4,0,C B )(1,5,0,C A )...(5,5,0,C A );(1,1,1,C A )...(5,1,1,C A ),(5,2,1,C B )...(1,2,1,C B ),(1,3,1,C A )...(5,3,1,C A ),(5,4,1,C B )...(1,4,1,C B )(1,5,1,C A )...(5,5,1,C A );...}.

[0090] Through the coordinate transformation law, the three-dimensional forming path P in this example can be 3 ={x,y,C} is transformed into a one-dimensional shaping path P 1 =

[0091] {d,C}, where so

[0092] P 1 ={(1,C A ),(2,C B ),(3,C A )…(25,C A );(26,C A )…} (13)

[0093]Similarly, according to this rule, the alloy composition function C(...

Embodiment 2

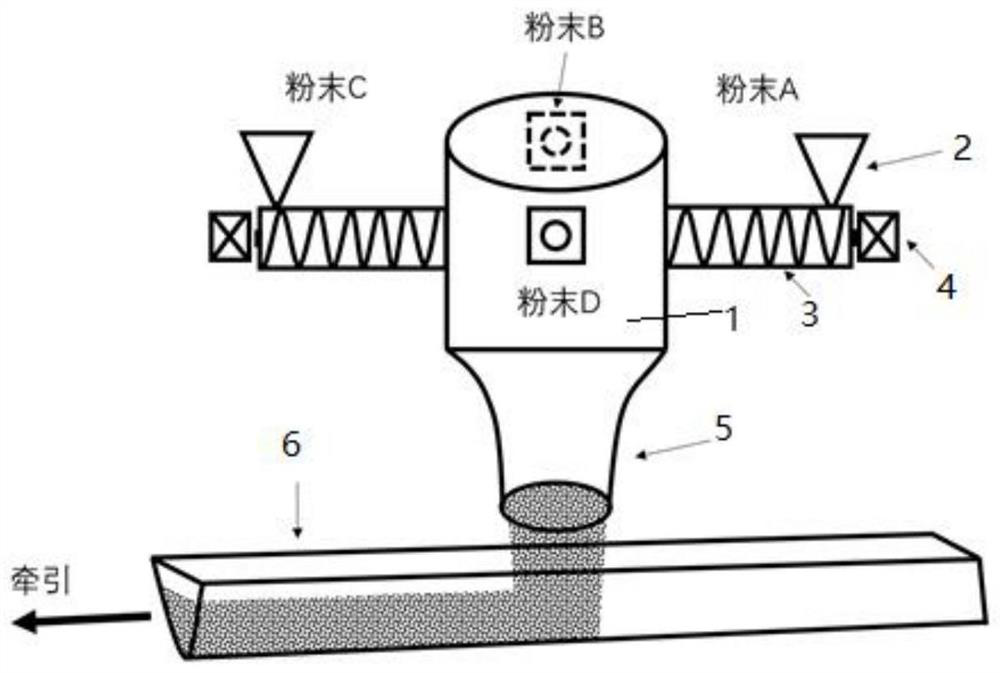

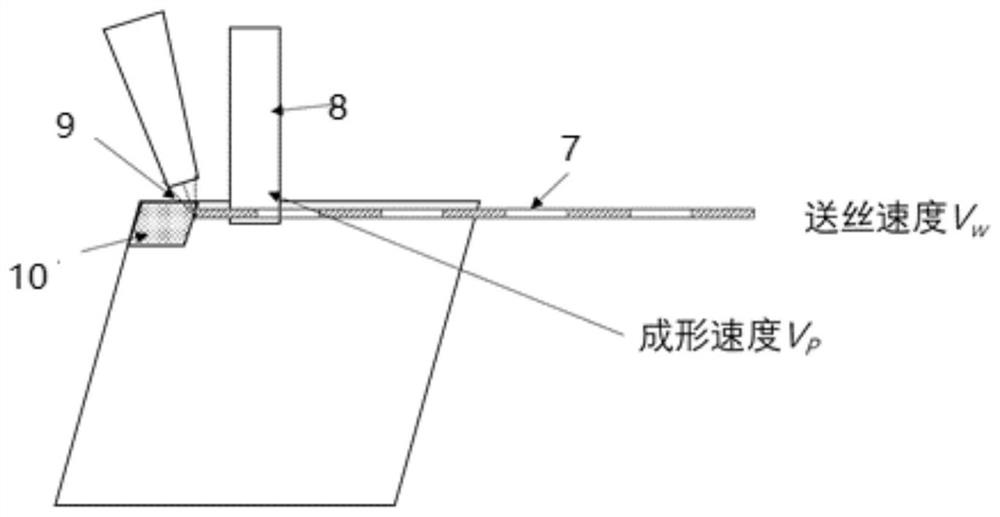

[0104] In a typical implementation of this application, such as Figure 2-Figure 4 shown. according to Figure 4 , for a given part composition set Q={ρ,θ,z,C}, which is composed of components A and B intervals, where the components And, the forming speed is

[0105] Further, plan the 3D forming path And according to the coordinate transformation law, the three-dimensional forming path P 3 {ρ,θ,C} into a one-dimensional shaped path

[0106] Similarly, according to this rule, the three-dimensional alloy composition function can be transformed into a one-dimensional alloy composition function Set the wire feed speed to Where l is the length of the powder core wire. Among them, the one-dimensional forming path distance d and the powder core wire length l satisfy the relationship: (in this example set ). Therefore, combining the above formulas, we can get

[0107] And, add a redundant segment with a length of a (in this example, a=2.3) and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com