Plate chambering machine

A technology of chamfering machines and plates, which is applied to machine tool parts, metal processing machinery parts, manufacturing tools, etc. It can solve the problems that the chamfering machine cannot meet the chamfering efficiency and the chamfering efficiency cannot meet the production demand, so as to improve processing efficiency and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

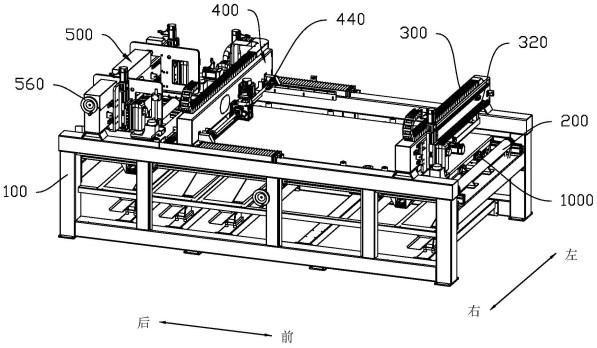

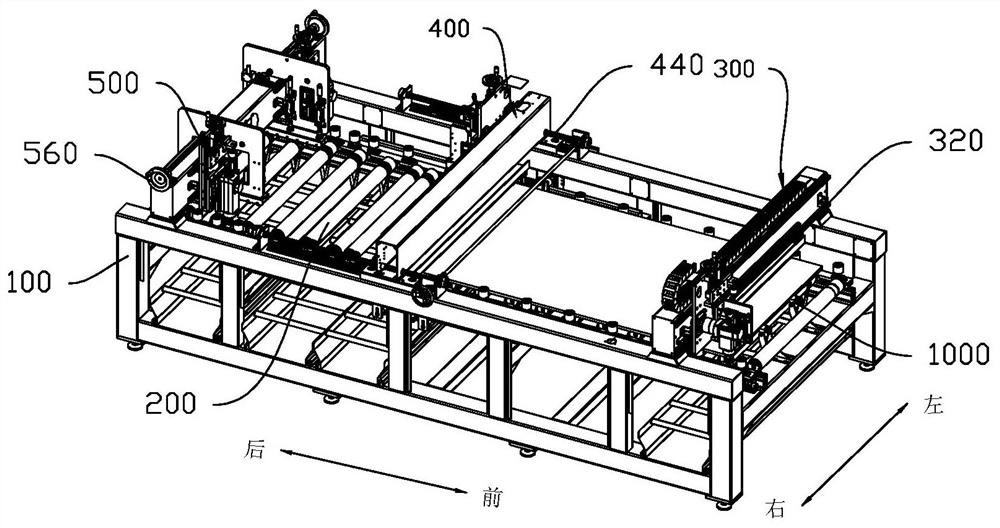

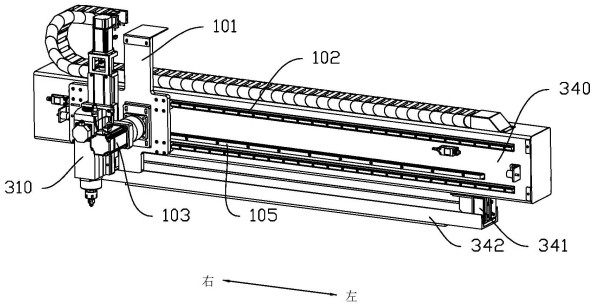

[0056] refer to Figures 1 to 2 As shown, a plate chamfering machine includes a frame 100, a conveying mechanism 200, a first single-side chamfering unit 300, a second single-side chamfering unit 400, and a double-sided chamfering unit 500; the conveying mechanism 200 is horizontally arranged on the machine On the top of the frame 100, the first single-side chamfering unit 300 and the double-side chamfering unit 500 are located above both ends of the frame 100, and the second single-side chamfering unit 400 is located between the first s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap