A radish slicer

A slicing device and radish technology, applied in the direction of metal processing, etc., can solve the problems of difficult control of slice thickness and uneven slice, and achieve the effect of solving difficult control of slice thickness, solving uneven slice, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

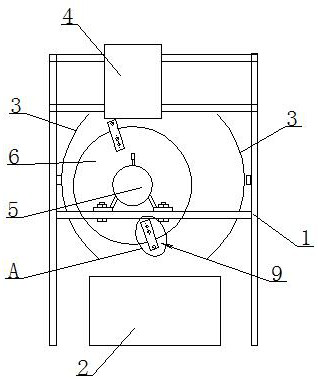

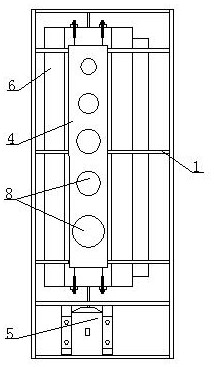

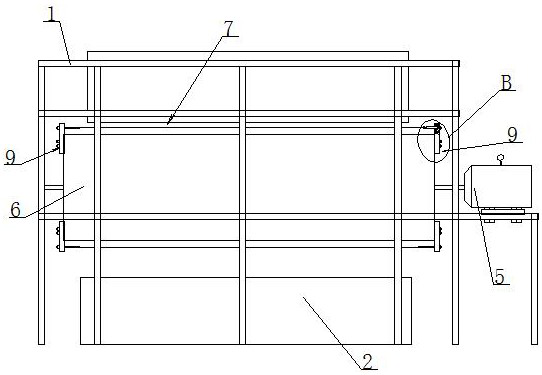

[0021] This radish slicing device comprises a frame 1, a container 2, a protective plate 3, a feeder 4, a driving motor 5, a drum 6 and a slicing steel wire 7 (see the appendix of the instruction manual) figure 1 and 2 ).

[0022] Roller 6 is housed by drive motor 5 on the frame 1 (referring to instruction manual appendix figure 1 and 2 ); the driving motor 5 can drive the drum 6 to rotate synchronously when it works.

[0023] The frame 1 above the drum 6 is equipped with a feeder 4 (referring to the instructions attached figure 1 and 2 ); the feeder 4 has a "strip-like" structure; the feeder 4 is provided with a plurality of feeding holes 8 at intervals; when working, the radish is placed in the feeding hole 8, and the radish is vertically The straight state maintains a falling tendency, so that the radish slicing device can smoothly complete the slicing work of radish.

[0024] The aperture size of each blanking hole 8 is inconsistent, so the purpose of setting blankin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com