Bamboo flattening and rough milling fluffer and processing method

A technology of deflagging machine and bamboo, which is applied in the direction of sugarcane mechanical processing, mechanical equipment, etc., can solve the problems of high labor cost, low processing efficiency, and thick connecting strips, so as to reduce labor intensity, reduce production and processing costs, and improve production and processing. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

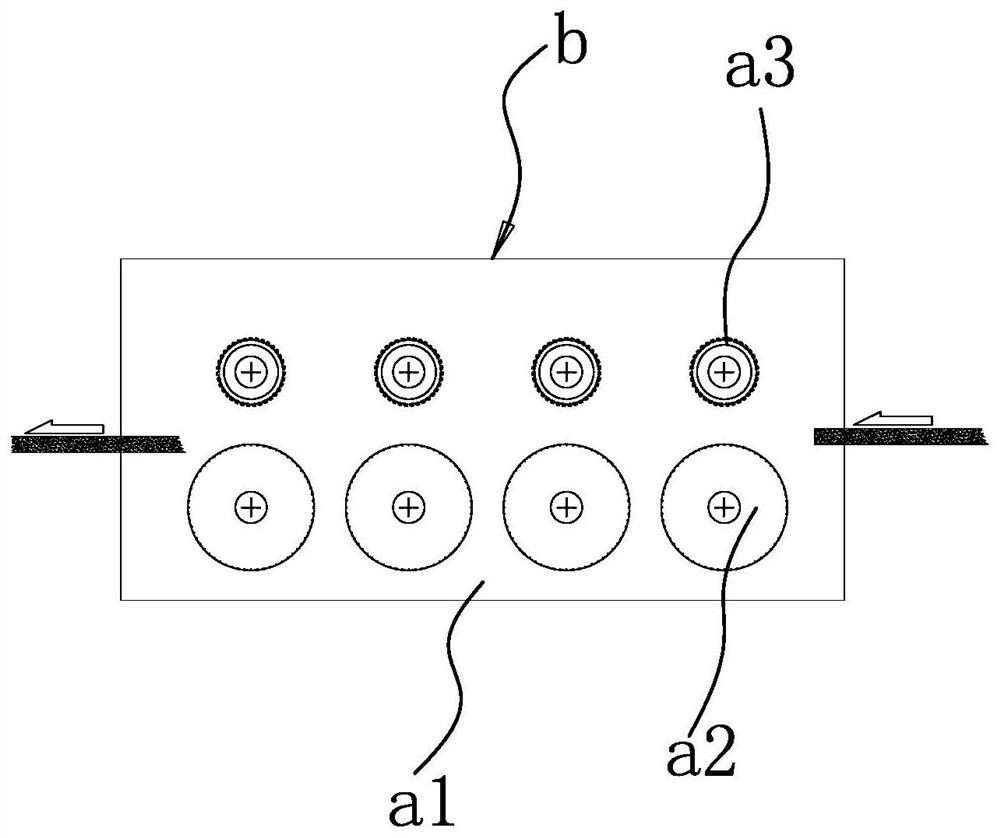

[0067] Such as Figure 11 with 12 As shown, the bamboo flattening rough milling and deflaking machine includes a bamboo feeding device d that transports the bamboo with the yellow side upwards. The bamboo feeding device d includes several groups of feeding wheels that are evenly spaced, artificially or mechanically feeding and making the bamboo It enters from the feeding end of the bamboo feeding device d, and is output from the output end of the bamboo feeding device d through the bamboo feeding device d. During this process, the yellow side of the bamboo faces upward, and the feeding wheel can turn the yellow side The upper inner huang joint blocks are crushed to facilitate subsequent flattening and improve smoothness of flattening.

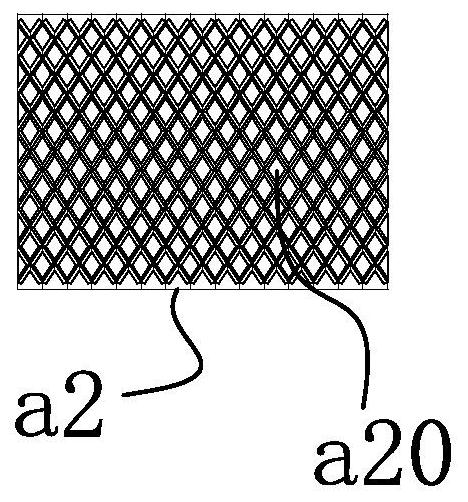

[0068] Such as Figure 13-14 with Figure 18 As shown, the bamboo green surface profiling removal device e is used to remove the green surface on both sides of the bamboo green surface. Because the cross-section of the bamboo at this time i...

Embodiment 2

[0132] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the different structures are: S2, chamfering the edges and corners of the green surface, the bamboo material feeding device d transports the bamboo to the green surface copying device e for the green surface of the bamboo material, and the green surface of the bamboo material imitates The shape removal device e chamfers the two sides of the green surface of the bamboo to remove the green. That is, at this moment, the angle formed by the two green flat knives for chamfering and removing blue is smaller than the angle formed by the two green flat knives when only removing green on both sides of embodiment one, and the green surface is removed while chamfering .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com