Cutting mechanism for producing light wall material

A cutting mechanism and lightweight wall technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of low efficiency of mass production, inconsistent size of mass production, and affecting the quality of wall construction, etc. Achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

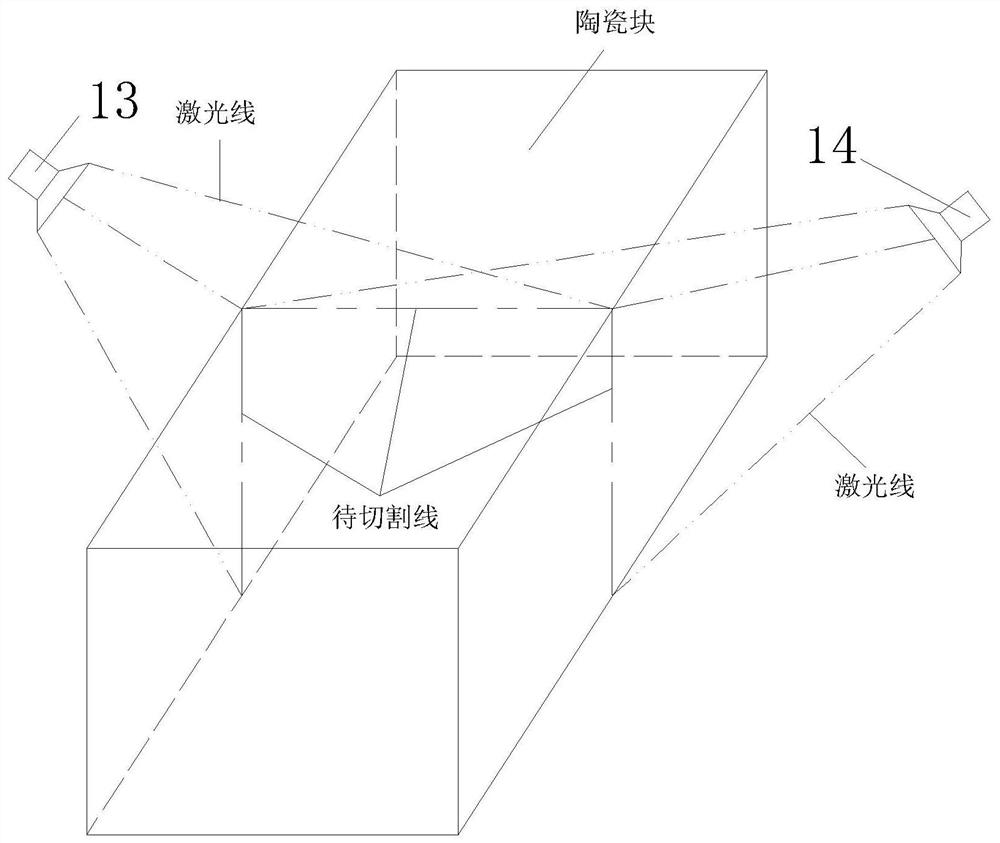

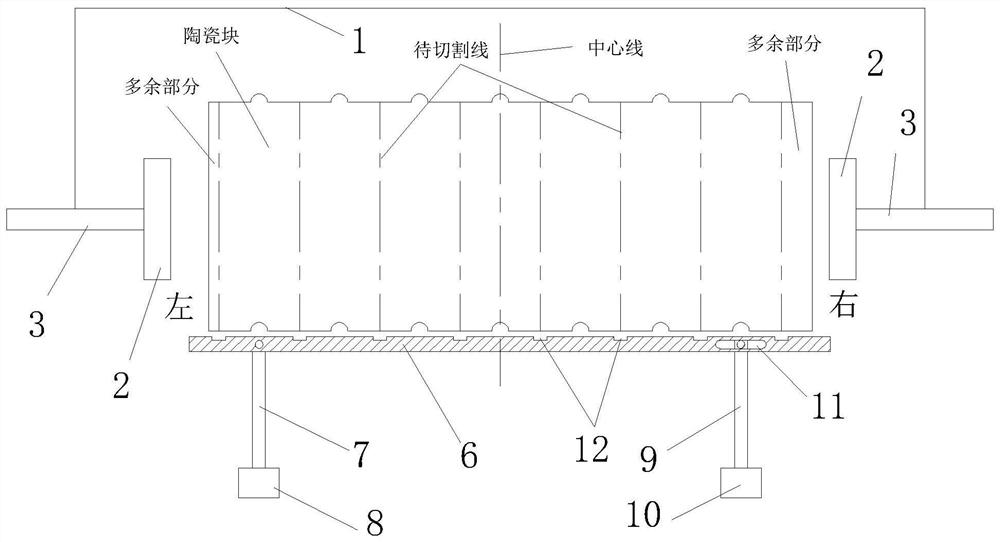

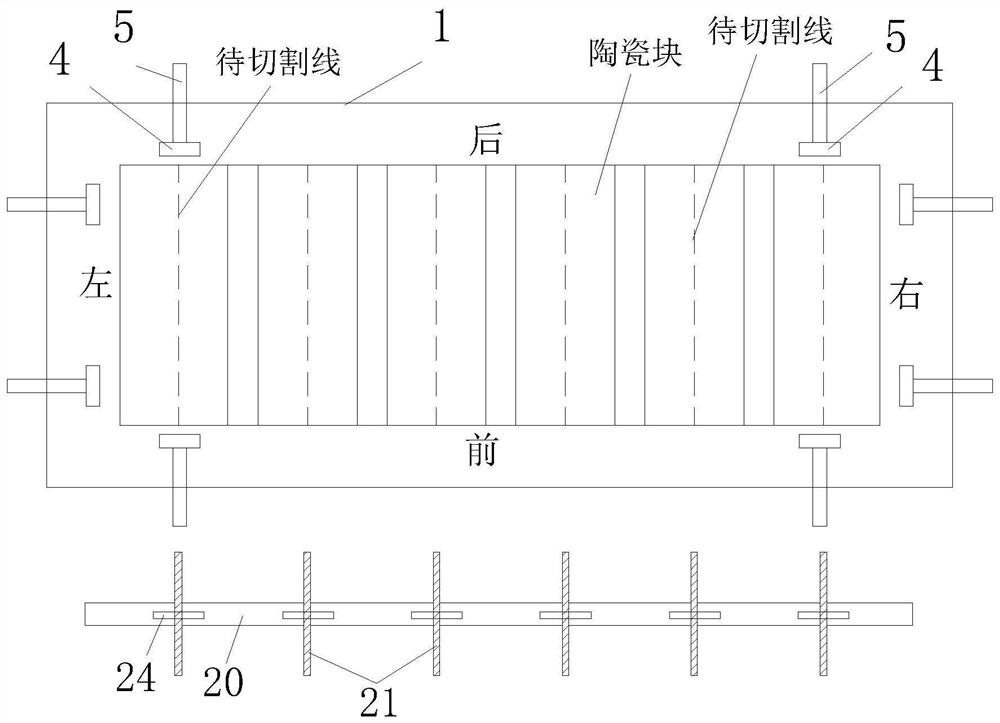

[0039] Such as Figure 1 to Figure 8 As shown, this embodiment discloses a cutting mechanism for producing lightweight wall materials, which mainly includes a fixed frame, a stick, a lifting platform for driving the fixed frame to move up and down, a posture adjustment device, a mounting frame 1, and a 1 horizontal adjustment device, vertical adjustment device, laser positioning device, and cutting device. The lifting platform is fixedly arranged on the adjustment station, and the fixing frame is fixedly arranged on the lifting platform. Several sticks are arranged side by side on the fixed frame, and can rotate on the fixed frame. The posture adjustment device is arranged at the bottom of the fixed frame, and lifts the ceramic block to be positioned and cut from bottom to top. The installation frame 1 is located above the fixed frame. The horizontal adjustment device is arranged on the left and right sides of the installation frame 1, and fine-tunes its position from the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com