Automatic batching device for PVC plastic production

An automatic batching and plastic technology, applied in the field of PVC plastic production, can solve the problems of reducing the working efficiency of batching, unable to monitor the weight of raw materials, unable to proportion the raw materials, etc., and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

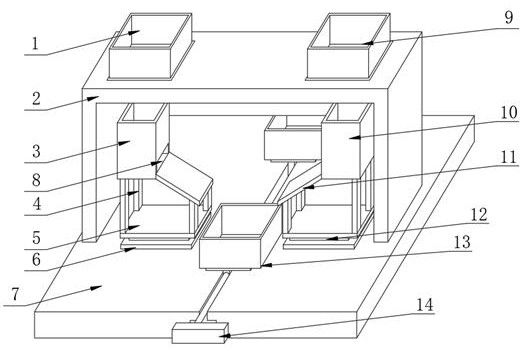

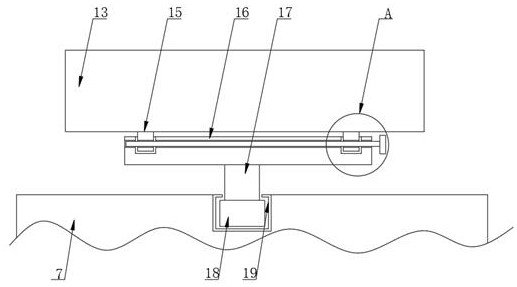

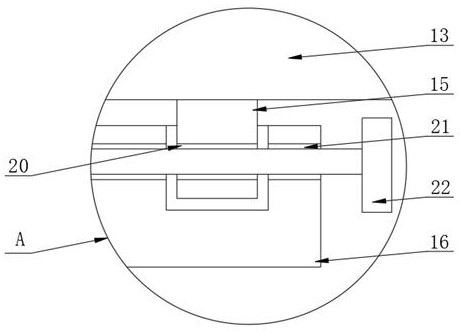

[0026] see Figure 1-7 , in an embodiment of the present invention, an automatic batching device for PVC plastic production, including a workbench 7, the upper surface of the workbench 7 is integrally installed with a support frame 2, and the upper surface of the support frame 2 is respectively arranged from left to right There are a first raw material box 1 and a second raw material box 9, one side of the first raw material box 1 is fixedly connected with a connection plate 30, the upper surface of the connection plate 30 is provided with a material control electric telescopic rod 33, and the material control electric telescopic rod 33 The telescoping end is connected with a connecting sleeve 31, and the outside of the connecting sleeve 31 is provided with a fastening bolt 32, and one end of the connecting sleeve 31 is connected with a baffle plate 27, and one side of the first raw material box 1 is provided with a third through hole 29, and the second The inside of a materia...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap