Cleaning and defrosting structure for front window glass of wheel excavator and using method thereof

A front window glass and excavator technology, which is applied to vehicle cleaning, soil movers/excavators, drinking water devices, etc., can solve the inconvenience of drivers, weaken the clarity of vision, and inconvenient cleaning and removal of front window glass problems such as fog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

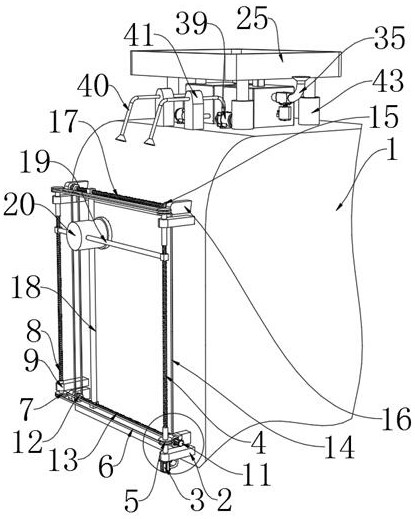

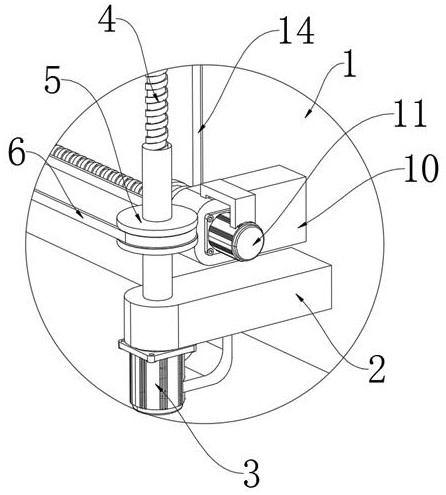

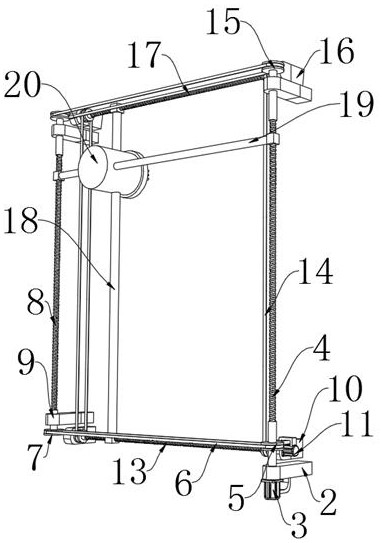

[0039] refer to Figure 1-9, a cleaning and defrosting structure for the front window glass of a wheeled excavator, including a cab 1, a first support block 2 welded to the bottom of one side of the cab 1, and a first motor 3 fixed to the bottom of the first support block 2 , the output end of the first motor 3 is welded with a first threaded rod 4 on the top of the first support block 2, and a first rotating shaft 5 is fixed on the outside of the first threaded rod 4 and at the top of the first support block 2. The outside of a rotating shaft 5 is equipped with a first conveyor belt 6, the inboard of one end of the first conveyor belt 6 is equipped with a second rotating shaft 7, the top of the second rotating shaft 7 is equipped with a second threaded rod 8, one side of the cab 1 and A second support block 9 is welded on the outside of the second threaded rod 8;

[0040] One side of the cab 1 and the top of the first support block 2 are welded with a third support block 10,...

Embodiment 2

[0045] On the basis of above-mentioned embodiment 1, disclose its method of use:

[0046] The first step: start the first motor 3, so that the output end of the first motor 3 drives the first threaded rod 4 to rotate, and then the second moving rod 19 is moved before the front window glass of the excavator;

[0047] Second step: start the second motor 11, so that the output end of the second motor 11 drives the third threaded rod 13 to rotate, and then the second moving rod 19 is moved before the front window glass of the excavator;

[0048] The 3rd step: start the 3rd motor 21, make the output end of the 3rd motor 21 drive the cleaning disc 22 to clean and defrost the front window glass of the excavator;

[0049] Step 4: Through the setting of the collection container 25, the rainwater on the top of the excavator can be collected, and then through the mutual cooperation between the sliding rod 23, the damping spring 24 and the fixed column 43, the collection container 25 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com